Technical data

11 Identification

11.1 Engine number, engine data

12 Safety instructions

22.1 Safety precautions when working on fuel supply system

22.2 Safety precautions when working on vehicles with a Start/Stop system

22.4 Safety precautions when working on cooling system

32.5 Safety precautions when working on ignition system

33 Repair instructions

43.1 Rules for cleanliness

43.2 Foreign objects in engine

43.3 Contact corrosion

43.4 Routing and securing lines

43.5 Installing coolers, condensers and radiators

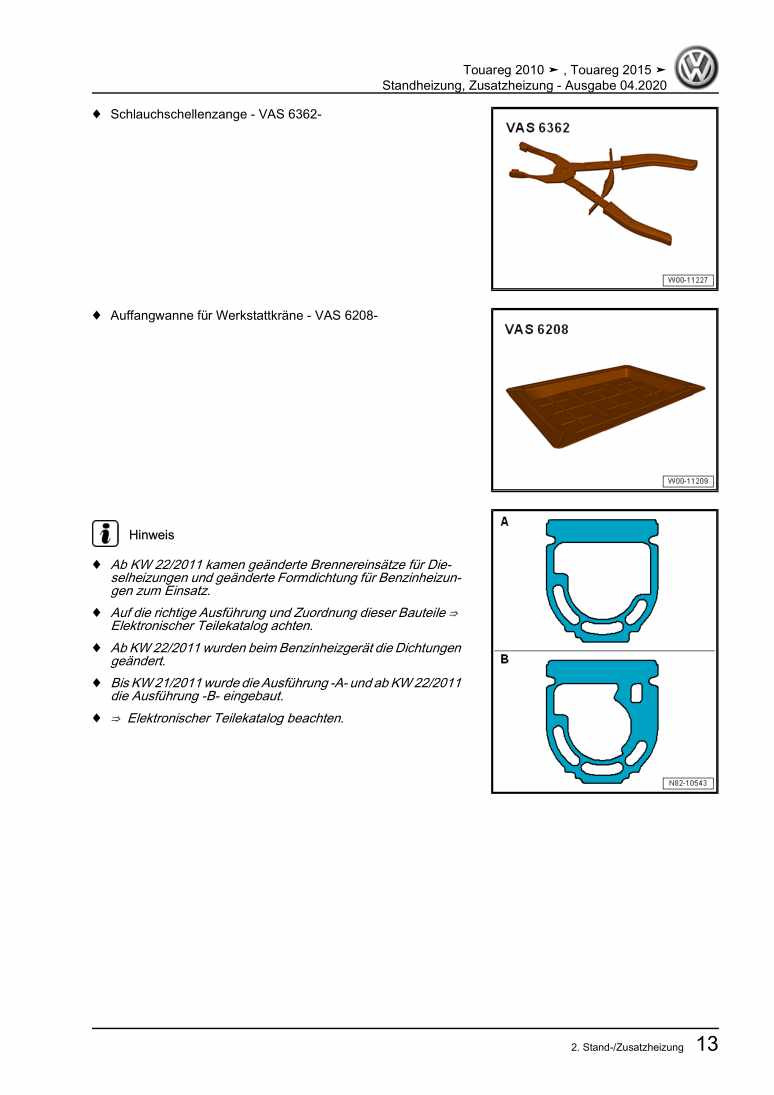

5Removing and installing engine

61 Removing and installing engine

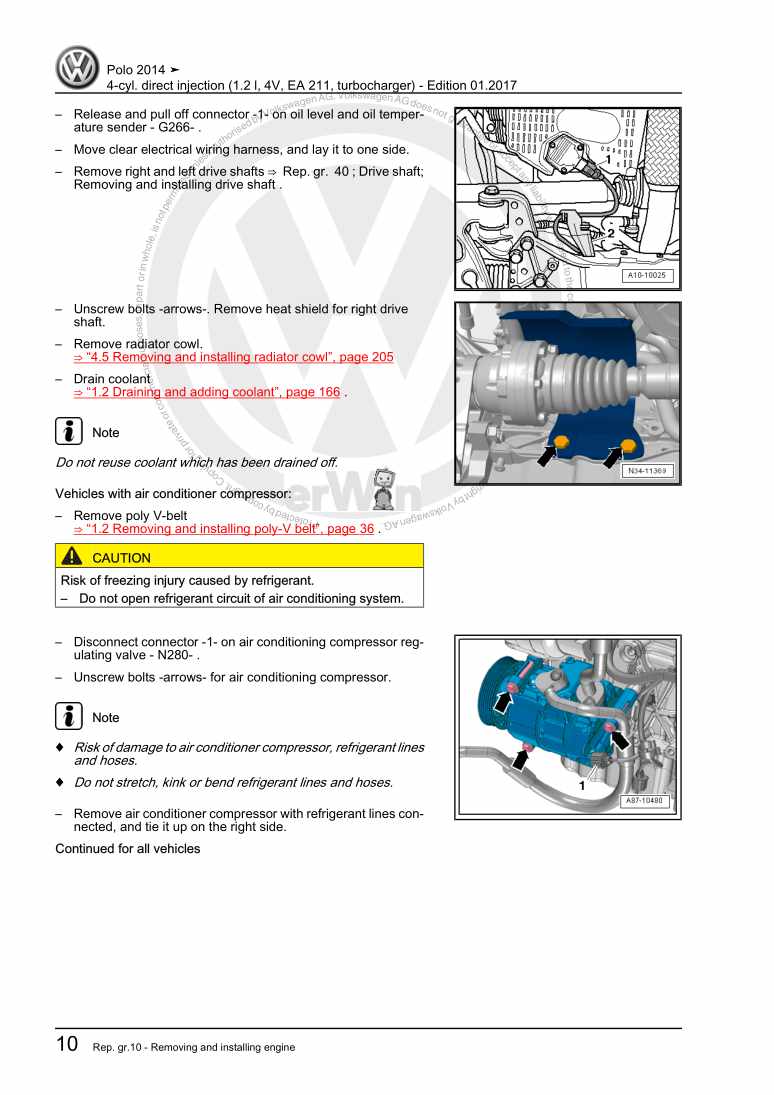

61.1 Removing engine

61.2 Separating engine and gearbox

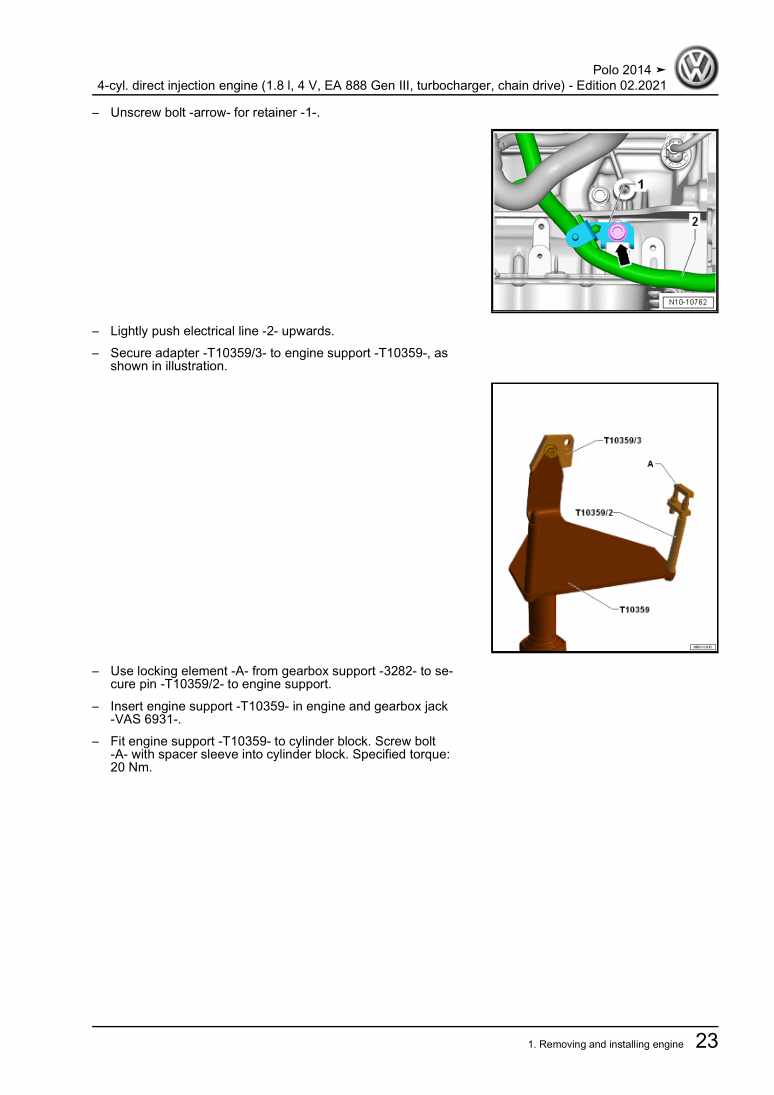

151.3 Securing engine on engine and gearbox support

171.4 Installing engine

182 Assembly mountings

212.1 Assembly overview - assembly mountings

212.2 Supporting engine in installation position

262.3 Removing and installing engine mountings

292.4 Removing and installing gearbox mounting

312.5 Removing and installing pendulum support

32Crankshaft group

351 Cylinder block (pulley end)

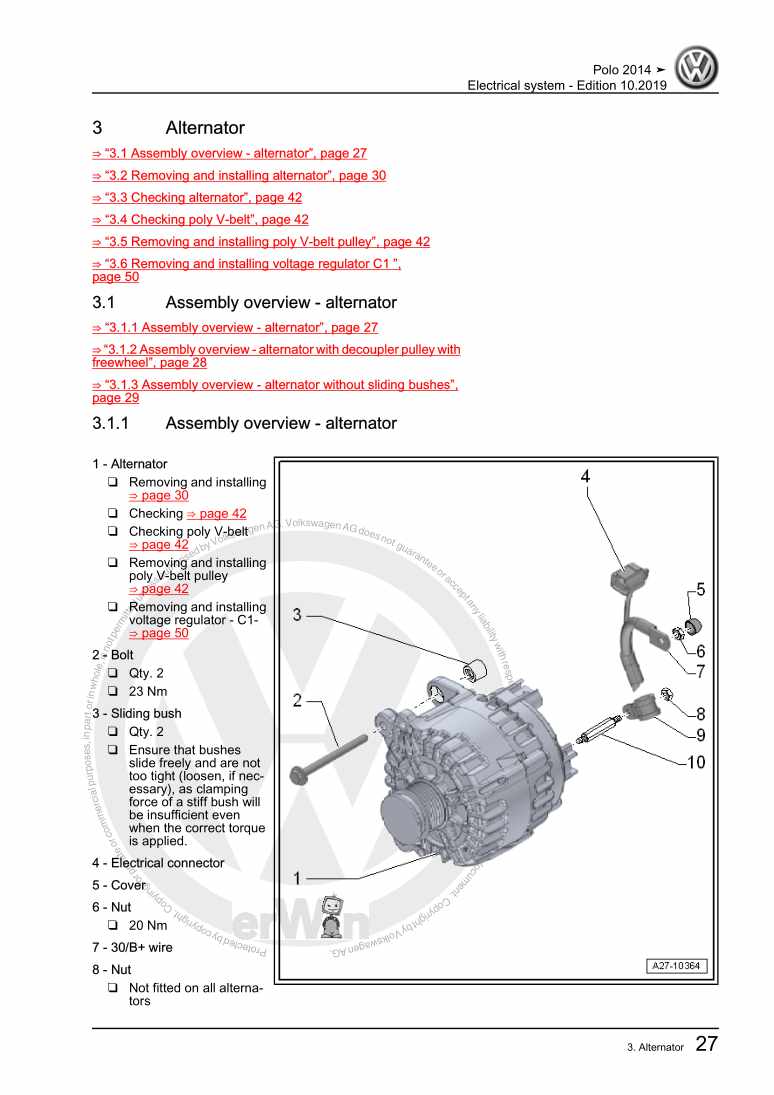

351.1 Assembly overview - poly V-belt drive

351.2 Assembly overview - Sealing flange, belt pulley end

381.3 Removing and installing poly V-belt

391.4 Removing and installing tensioner for poly V-belt

421.5 Removing and installing vibration damper

421.6 Removing and installing engine support

431.7 Renewing crankshaft oil seal - belt pulley end

471.8 Removing and installing sealing flange on pulley end

492 Cylinder block, gearbox end

522.1 Assembly overview - cylinder block, gearbox end

522.2 Removing and installing flywheel

532.3 Removing and installing sealing flange on gearbox side

543 Crankshaft

633.1 Renewing needle bearing in crankshaft

633.2 Crankshaft dimensions

643.3 Measuring axial clearance of crankshaft

644 Pistons and conrods

664.1 Assembly overview - pistons and conrods

664.2 Separating new conrod

684.3 Removing and installing pistons

684.4 Removing and installing oil spray jets

694.5 Checking piston and cylinder bore

704.6 Checking radial clearance of conrods

71Cylinder head, valve gear

721 Toothed belt drive

721.1 Assembly overview - toothed belt cover

721.2 Assembly overview - toothed belt

731.3 Checking valve timing

741.4 Detaching toothed belt from camshaft

801.5 Removing and installing toothed belt

942 Cylinder head

1092.1 Assembly overview - cylinder head

1092.2 Assembly overview - camshaft housing

1112.3 Removing and installing cylinder head

1122.4 Removing and installing camshaft housing

1162.5 Checking compression

1203 Valve gear

1233.1 Assembly overview - valve gear

1233.2 Removing and installing camshaft control valve 1 N205 / N318

1243.3 Removing and installing cam actuators

1253.4 Removing and installing camshaft adjuster

1283.5 Measuring axial play of camshaft

1293.6 Removing and installing camshaft oil seal

1303.7 Removing and installing valve stem seals

1354 Inlet and exhaust valves

1444.1 Checking valve guides

1444.2 Checking valves

1444.3 Valve dimensions

145Lubrication

1461 Sump, oil pump

1461.1 Assembly overview - sump, oil pump

1461.2 Removing and installing oil level and oil temperature sender G266

1491.3 Removing and installing lower part of sump

1491.4 Removing and installing oil pump

1521.5 Removing and installing upper part of sump

1531.6 Engine oil

1562 Engine oil cooler

1572.1 Assembly overview - engine oil cooler

1572.2 Removing and installing engine oil cooler

1573 Crankcase breather

1593.1 Assembly overview - crankcase breather system

1593.2 Removing and installing oil separator

1604 Oil filter, oil pressure switch

1624.1 Assembly overview - oil filter/oil pressure switch

1624.2 Removing and installing oil pressure switch F1

1634.3 Removing and installing oil pressure switch for reduced oil pressure F378

1644.4 Removing and installing oil pressure regulating valve N428

1654.5 Checking oil pressure

166Cooling

1691 Cooling system, coolant

1691.1 Coolant hose schematic diagram

1691.2 Draining and filling coolant

1721.3 Checking cooling system for leaks

1782 Coolant pump, regulation of cooling system

1812.1 Assembly overview - coolant pump, thermostat

1812.2 Assembly overview - electric coolant pump

1832.3 Assembly overview - coolant temperature sender

1852.4 Removing and installing coolant pump

1862.5 Removing and installing toothed belt pulley for coolant pump

1902.6 Removing and installing thermostat

1942.7 Removing and installing electric coolant pump

1972.8 Removing and installing coolant temperature sender G62

1993 Coolant pipes

2023.1 Assembly overview - coolant pipes

2023.2 Removing and installing coolant pipes

2024 Radiator, radiator fan

2064.1 Assembly overview - radiator/radiator fan

2064.2 Assembly overview - radiator cowl and radiator fan

2084.3 Removing and installing radiator

2104.4 Removing and installing cooler for charge air cooling circuit

2134.5 Removing and installing radiator cowling with radiator fan

2174.6 Removing and installing radiator fan V7

218Turbocharging/supercharging

2201 Turbocharger

2201.1 Assembly overview - turbocharger

2201.2 Removing and installing turbocharger

2221.3 Removing and installing charge pressure positioner V465

2262 Charge air system

2302.1 Assembly overview - charge air system

2302.2 Removing and installing charge pressure sender GX26

2322.3 Removing and installing charge air cooler

2322.4 Checking charge air system for leaks

234Mixture preparation - injection

2361 Injection system

2361.1 Overview of fitting locations - injection system

2361.2 Releasing high pressure in fuel system

2392 Air filter

2412.1 Assembly overview - air filter housing

2412.2 Removing and installing air filter housing

2423 Intake manifold

2433.1 Assembly overview - intake manifold

2433.2 Removing and installing intake manifold

2453.3 Removing and installing throttle valve module GX3

2473.4 Cleaning throttle valve module GX3

2494 Injectors

2504.1 Assembly overview - fuel rail with injectors

2504.2 Removing and installing fuel rail

2514.3 Removing and installing injectors

2524.4 Cleaning injectors

2565 Senders and sensors

2585.1 Removing and installing intake manifold sender GX9

2585.2 Removing and installing fuel pressure sender G247

2585.3 Checking fuel pressure sender G247

2596 High-pressure pump

2636.1 Assembly overview - high-pressure pump

2636.2 Removing and installing high-pressure pump

2646.3 Removing and installing high-pressure pipe

2657 Lambda probe

2677.1 Assembly overview - Lambda probe

2677.2 Removing and installing Lambda probe

2688 Engine control unit

2708.1 Removing and installing engine control unit J623

2708.2 Removing and installing engine control unit J623 with protective housing

271Exhaust system

2731 Exhaust pipes, silencers

2731.1 Assembly overview - silencers

2731.2 Removing and installing silencer

2741.3 Separating exhaust pipes, silencers

2751.4 Aligning exhaust system free of stress

2761.5 Checking exhaust system for leaks

2772 Emission control

2782.1 Assembly overview - emission control

2782.2 Removing and installing catalytic converter

279Ignition system

2841 Ignition system

2841.1 Assembly overview - ignition system

2841.2 Test data, spark plugs

2851.3 Removing and installing ignition coils with output stage

2851.4 Removing and installing knock sensor 1 G61

2871.5 Removing and installing Hall sender

2881.6 Removing and installing engine speed sender G28

290