Technical data

11 Safety information

11.1 Safety measures when working on vehicles with start/stop system

11.2 Safety precautions when working on subframe

12 Repair instructions

22.1 Leaks at shock absorbers

22.2 Noises from shock absorbers

22.3 Checking shock absorbers when removed

32.4 Steering rack

32.5 Gaskets and seals

42.6 Nuts and bolts

42.7 Electrical components

42.8 Raising suspension to unladen position (vehicles with coil springs)

53 Evaluating accident vehicles

163.1 Check list for evaluating running gear on accident vehicles

164 Technical data

184.1 Running gear

185 Disposal

195.1 Releasing gas and draining front gas-filled shock absorbers

195.2 Releasing gas and draining rear gas-filled shock absorbers

196 Hazard classification of high-voltage system

21Front suspension

221 Front axle

221.1 Overview of fitting locations – front axle

222 Subframe

232.1 Assembly overview – subframe

232.2 Removing and installing subframe without steering rack

262.3 Removing and installing subframe with steering rack

342.4 Repairing subframe

482.5 Removing and installing anti-roll bar

702.6 Removing and installing coupling rod

782.7 Repairing thread in longitudinal member

792.8 Fixing subframe in position

792.9 Lowering subframe

853 Suspension strut, upper suspension link

933.1 Assembly overview - suspension strut, upper suspension link

933.2 Removing and installing suspension strut

953.3 Repairing suspension strut

1024 Lower suspension link, swivel joint

1074.1 Assembly overview - lower suspension link, swivel joint

1074.2 Removing and installing lower suspension link

1104.3 Renewing mounting bracket with suspension link bush

1224.4 Checking swivel joint

1254.5 Removing and installing swivel joint

1264.6 Renewing bonded rubber bush for lower suspension link

1295 Wheel bearing

1405.1 Assembly overview – wheel bearing assembly

1405.2 Removing and installing wheel bearing housing

1425.3 Removing and installing wheel bearing unit

1486 Drive shaft

1536.1 Overview - drive shaft

1536.2 Assembly overview – drive shaft

1546.3 Removing and installing drive shaft

1606.4 Loosening and tightening threaded connections of drive shaft

1686.5 Dismantling and assembling drive shaft

1696.6 Checking outer constant velocity joint

1876.7 Checking inner constant velocity joint

188Rear suspension

1921 Rear axle

1921.1 Overview – rear axle

1921.2 Removing and installing rear axle shaft

1932 Axle beam

1942.1 Assembly overview – axle beam

1942.2 Removing and installing axle beam

1952.3 Renewing bonded rubber bush for axle beam

2023 Anti-roll bar

2053.1 Assembly overview – anti-roll bar

2053.2 Removing and installing anti-roll bar

2053.3 Removing and installing coupling rod

2074 Suspension strut, shock absorber, spring

2094.1 Assembly overview - suspension strut, shock absorber, spring

2094.2 Removing and installing shock absorber

2114.3 Removing and installing spring

2164.4 Renewing bonded rubber bush for spring

2194.5 Removing and installing shackle

2205 Wheel bearing assembly, trailing arm

2225.1 Assembly overview – wheel bearing assembly

2225.2 Removing and installing wheel bearing unit

224Self-levelling suspension

2301 Vehicle level sender

2301.1 Assembly overview – front vehicle level senders

2301.2 Assembly overview – rear vehicle level senders

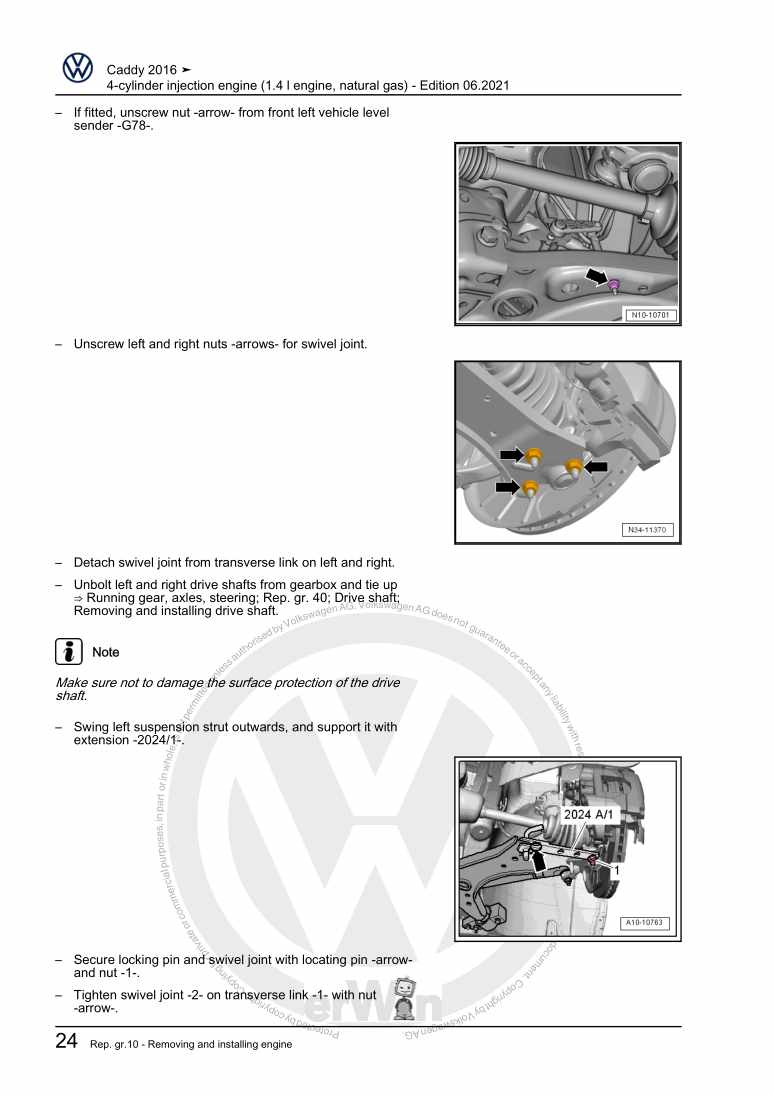

2311.3 Removing and installing front vehicle level senders G78/G289

2311.4 Removing and installing rear vehicle level senders G76/G77

233Wheels, tyres, vehicle geometry

2351 Wheels, tyres

2351.1 Removing tyre from wheel

2351.2 Fitting tyre

2351.3 Wheel change

2361.4 Specified torques for wheel bolts

2411.5 Pressing tyre off wheel rim

2411.6 Tyre sealant disposal

2421.7 Models with breakdown set

2422 Tyre Pressure Monitoring System

2432.1 System description – Tyre Pressure Monitoring System

2433 Wheel alignment

2453.1 Notes for wheel alignment

2453.2 Conditions for testing

2453.3 Test preparations

2463.4 Specifications for wheel alignment

2483.5 Wheel alignment procedure

2513.6 Necessity of wheel alignment

2523.7 Adjusting camber at front wheels

2533.8 Adjusting camber on rear axle

2573.9 Adjusting toe at rear axle

2573.10 Adjusting front axle toe

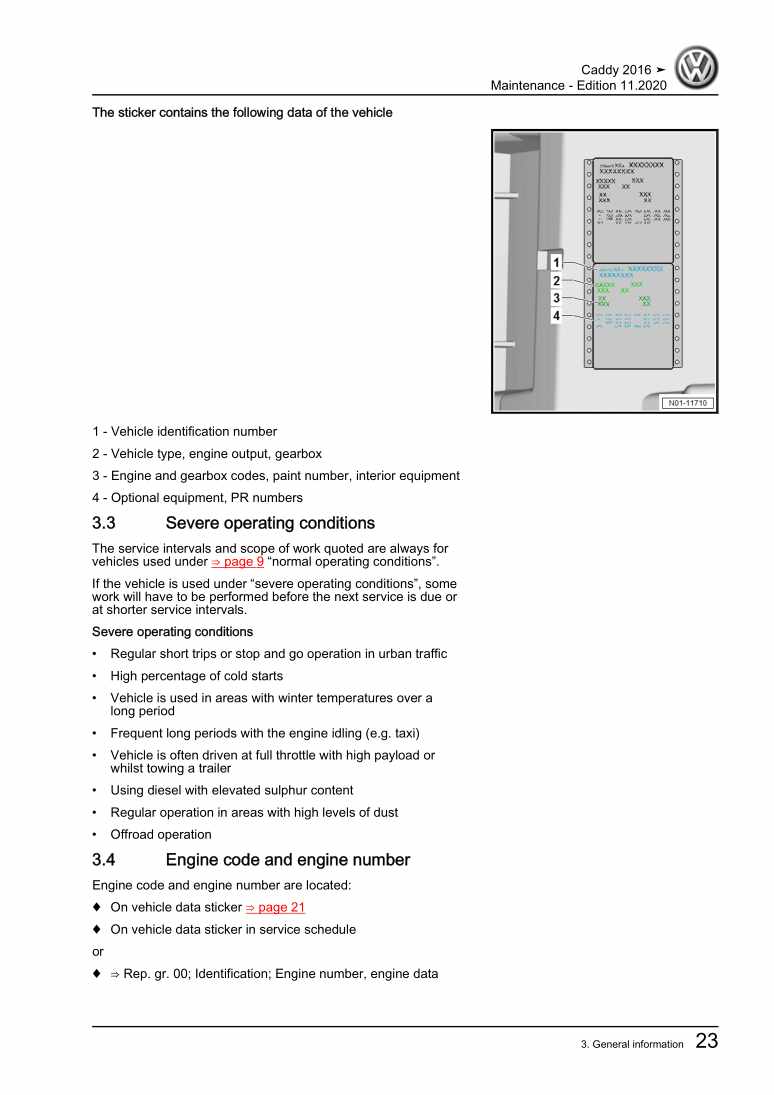

2573.11 Vehicle data sticker

2584 Adaptive cruise control

2604.1 Calibrating adaptive cruise control

2605 Front camera for assist systems

2675.1 Calibrating front camera for assist systems

267Steering

2751 Steering wheel

2751.1 Assembly overview – steering wheel

2751.2 Removing and installing steering wheel

2752 Steering column

2782.1 Assembly overview – steering column

2782.2 Checking steering column for damage

2802.3 Handling and transporting steering column

2802.4 Removing and installing steering column

2822.5 Removing and installing mounting bracket with strut

2953 Steering rack

2973.1 Assembly overview – steering rack

2973.2 Removing and installing steering rack

2993.3 Removing and installing bellows

3123.4 Removing and installing track rod

3153.5 Removing and installing track rod ball joint

3203.6 Repairing steering rack

3224 Sensors

3254.1 Removing and installing steering angle sender G85

325