Technical data

11 Identification

11.1 Engine number/engine data

12 General information

32.1 Numbering of cylinders

33 Safety information

43.1 Safety precautions when working on fuel system

43.2 Safety measures when working on vehicles with a start/stop system

53.4 Safety precautions when working on the cooling system

64 Repair instructions

74.1 Rules for cleanliness

74.2 Foreign objects in engine

74.3 Checking vacuum system

8Removing and installing engine

91 Removing and installing engine

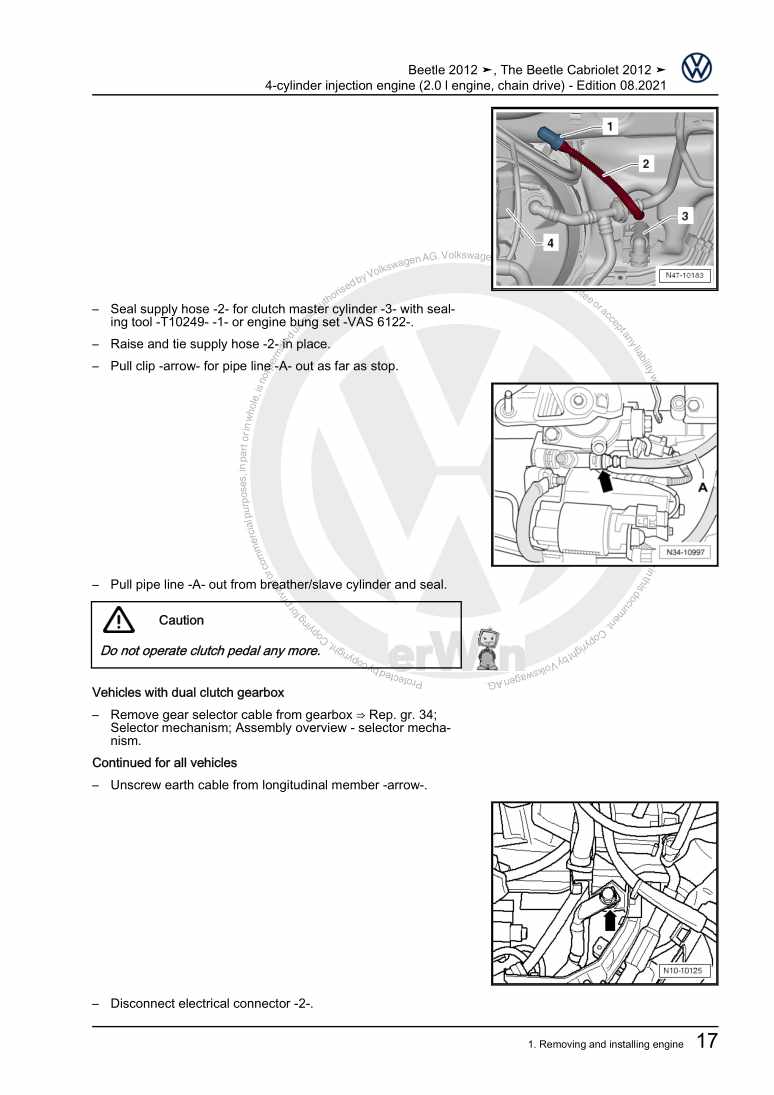

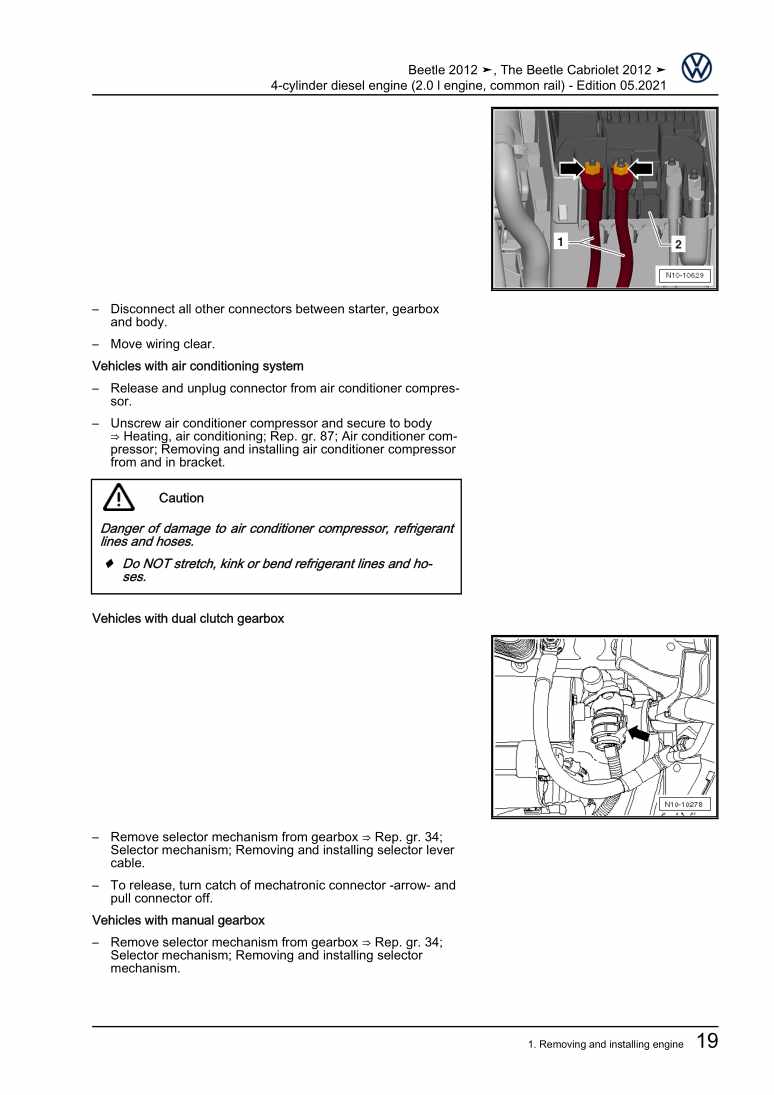

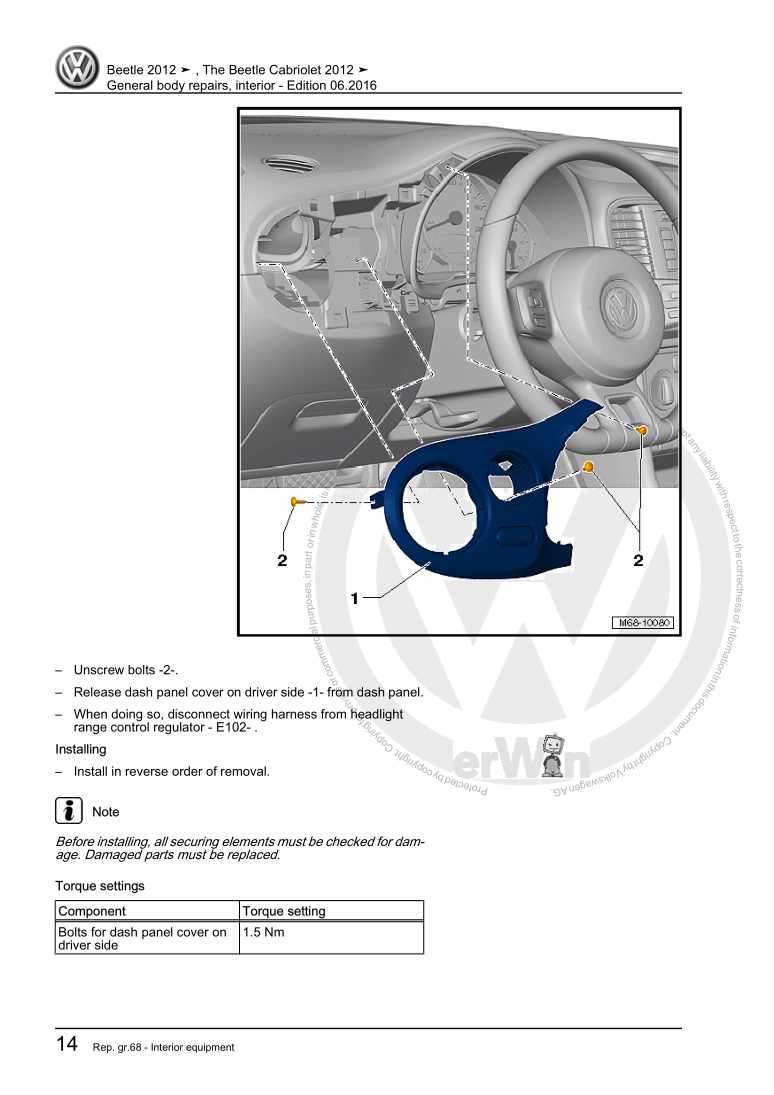

91.1 Removing engine

91.2 Separating engine and gearbox

231.3 Securing engine on engine and gearbox support

281.4 Installing engine

302 Assembly mountings

342.1 Assembly overview - assembly mountings

342.2 Removing and installing engine mounting

362.3 Supporting engine in installation position

452.4 Adjusting assembly mountings

542.5 Checking adjustment of assembly mountings

563 Engine cover panel

583.1 Removing and installing engine cover

58Crankshaft group

601 Cylinder block (pulley end)

601.1 Assembly overview - poly V-belt drive

601.2 Removing and installing poly-V belt

641.3 Removing and installing tensioner for poly V-belt

691.4 Removing and installing vibration damper

711.5 Removing and installing bracket for ancillaries

721.6 Removing and installing engine bracket

741.7 Assembly overview - sealing flange, belt pulley end

771.8 Renewing crankshaft oil seal - belt pulley end

791.9 Removing and installing sealing flange on pulley end

812 Cylinder block, gearbox end

862.1 Assembly overview - cylinder block, gearbox end

862.2 Removing and installing flywheel

872.3 Removing and installing sealing flange on gearbox side

893 Crankshaft

1033.1 Assembly overview - crankshaft

1033.2 Crankshaft dimensions

1043.3 Renewing needle bearing in crankshaft

1043.4 Measuring axial clearance of crankshaft

1063.5 Measuring radial clearance of crankshaft

1074 Pistons and conrods

1084.1 Assembly overview - pistons and conrods

1084.2 Measuring piston projection at TDC

1104.3 Checking pistons and cylinder bores

1124.4 Separating new conrod

1154.5 Checking radial clearance of conrods

116Cylinder head, valve gear

1171 Cylinder head

1171.1 Assembly overview - cylinder head

1171.2 Assembly overview - cylinder head cover

1211.3 Removing and installing cylinder head

1231.4 Removing and installing cylinder head cover

1391.5 Removing and installing vacuum pump

1421.6 Checking compression

1442 Toothed belt drive

1472.1 Assembly overview - toothed belt

1472.2 Removing and installing toothed belt

1493 Valve gear

1733.1 Assembly overview - valve gear

1733.2 Measuring axial play of camshaft

1753.3 Measuring radial play of camshaft

1763.4 Removing and installing camshaft oil seal

1773.5 Removing and installing camshaft

1853.6 Checking hydraulic compensation elements

1943.7 Removing and installing valve stem seal

1954 Inlet and exhaust valves

2044.1 Reworking valve seats

2044.2 Checking valve guides

2044.3 Checking valves

2054.4 Valve dimensions

205Lubrication

2061 Sump, oil pump

2061.1 Assembly overview - sump/oil pump

2061.2 Removing and installing oil sump

2121.3 Removing and installing oil pump

2171.4 Removing and installing oil level and oil temperature sender G 266

2192 Engine oil cooler

2212.1 Assembly overview - engine oil cooler

2212.2 Removing and installing engine oil cooler

2213 Oil filter, oil pressure switch

2253.1 Assembly overview - oil filter housing, oil pressure switch

2253.2 Removing and installing oil pressure switch F1

2263.3 Checking oil pressure

2273.4 Checking oil pressure and oil pressure switch

2283.5 Removing and installing oil filter housing

2294 Oil circuit

2354.1 Assembly overview - oil circuit

2354.2 Removing and installing oil return line for turbocharger

2355 Balancer shaft module

2415.1 Removing and installing balance shaft module

241Cooling

2511 Cooling system/coolant

2511.1 Coolant hose connection diagram

2511.2 Checking cooling system for leaks

2531.3 Draining and adding coolant

2542 Coolant pump, regulation of cooling system

2612.1 Assembly overview - coolant pump, thermostat

2612.2 Coolant circulation pump 2 V178

2612.3 Removing and installing coolant pump

2652.4 Removing and installing 4/2-way valve with thermostat

2672.5 Removing and installing coolant temperature sender

2733 Coolant pipes

2783.1 Assembly overview - coolant pipes

2783.2 Removing and installing coolant pipes

2804 Radiator, radiator fan

2934.1 Assembly overview - radiator, radiator fan

2934.2 Removing and installing radiator

2934.3 Removing and installing radiator cowl with radiator fan

2964.4 Removing and installing radiator fan

297Turbocharging/supercharging

2981 Turbocharger

2981.1 Assembly overview - turbocharger

2981.2 Removing and installing turbocharger

3001.3 Renewing vacuum unit for turbocharger

3072 Charge air system

3142.1 Assembly overview - charge air system

3142.2 Assembly overview - charge-air hose connections

3162.3 Removing and installing charge air cooler

3182.5 Checking charge air system for leaks

321Mixture preparation - injection

3251 Injection system

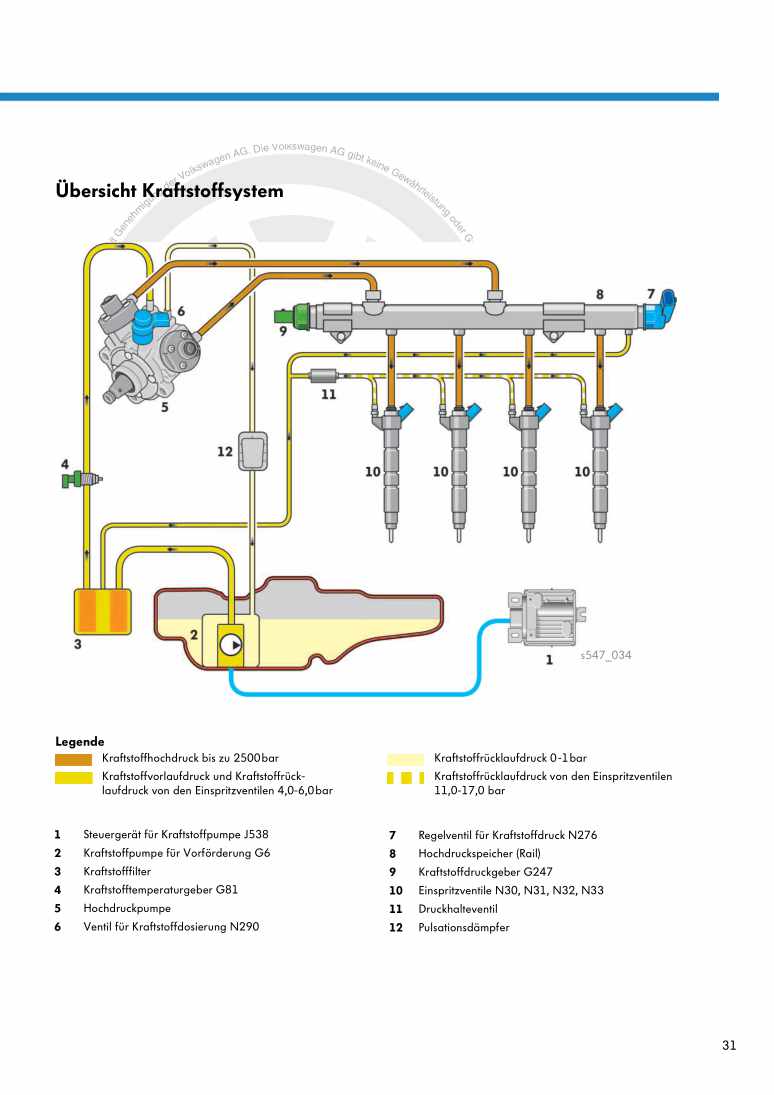

3251.1 Schematic overview - fuel system

3251.2 Filling/bleeding fuel system

3271.3 Checking fuel system for leaks

3282 Vacuum system

3292.1 Connection diagram - vacuum system

3292.2 Checking vacuum system

3303 Injectors/high-pressure accumulator (rail)

3333.1 Assembly overview - injectors

3333.2 Adapting correction values for injectors

3363.3 Testing jammed-open injectors

3373.4 Removing and installing injectors

3393.5 Removing and installing fuel rail

3433.6 Removing and installing high-pressure lines

3474 High-pressure pump

3524.1 Assembly overview - high-pressure pump

3524.2 Removing and installing high-pressure pump

3545 Senders and sensors

3605.1 Checking fuel pressure regulating valve

3605.2 Removing and installing fuel pressure regulating valve

3615.3 Removing and installing fuel pressure sender

3635.4 Removing and installing air mass meter

3665.5 Removing and installing differential pressure sensor

3676 Intake manifold

3696.1 Assembly overview – intake manifold

3696.2 Removing and installing intake manifold

3706.3 Removing and installing throttle valve module

3757 Lambda probe

3777.1 Removing and installing Lambda probe G39 with Lambda probe heater Z19

3778 Air filter

3798.1 Assembly overview - air filter housing

3798.2 Removing and installing air filter housing

3818.3 Checking changeover flap for intake air preheating

3838.4 Removing and installing changeover flap for intake air preheating

3849 Engine control unit

3879.1 Removing and installing engine control unit

3879.2 Removing and installing engine control unit with protective housing

388Exhaust system

3911 Exhaust pipes and silencers

3911.1 Assembly overview – silencers

3911.2 Separating exhaust pipes from silencers

3921.3 Aligning exhaust system free of stress

3941.4 Installation position of clamp

3952 Emission control

3972.1 Assembly overview – emission control

3972.2 Removing and installing particulate filter

4003 Exhaust gas temperature regulation

4093.1 Removing and installing parts of exhaust gas temperature regulation

4094 Exhaust gas recirculation

4164.1 Assembly overview – exhaust gas recirculation

4164.2 Removing and installing exhaust gas recirculation cooler

4174.3 Checking changeover for exhaust gas recirculation cooler

4204.4 Checking exhaust gas recirculation cooler for leaks

4214.5 Cleaning exhaust gas recirculation system

426Glow plug system

4341 Glow plug system

4341.1 Removing and installing glow plug

4341.2 Removing and installing automatic glow period control unit J179

4361.3 Removing and installing Hall sender G40

4381.4 Removing and installing engine speed sender G28

439