Technical data

11 Checklist for evaluating running gear of accident vehicles

12 General information

3Front suspension

41 Evaluating accident vehicles

42 Repairing front wheel suspension

52.1 Overview - front axle

52.2 Raising wheel suspension to unladen position

63 Subframe, anti-roll bar, suspension links

93.1 Assembly overview: subframe, anti-roll bar, suspension links

93.2 Repairing thread in longitudinal member

113.3 Fixing position of subframe (all vehicles except for R WRC)

113.4 Fixing position of subframe (R WRC)

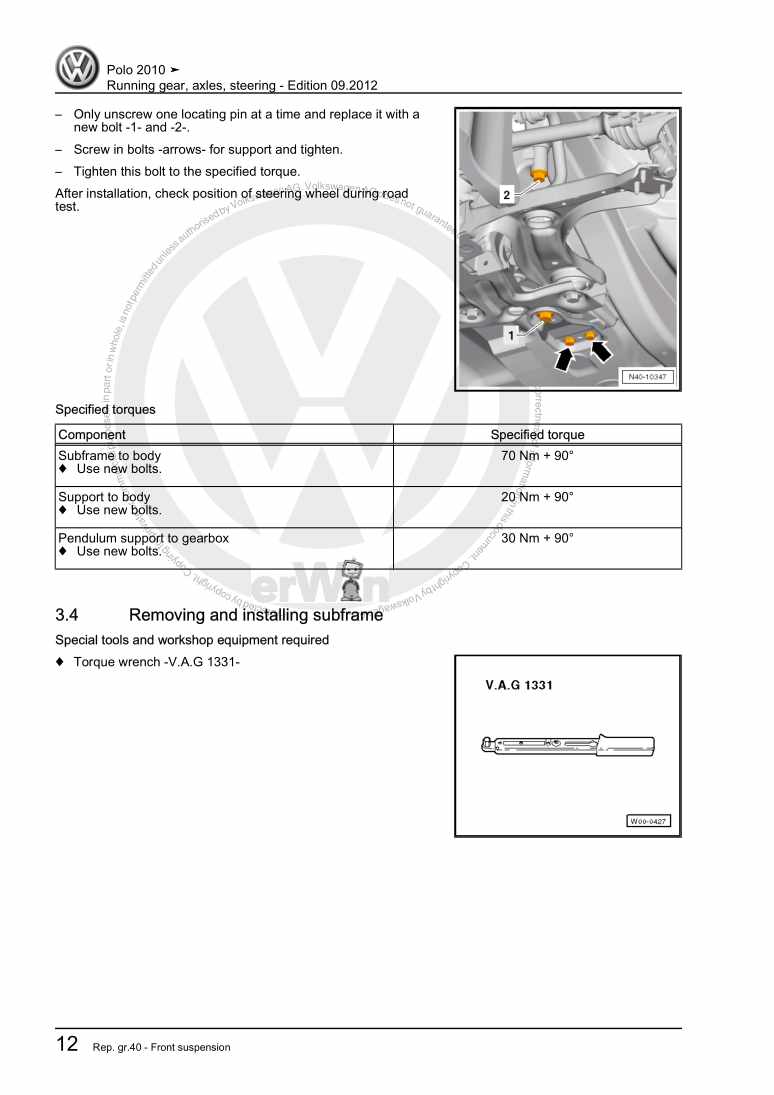

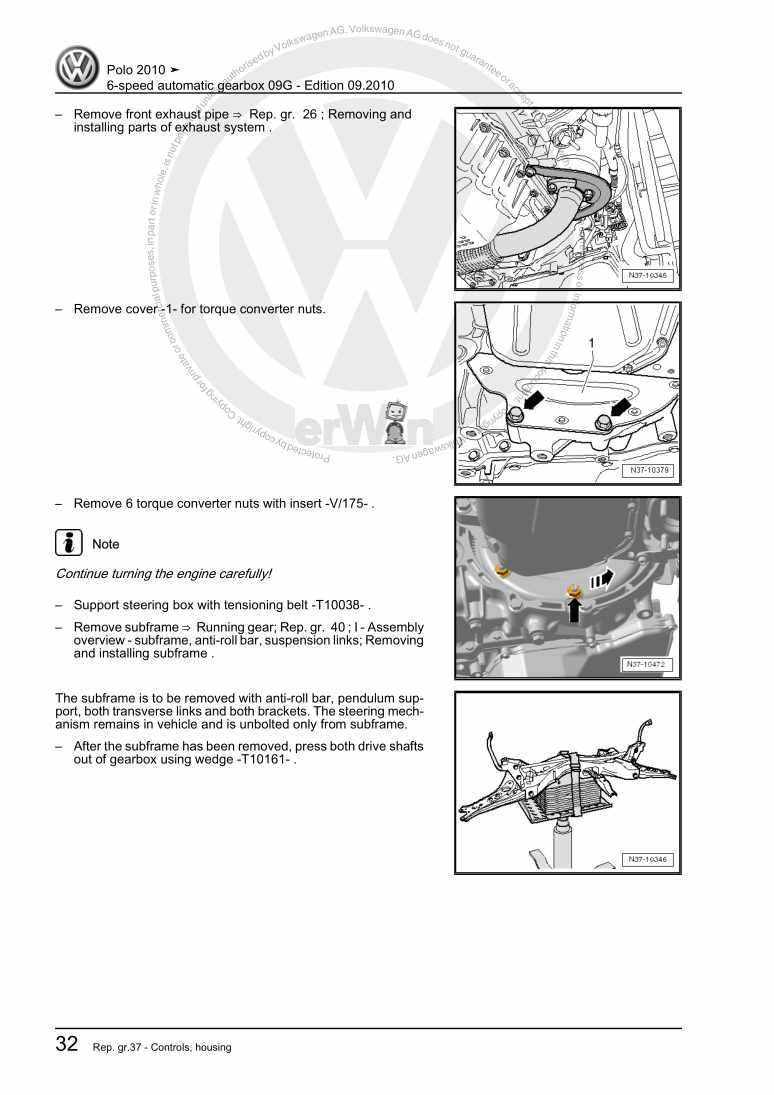

143.5 Removing and installing subframe

163.6 Checking swivel joint

183.7 Removing and installing swivel joint

183.8 Installation position of swivel joints

213.9 Removing and installing suspension link

223.10 Renewing front bonded rubber bush for suspension link

273.11 Renewing rear bonded rubber bush for suspension link

303.12 Removing and installing anti-roll bar

323.13 Removing and installing rubber bush for anti-roll bar

344 Assembly overview: wheel bearing

374.1 Pulling out and pulling in wheel hub with wheel bearing

384.2 Removing and installing wheel bearing housing

435 Assembly overview: suspension strut

475.1 Removing and installing suspension strut

485.2 Repairing front suspension strut

536 Removing and installing drive shafts

576.1 Removing and installing drive shaft with constant velocity joint

576.2 Removing and installing drive shaft with triple roller joint AAR 2000 (bolted-on)

597 Repairing drive shafts - overview of drive shafts

617.1 Heat shields for drive shafts

628 Assembly overview: drive shaft with VL90 or VL100 constant velocity joint

638.1 Dismantling and assembling drive shaft with VL90 or VL100 constant velocity joint

658.2 Checking outer constant velocity joint

708.3 Checking inner constant velocity joint

719 Assembly overview: drive shaft with VL107 constant velocity joint

739.1 Dismantling and assembling drive shaft with VL107 constant velocity joint

7510 Assembly overview: drive shaft with triple roller joint AAR 2000/108

8010.1 Dismantling and assembling drive shaft with triple roller joint AAR 2000/108

82Rear suspension

901 Evaluating accident vehicles

902 Repairing rear axle

912.1 Overview - rear axle

912.2 Rear axle in unladen position

933 Assembly overview: axle beam, drum brake

953.1 Removing and installing rear axle

973.2 Removing and installing bonded rubber bush

1013.3 Removing and installing coil spring, vehicles with small rear silencer

1073.4 Removing and installing coil spring, vehicles with large rear silencer

1084 Assembly overview: axle body, disc brake

1115 Assembly overview: shock absorber

1135.1 Removing and installing shock absorbers

1146 Assembly overview: wheel bearings, drum brake

1166.1 Removing and installing wheel hub with wheel bearing, vehicles with drum brakes

1177 Assembly overview: wheel bearings, disc brake

120Self-levelling suspension

1231 Assembly overview: rear left vehicle level sender G76 , front-wheel drive

1231.1 Removing and installing rear left vehicle level sender G76

123Wheels, tyres, vehicle geometry

1251 Evaluating accident vehicles

1252 Specified torques for wheel bolts

1263 Removing and fitting tyres with run-flat properties to wheel rims

1273.1 Notes on safety and prerequisites

1273.2 Fittings instructions

1273.3 Pressing tyre off wheel rim

1283.4 Removing tyre from wheel

1293.5 Fitting tyre to wheel rim

1304 Tyre pressure monitor display

1335 Vehicle alignment check

1355.1 General information

1355.2 Conditions for testing

1375.3 Test preparations

1375.4 Wheel alignment specifications

1385.5 Transverse vehicle inclination “zero position”

1405.6 Overview - wheel alignment procedure

1405.7 Correcting front axle camber

1415.8 Check rear axle camber

1425.9 Check rear axle toe

1425.10 Adjusting front axle toe

1435.11 Checking left and right-hand wheel lock

1435.12 Vehicle data sticker

1446 Wheels, tyres

1456.1 Models with breakdown set

1456.2 Tyre sealant

1456.3 Removing a tyre

1456.4 Fitting a new tyre

1466.5 Tyre sealant disposal

1467 Instructions for changing or fitting wheels

1477.1 Fitting wheels

1488 Protecting wheel centring seat against corrosion

1499 Wheel change, installation requirements

15010 Vibration due to wheels/tyres - causes and rectification

15210.1 Causes of rough running

15210.2 Balancing wheels

15210.3 Conducting a road test before balancing wheels

15310.4 Balancing wheels on stationary wheel balancing machine

15310.5 Vibration control system VAS 6230 A

15610.6 Finish balancer

15610.7 Radial and lateral runout of wheels and tyres

15710.9 Checking radial and lateral run-out on wheel rim

15810.10 Matching

15910.11 Flat spots caused by storage or handling

160Steering

1621 Evaluating accident vehicles

1622 General repair instructions

1632.1 Steering rack

1632.2 Gaskets and seals

1632.3 Nuts and bolts

1632.4 Electrical components

1642.5 Guided fault finding, vehicle self-diagnosis and test instruments

1643 Steering column

1653.1 Removing and installing steering wheel

1653.2 Assembly overview: steering column, left-hand drive

1683.3 Removing and installing steering column, left-hand drive vehicle

1683.4 Assembly overview: steering column, right-hand drive

1733.5 Removing and installing steering column, right-hand drive vehicle

1743.6 Handling and transporting steering column

1794 Electro-hydraulic power steering

1814.2 Removing and installing power-assisted steering rack, left-hand drive vehicle

1824.3 Removing and installing power steering sensor G250 , left-hand drive vehicle

1884.4 Assembly overview for electrohydraulic power steering, right-hand drive vehicle

1884.5 Removing and installing power steering rack, right-hand drive vehicle

1904.6 Removing and installing power steering sensor G250 , right-hand drive vehicle

1955 Repairing power steering rack

1975.1 Assembly overview: power steering rack, left-hand drive vehicle

1975.2 Assembly overview: power steering rack, right-hand drive vehicle

1995.3 Removing and installing track rod

2015.4 Checking play, security and boots of track rod ends

2025.5 Checking and adjusting left track rod length

2025.6 Allocation of track rod ball joints

2035.7 Allocation of track rod ball joints for GTI and R WRC

2035.8 Determining centre position of steering rack

2045.9 Adjusting steering rack

2046 Motor/pump unit

2056.1 Assembly overview: engine pump unit

2056.2 Removing and installing motor/pump unit

2066.3 Renewing reservoir for motor/pump unit

2096.4 Checking delivery pressure of motor/pump unit

2117 Bleeding steering system, checking for leaks and checking fluid level

2157.1 Bleeding steering system

2157.2 Check steering system for leaks

2157.3 Checking hydraulic fluid level of power steering

216