Technical data

11 Safety information

11.1 Safety measures when working on fuel system

11.2 Safety measures when working on vehicles with a start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on exhaust system

21.6 Safety precautions when working on the SCR system

31.7 Safety regulations for working on glow plug system

51.8 Safety precautions when working on subframe

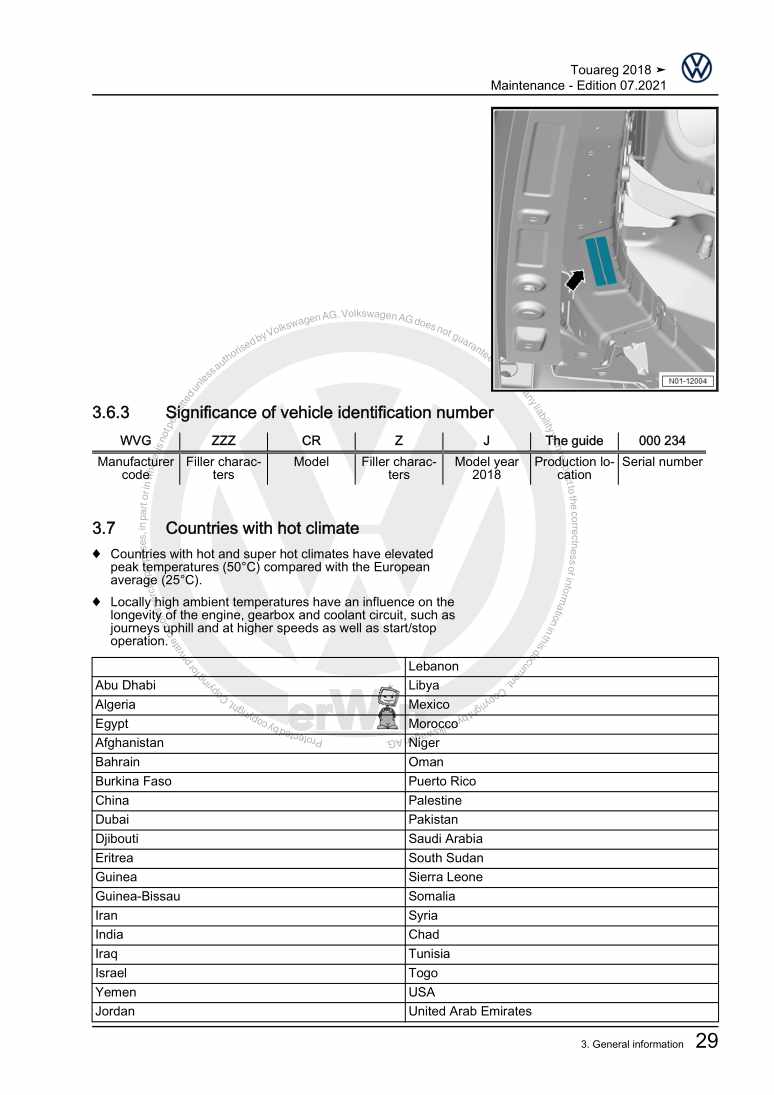

52 Identification

62.1 Engine number/engine data

63 Repair instructions

83.1 Rules for cleanliness

83.2 General information

83.3 General repair notes

93.4 Adapting learnt value for SCR system

103.5 Foreign objects in engine

103.6 Contact corrosion

103.7 Routing and attachment of lines

113.8 Fitting radiator and condensers

113.9 Checking vacuum system

11Removing and installing engine

121 Removing and installing engine

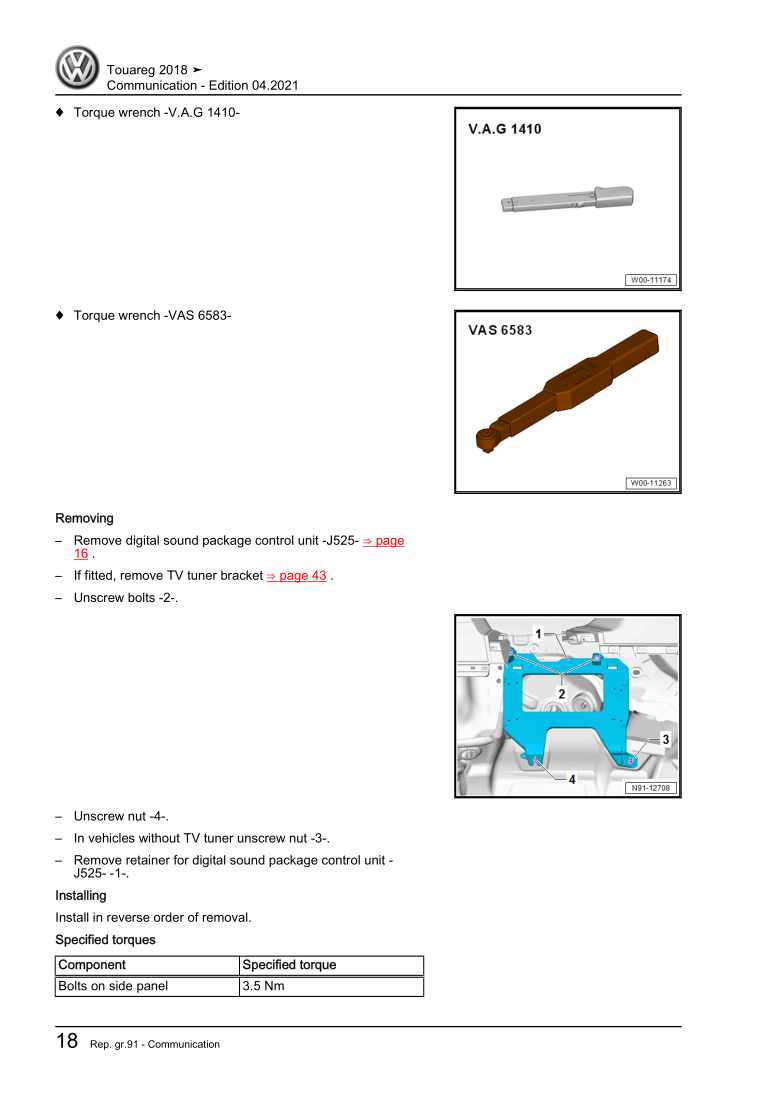

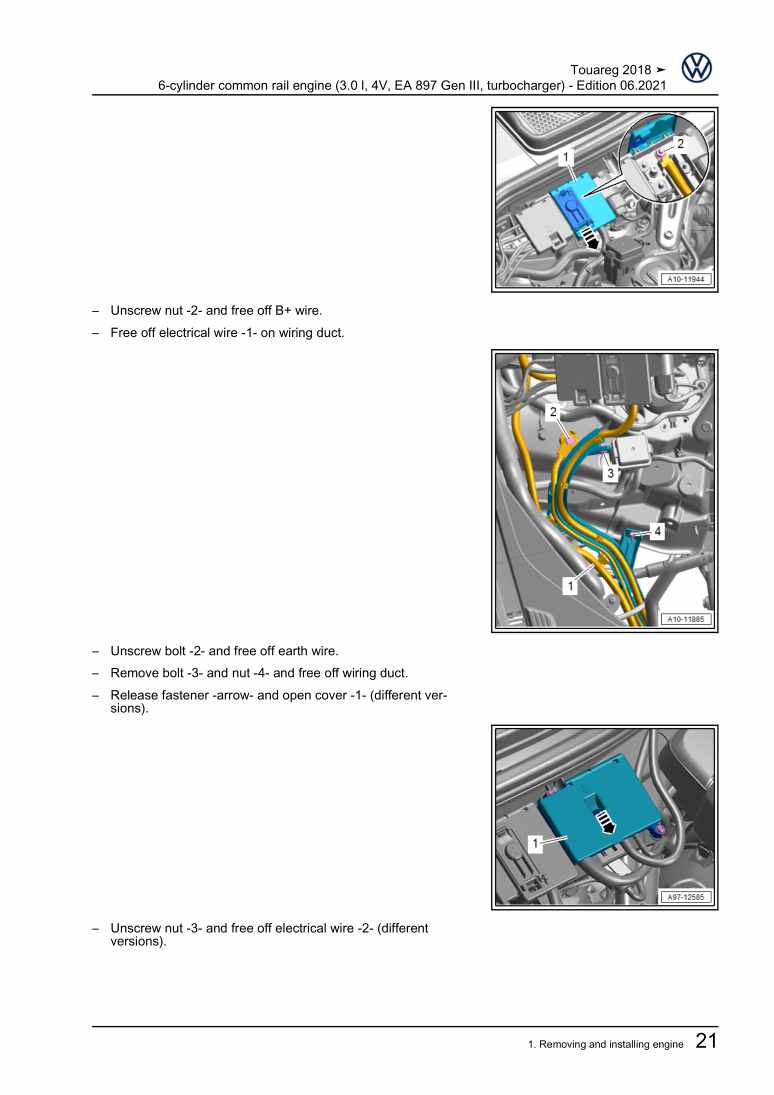

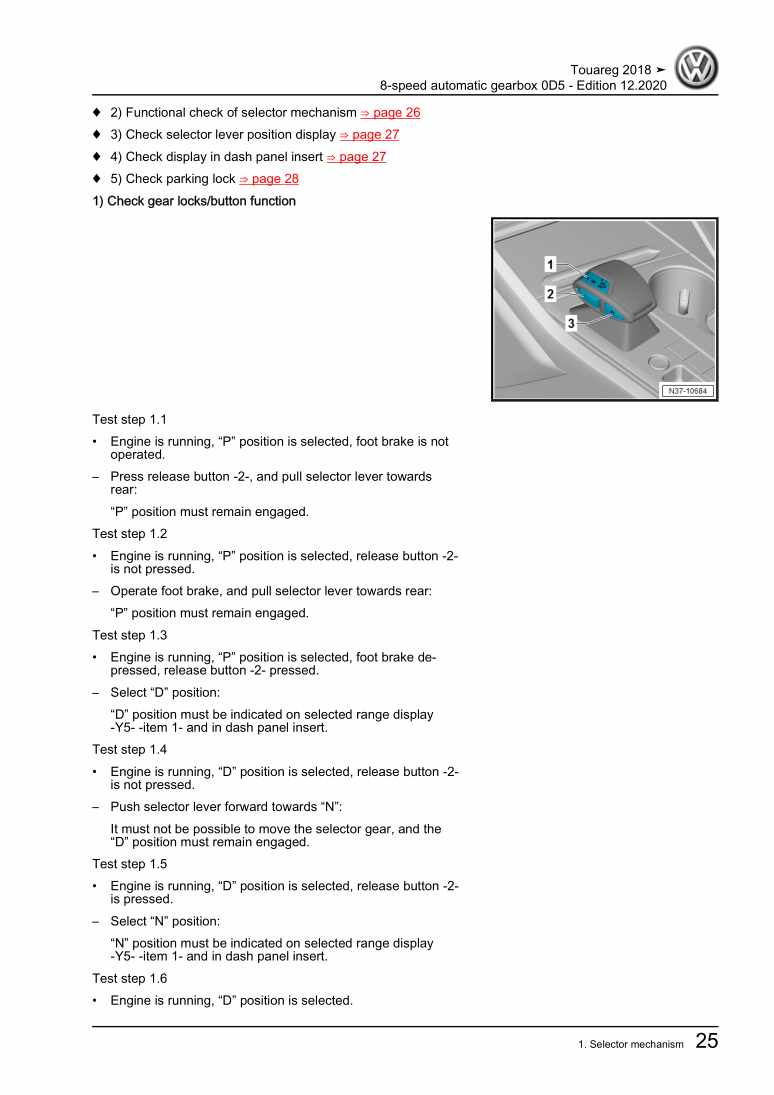

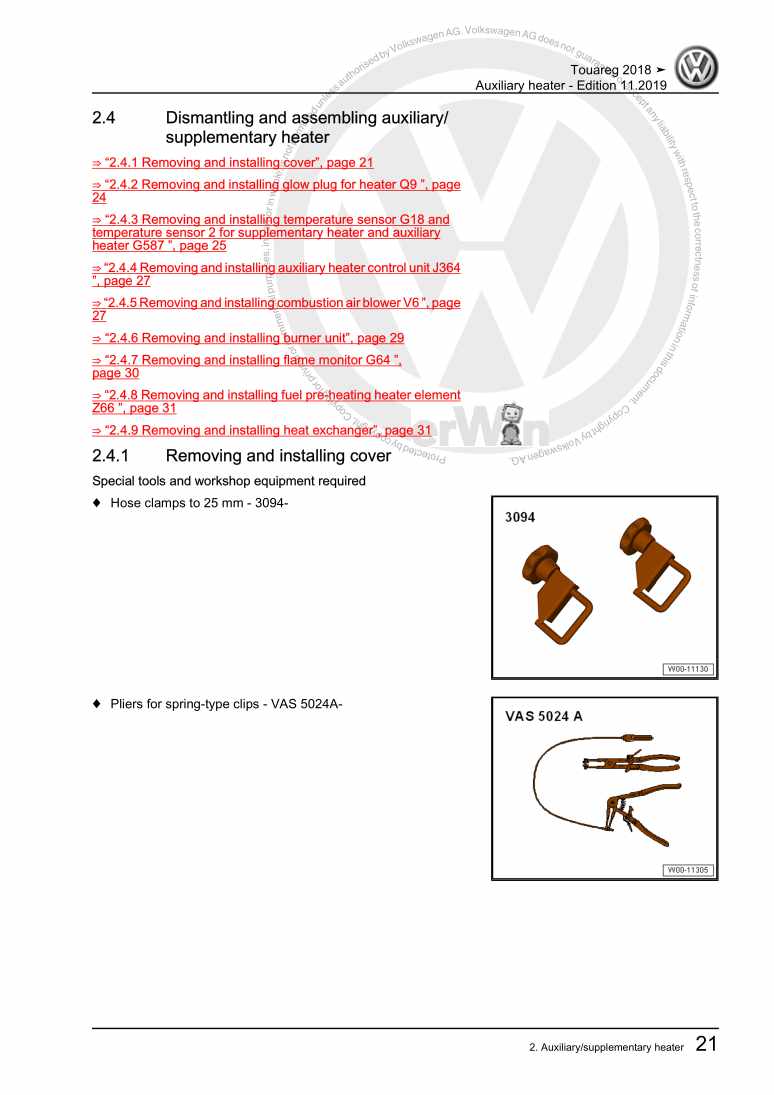

121.1 Removing engine

121.2 Separating engine and gearbox

341.3 Securing engine on engine and gearbox support

401.4 Installing engine

442 Assembly mountings

522.1 Assembly overview – assembly mountings

522.2 Removing and installing engine mounting

562.3 Removing and installing gearbox mounting

572.4 Supporting engine in installation position

612.5 Removing and installing power unit mounting senders

632.6 Removing and installing power unit mounting control unit J931

642.7 Calibrating electrohydraulic engine mounting

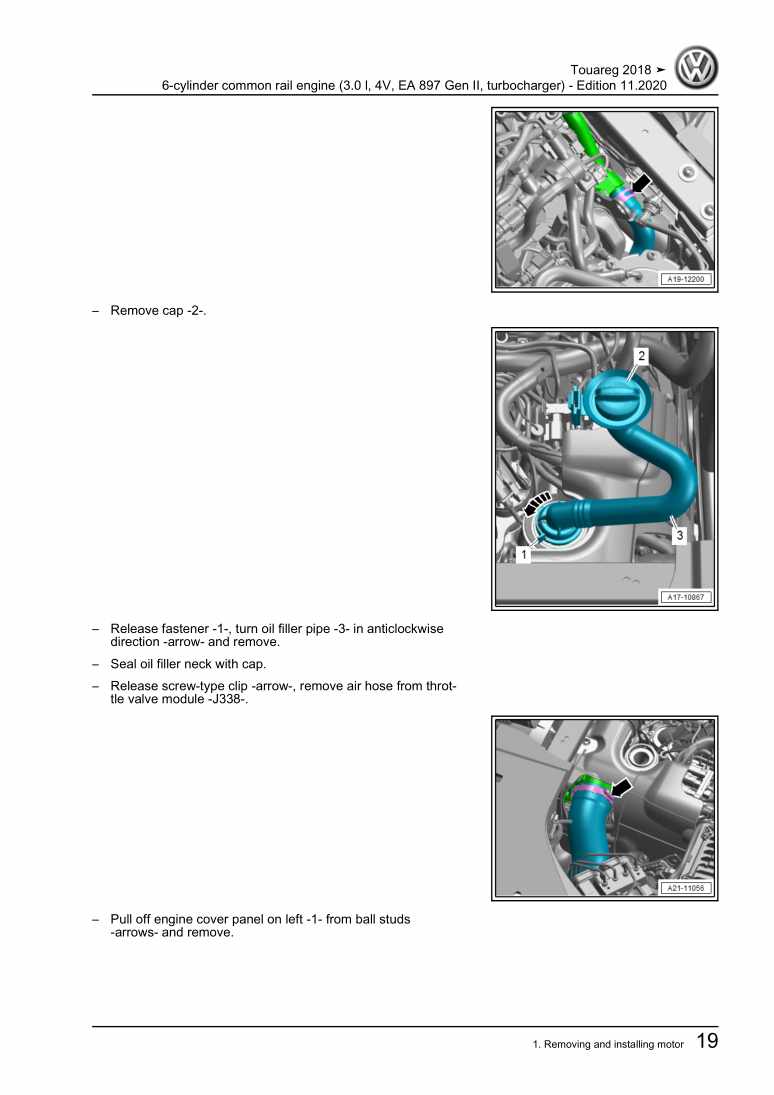

663 Engine cover panel

673.1 Removing and installing engine cover

67Crankshaft group

691 Cylinder block (pulley end)

691.1 Assembly overview - cylinder block (pulley end)

691.2 Assembly overview - sealing flange, belt pulley end

731.3 Removing and installing poly-V belt

741.4 Removing and installing tensioner for poly V-belt

751.5 Removing and installing bracket for ancillaries

761.6 Removing and installing engine support

781.7 Removing and installing pulley

791.8 Renewing crankshaft oil seal - belt pulley end

811.9 Removing and installing sealing flange on pulley end

832 Cylinder block, gearbox end

852.1 Assembly overview - cylinder block, gearbox end

852.2 Removing and installing drive plate

852.3 Renewing crankshaft oil seal (gearbox end)

873 Crankshaft

903.1 Assembly overview - crankshaft

903.2 Crankshaft dimensions

923.3 Allocation of main bearing shells

923.4 Measuring axial clearance of crankshaft

943.5 Measuring radial clearance of crankshaft

953.6 Checking sender wheel

954 Balancer shaft

974.1 Assembly overview - balance shaft

974.2 Removing and installing balance shaft

975 Pistons and conrods

995.1 Assembly overview - pistons and conrods

995.2 Removing and installing pistons

1015.3 Measuring piston projection at TDC

1055.4 Checking pistons and cylinder bores

1075.5 Checking radial clearance of conrods

1095.6 Removing and installing oil spray jets

109Cylinder head, valve gear

1111 Cylinder head

1111.1 Assembly overview - cylinder head

1111.2 Assembly overview - cylinder head cover

1131.3 Removing and installing cylinder head

1161.4 Removing and installing cylinder head cover

1291.5 Removing and installing injector seals

1381.6 Checking compression

1402 Cover for timing chain

1432.1 Assembly overview - cover for timing chain

1432.2 Removing and installing timing chain cover

1473 Chain drive

1573.1 Assembly overview - camshaft timing chains

1573.2 Assembly overview - drive chain for high pressure pump

1593.3 Assembly overview - drive chain for oil pump

1593.4 Removing and installing camshaft timing chain

1603.5 Removing camshaft timing chain from camshafts

1713.6 Removing and installing drive chain for high-pressure pump

1833.7 Installing intermediate drive

1854 Valve gear

1924.1 Assembly overview - valve gear

1924.2 Measuring axial play of camshaft

2004.3 Measuring radial play of camshaft

2024.4 Removing and installing camshaft

2024.5 Removing and installing cam actuators

2184.6 Removing and installing valve stem seals

2275 Inlet and exhaust valves

2375.1 Reworking valve seats

2375.2 Checking valve guides

2375.3 Checking valves

2385.4 Valve dimensions

239Lubrication

2401 Sump, oil pump

2401.1 Assembly overview - sump/oil pump

2401.2 Engine oil:

2461.3 Removing and installing lower part of sump

2471.4 Removing and installing upper part of sump

2491.5 Removing and installing oil pump

2541.6 Removing and installing oil level and oil temperature sender G266

2562 Engine oil cooler

2582.1 Assembly overview - engine oil cooler

2582.2 Removing and installing engine oil cooler

2593 Crankcase ventilation

2623.1 Assembly overview - crankcase breather system

2623.2 Removing and installing crankcase breather module

2634 Oil filter, oil pressure switch

2654.1 Assembly overview - oil filter

2654.2 Removing and installingoil temperature sender G8

2654.3 Removing and installing oil pressure sender G10

2674.4 Checking oil pressure

2674.5 Removing and installing oil filter housing

2684.6 Removing and installing oil pressure regulating valve N428

269Cooling

2701 Cooling system/coolant

2701.1 Connection diagram - coolant hoses

2701.2 Checking cooling system for leaks

2741.3 Draining and adding coolant

2772 Coolant pump, regulation of cooling system

2882.1 Assembly overview - coolant pump

2882.2 Assembly overview - electric coolant pump

2892.3 Assembly overview - thermostat

2902.4 Assembly overview – coolant valves

2922.5 Assembly overview - coolant temperature sender

2932.6 Removing and installing auxiliary pump for heating V488

2942.7 Removing and installing coolant pump

2962.8 Removing and installing map-controlled engine cooling thermostat F265

2962.9 Removing and installing coolant temperature sender G62/G83

3022.10 Removing and installing coolant temperature sender 3 G812

3032.11 Removing and installing coolant valves

3043 Coolant pipes

3083.1 Assembly overview - coolant pipes

3083.2 Removing and installing coolant pipes

3133.3 Removing and installing coolant pipes for gearbox

3284 Radiator, radiator fan

3304.1 Assembly overview - radiator/radiator fan

3304.2 Removing and installing radiator

3324.3 Removing and installing radiator fan V7 and radiator fan 2 V177

337Turbocharging/supercharging

3381 Turbocharger

3381.1 Assembly overview - turbocharger

3381.2 Assembly overview - recirculation valve

3471.3 Removing and installing turbocharger

3481.4 Removing and installing recirculation valve

3561.5 Removing and installing sender 1 for turbocharger speed G688

3581.6 Removing and installing sender 2 for turbocharger speed G689

3591.7 Removing and installing temperature sender for engine cover panel G765

3602 Charge air system

3632.1 Assembly overview - charge air system

3632.2 Assembly overview - charge-air hose connections

3682.3 Removing and installing charge air cooler

3682.4 Checking charge air system for leaks

371Mixture preparation - injection

3761 Injection system

3761.1 Schematic overview - fuel system

3761.2 Overview of fitting locations - injection system

3761.3 Filling/bleeding fuel system

3881.4 Checking fuel system for leaks

3892 Vacuum system

3902.1 Connection diagram - vacuum system

3902.2 Checking vacuum system

3913 Injectors/high-pressure accumulator (rail)

3933.1 Assembly overview - injectors

3933.2 Testing injectors

3973.3 Adapting correction values for injectors

3983.4 Checking return flow rate of injectors with engine running

3993.5 Checking return flow rate of injectors at starter speed

4033.6 Testing jammed-open injectors

4063.7 Checking restrictor in fuel return line

4103.8 Removing and installing injectors

4113.9 Removing and installing high-pressure lines

4193.10 Removing and installing fuel rail

4214 Air filter

4274.1 Assembly overview - air filter housing

4274.2 Removing and installing air filter housing

4295 Intake manifold

4325.1 Assembly overview – intake manifold

4325.2 Removing and installing intake manifold

4335.4 Removing and installing throttle valve module GX3/throttle valve module 2 GX4

4376 Senders and sensors

4396.2 Removing and installing actuator for structure-borne sound R214

4406.3 Removing and installing control unit for structure-borne sound J869

4416.4 Removing and installing fuel pressure regulating valve N276

4426.5 Checking fuel pressure regulating valve N276

4446.6 Removing and installing fuel pressure sender G247

4466.7 Removing and installing fuel pressure sender for low-pressure G410

4496.8 Removing and installing air mass meter G70/air mass meter 2 G246

4506.9 Removing and installing pressure differential sender G505

4516.10 Removing and installing intake manifold pressure sender G71

4522 G299

4526.12 Removing and installing fuel temperature sender G81

4537 Engine control unit

4557.1 Assembly overview – motor control unit

4557.2 Removing and installing engine control unit J623

4568 High-pressure pump

4578.1 Assembly overview - high-pressure pump

4578.2 Removing and installing high-pressure pump

4609 Lambda probe

4659.1 Assembly overview - Lambda probe

4659.2 Removing and installing Lambda probe

4679.3 Removing and installing NOx sender

4709.4 Removing and installing particle sensor G784

474Exhaust system

4771 Exhaust pipes and silencers

4771.1 Assembly overview – silencers

4771.2 Removing and installing front exhaust pipe

4801.3 Removing and installing silencer

4821.4 Aligning exhaust system free of stress

4831.5 Checking exhaust system for leaks

4852 Emission control

4862.1 Assembly overview – emission control

4862.2 Removing and installing emission control module

4883 SCR system (selective catalytic reduction)

4943.1 Assembly overview - tank for reducing agent

4943.2 Assembly overview - reducing agent supply line

4963.3 Assembly overview - injector for reducing agent

4973.4 Assembly overview - control unit for reducing agent metering system

4983.5 Removing and installing reducing agent tank

4993.6 Removing and installing injector for reduction agent N474

5023.7 Draining reducing agent tank

5043.8 Removing and installing control unit for reducing agent metering system J880

5053.9 Removing and installing reducing agent quality sensor G849

5064 Exhaust gas temperature regulation

5074.1 Assembly overview – exhaust gas temperature regulation

5074.2 Removing and installing parts of exhaust gas temperature regulation

5095 Exhaust gas recirculation

5205.1 Assembly overview – exhaust gas recirculation

5205.2 Removing and installing exhaust gas recirculation cooler

5225.3 Removing and installing exhaust gas recirculation temperature sensor G98

5245.4 Removing and installing pressure sender for exhaust gas recirculation G691

5256 Exhaust manifold

5276.1 Assembly overview - exhaust manifold

5276.2 Removing and installing exhaust manifold

531Glow plug system

5371 Glow plug system

5371.1 Assembly overview - glow plug system

5371.2 Removing and installing glow plug

5391.4 Removing and installing Hall sender G40

5451.5 Removing and installing engine speed sender G28

545