Technical data

11 Checklist for evaluating running gear of accident vehicles

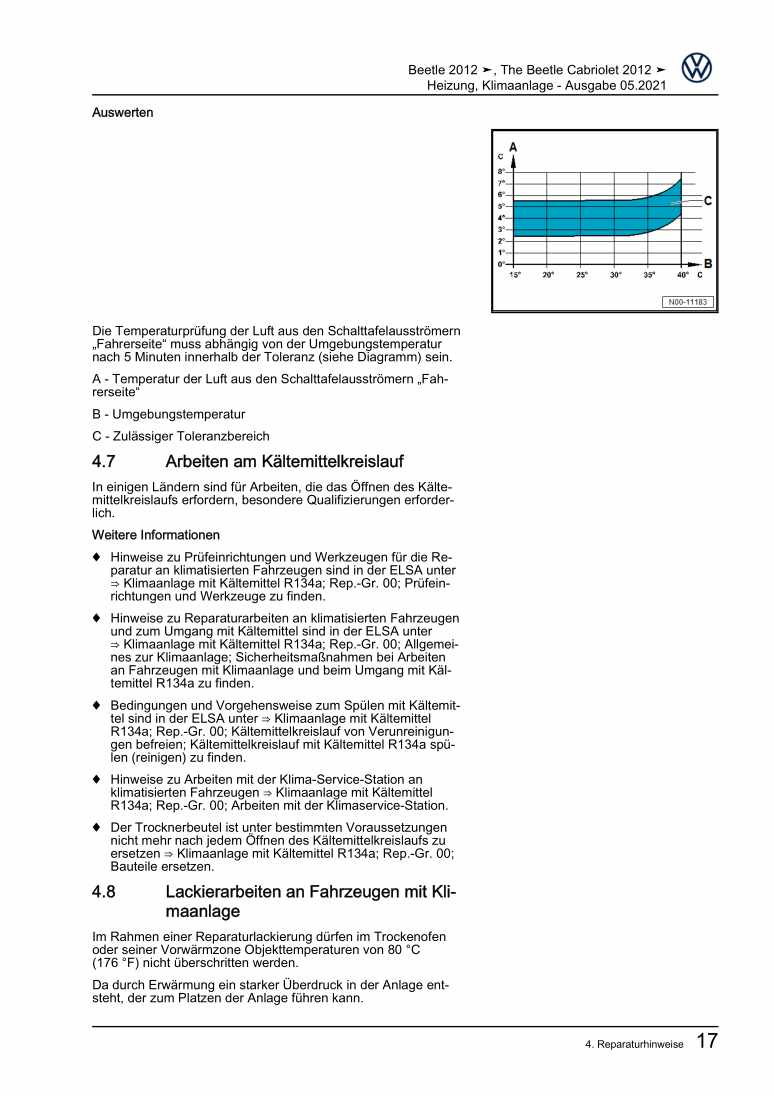

12 General information

3Front suspension

41 Appraisal of accident vehicles

42 Raising wheel bearing to unladen position

53 Repairing front suspension

74 I: Assembly overview: subframe, anti-roll bar, lower suspension link

94.1 Repairing thread in longitudinal member

104.2 Fixing position of subframe

114.3 Removing and installing subframe

134.4 Repairing subframe

194.5 Removing and installing subframe front bonded rubber bush

224.6 Removing and installing subframe rear bonded rubber bush

244.7 Checking swivel joint

254.8 Removing and installing lower suspension link

255 Assembly overview: disengageable anti-roll bar

365.1 Removing and installing disengageable anti-roll bar

375.3 Bleeding disengageable anti-roll bar

416 II: Assembly overview: front suspension

436.1 Repairing upper suspension link

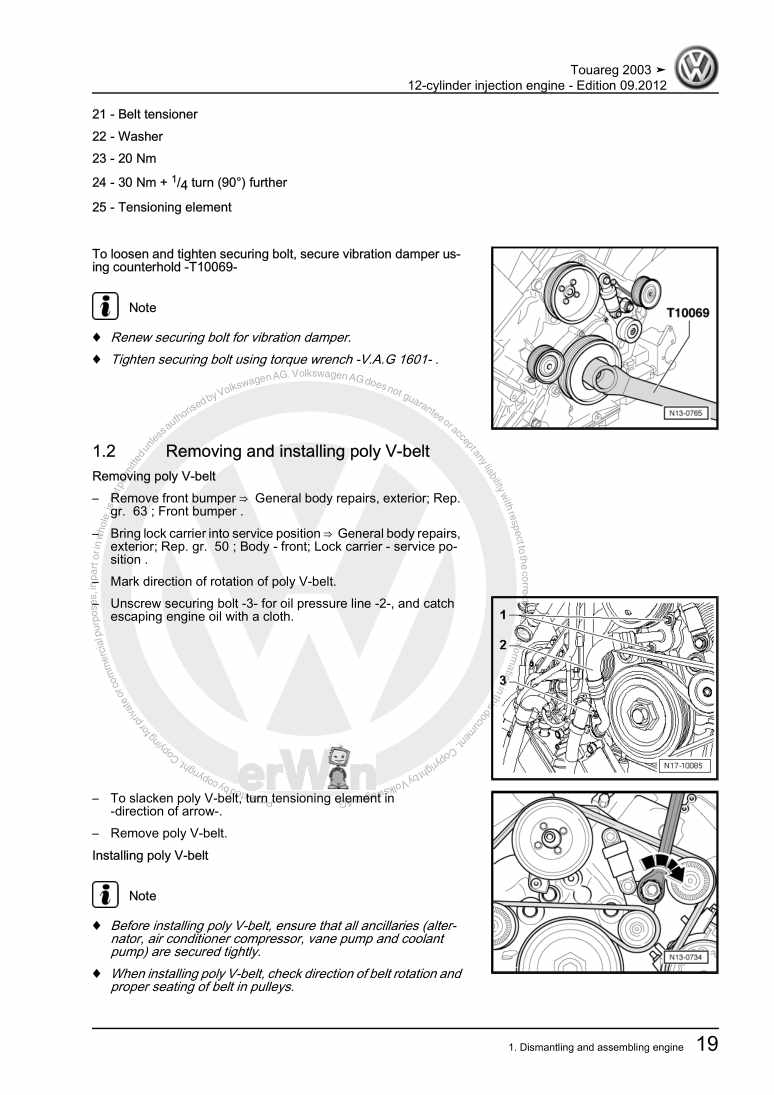

456.2 Removing and installing suspension strut

476.3 Removing and installing air spring strut

496.4 Charging air spring strut

547 III: Assembly overview: wheel bearing

617.1 Removing and installing wheel hub with bearing for 16" inch wheels

627.2 Removing and installing wheel bearing for 17"/18"/18" plus running gear

658 IV: Assembly overview: suspension strut

718.1 Allocation of lower spacer

718.2 Repairing front coil spring suspension strut

719 V - Front air spring strut

759.1 Instructions for repairing air spring struts

759.2 Air spring strut

759.3 Residual pressure valve

759.4 Gaskets and seals

769.5 Nuts and bolts

769.6 Front air spring strut components

769.7 Assembly overview - front air spring strut

789.8 Repairing front air spring strut

789.9 Removing and installing residual pressure valve

8510 Assembly overview: drive shaft

8710.1 Removing and installing jointed shaft

8810.2 Dismantling and assembling drive shaft

9110.3 Checking outer joint

95Rear suspension

971 Appraisal of accident vehicles

972 Repairing rear suspension

983 I - Assembly overview: subframe, anti-roll bar, stone deflector

1003.1 Repairing thread in rear longitudinal member

1013.2 Fixing position of subframe

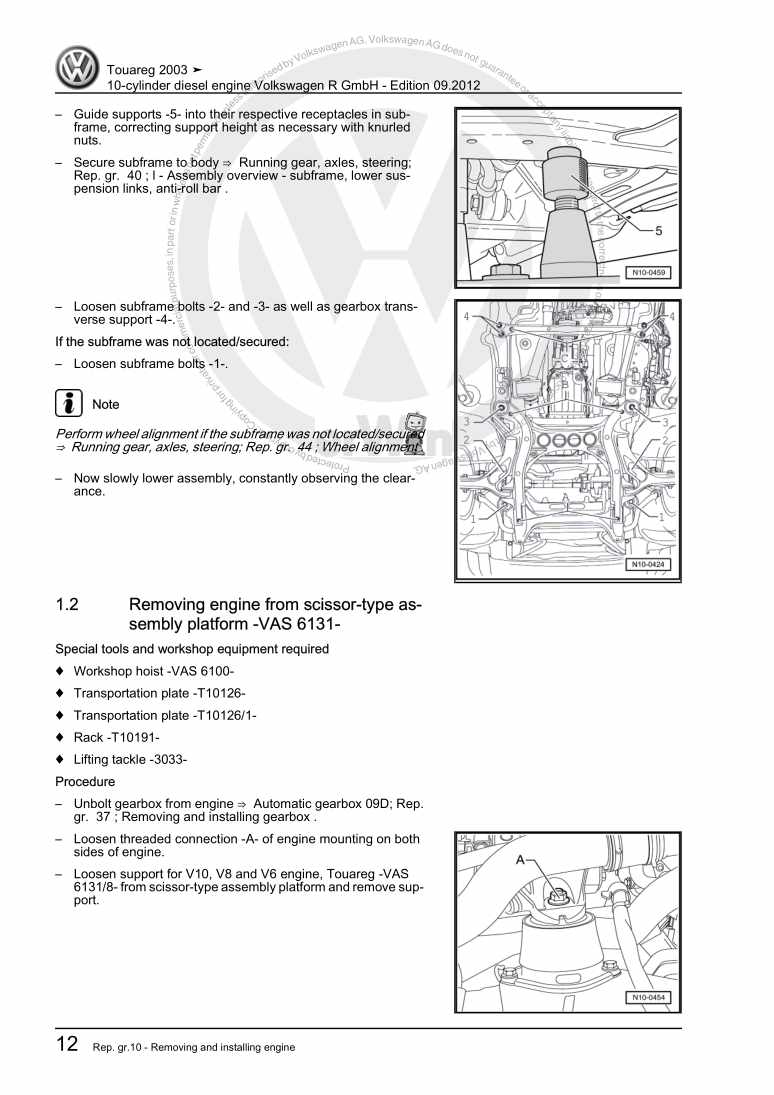

1023.3 Removing and installing subframe

1033.4 Repairing subframe

1074 Removing and installing rear vehicle level senders G76/G77

1115 Assembly overview: disengageable anti-roll bar

1135.1 Removing and installing disengageable anti-roll bar

1145.3 Bleeding disengageable anti-roll bar

1176 Assembly overview: motor/pump unit for disengageable anti-roll bars

1196.1 Removing and installing motor/pump unit

1216.2 Removing and installing anti-roll bar uncoupling control unit J742

1236.3 Line routing for disengageable anti-roll bars

1237 II - Assembly overview: suspension link, track rod

1258 III - Assembly overview: rear suspension

1288.1 Removing and installing suspension strut

1298.2 Removing and installing air spring strut

1308.3 Charging air spring strut

1329 IV - Assembly overview: wheel bearing

1349.1 Pressing wheel hub with wheel bearing for 16" running gear out and in

1359.2 Pressing wheel bearing for 17"/18"/18" plus running gear out and in

1389.3 Repairing wheel bearing housing

14410 V - Assembly overview: suspension strut

14810.1 Allocation of lower spacer

14810.2 Repairing rear coil spring strut

14911 VI - Rear air spring strut

15211.1 Instructions for repairing air spring struts

15211.2 Air spring strut

15211.3 Residual pressure valve

15211.4 Gaskets and seals

15311.5 Nuts and bolts

15311.6 Rear air spring strut components

15311.7 Assembly overview - rear air spring strut

15511.8 Repairing rear air spring strut

15511.9 Removing and installing residual pressure valve

16212 VII - Assembly overview: drive shaft

16412.1 Removing and installing rear drive shaft

16512.2 Dismantling and assembling drive shaft

16912.3 Checking inner joint

170Self-levelling suspension

1721 Appraisal of accident vehicles

1722 Jacking mode

1733 Repairing self-levelling suspension

1743.1 Fault finding, air spring strut and self-levelling suspension

1743.2 Self-levelling suspension components and fitting locations

1763.3 Assembly overview: air supply unit with solenoid valve block

1793.4 Removing and installing air supply unit without solenoid valve block

1803.5 Removing and installing air supply unit with solenoid valve block

1823.6 Assembly overview - air supply unit

1833.7 Renewing piston ring

1843.8 Removing and installing adaptive suspension control unit J197

1883.9 Repairing air line

1893.10 Basic settings for self-levelling suspension

1903.11 Measuring ride height

190Wheels, tyres, vehicle geometry

1911 Appraisal of accident vehicles

1912 Torque settings for wheel bolts and tyre assembly

1922.1 Specified torque for wheel bolts

1922.2 Fitting tyre

1923 Removing and fitting tyres (wheels with tyre pressure monitoring)

1933.2 Wheel change

1933.3 Fittings instructions

1943.4 Pressing tyre off wheel rim

1953.5 Removing tyre from wheel

1963.6 Fitting tyre to wheel rim

1964 Protecting wheel centring seat against corrosion

1985 Wheel alignment

1995.1 General

1995.2 Wheel alignment specifications

1996 Repairing tyre pressure monitor, 1st generation

2026.1 Component overview - tyre pressure monitor

2026.2 Component overview - tyre pressure sensor and metal valve

2036.3 Removing and installing tyre pressure sensor

2046.4 Removing and installing metal valve

2046.5 Removing and installing front tyre pressure monitor aerials R59/R60

2056.6 Removing and installing rear tyre pressure monitor aerials R61/R62

2066.7 Removing and installing tyre pressure monitor control unit J502

2076.8 Fitting tyres on wheels with tyre pressure monitors

2076.9 Storing current tyre inflation pressure

2087 Repairing tyre pressure monitor, 2nd generation

2097.1 Component overview - tyre pressure monitor

2097.2 Component overview - tyre pressure sensor and metal valve

2107.3 Removing and installing tyre pressure sensor

2117.4 Removing and installing metal valve

2117.5 Removing and installing tyre pressure monitor sender unit in front left wheel housing G431

2127.6 Removing and installing tyre pressure monitor sender unit in front right wheel housing G432

2137.7 Removing and installing tyre pressure monitor sender unit in rear left wheel housing G433

2147.8 Removing and installing tyre pressure monitor sender unit in rear right wheel housing G434

2147.9 Removing and installing tyre pressure monitor aerial R207

2157.10 Removing and installing tyre pressure monitor control unit J502

2167.11 Fitting tyres on wheels with tyre pressure monitors

2168 Adaptive Cruise Control (ACC)

2188.1 General information on ACC calibration

2188.2 ACC calibration during vehicle alignment

2188.3 ACC calibration without prior vehicle alignment

2209 Wheels, tyres

2239.1 Models with breakdown set

2239.2 Tyre sealant

2239.3 Removing a tyre

2239.4 Fitting a new tyre

2249.5 Tyre sealant disposal

22410 Instructions for changing or fitting wheels

22510.1 Fitting wheels

22611 Protecting wheel centring seat against corrosion

22712 Rough running due to wheels/tyres - causes and rectification

22812.1 Causes of rough running

22812.2 Balancing wheels

22812.3 Conducting a road test before balancing wheels

22812.4 Balancing wheels on stationary wheel balancing machine

22912.5 Vibration control system

23212.6 Finish balancer

23212.7 Radial and lateral runout of wheels and tyres

23312.9 Checking radial and lateral runout on wheel rim

23412.10 Matching

23512.11 Flat spots caused by storage or handling

236Steering

2381 Appraisal of accident vehicles

2382 Steering column

2392.1 Assembly overview: steering column

2392.2 Removing and installing steering column

2402.3 Removing and installing sealing boot

2433 Power steering

2443.1 Assembly overview: power steering, left-hand drive vehicle

2443.2 Removing and installing power steering box, left-hand drive vehicle

2453.3 Assembly overview: power steering, right-hand drive vehicle

2473.4 Removing and installing power steering box, right-hand drive vehicle

2494 Repairing power steering box

2534.1 Assembly overview: steering box

2534.2 Removing and installing track rod

2545 Vane pump, 5-cylinder diesel engine

2575.1 Checking vane pump delivery pressure, 5-cylinder diesel engine

2575.2 Assembly overview: vane pump, 5-cylinder diesel engine

2595.3 Removing and installing vane pump, 5-cylinder diesel engine

2606 Vane pump, 6-cylinder diesel engine to model year 2008

2656.2 Assembly overview: vane pump, 6-cylinder diesel engine to model year 2008

2686.3 Removing and installing vane pump, 6-cylinder diesel engine to model year 2008

2697 Vane pump, 6-cylinder diesel engine from model year 2009

2727.1 Checking delivery pressure of vane pump, 6-cylinder diesel engine from model year 2009

2727.2 Assembly overview: vane pump, 6-cylinder diesel engine from model year 2009

2768 Vane pump, 6-cylinder petrol engine

2818.1 Checking vane pump delivery pressure, 6-cylinder petrol engine

2818.2 Assembly overview: vane pump, 6-cylinder petrol engine

2838.3 Removing and installing vane pump, 6-cylinder petrol engine

2849 Vane pump, 8-cylinder petrol engine

2879.1 Checking vane pump delivery pressure, 8-cylinder petrol engine

2879.2 Assembly overview: vane pump, 8-cylinder petrol engine

2899.3 Removing and installing vane pump, 8-cylinder petrol engine

29010 Vane pump, V8 FSI engine

29410.1 Checking vane pump delivery pressure, V8 FSI engine

29410.2 Assembly overview - V8 FSI engine

29710.3 Removing and installing vane pump, V8 FSI engine

29911 Vane pump, 10-cylinder diesel engine

30411.1 Checking vane pump delivery pressure, 10-cylinder diesel engine

30411.2 Assembly overview: vane pump, 10-cylinder diesel engine

30711.3 Removing and installing vane pump, 10-cylinder diesel engine

30912 Vane pump, W12 petrol engine

31112.1 Checking vane pump delivery pressure, W12 petrol engine

31112.2 Assembly overview - vane pump, W12 petrol engine

31312.3 Removing and installing vane pump, W12 petrol engine

31413 Removing and installing oil cooler

31914 Bleeding steering system and checking for leaks

32114.1 Bleeding steering system

32114.2 Checking steering system for leaks

321