Original Volkswagen repair manual

13,34 €7% VAT incl.

Immediately available for download

Language: English

Digital PDF file

1.789 KB

155 Sites

Detailed technical data

Immediately readable

Repair manual Caddy Kasten/Kombi / Polo Classic / Polo Variant Motronic inj. and ignition system PDF download has the following content:

Chapter overview

| Manufacturer's designation | Motronic inj. and ignition system (2-valve, roller rocker finger) |

| Manufacturer | Volkswagen |

| Suitable for | Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002) |

| Suitable car types | 9K, 6V |

| Engine code | ANW, AUD |

| Category | Reparaturanleitung |

There are no reviews for this product at the moment.

Similar repair manuals

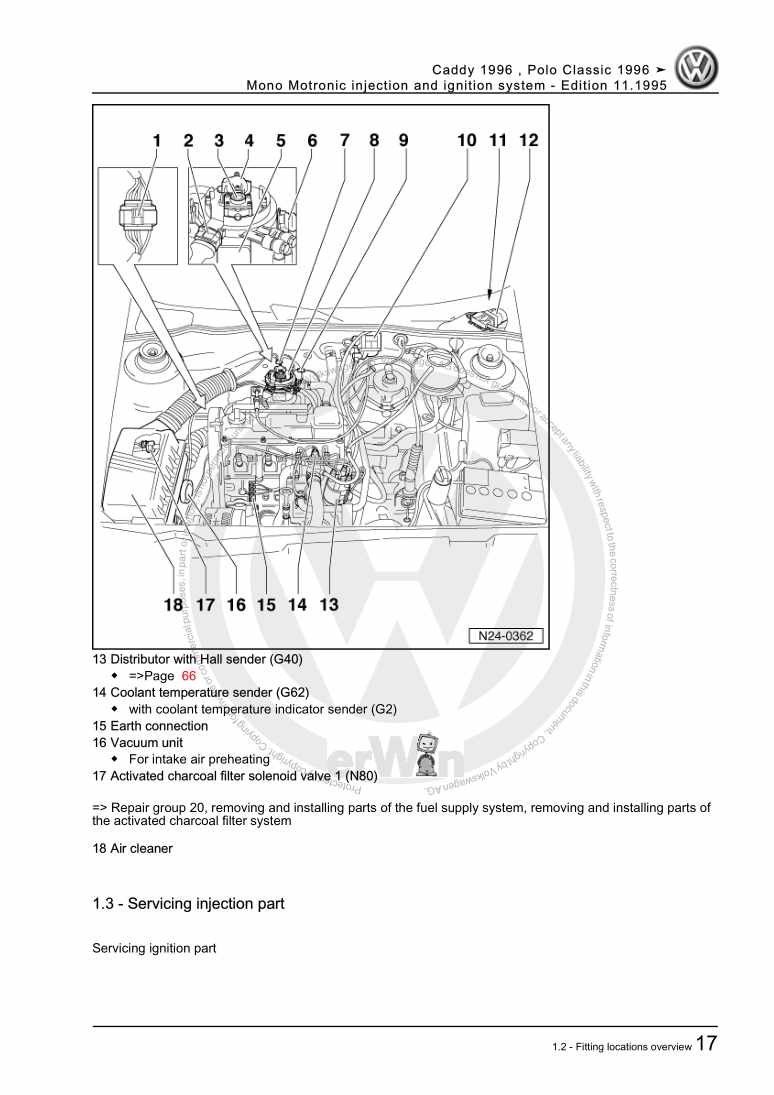

Mono Motronic injection and ignition system

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

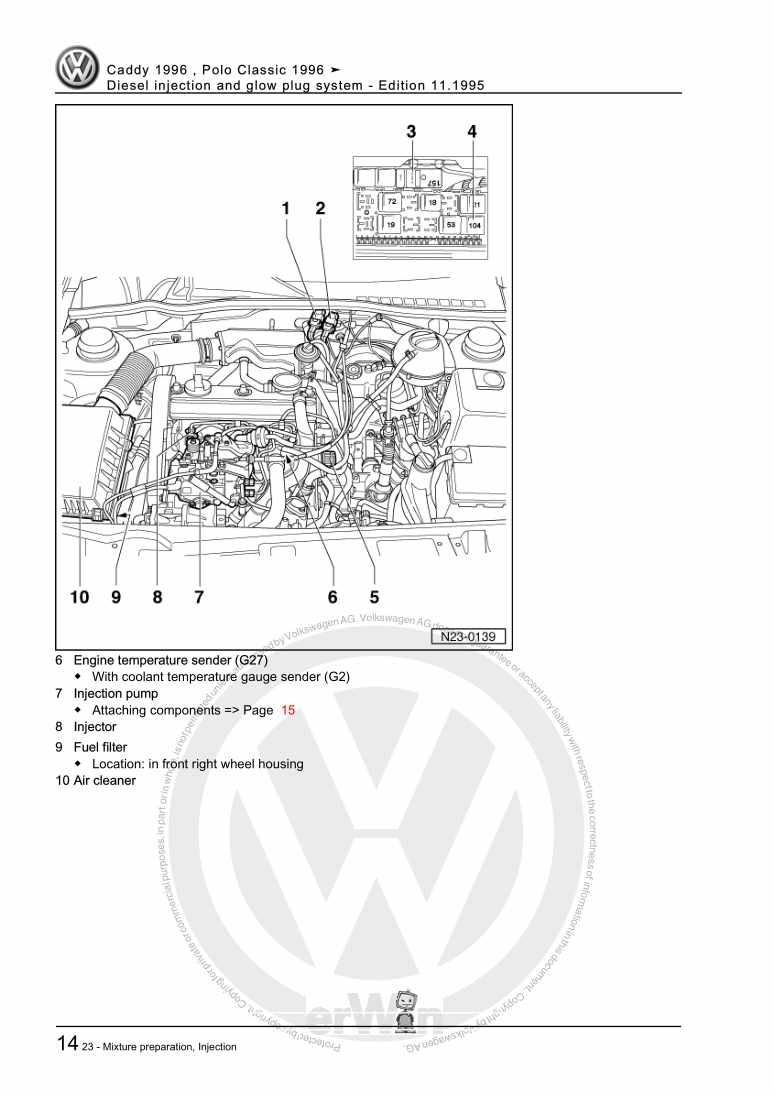

Diesel injection and glow plug system

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

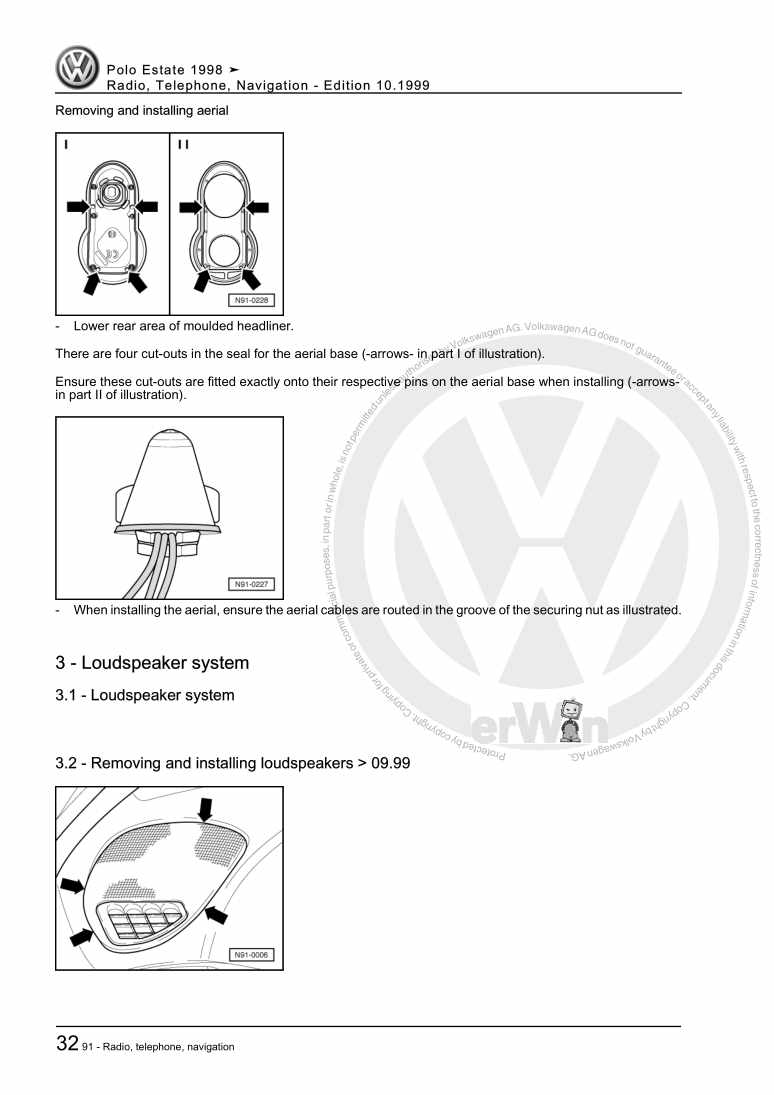

Radio, Telephone, Navigation

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

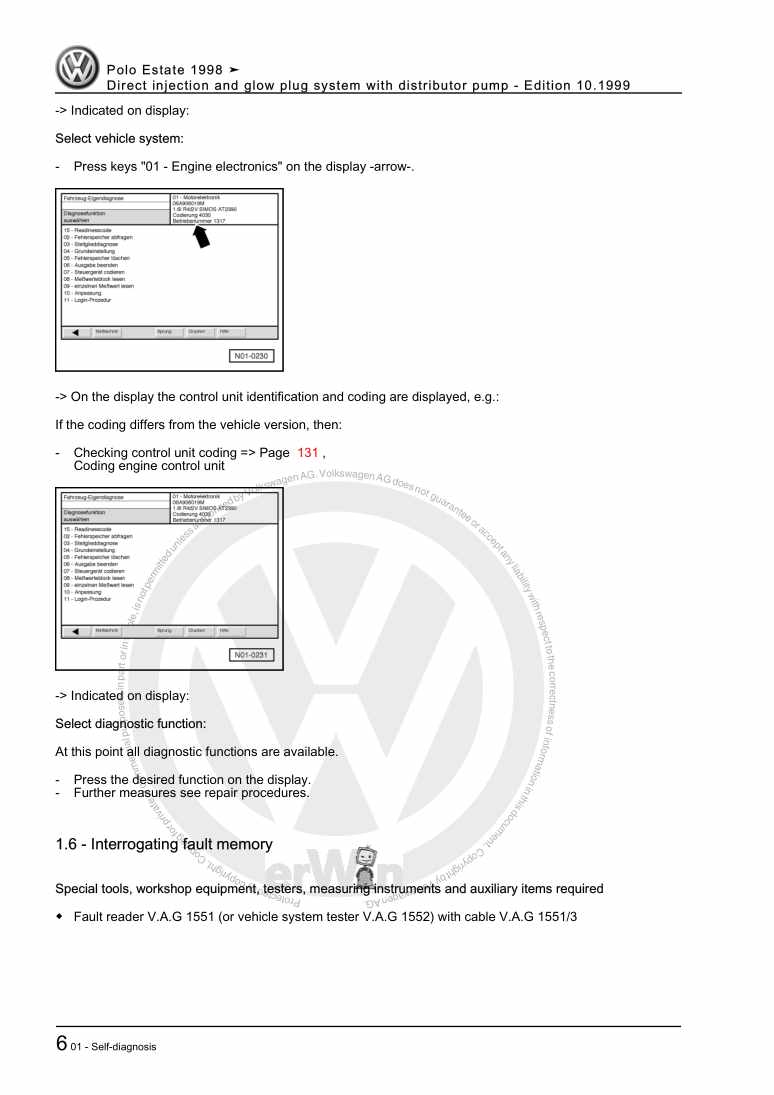

Direct injection and glow plug system with distributor pump

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

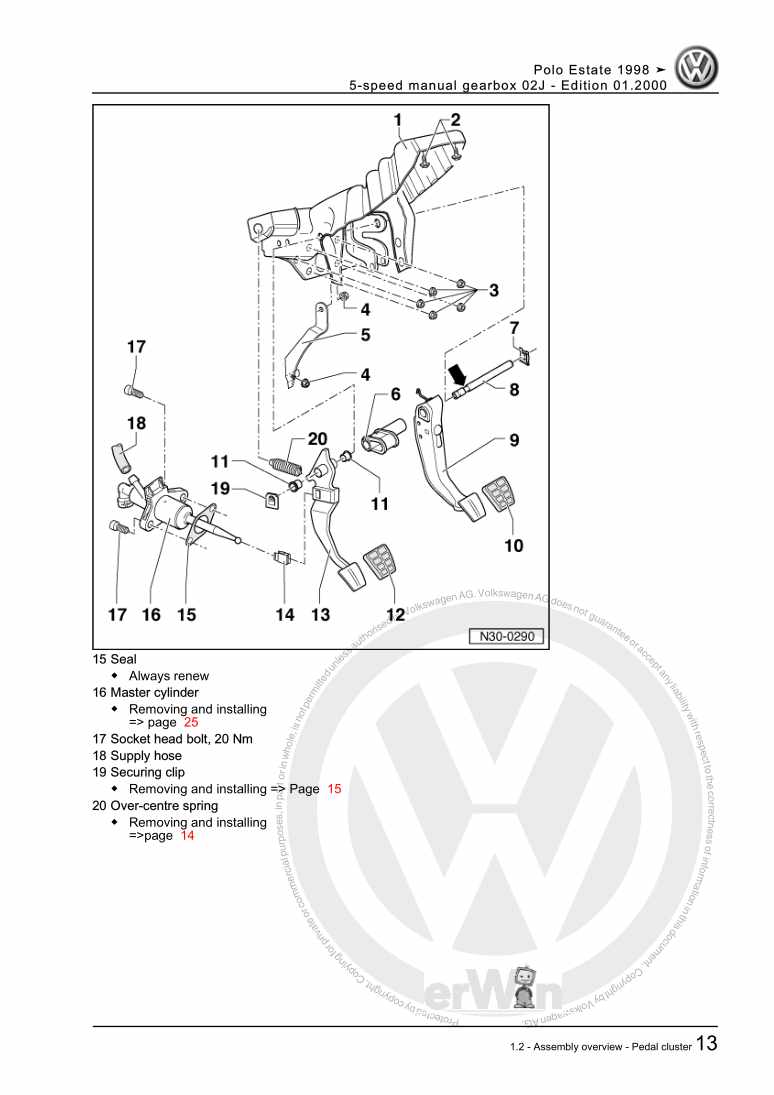

5-speed manual gearbox 02J

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

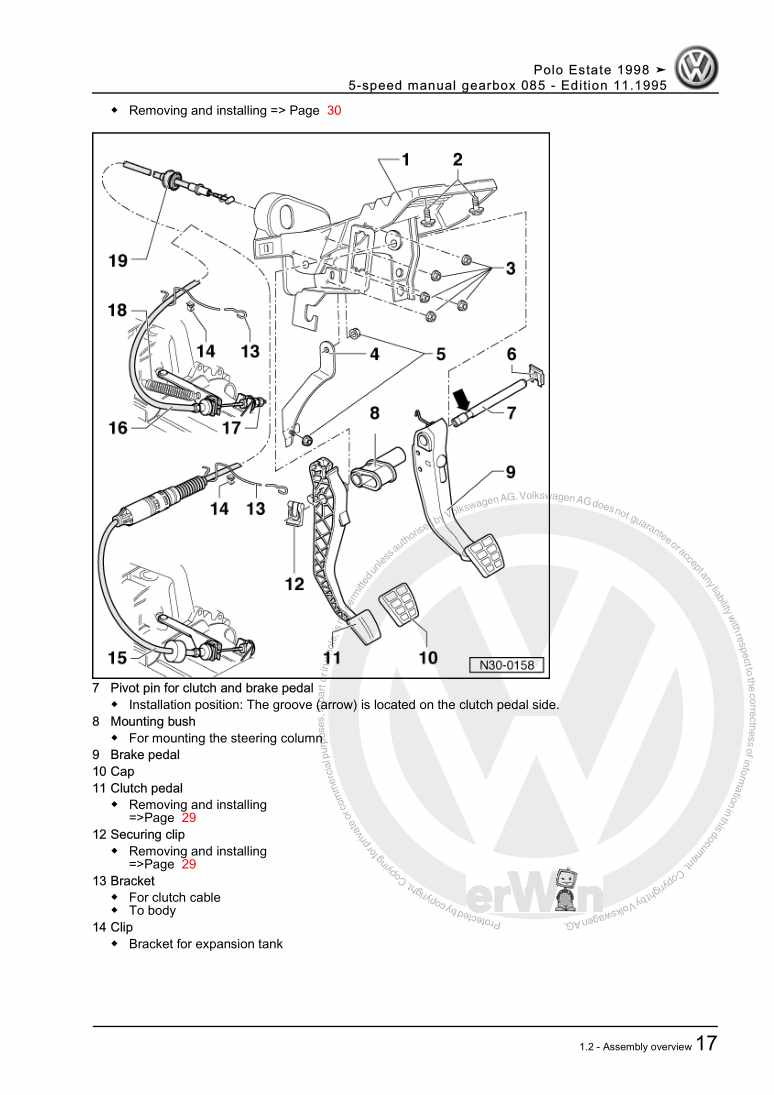

5-speed manual gearbox 085

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

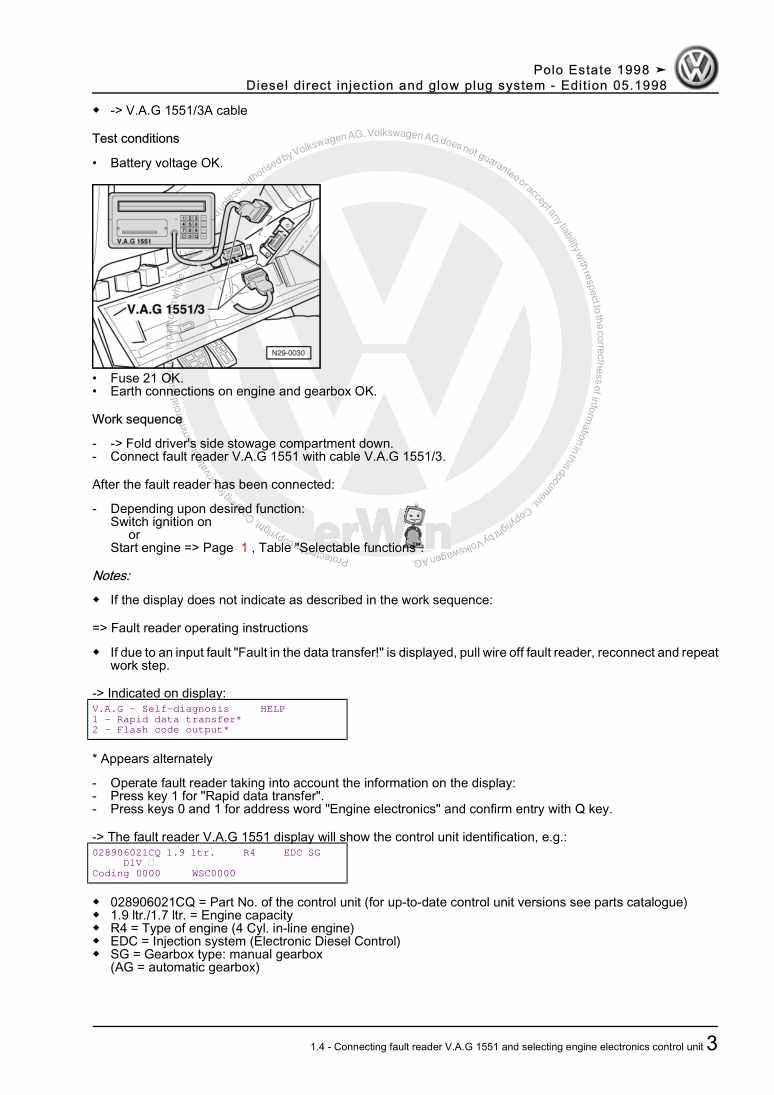

Diesel direct injection and glow plug system

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

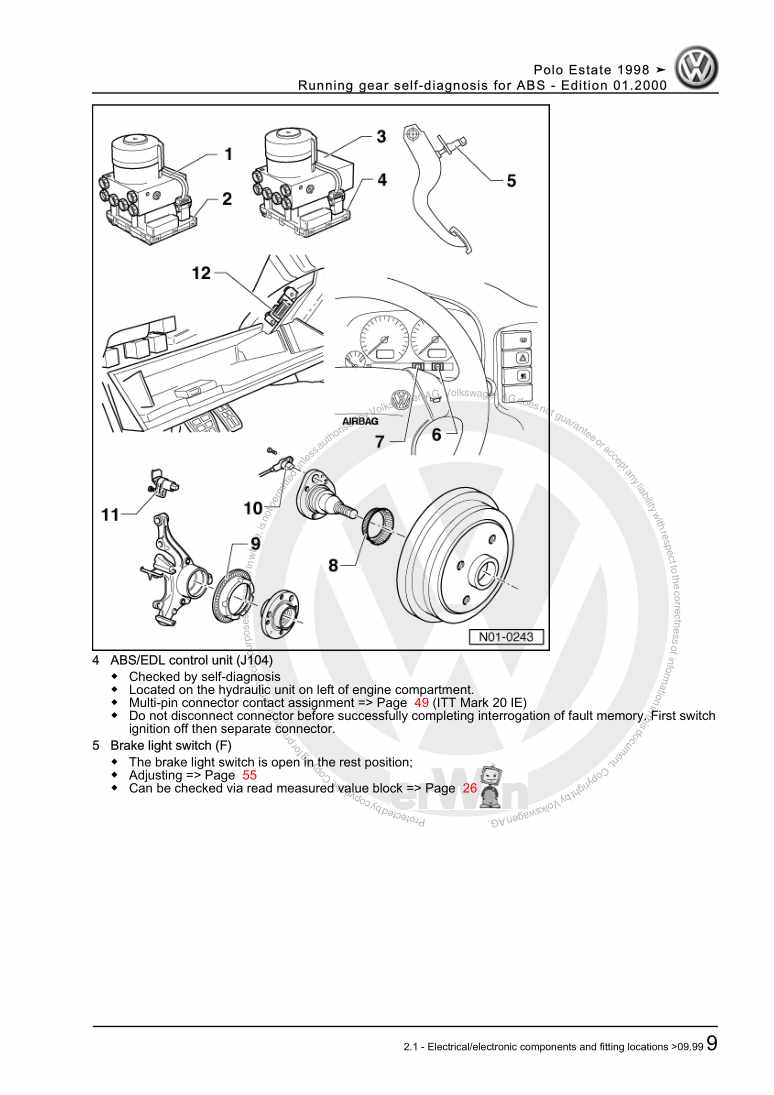

Running gear self-diagnosis for ABS

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

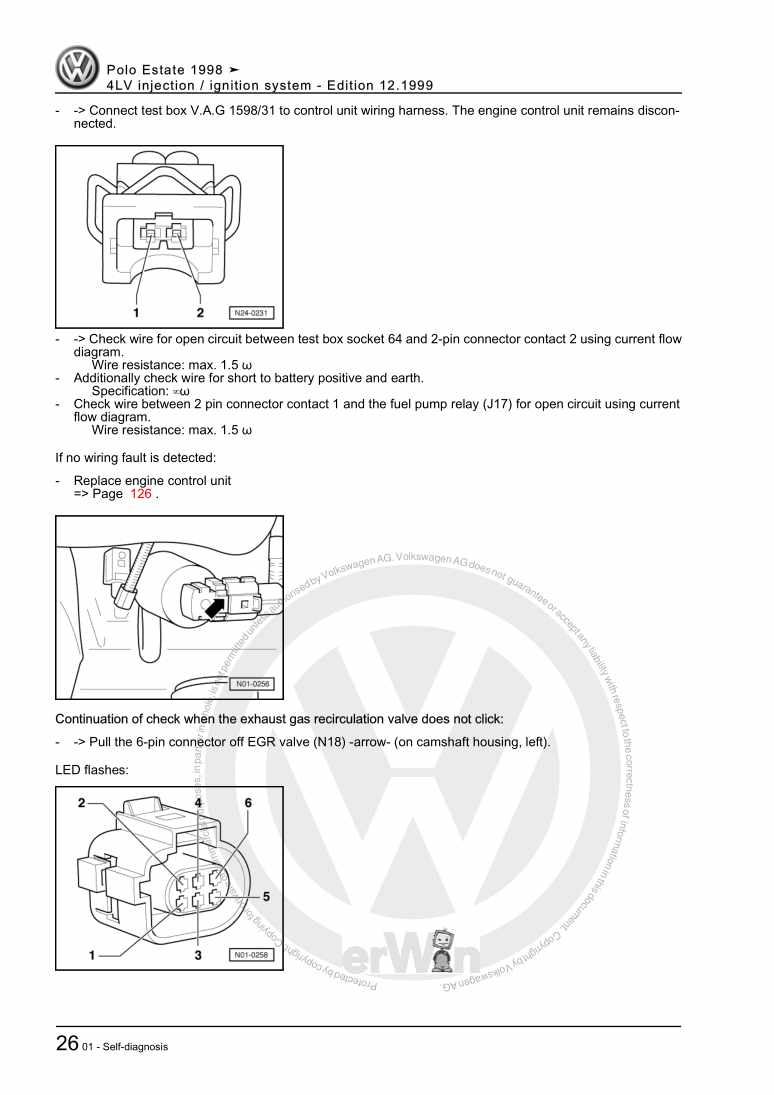

4LV injection / ignition system

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

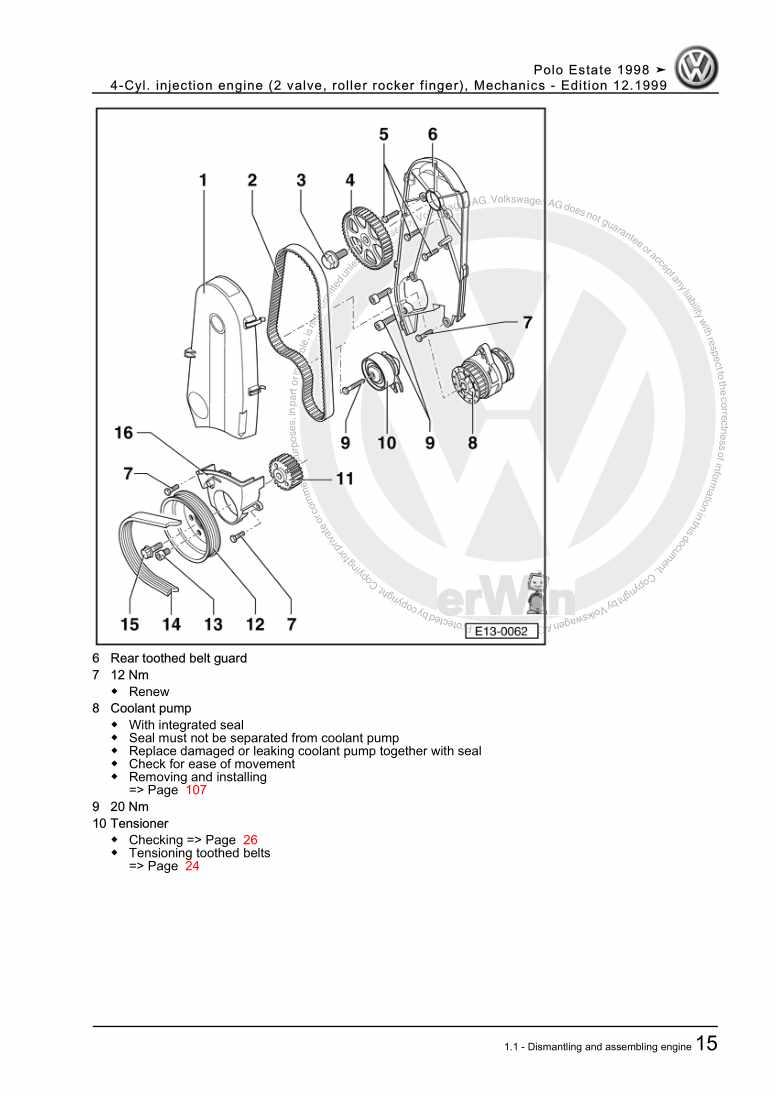

4-Cyl. injection engine (2 valve, roller rocker finger), Mechanics

For Caddy Kasten/Kombi (1996 - 2003) / Polo Classic / Polo Variant (1996 - 2002)

Our Best Sellers

Did you know? We also offer original spare parts.

About Clonck

Original repair manuals und spare parts

Our repair manuals are original, come directly from Volkswagen and meet the highest quality standards.

In our original parts shop we sell high-quality original spare parts from car manufacturers. Use the search function to enter the desired part number (OE number) and order the required spare part quickly and easily.Highest quality standards

At Clonck, we want to make car mechanics and car professionals happy. That's why you will only find professional and high-quality repair manuals at Clonck that will help you to repair your vehicle professionally.Clonck: The car repair shop - also as app!

With Clonck you can order the right original spare parts in no time.