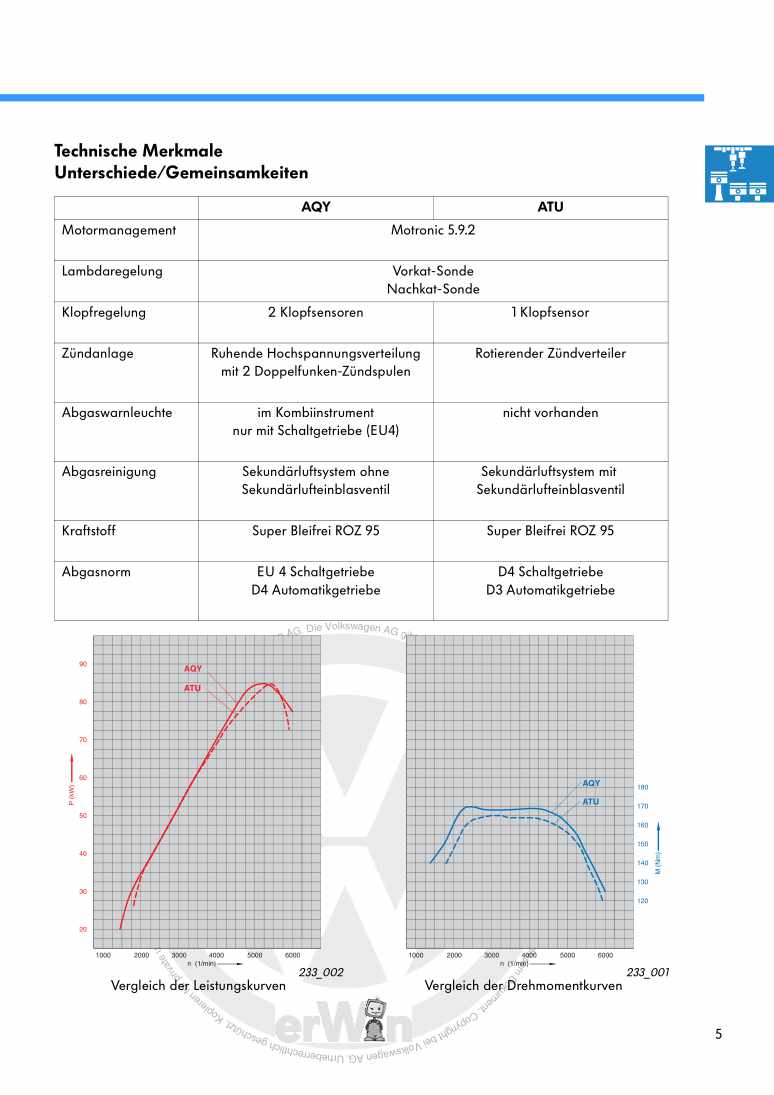

Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with a start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on ignition system

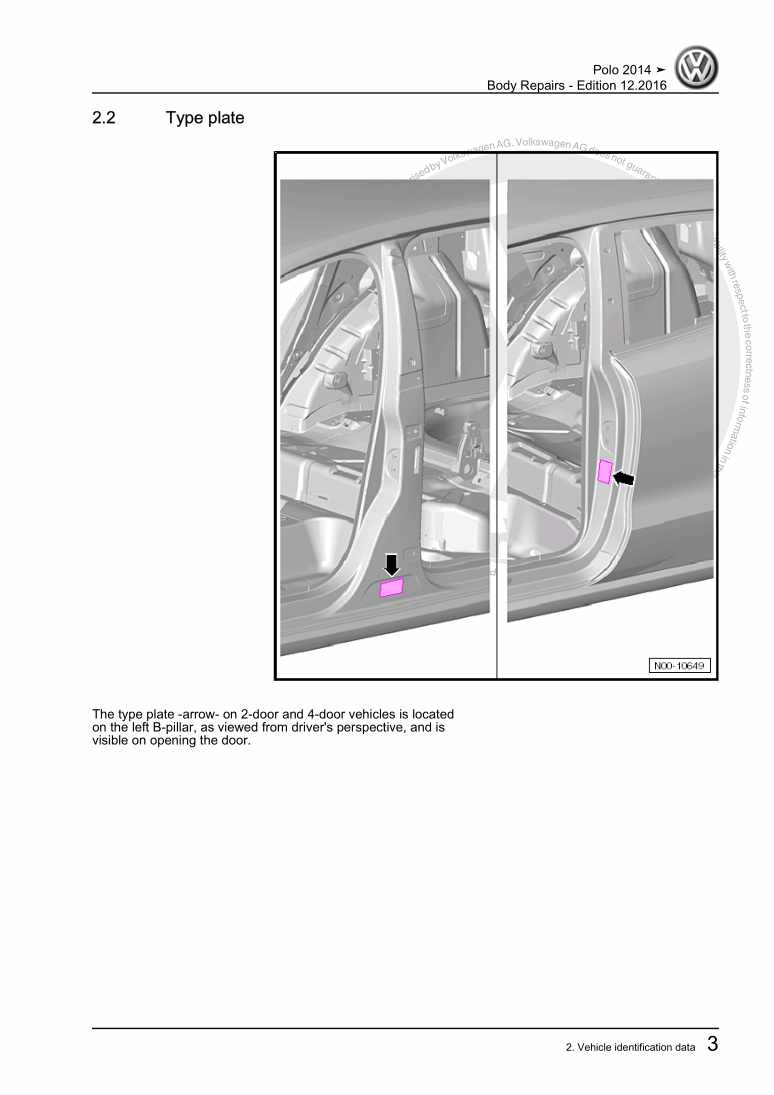

21.6 Identification

32 Repair notes

42.1 Rules for cleanliness

42.2 Foreign objects in engine

42.3 Contact corrosion

42.4 Pipe/wire routing and attachment

42.5 Fitting radiator and condensers

5Removing and installing engine

61 Removing and installing engine

61.1 Removing engine

61.2 Separating engine and gearbox

161.3 Securing engine on engine and gearbox support

171.4 Installing engine

192 Assembly mountings

222.1 Assembly overview - assembly mountings

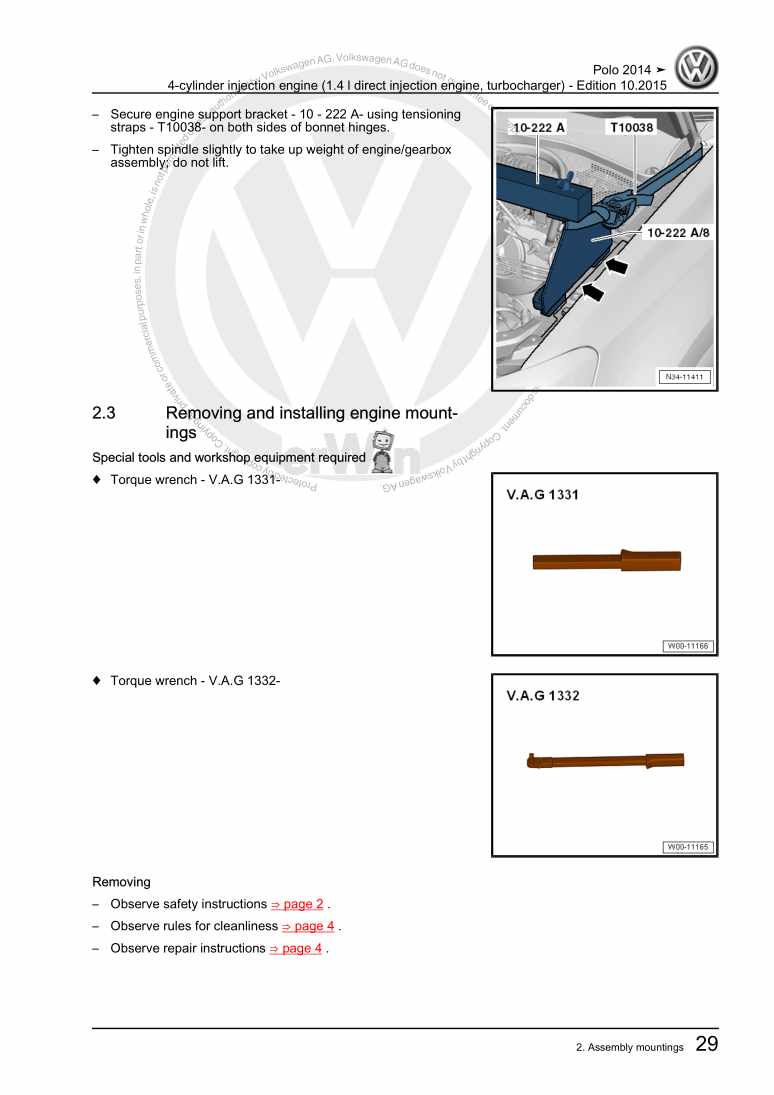

222.2 Supporting engine in installation position

242.3 Removing and installing motor mounting

272.4 Removing and installing gearbox mounting

292.5 Removing and installing pendulum support

30Crankshaft group

321 Cylinder block (pulley end)

321.1 Assembly overview - poly V-belt drive

321.2 Removing and installing poly-V belt

361.3 Removing and installing tensioner for poly V-belt

391.4 Removing and installing vibration damper

391.5 Removing and installing engine support

401.6 Renewing crankshaft oil seal - belt pulley end

432 Cylinder block, gearbox end

462.1 Assembly overview - cylinder block, gearbox end

462.2 Removing and installing flywheel

472.3 Removing and installing sealing flange on gearbox side

483 Crankshaft

573.1 Crankshaft dimensions

573.2 Measuring axial clearance of crankshaft

573.3 Renewing needle bearing in crankshaft

584 Pistons and conrods

624.1 Assembly overview - pistons and conrods

624.2 Separating new conrod

644.3 Removing and installing pistons

644.4 Removing and installing oil spray jets

654.5 Checking pistons and cylinder bores

664.6 Checking radial clearance of conrods

67Cylinder head, valve gear

691 Cylinder head

691.1 Assembly overview - cylinder head

691.2 Assembly overview - camshaft housing

701.3 Removing and installing cylinder head

721.4 Removing and installing camshaft housing

761.5 Checking compression

802 Toothed belt drive

832.1 Assembly overview - toothed belt cover

832.2 Assembly overview - toothed belt

842.3 Checking valve timing

852.4 Removing toothed belt from camshaft

912.5 Removing and installing toothed belt

1033 Valve gear

1173.1 Assembly overview - valve gear

1173.2 Measuring axial play of camshaft

1193.3 Removing and installing camshaft adjuster

1203.4 Removing and installing toothed belt pulley

1233.5 Removing and installing camshaft oil seal

1253.6 Removing and installing camshaft control valve 1 N205

1303.7 Removing and installing valve stem seals

1314 Inlet and exhaust valves

1394.1 Checking valve guides

1394.2 Checking valves

1394.3 Valve dimensions

140Lubrication

1411 Sump, oil pump

1411.1 Assembly overview - sump/oil pump

1411.2 Engine oil:

1451.3 Removing and installing oil sump

1451.4 Removing and installing oil pump

1491.5 Removing and installing oil level and oil temperature sender G266

1522 Engine oil cooler

1532.1 Assembly overview - engine oil cooler

1532.2 Removing and installing engine oil cooler

1533 Crankcase ventilation

1553.1 Assembly overview - crankcase breather system

1553.2 Removing and installing oil separator

1564 Oil filter, oil pressure switch

1594.1 Assembly overview - oil filter/oil pressure switch

1594.2 Removing and installing oil pressure switch for reduced oil pressure F378

1604.3 Checking oil pressure and oil pressure switch

1614.4 Removing and installing oil filter housing

162Cooling

1641 Cooling system/coolant

1641.1 Connection diagram - coolant hoses

1641.2 Draining and adding coolant

1661.3 Checking cooling system for leaks

1712 Coolant pump, regulation of cooling system

1732.1 Assembly overview - coolant pump, thermostat

1732.2 Assembly overview - electric coolant pump

1752.3 Assembly overview - coolant temperature sender

1772.4 Removing and installing coolant pump

1782.5 Removing and installing toothed belt pulley for coolant pump

1822.6 Removing and installing thermostat

1832.7 Removing and installing electric coolant pump

1862.8 Removing and installing coolant temperature sender G62

1882.9 Removing and installing radiator fan thermal switch F18

1903 Coolant pipes

1923.1 Assembly overview - coolant pipes

1923.2 Removing and installing coolant pipes

1924 Radiator, radiator fan

1964.1 Assembly overview - radiator/radiator fan

1964.2 Assembly overview - radiator cowl and radiator fan

1984.3 Removing and installing radiator

1994.4 Removing and installing water radiator for charge air cooling circuit

2024.5 Removing and installing radiator cowl

2054.6 Removing and installing radiator fan V7

207Turbocharging/supercharging

2091 Exhaust turbocharger

2091.1 Assembly overview - turbocharger

2091.2 Removing and installing turbocharger

2111.3 Removing and installing charge pressure positioner V465

2151.4 Removing and installing connection for turbocharger

2162 Charge air system

2202.1 Assembly overview - charge air system

2202.2 Removing and installing air pipe

2222.3 Removing and installing charge pressure sender GX26

2232.4 Removing and installing charge air cooler

2232.5 Checking charge air system for leaks

226Mixture preparation - injection

2291 Injection system

2291.1 Overview of fitting locations - injection system

2292 Air filter

2332.1 Assembly overview - air filter housing

2332.2 Removing and installing air filter housing

2342.3 Removing and installing resonator for intake air

2353 Intake manifold

2363.1 Assembly overview - intake manifold

2363.2 Removing and installing intake manifold

2383.3 Removing and installing throttle valve module GX3

2403.4 Cleaning throttle valve module GX3

2414 Injectors

2434.1 Assembly overview - fuel rail with injectors

2434.2 Removing and installing fuel rail

2444.3 Removing and installing injectors

2455 Senders and sensors

2505.1 Removing and installing intake manifold sender GX9

2505.2 Removing and installing fuel pressure sender G247

2505.3 Checking fuel pressure sender G247

2516 High-pressure pump

2546.1 Assembly overview - high-pressure pump

2546.2 Removing and installing high-pressure pump

2556.3 Removing and installing high-pressure pipe

2567 Lambda probe

2587.1 Assembly overview - Lambda probe

2587.2 Removing and installing Lambda probe

2598 Engine (motor) control unit

2628.1 Assembly overview - engine control unit

2628.2 Removing and installing engine (motor) control unit J623

263Exhaust system

2651 Exhaust pipes, silencers

2651.1 Assembly overview - silencers

2651.2 Separating exhaust pipes, silencers

2661.3 Removing and installing silencer

2681.4 Aligning exhaust system free of tension

2701.5 Check exhaust system for leaks

2701.6 Installation position of clamp

2712 Exhaust gas cleaning

2722.1 Assembly overview - emission control

2722.2 Removing and installing catalytic converter

273Ignition system

2781 Ignition system

2781.1 Assembly overview - ignition system

2781.2 Test data, spark plugs

2791.3 Removing and installing ignition coils with output stage

2791.4 Removing and installing knock sensor 1 G61

2811.5 Removing and installing Hall sender G40

2811.6 Removing and installing engine speed sender G28

282