Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with a start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on ignition system

21.6 Safety precautions when working on exhaust system

32 Identification

42.1 Engine number/engine data

43 Repair instructions

63.1 Rules for cleanliness

63.2 General information

73.3 Foreign objects in engine

73.4 Contact corrosion

83.5 Routing and attachment of lines

83.6 Fitting radiator and condensers

83.7 Checking vacuum system

8Removing and installing engine

101 Removing and installing engine

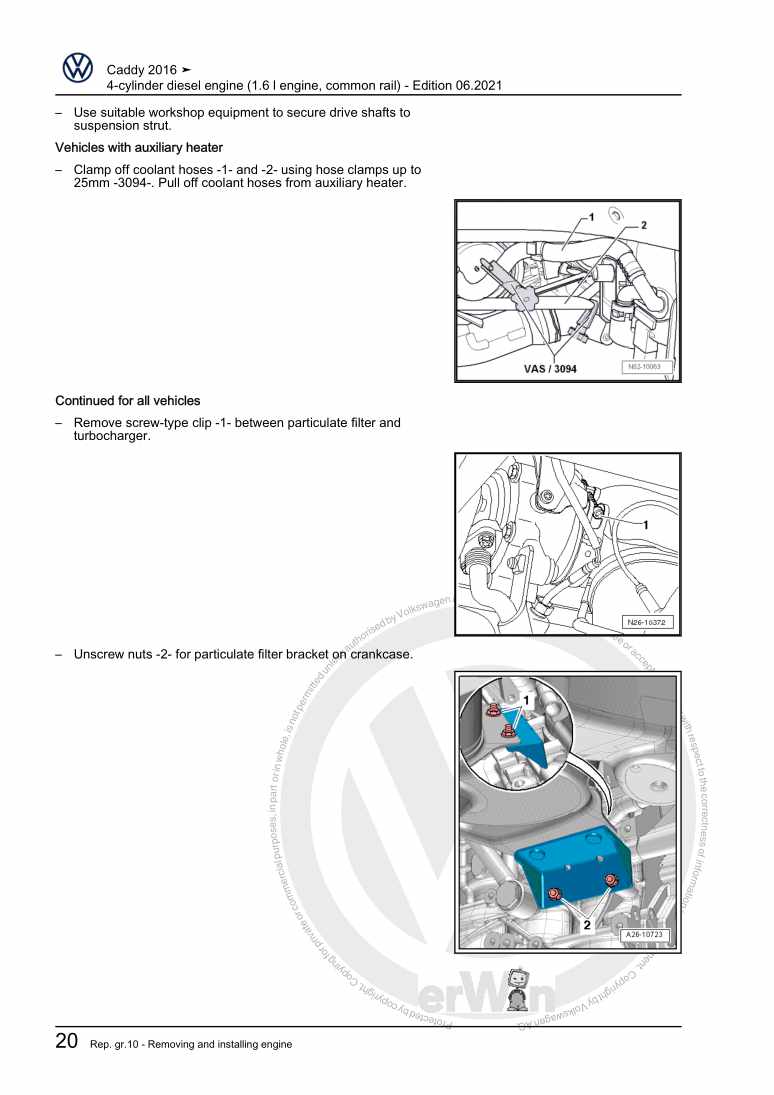

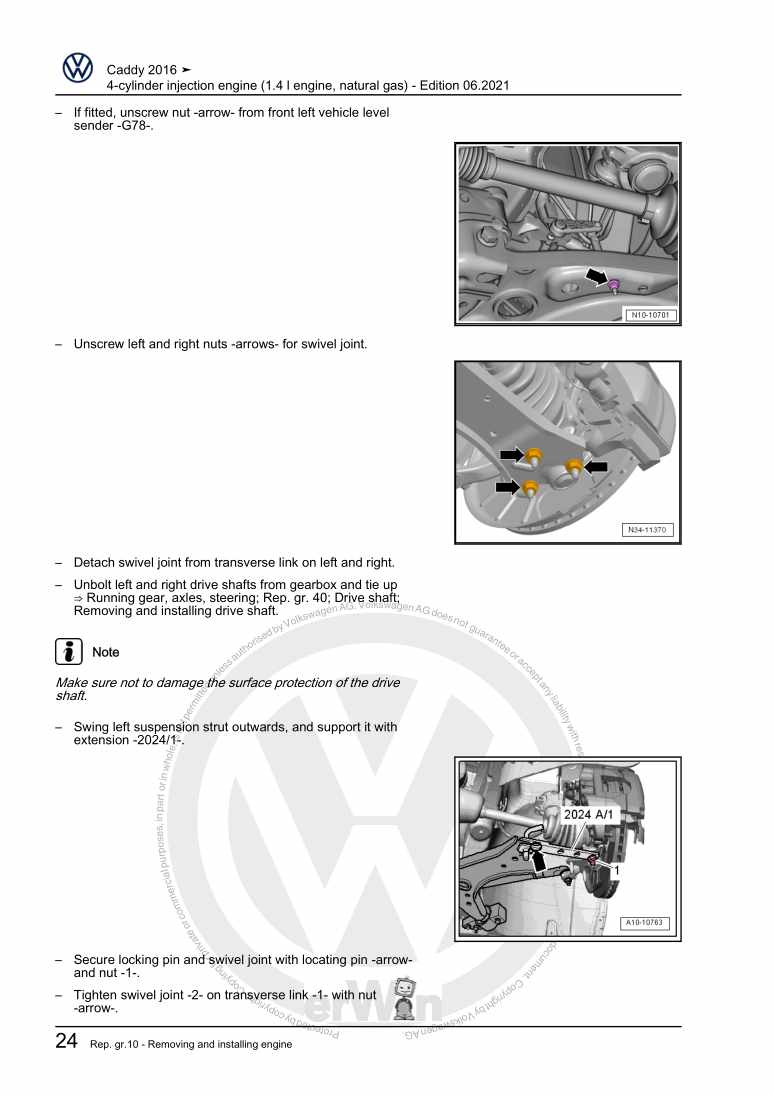

101.1 Removing engine

101.2 Separating engine and gearbox

181.3 Securing engine on engine and gearbox support

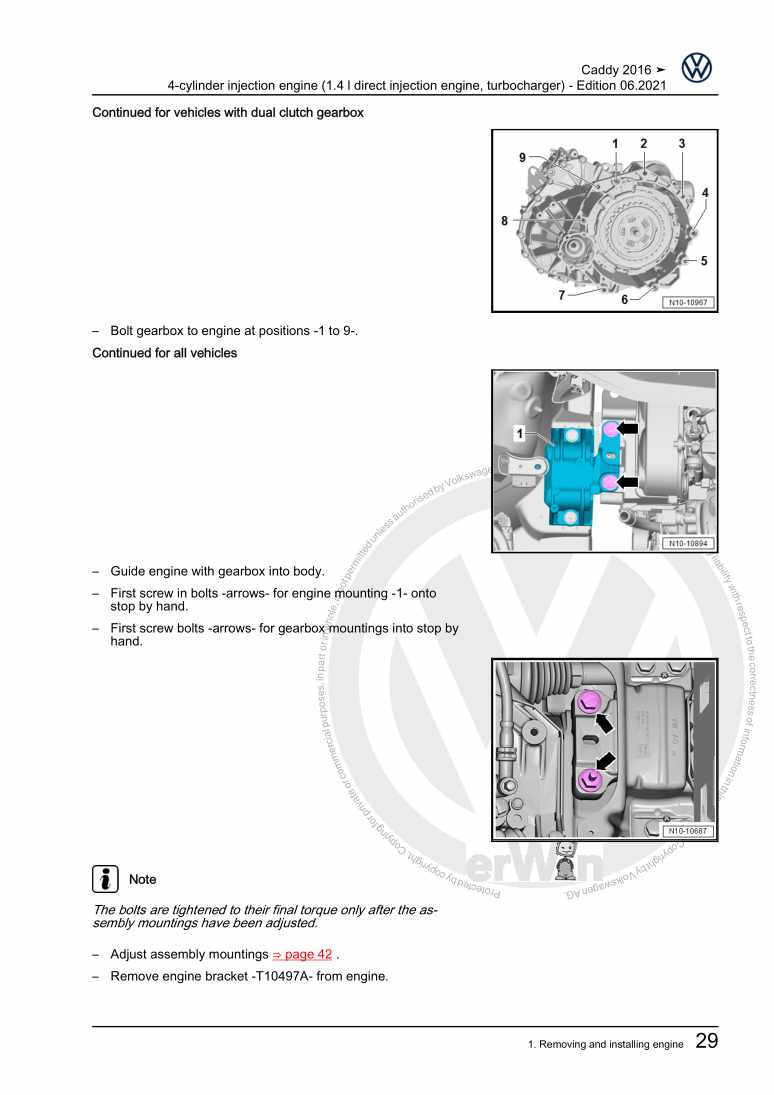

201.4 Installing engine

212 Assembly mountings

262.1 Assembly overview - assembly mountings

262.2 Removing and installing engine mounting

282.3 Removing and installing gearbox mounting

302.4 Removing and installing pendulum support

322.5 Supporting engine in installation position

332.6 Adjusting assembly mountings

352.7 Checking adjustment of assembly mountings

38Crankshaft group

401 Cylinder block (pulley end)

401.1 Assembly overview - poly V-belt drive

401.2 Removing and installing poly-V belt

441.3 Removing and installing tensioner for poly V-belt

481.4 Removing and installing vibration damper

491.5 Removing and installing engine support

531.6 Renewing crankshaft oil seal - belt pulley end

572 Cylinder block, gearbox end

612.1 Assembly overview - cylinder block, gearbox end

612.2 Removing and installing flywheel

622.3 Removing and installing sealing flange on gearbox side

633 Crankshaft

743.1 Crankshaft dimensions

743.2 Renewing needle bearing in crankshaft

743.3 Measuring axial clearance of crankshaft

774 Pistons and conrods

794.1 Assembly overview - pistons and conrods

794.2 Removing and installing pistons

824.3 Checking pistons and cylinder bores

834.4 Separating new conrod

854.5 Checking radial clearance of conrods

864.6 Removing and installing oil spray jets

86Cylinder head, valve gear

881 Cylinder head

881.1 Assembly overview - cylinder head

881.2 Assembly overview - camshaft housing

901.3 Removing and installing cylinder head

921.4 Removing and installing camshaft housing

961.5 Checking compression

1002 Toothed belt drive

1032.1 Assembly overview - toothed belt cover

1032.2 Assembly overview - toothed belt

1032.3 Removing and installing toothed belt

1052.4 Checking valve timing

1112.5 Adjusting valve timing

1162.6 Removing toothed belt from camshaft

1193 Valve gear

1243.1 Assembly overview - valve gear

1243.2 Measuring axial play of camshaft

1263.3 Removing and installing camshaft oil seal

1273.4 Removing and installing camshaft adjuster

1343.5 Removing and installing camshaft control valve 1 N205

1353.6 Removing and installing exhaust camshaft control valve 1 N318

1363.7 Removing and installing valve stem seals

1374 Inlet and exhaust valves

1474.1 Reworking valve seats

1474.2 Checking valve guides

1494.3 Checking valves

1504.4 Valve dimensions

150Lubrication

1511 Sump, oil pump

1511.1 Assembly overview - sump/oil pump

1511.2 Engine oil:

1551.3 Removing and installing sump

1561.4 Removing and installing oil pump

1621.5 Removing and installing oil level and oil temperature sender G266

1642 Engine oil cooler

1652.1 Assembly overview - engine oil cooler

1652.2 Removing and installing engine oil cooler

1653 Crankcase ventilation

1673.1 Assembly overview - crankcase breather system

1673.2 Removing and installing oil separator

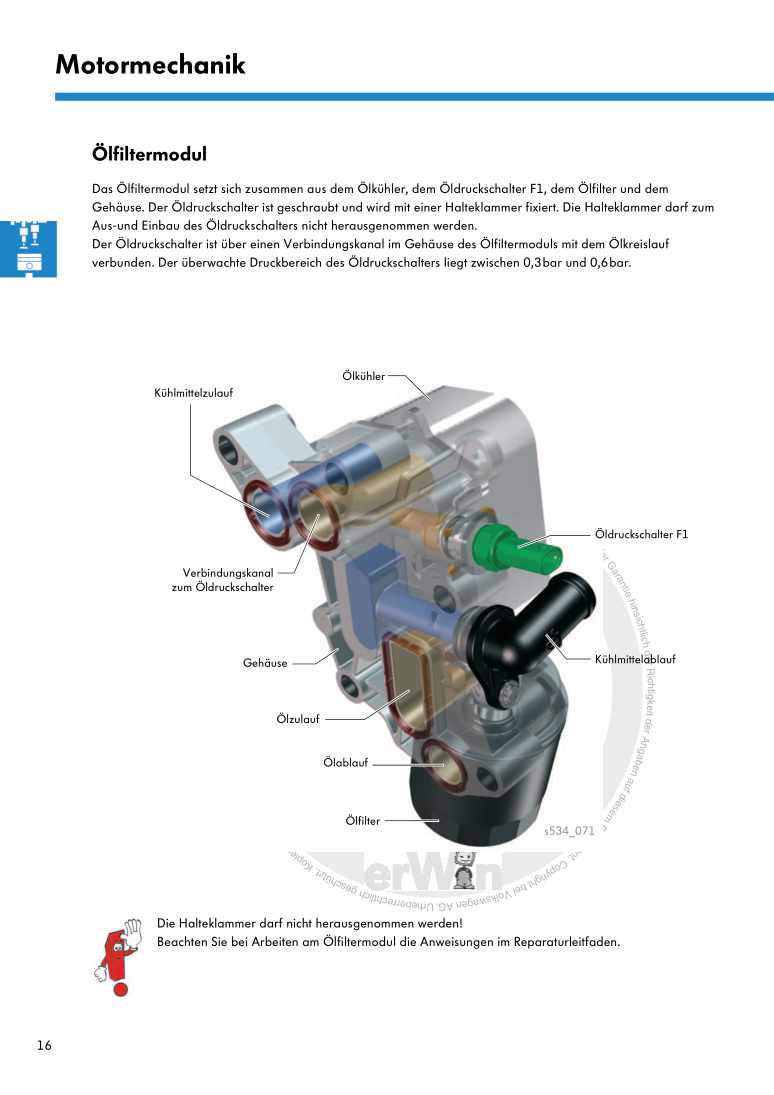

1684 Oil filter, oil pressure switch

1724.1 Assembly overview - oil filter/oil pressure switch

1724.2 Removing and installing oil pressure sender G10

1744.3 Checking oil pressure

1754.4 Removing and installing oil pressure regulating valve N428

176Cooling

1781 Cooling system/coolant

1781.1 Connection diagram - coolant hoses

1781.2 Checking cooling system for leaks

1801.3 Draining and adding coolant

1822 Coolant pump, regulation of cooling system

1902.1 Assembly overview - coolant pump, thermostat

1902.2 Assembly overview - electric coolant pump

1932.3 Assembly overview - coolant temperature sender

1942.4 Removing and installing electric coolant pump

1952.5 Removing and installing coolant pump

1972.6 Removing and installing thermostat

2032.7 Removing and installing toothed belt pulley for coolant pump

2072.8 Removing and installing coolant temperature sender G62

2092.9 Removing and installing radiator outlet coolant temperature sender G83

2113 Coolant pipes

2133.1 Assembly overview - coolant pipes

2133.2 Removing and installing coolant pipes

2134 Radiator, radiator fan

2164.1 Assembly overview - radiator/radiator fan

2164.2 Assembly overview – radiator cowl and radiator fan

2184.3 Removing and installing radiator

2194.4 Removing and installing radiator cowl with radiator fan

2234.5 Removing and installing radiator fan V7

225Turbocharging/supercharging

2271 Turbocharger

2271.1 Assembly overview - turbocharger

2271.2 Removing and installing turbocharger

2291.3 Removing and installing charge pressure positioner V465

2352 Charge air system

2382.1 Assembly overview - charge air system

2382.2 Removing and installing charge air cooler

2412.4 Checking charge air system for leaks

2442.5 Removing and installing air pipe

246Mixture preparation - injection

2481 Injection system

2481.1 Overview of fitting locations - injection system

2482 Injectors

2522.1 Assembly overview - fuel rail with injectors

2522.2 Removing and installing fuel rail

2542.3 Removing and installing injectors

2542.4 Renewing seals on injectors

2592.5 Cleaning injectors

2643 Air filter

2663.1 Assembly overview - air filter housing

2663.2 Removing and installing air filter housing

2674 Intake manifold

2704.1 Assembly overview – intake manifold

2704.2 Removing and installing intake manifold

2724.3 Removing and installing throttle valve module GX3

2754.4 Cleaning throttle valve module

2765 Senders and sensors

2785.1 Removing and installing fuel pressure sender G247

2785.2 Checking fuel pressure sender G247

2795.3 Removing and installing exhaust gas pressure sensor 1 G450

2825.4 Removing and installing intake manifold sender GX9

2836 Engine control unit

2846.1 Removing and installing engine (motor) control unit J623 with protective housing

2847 High-pressure pump

2877.1 Assembly overview - high-pressure pump

2877.2 Removing and installing high-pressure pump

2887.3 Removing and installing high-pressure pipe

2898 Lambda probe

2918.1 Assembly overview - Lambda probe

2918.2 Removing and installing Lambda probe

292Exhaust system

2941 Exhaust pipes and silencers

2941.1 Assembly overview – silencers

2941.2 Separating exhaust pipes from silencers

2951.3 Aligning exhaust system free of stress

2971.4 Checking exhaust system for leaks

2981.5 Installation position of clamp

2982 Emission control

3012.1 Assembly overview – emission control

3012.2 Removing and installing catalytic converter

304Ignition system

3071 Ignition system

3071.1 Assembly overview - ignition system

3071.2 Removing and installing ignition coils with output stage

3091.3 Removing and installing knock sensor 1 G61

3111.4 Removing and installing Hall sender

3121.5 Removing and installing engine speed sender G28

313