Technical data

11 Marking

11.1 Engine number/engine data

12 General information

32.1 Numbering of cylinders

33 Safety information

43.1 Safety precautions when working on fuel system

43.2 Safety measures when working on vehicles with a start/stop system

53.4 Safety precautions when working on the cooling system

64 Repair instructions

74.1 Rules for cleanliness

74.2 Foreign objects in engine

84.3 Checking vacuum system

8Removing and installing engine

91 Removing and installing motor

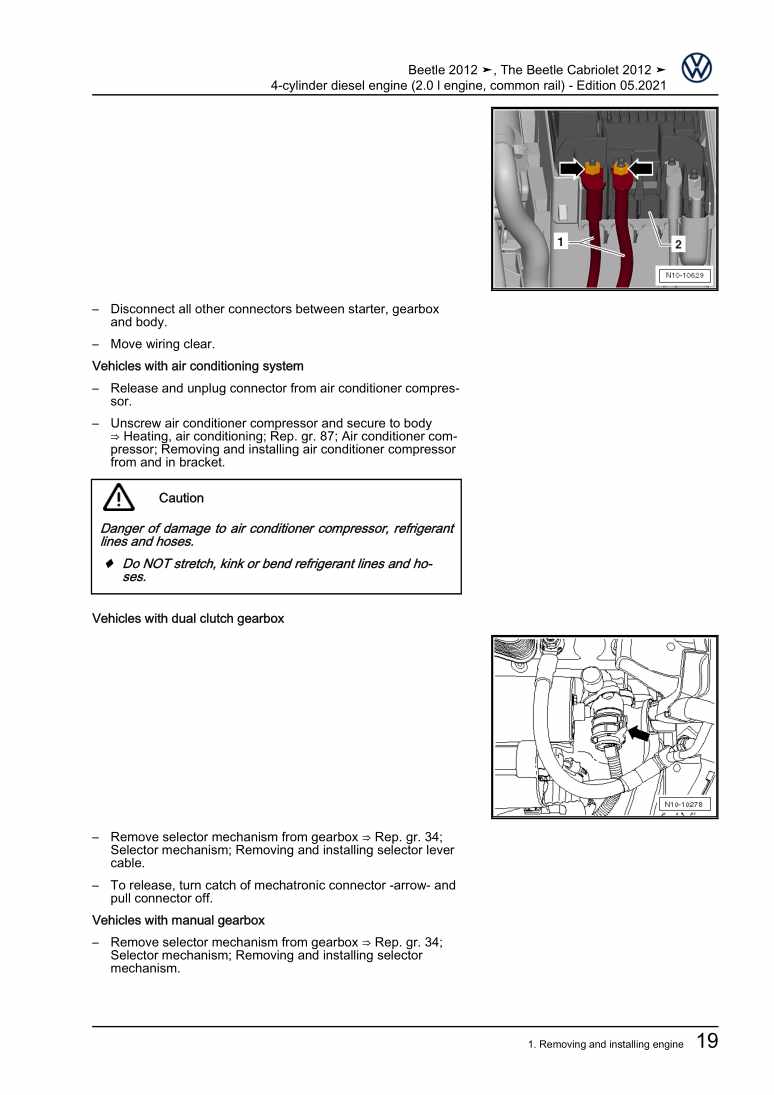

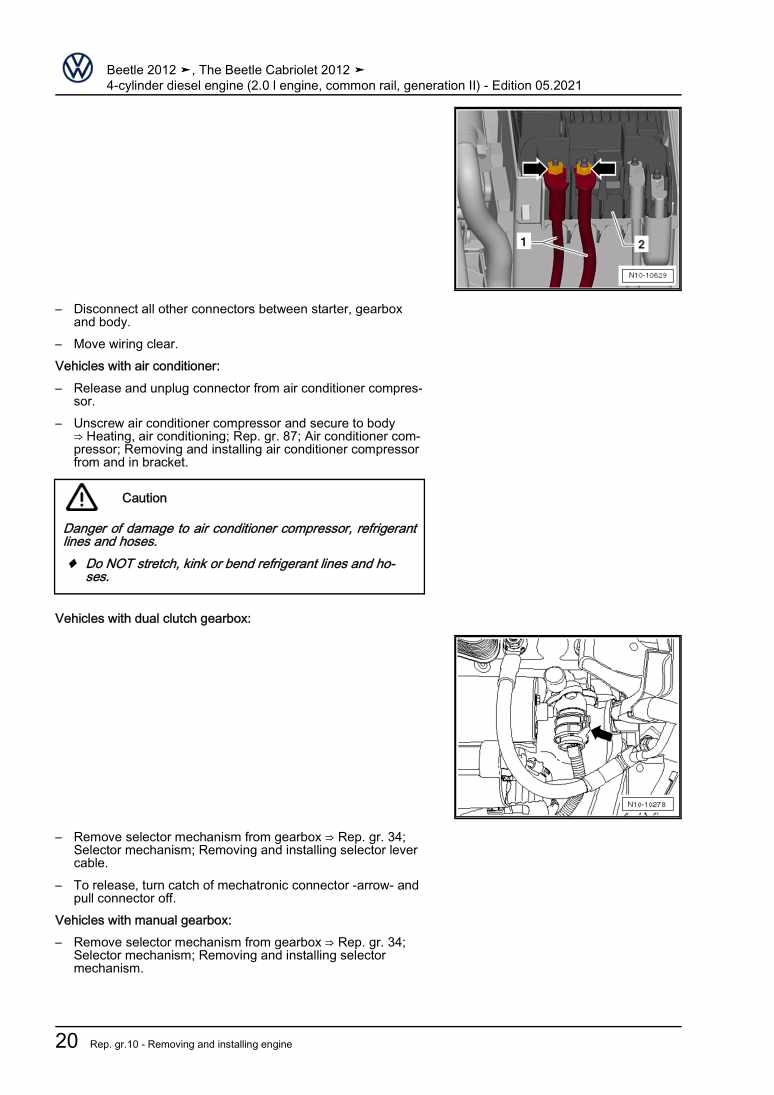

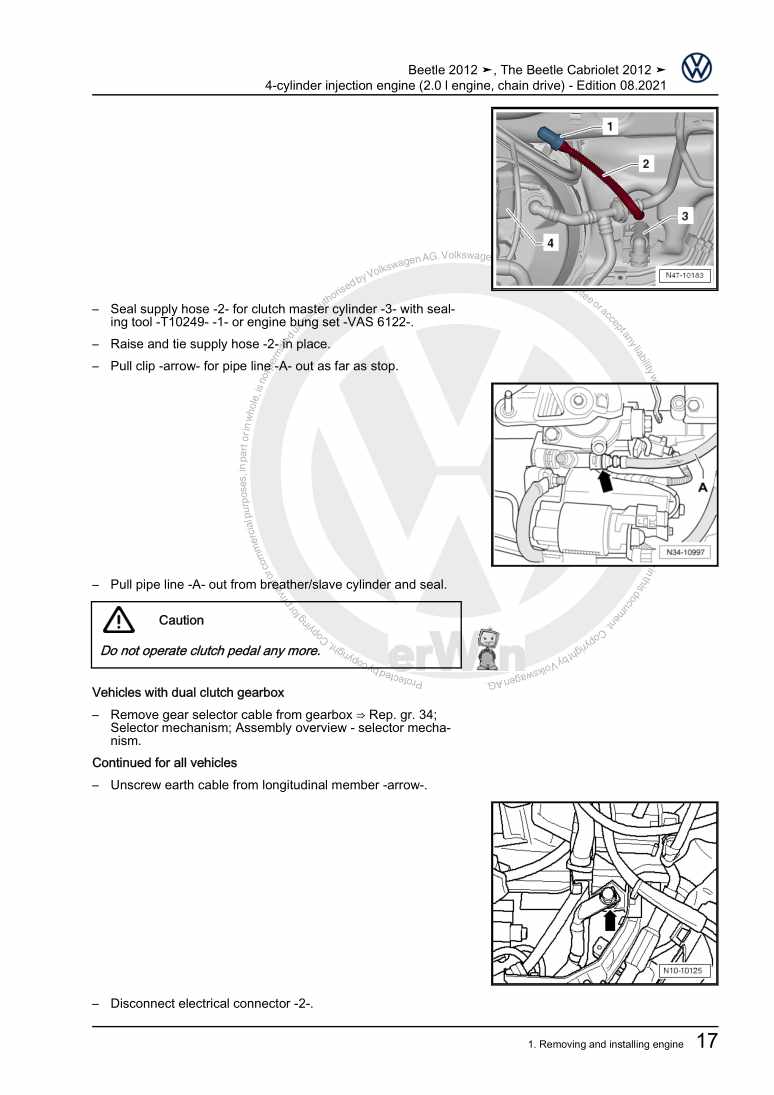

91.1 Removing motor

91.2 Separating engine and gearbox

211.3 Securing engine on engine and gearbox support

261.4 Installing engine

282 Assembly mountings

322.1 Assembly overview - assembly mountings

322.2 Removing and installing engine mounting

342.3 Removing and installing gearbox mounting

422.4 Removing and installing pendulum support

432.5 Supporting engine in installation position

442.6 Adjusting assembly mountings

512.7 Checking adjustment of assembly mountings (engine and gearbox mountings)

533 Engine cover panel

553.1 Removing and installing engine cover

55Crankshaft group

561 Cylinder block (pulley end)

561.1 Assembly overview - poly V-belt drive

561.2 Assembly overview - sealing flange, belt pulley end

601.3 Removing and installing poly-V belt

621.4 Removing and installing tensioner for poly V-belt

661.5 Removing and installing vibration damper

681.6 Removing and installing bracket for ancillaries

691.7 Removing and installing engine bracket

711.8 Renewing crankshaft oil seal - belt pulley end

741.9 Removing and installing sealing flange on pulley end

772 Cylinder block, gearbox end

822.1 Assembly overview - cylinder block, gearbox end

822.2 Removing and installing flywheel

832.3 Removing and installing sealing flange on gearbox side

853 Crankshaft

993.1 Assembly overview - crankshaft

993.2 Crankshaft dimensions

1003.3 Renewing needle bearing in crankshaft

1003.4 Measuring axial clearance of crankshaft

1023.5 Measuring radial clearance of crankshaft

1034 Pistons and conrods

1054.1 Assembly overview - pistons and conrods

1054.2 Measuring piston projection at TDC

1074.3 Checking pistons and cylinder bores

1094.4 Separating new conrod

1124.5 Checking radial clearance of conrods

113Cylinder head, valve gear

1141 Cylinder head

1141.1 Assembly overview - cylinder head

1141.2 Assembly overview - cylinder head cover

1181.3 Removing and installing cylinder head

1201.4 Removing and installing cylinder head cover

1351.5 Removing and installing injector seals

1381.6 Removing and installing vacuum pump

1391.7 Checking compression

1412 Toothed belt drive

1442.1 Assembly overview - toothed belt

1442.2 Removing and installing toothed belt

1473 Valve gear

1713.1 Assembly overview - valve gear

1713.2 Measuring axial play of camshaft

1733.3 Measuring radial play of camshaft

1743.4 Removing and installing camshaft oil seal

1753.5 Removing and installing camshaft

1833.6 Checking hydraulic compensation elements

1923.7 Removing and installing valve stem seals

1934 Inlet and exhaust valves

2024.1 Reworking valve seats

2024.2 Checking valve guides

2024.3 Checking valves

2034.4 Valve dimensions

203Lubrication

2041 Sump, oil pump

2041.1 Assembly overview - sump/oil pump

2041.2 Engine oil:

2101.3 Removing and installing oil sump

2111.4 Removing and installing oil pump

2151.5 Removing and installing oil level and oil temperature sender G266

2182 Engine oil cooler

2202.1 Assembly overview - engine oil cooler

2202.2 Removing and installing engine oil cooler

2203 Oil filter, oil pressure switch

2243.1 Assembly overview - oil filter housing, oil pressure switch

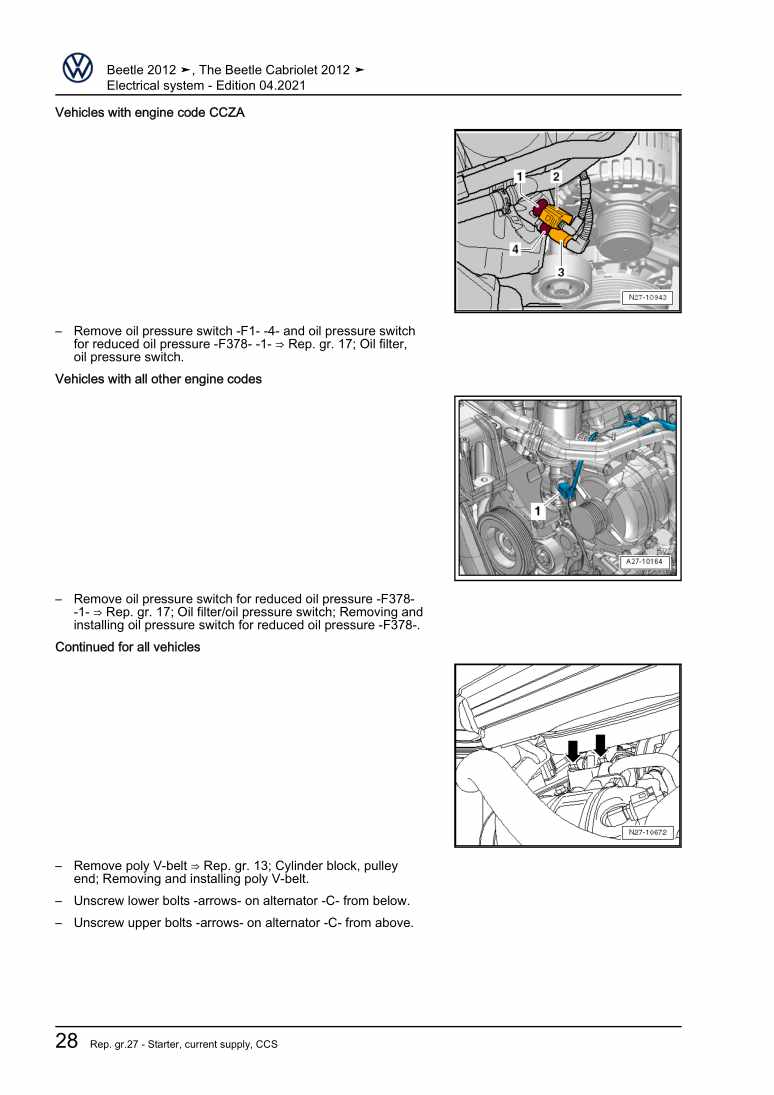

2243.2 Removing and installing oil pressure switch F1

2253.3 Checking oil pressure

2263.4 Checking oil pressure and oil pressure switch

2273.5 Removing and installing oil filter housing

2284 Oil circuit

2334.1 Assembly overview - oil circuit

2334.2 Removing and installing oil return line for turbocharger

2335 Balancer shaft module

2395.1 Removing and installing balance shaft module

239Cooling

2491 Cooling system/coolant

2491.1 Connection diagram - coolant hoses

2491.2 Checking cooling system for leaks

2511.3 Draining and adding coolant

2522 Coolant pump, regulation of cooling system

2612.1 Assembly overview - coolant pump, thermostat

2612.2 Assembly overview - electric coolant pump

2612.3 Removing and installing electric coolant pump

2622.4 Removing and installing coolant pump

2652.5 Removing and installing 4/2-way valve with thermostat

2672.6 Removing and installing coolant temperature sender G62

2732.7 Removing and installing radiator outlet coolant temperature sender G83

2753 Coolant pipes

2783.1 Assembly overview - coolant pipes

2783.2 Removing and installing coolant pipes

2804 Radiator, radiator fan

2934.1 Assembly overview - radiator/radiator fan

2934.2 Removing and installing radiator

2944.3 Removing and installing radiator cowl with radiator fan

2954.4 Removing and installing radiator fan

297Turbocharging/supercharging

2981 Turbocharger

2981.1 Assembly overview - turbocharger

2981.2 Removing and installing turbocharger

3001.3 Renewing vacuum unit for turbocharger

3072 Charge air system

3152.1 Assembly overview - charge air system

3152.2 Assembly overview - charge-air hose connections

3172.3 Removing and installing charge air cooler

3192.4 Removing and installing charge pressure sender G31

3212.5 Checking charge air system for leaks

322Mixture preparation - injection

3261 Injection system

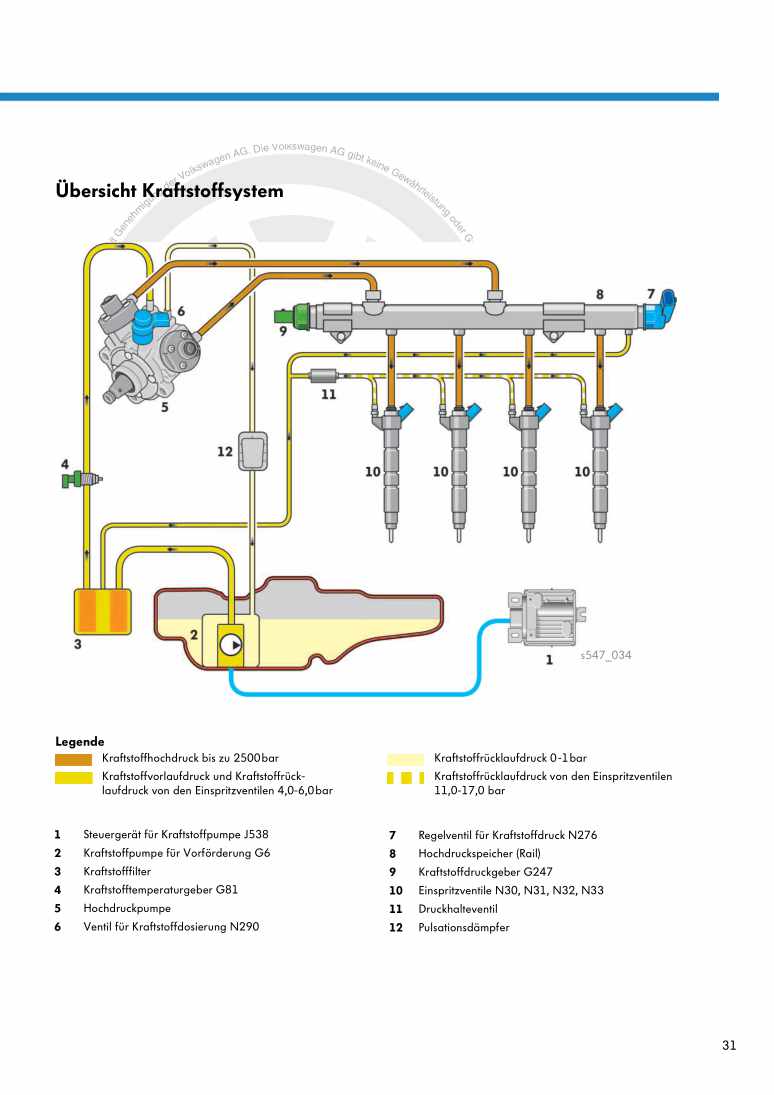

3261.1 Schematic overview - fuel system

3261.2 Filling/bleeding fuel system

3281.3 Checking fuel system for leaks

3292 Vacuum system

3302.1 Assembly overview - vacuum system

3302.2 Checking vacuum system

3313 Injectors/high-pressure accumulator (rail)

3353.1 Assembly overview - injectors

3353.2 Assembly overview - fuel system

3363.3 Adapting correction values for injectors

3393.4 Testing jammed-open injectors

3403.5 Removing and installing injectors

3413.6 Removing and installing high-pressure lines

3453.7 Removing and installing fuel rail

3494 Air filter

3544.1 Assembly overview - air filter housing

3544.2 Removing and installing air filter housing

3565 Intake manifold

3595.1 Assembly overview - intake manifold

3595.2 Removing and installing intake manifold

3615.3 Removing and installing throttle valve module J338

3656 Senders and sensors

3676.1 Checking fuel pressure regulating valve N276

3676.2 Removing and installing fuel pressure regulating valve N276

3686.3 Removing and installing fuel pressure sender G247

3706.4 Removing and installing air mass meter G70

3736.5 Removing and installing pressure differential sender G505

3747 Engine (motor) control unit

3787.1 Removing and installing engine control unit J623

3787.2 Removing and installing engine (motor) control unit J623 with protective housing

3798 High-pressure pump

3828.1 Assembly overview - high-pressure pump

3828.2 Removing and installing high-pressure pump

3849 Lambda probe

3919.1 Removing and installing Lambda probe

391Exhaust system

3931 Exhaust pipes and silencers

3931.1 Assembly overview - silencers

3931.2 Removing and installing rear silencer

3951.3 Aligning exhaust system free of stress

3971.4 Installation position of clamp

3982 Emission control

4002.1 Assembly overview - emission control

4002.2 Removing and installing particulate filter

4033 Exhaust gas temperature regulation

4123.1 Removing and installing parts of exhaust gas temperature regulation

4124 Exhaust gas recirculation

4194.1 Assembly overview - exhaust gas recirculation

4194.2 Removing and installing exhaust gas recirculation cooler

4214.3 Checking changeover for exhaust gas recirculation cooler

4244.4 Checking exhaust gas recirculation cooler for leaks

4254.5 Cleaning exhaust gas recirculation system

430Glow plug system

4381 Glow plug system

4381.1 Removing and installing glow plug

4381.2 Removing and installing automatic glow period control unit J179

4401.3 Removing and installing Hall sender G40

4421.4 Removing and installing engine speed sender G28

443