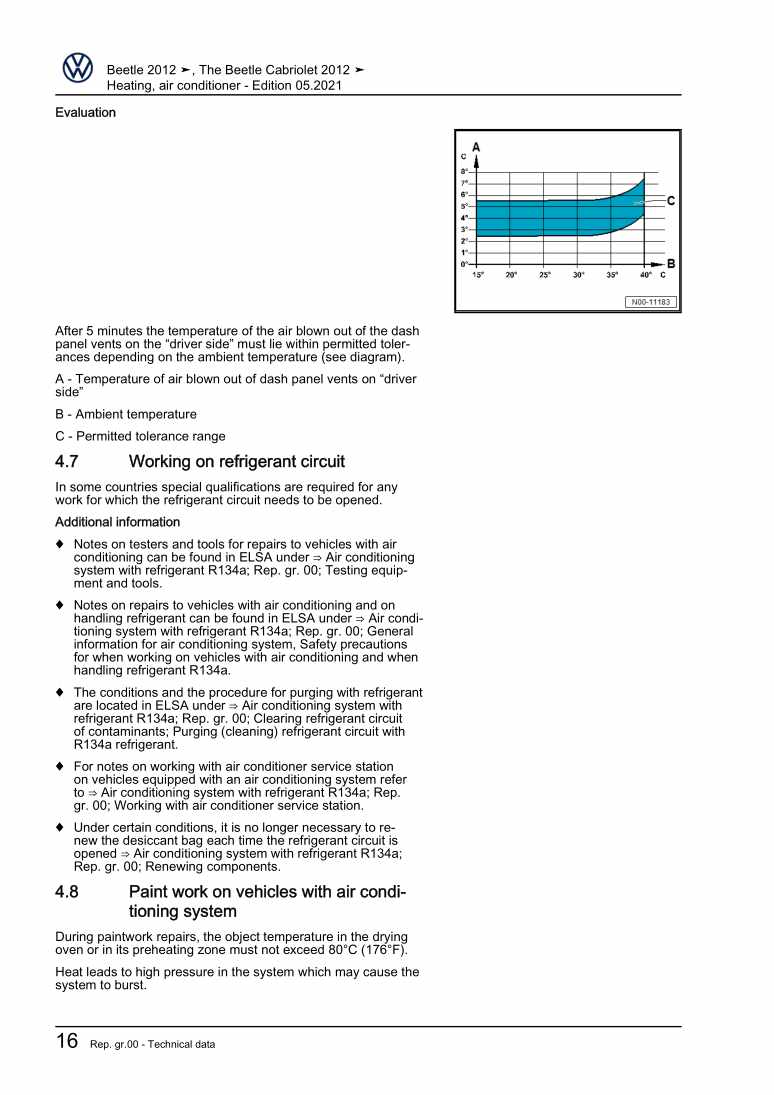

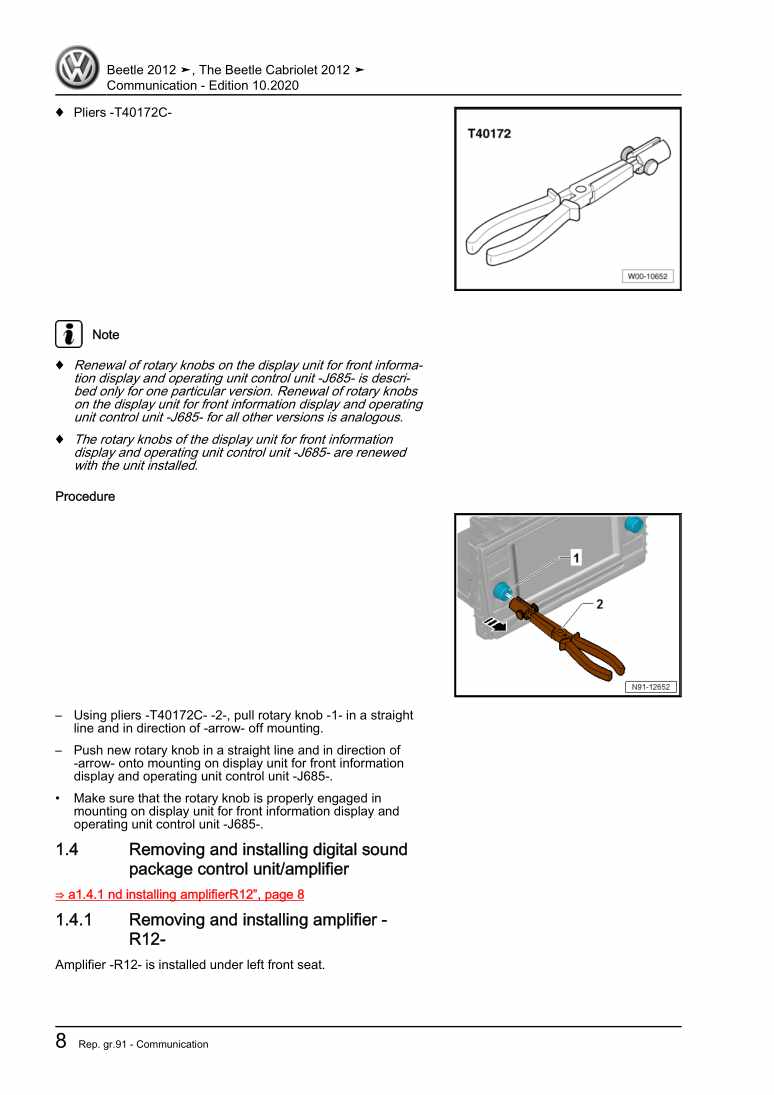

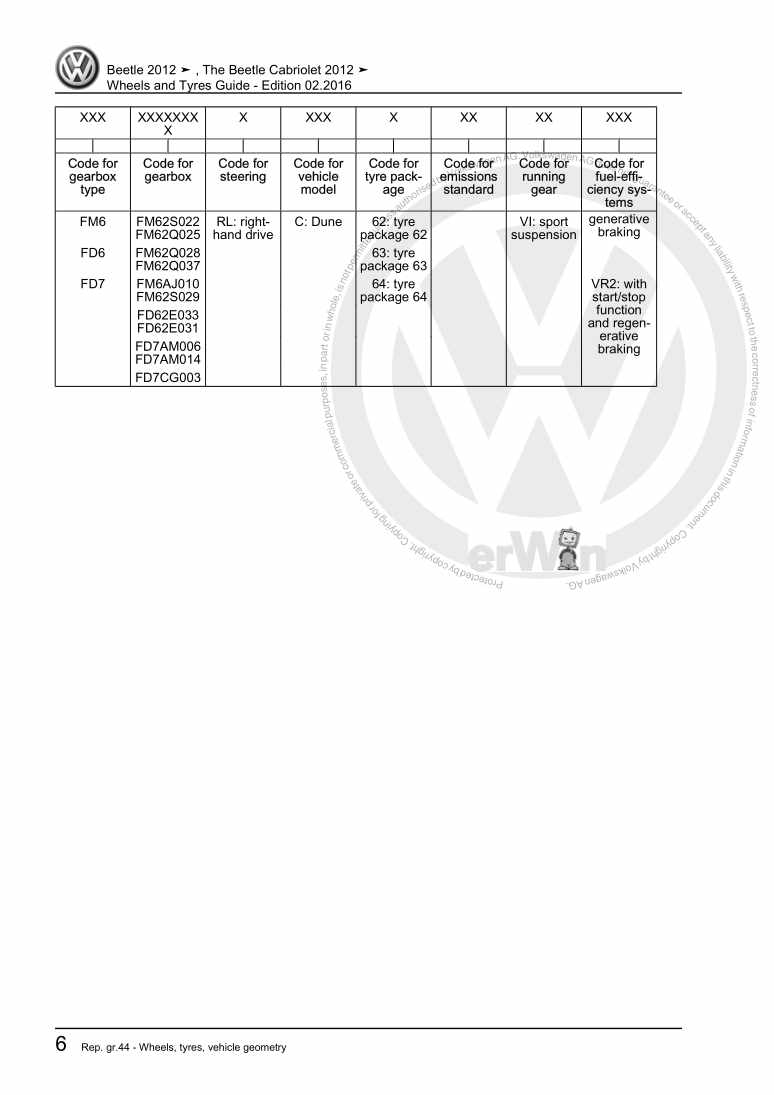

Technical data

11 Identification

11.1 Engine number/engine data

12 Safety information

32.1 Safety precautions when working on fuel system

32.2 Safety measures when working on vehicles with a start/stop system

42.4 Safety precautions when working on the cooling system

53 Repair instructions

63.1 Rules for cleanliness

63.2 Foreign objects in engine

73.3 Checking vacuum system

7Removing and installing engine

81 Removing and installing engine

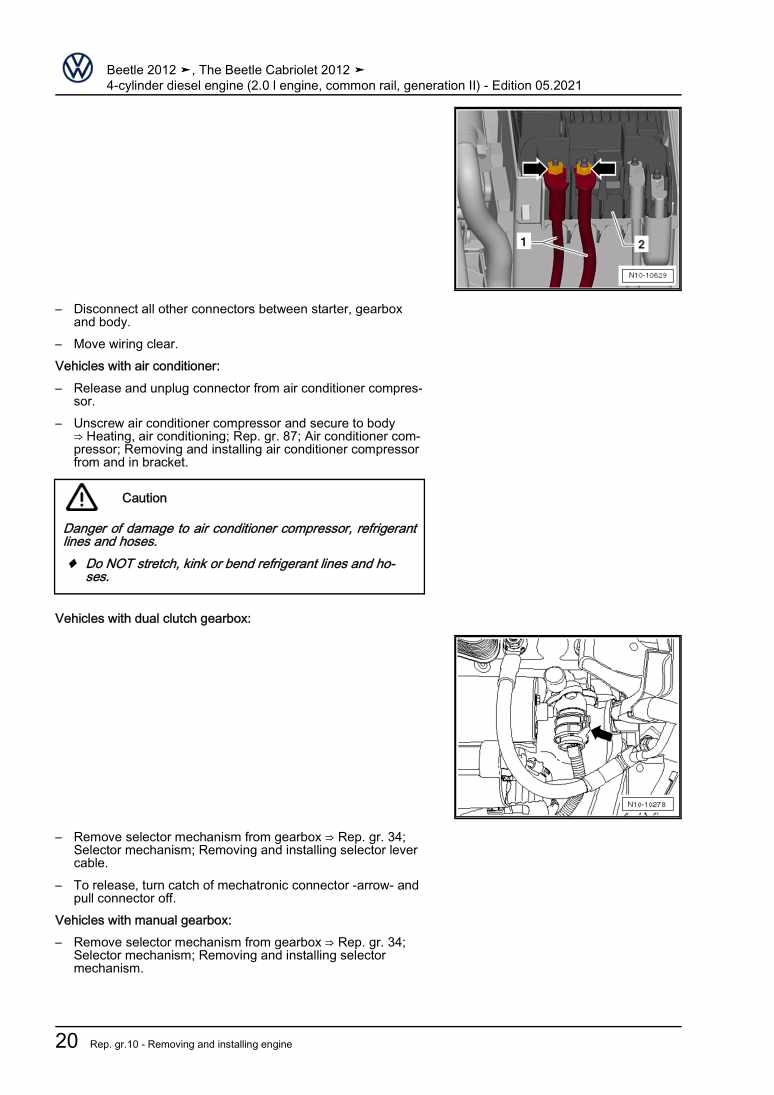

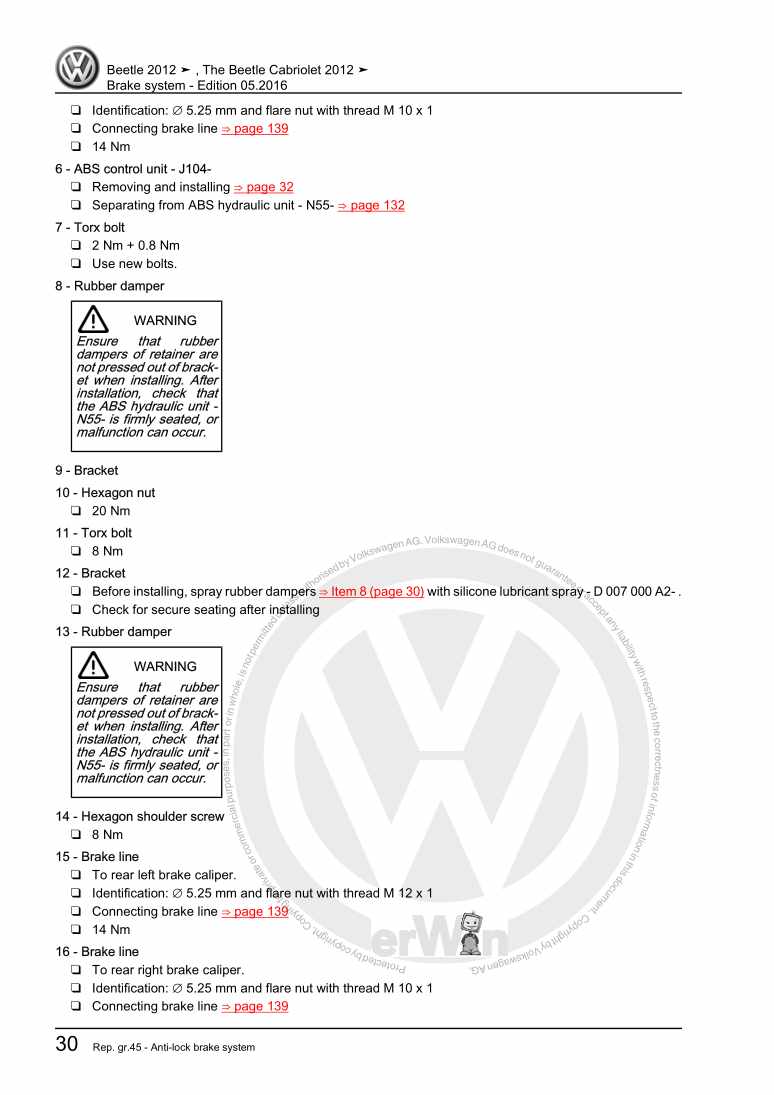

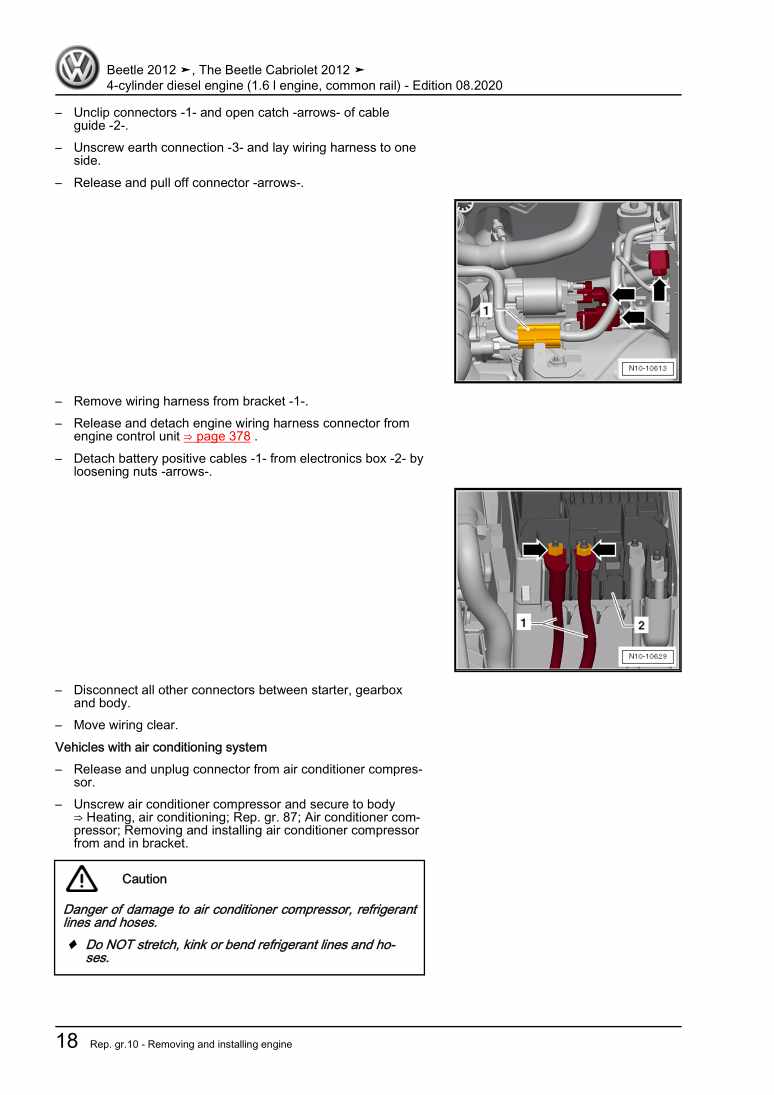

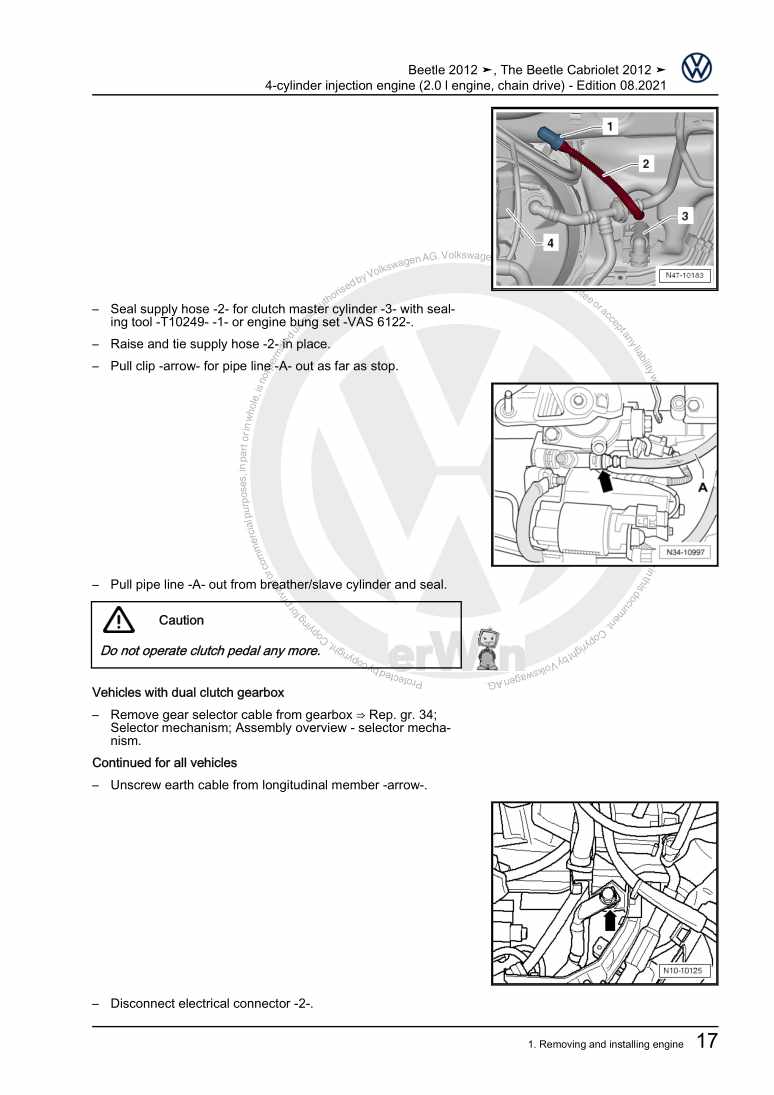

81.1 Removing engine

81.2 Separating engine and gearbox

221.3 Securing engine on engine and gearbox support

261.4 Installing engine

282 Assembly mountings

322.1 Assembly overview - assembly mountings

322.2 Removing and installing engine mounting

342.3 Supporting engine in installation position

432.4 Adjusting assembly mountings

522.5 Checking adjustment of assembly mountings

533 Engine cover panel

553.1 Removing and installing engine cover

55Crankshaft group

571 Cylinder block (pulley end)

571.1 Assembly overview - poly V-belt drive

571.2 Removing and installing poly-V belt

611.3 Removing and installing tensioner for poly V-belt

661.4 Removing and installing vibration damper

671.5 Removing and installing bracket for ancillaries

691.6 Removing and installing engine bracket

711.7 Assembly overview - sealing flange, belt pulley end

741.8 Renewing crankshaft oil seal - belt pulley end

761.9 Removing and installing sealing flange on pulley end

782 Cylinder block, gearbox end

832.1 Assembly overview - cylinder block, gearbox end

832.2 Removing and installing flywheel

842.3 Removing and installing sealing flange on gearbox side

863 Crankshaft

1003.1 Assembly overview - crankshaft

1003.2 Crankshaft dimensions

1013.3 Renewing needle bearing in crankshaft

1013.4 Measuring axial clearance of crankshaft

1033.5 Measuring radial clearance of crankshaft

1044 Pistons and conrods

1054.1 Assembly overview - pistons and conrods

1054.2 Measuring piston projection at TDC

1074.3 Checking pistons and cylinder bores

1094.4 Separating new conrod

1124.5 Checking radial clearance of conrods

113Cylinder head, valve gear

1141 Cylinder head

1141.1 Assembly overview - cylinder head

1141.2 Assembly overview - cylinder head cover

1181.3 Removing and installing cylinder head

1201.4 Removing and installing cylinder head cover

1351.5 Removing and installing injector seals

1371.6 Removing and installing vacuum pump

1381.7 Checking compression

1402 Toothed belt drive

1432.1 Assembly overview - toothed belt

1432.2 Removing and installing toothed belt

1453 Valve gear

1573.1 Assembly overview - valve gear

1573.2 Measuring axial play of camshaft

1593.3 Measuring radial play of camshaft

1603.4 Removing and installing camshaft oil seal

1613.5 Removing and installing camshaft

1693.6 Checking hydraulic compensation elements

1783.7 Removing and installing valve stem seal

1794 Inlet and exhaust valves

1884.1 Reworking valve seats

1884.2 Checking valve guides

1884.3 Checking valves

1894.4 Valve dimensions

189Lubrication

1901 Engine oil:

1901.1 Oil capacities

1901.2 Checking engine oil level

1902 Sump, oil pump

1922.1 Assembly overview - sump/oil pump

1922.2 Removing and installing oil sump

1952.3 Removing and installing oil pump

2002.4 Removing and installing oil level and oil temperature sender G 266

2013 Oil filter, oil pressure switch

2033.1 Assembly overview - oil filter housing, oil pressure switch

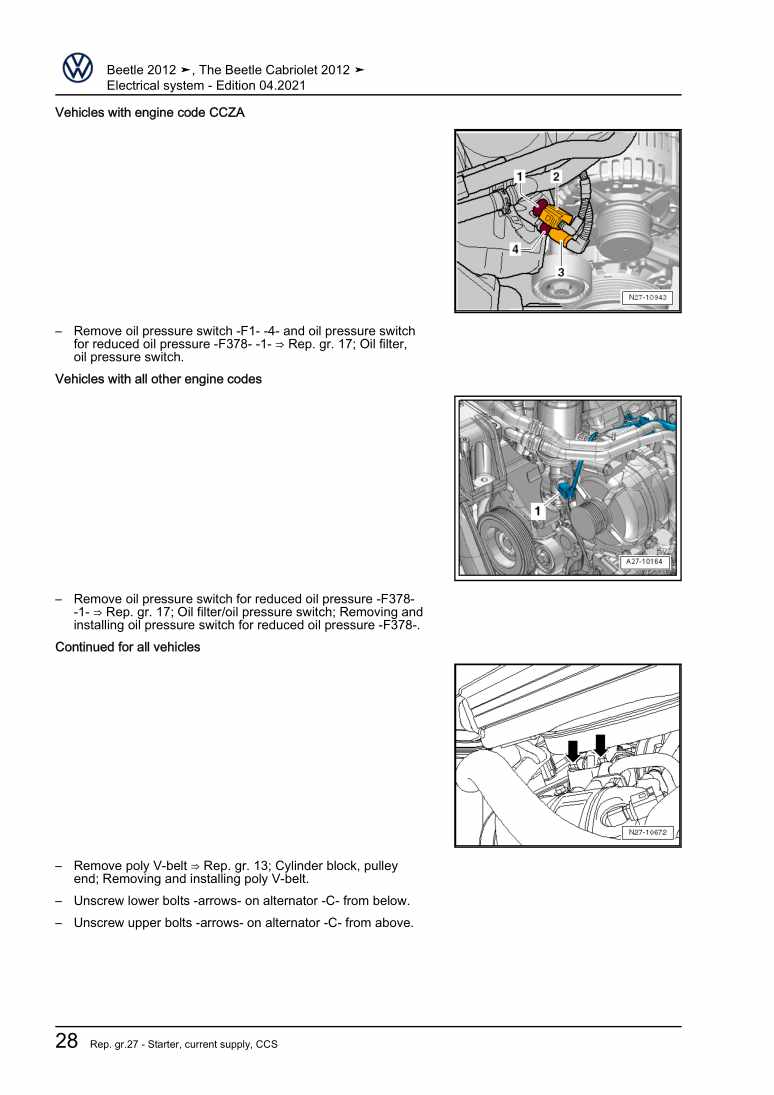

2033.2 Removing and installing oil pressure switch F1

2053.3 Checking oil pressure

2063.4 Checking oil pressure and oil pressure switch

2073.5 Removing and installing oil filter housing

2094 Oil circuit

2144.1 Assembly overview - oil circuit

2144.2 Removing and installing oil supply line to turbocharger

2144.3 Removing and installing oil return line for turbocharger

216Cooling

2231 Cooling system/coolant

2231.1 Coolant hose connection diagram

2231.2 Overview of fitting locations – cooling system

2251.3 Engine preheater

2291.4 Checking cooling system for leaks

2311.5 Draining and adding coolant

2332 Coolant pump, regulation of cooling system

2392.1 Assembly overview - coolant pump, thermostat

2392.2 Coolant circulation pump 2 V178

2392.3 Removing and installing coolant pump

2432.4 Removing and installing 4/2-way valve with thermostat

2452.5 Removing and installing coolant temperature sender

2513 Coolant pipes

2563.1 Assembly overview - coolant pipes

2563.2 Removing and installing coolant pipes

2584 Radiator, radiator fan

2684.1 Assembly overview - radiator/radiator fan

2684.2 Removing and installing radiator

2694.3 Removing and installing radiator cowl with radiator fan

2724.4 Removing and installing radiator fan

273Turbocharging/supercharging

2741 Turbocharger

2741.1 Assembly overview - turbocharger

2741.2 Removing and installing turbocharger

2781.3 Renewing vacuum unit for turbocharger

2822 Charge air system

2922.1 Assembly overview - charge air system

2922.2 Assembly overview - charge-air hose connections

2942.3 Removing and installing charge air cooler

2962.5 Checking charge air system for leaks

300Mixture preparation - injection

3051 Injection system

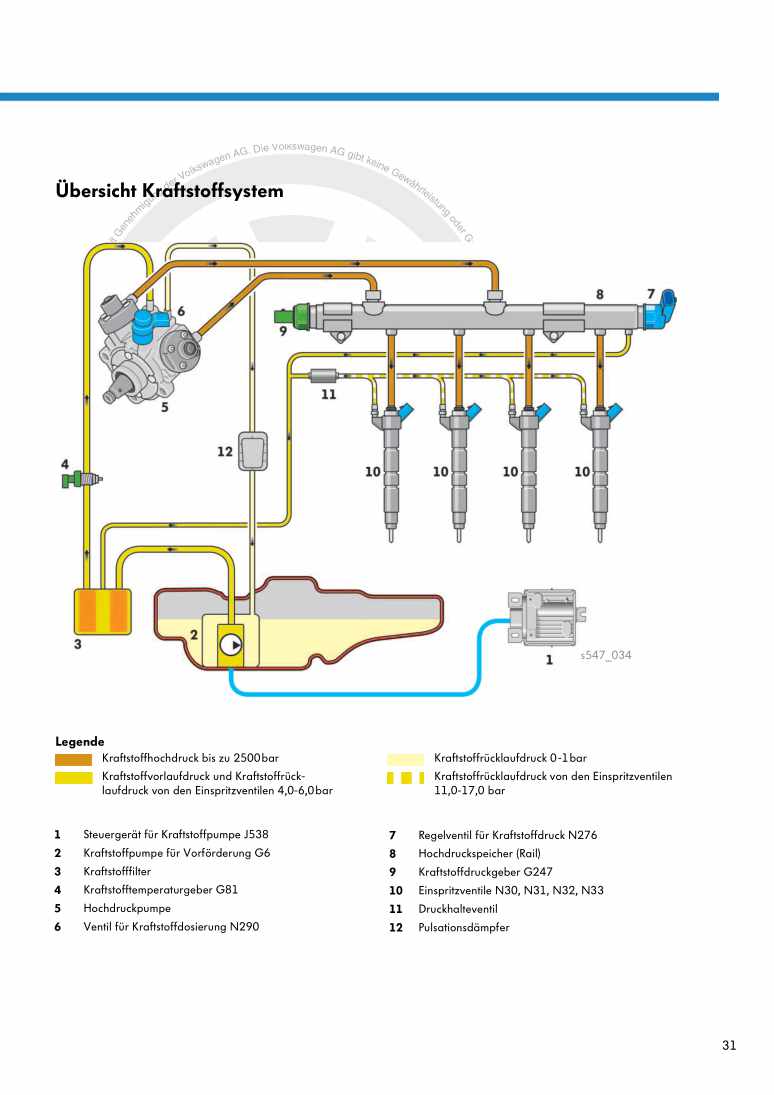

3051.1 Schematic overview - fuel system

3051.2 Filling/bleeding fuel system

3071.3 Checking for leaks in the fuel system

3082 Vacuum system

3092.1 Connection diagram - vacuum system

3092.2 Checking vacuum system

3103 Injectors/high-pressure accumulator (rail)

3133.1 Assembly overview - injectors

3133.2 Removing and installing injectors

3173.3 Installing high-pressure lines

3224 High-pressure pump

3254.1 Assembly overview - high-pressure pump

3254.2 Removing and installing high-pressure pump

3275 Senders and sensors

3325.1 Checking fuel pressure regulating valve N276

3325.2 Check pressure retention valve in fuel return line

3335.3 Removing and installing fuel pressure regulating valve N276

3345.4 Removing and installing fuel pressure sender G247

3365.5 Removing and installing air mass meter G70

3385.6 Removing and installing differential pressure sensor

3406 Intake manifold

3426.1 Assembly overview – intake manifold

3426.2 Removing and installing intake manifold

3436.3 Removing and installing throttle valve module

3487 Lambda probe

3517.1 Removing and installing Lambda probe G39

3518 Air filter

3538.1 Assembly overview - air filter

3538.2 Removing and installing air filter housing

3558.3 Removing and installing air filter element

3568.4 Checking changeover flap for intake air preheating

3588.5 Removing and installing changeover flap for intake air preheating

3609 Engine control unit

3639.1 Removing and installing engine control unit

3639.2 Removing and installing engine control unit with protective housing

364Exhaust system

3671 Exhaust pipes and silencers

3671.1 Assembly overview – silencers

3671.2 Separating exhaust pipes/silencers, saloon

3701.3 Removing and installing rear silencer, Cabriolet

3711.4 Aligning exhaust system free of stress

3721.5 Installation position of clamp

3732 Emission control

3752.1 Assembly overview – emission control

3752.2 Removing and installing particulate filter with NOx storage catalytic converter

3863 Exhaust gas temperature regulation

3943.1 Removing and installing parts of exhaust gas temperature regulation

3944 Exhaust gas recirculation

4054.1 Assembly overview – exhaust gas recirculation

4054.2 Removing and installing exhaust gas recirculation filter

4074.3 Removing and installing exhaust gas recirculation cooler

4094.4 Checking changeover for exhaust gas recirculation cooler

412Glow plug system

4141 Glow plug system

4141.1 Removing and installing glow plug

4141.2 Removing and installing connectors for glow pin plugs

4171.3 Removing and installing automatic glow period control unit J179

4201.4 Removing and installing Hall sender G40

4211.5 Removing and installing engine speed sender G28

424