Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with a start/stop system

21.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on SCR system

32 Identification

42.1 Engine number/engine data

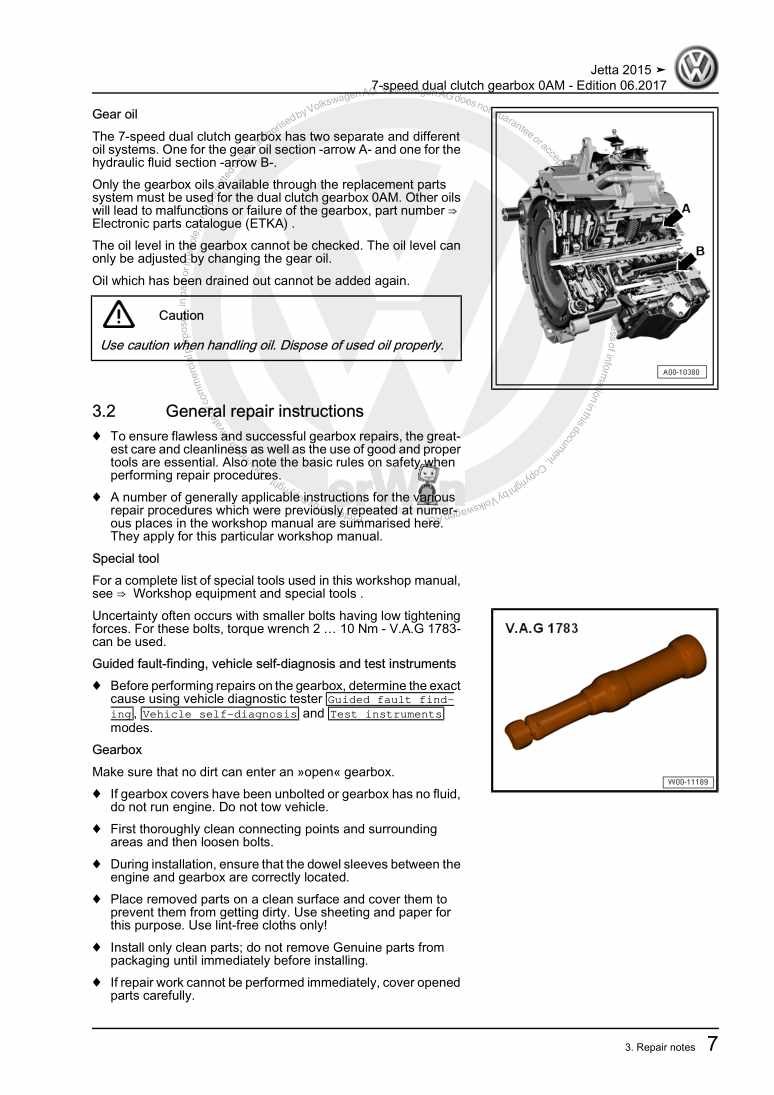

43 Repair instructions

63.1 Rules for cleanliness

63.2 Adapting learnt value for SCR system

63.3 Foreign objects in engine

63.4 Contact corrosion

73.5 Routing and attachment of lines

73.6 Fitting radiator and condensers

74 Technical data

84.1 Coolant

8Removing and installing engine

91 Removing and installing engine

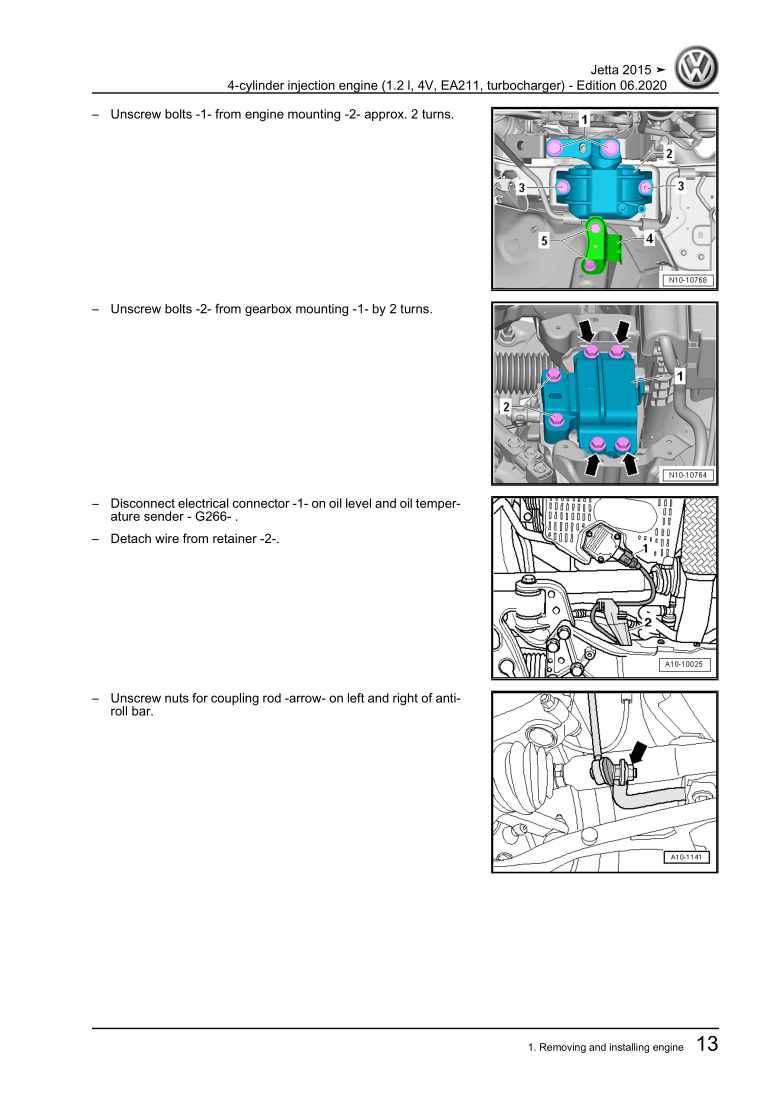

91.1 Removing engine

91.2 Separating engine and gearbox

191.3 Securing engine on engine and gearbox support

201.4 Installing engine

222 Assembly mountings

262.1 Assembly overview - assembly mountings

262.2 Removing and installing engine mounting

282.3 Removing and installing gearbox mounting

292.4 Removing and installing pendulum support

302.5 Supporting engine in installation position

312.6 Adjusting assembly mountings

352.7 Checking adjustment of assembly mountings (engine and gearbox mountings)

363 Engine cover panel

373.1 Removing and installing engine cover

37Crankshaft group

381 Cylinder block (pulley end)

381.1 Assembly overview - cylinder block (pulley end)

381.2 Assembly overview - sealing flange, belt pulley end

401.3 Removing and installing poly-V belt

401.4 Removing and installing tensioner for poly V-belt

421.5 Removing and installing vibration damper

421.6 Removing and installing bracket for ancillaries

431.7 Removing and installing engine support

441.8 Removing and installing sealing flange on pulley end

452 Cylinder block, gearbox end

482.1 Assembly overview - cylinder block, gearbox end

482.2 Removing and installing flywheel

492.3 Removing and installing sealing flange on gearbox side

503 Crankshaft

593.1 Assembly overview - crankshaft

593.2 Crankshaft dimensions

603.3 Renewing needle bearing in crankshaft

603.4 Measuring axial clearance of crankshaft

624 Pistons and conrods

644.1 Assembly overview - pistons and conrods

644.2 Removing and installing pistons

664.3 Measuring piston projection at TDC

674.4 Checking pistons and cylinder bores

694.5 Separating new conrod

714.6 Checking radial clearance of conrods

714.7 Removing and installing oil spray jets

71Cylinder head, valve gear

731 Cylinder head

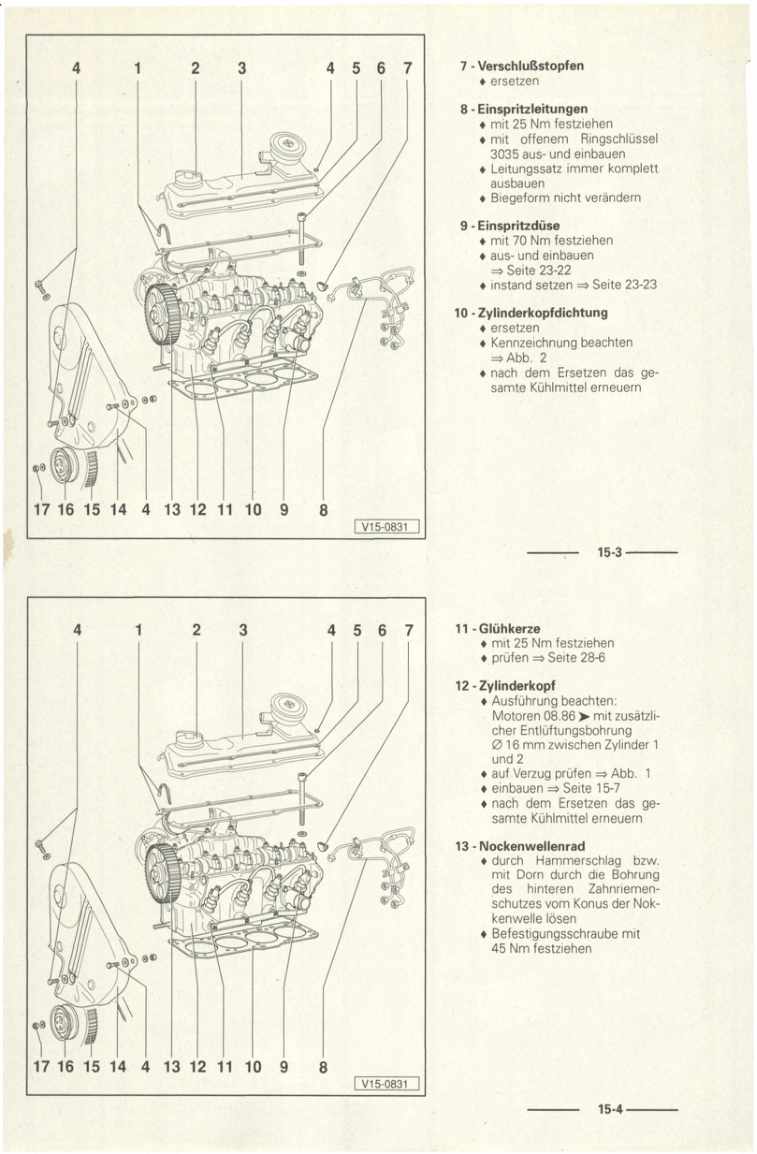

731.1 Assembly overview - cylinder head

731.2 Assembly overview - cylinder head cover

751.3 Removing and installing cylinder head

771.4 Removing and installing cylinder head cover

861.5 Removing and installing injector seals

881.6 Removing and installing camshaft housing

891.7 Checking compression

942 Toothed belt drive

962.1 Assembly overview - toothed belt cover

962.2 Assembly overview - toothed belt

972.3 Removing and installing toothed belt guard

982.4 Removing and installing toothed belt

1012.5 Removing toothed belt from camshaft

1123 Valve gear

1173.1 Assembly overview - valve gear

1173.2 Measuring axial play of camshaft

1203.3 Removing and installing camshaft oil seal

1213.4 Removing and installing camshaft adjuster

1223.5 Removing and installing camshaft control valve 1 N205

1253.6 Removing control valve from and installing on inlet camshaft control valve 1 N205

1263.7 Checking hydraulic compensation elements

1283.8 Removing and installing valve stem seals

1294 Inlet and exhaust valves

1364.1 Checking valve guides

1364.2 Checking valves

1374.3 Valve dimensions

137Lubrication

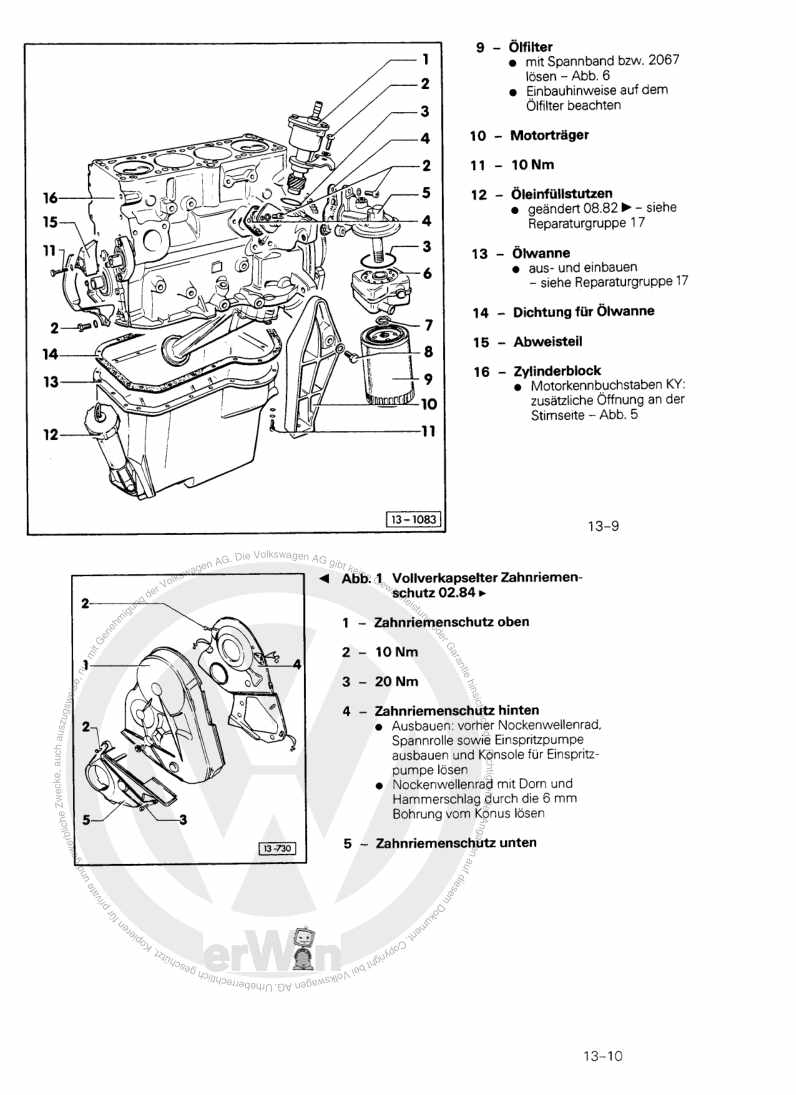

1381 Sump, oil pump

1381.1 Assembly overview - sump/oil pump

1381.2 Engine oil:

1431.3 Removing and installing sump

1431.4 Removing and installing lower part of sump

1461.5 Removing and installing upper part of sump

1501.6 Removing and installing oil pump

1541.7 Removing and installing oil level and oil temperature sender G266

1552 Engine oil cooler

1572.1 Removing and installing engine oil cooler

1573 Oil filter, oil pressure switch

1583.1 Assembly overview - oil filter housing, oil pressure switch

1583.2 Removing and installing oil pressure switch F1

1593.3 Removing and installing oil pressure switch for reduced oil pressure F378

1603.4 Checking oil pressure

1613.5 Removing and installing oil filter housing

1613.6 Removing and installing oil pressure regulating valve N428

163Cooling

1651 Cooling system/coolant

1651.1 Connection diagram - coolant hoses

1651.2 Assembly overview - engine preheater

1711.3 Checking cooling system for leaks

1711.4 Draining coolant

1731.5 Filling with coolant

1751.6 Checking electric vacuum pump VAS 6096/2

1841.7 Flushing cooling system

1841.8 Flushing cooling system, quick reference guide

2052 Coolant pump, regulation of cooling system

2072.1 Assembly overview - coolant pump, thermostat

2072.2 Assembly overview - electric coolant pump

2092.3 Assembly overview - coolant temperature sender

2142.4 Removing and installing electric coolant pump

2152.5 Removing and installing coolant pump

2262.6 Removing and installing thermostat

2272.7 Checking thermostat

2272.8 Removing and installing coolant valve for cylinder head N489

2282.9 Removing and installing coolant temperature sender G62

2282.10 Removing and installing radiator outlet coolant temperature sender G83

2293 Coolant pipes

2313.1 Assembly overview - coolant pipes

2313.2 Removing and installing coolant pipes

2324 Radiator, radiator fan

2424.1 Assembly overview - radiator/radiator fan

2424.2 Removing and installing radiator

2444.3 Removing and installing water radiator for charge air cooling circuit

2454.4 Removing and installing radiator cowl with radiator fan

2484.5 Removing and installing radiator fan

249Turbocharging/supercharging

2501 Exhaust turbocharger

2501.1 Assembly overview - turbocharger

2501.2 Removing and installing turbocharger

2521.3 Renewing vacuum unit for turbocharger

2551.4 Removing and installing connection for turbocharger

2602 Charge air system

2622.1 Assembly overview - charge air system

2622.2 Removing and installing charge pressure sender G31

2642.3 Checking charge air system for leaks

264Mixture preparation - injection

2671 Injection system

2671.1 Schematic overview - fuel system

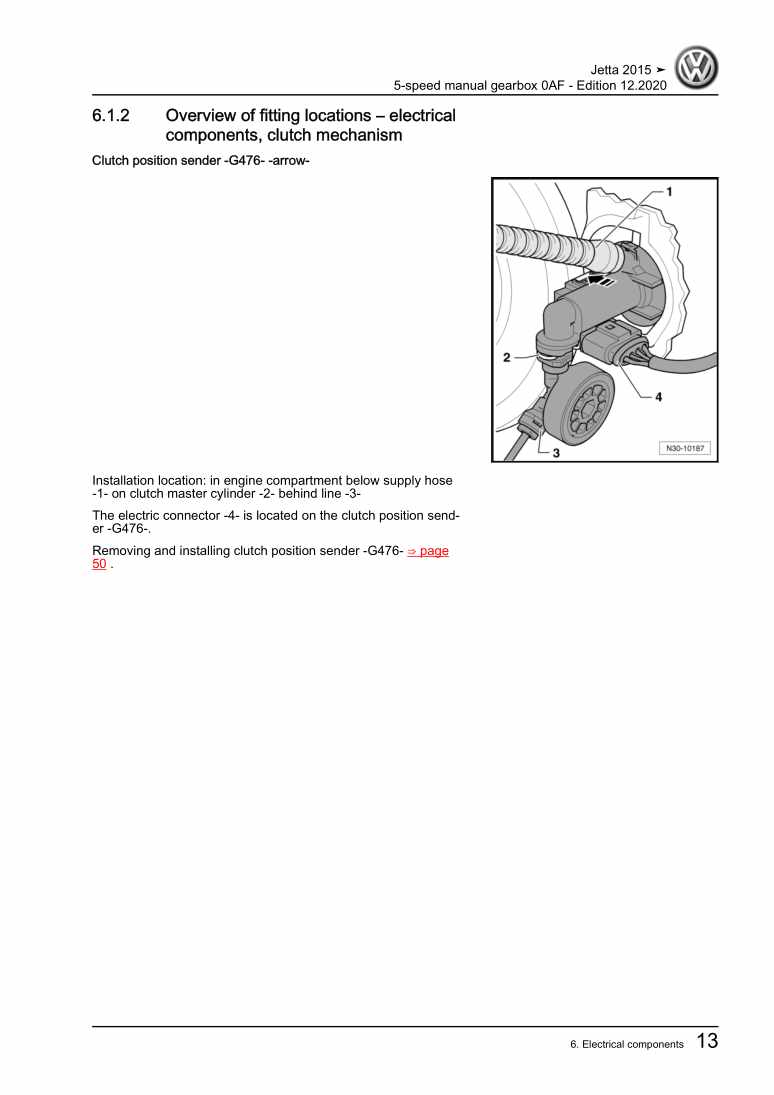

2671.2 Overview of fitting locations - injection system

2681.3 Filling/bleeding fuel system

2741.4 Checking fuel system for leaks

2742 Vacuum system

2752.1 Connection diagram - vacuum system

2752.2 Checking vacuum system

2763 Injectors/high-pressure accumulator (rail)

2773.1 Assembly overview - injectors

2773.2 Assembly overview - fuel rail

2793.3 Adapting correction values for injectors

2803.4 Testing injectors

2803.5 Checking return flow rate of injectors with engine running

2803.6 Checking return flow rate of injectors at starter speed

2833.7 Testing jammed-open injectors

2843.8 Removing and installing injectors

2853.9 Removing and installing high-pressure lines

2883.10 Removing and installing fuel rail

2904 Air filter

2924.1 Assembly overview - air filter housing

2924.2 Removing and installing air filter housing

2935 Intake manifold

2965.1 Assembly overview - intake manifold

2965.2 Removing and installing intake manifold

2985.3 Removing and installing throttle valve module J338

3016 Senders and sensors

3046.1 Removing and installing fuel pressure regulating valve N276

3046.2 Checking fuel pressure regulating valve N276

3106.3 Removing and installing fuel pressure sender G247

3116.4 Removing and installing air mass meter G70

3126.5 Removing and installing pressure differential sender G505

3146.6 Removing and installing exhaust gas pressure sensor 1 G450

3156.7 Removing and installing NOx sender 2 G687

3166.8 Removing and installing control unit for NOx sender GX30

3186.10 Removing and installing fuel temperature sender G81

3247 Engine control unit

3277.1 Removing and installing engine (motor) control unit J623

3278 High-pressure pump

3318.1 Assembly overview - high-pressure pump

3318.2 Removing and installing high-pressure pump

3319 Lambda probe

3359.1 Assembly overview - Lambda probe

3359.2 Removing and installing Lambda probe

337Exhaust system

3411 Exhaust pipes and silencers

3411.1 Assembly overview - silencers

3411.2 Assembly overview - front exhaust pipe

3431.3 Removing and installing front exhaust pipe

3441.4 Separating exhaust pipes from silencers

3451.5 Removing and installing rear silencer

3461.6 Aligning exhaust system free of stress

3471.7 Checking exhaust system for leaks

3471.8 Installation position of clamp

3481.9 Align end exhaust pipes

3482 Exhaust gas cleaning

3502.1 Assembly overview - emission control

3502.2 Removing and installing emission control module

3522.3 Removing and installing exhaust flap control unit J883

3583 SCR system (selective catalytic reduction)

3603.1 Assembly overview - tank for reducing agent

3603.2 Assembly overview - reducing agent delivery line

3623.3 Assembly overview - delivery module for reducing agent

3633.4 Assembly overview - injector for reducing agent

3643.5 Removing and installing reducing agent tank

3653.6 Removing and installing reducing agent supply line

3673.7 Disconnecting reducing agent supply line

3703.8 Removing and installing delivery module for reducing agent

3743.9 Removing and installing injector for reduction agent N474

3763.10 Removing and installing control unit for reducing-agent heater J891

3773.11 Draining reducing agent tank

3784 Exhaust gas temperature regulation

3814.1 Assembly overview - exhaust gas temperature regulation

3814.2 Removing and installing exhaust gas temperature sender 1 G235

3844.3 Removing and installing exhaust gas temperature sender 2 G448

3854.4 Removing and installing exhaust gas temperature sender 3 G495

3884.5 Removing and installing exhaust gas temperature sender 4 G648

3895 Exhaust gas recirculation

3925.1 Assembly overview - exhaust gas recirculation

3925.2 Assembly overview - exhaust gas recirculation valve 1 GX5

3965.3 Removing and installing exhaust gas recirculation cooler

3965.4 Checking exhaust gas recirculation cooler for leaks

3995.5 Removing and installing exhaust gas recirculation valve 1 GX5

4015.6 Removing and installing exhaust gas recirculation valve 2 GX6

4025.7 Removing and installing exhaust gas recirculation temperature sensor G98

405Glow plug system

4071 Glow plug system

4071.1 Assembly overview - glow plug system

4071.2 Removing and installing glow plug

4091.3 Removing and installing automatic glow period control unit J179

4111.4 Removing and installing Hall sender G40

4121.5 Removing and installing engine speed sender G28

412