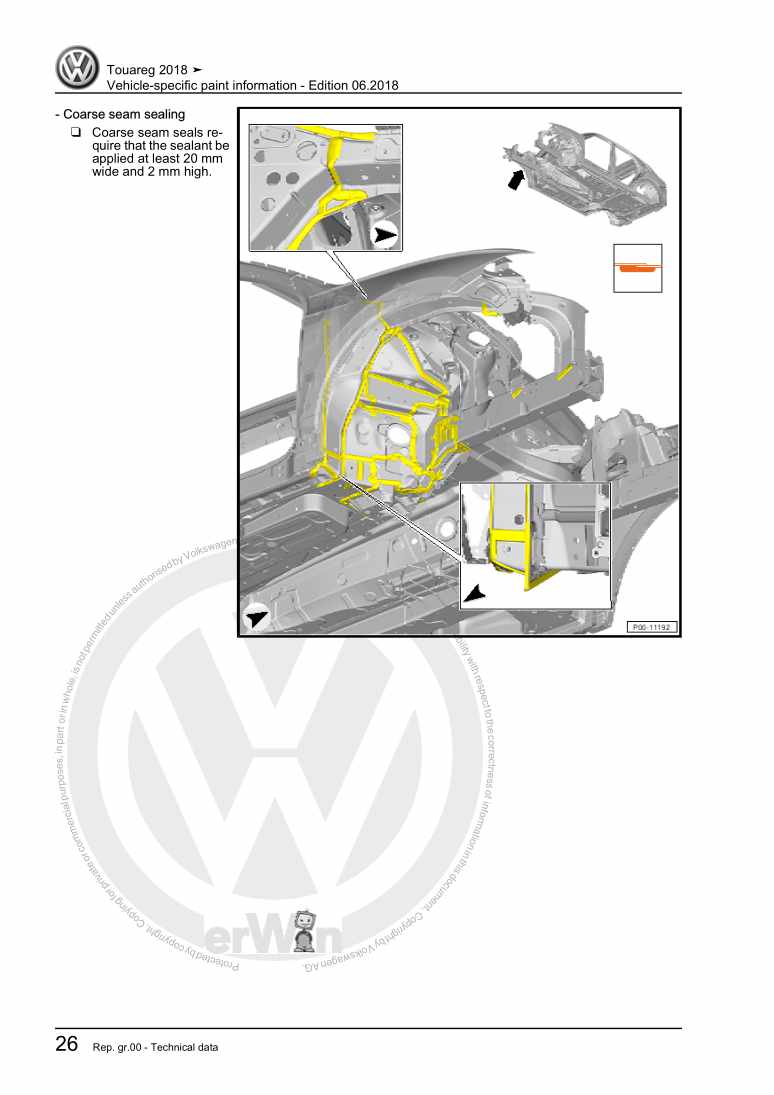

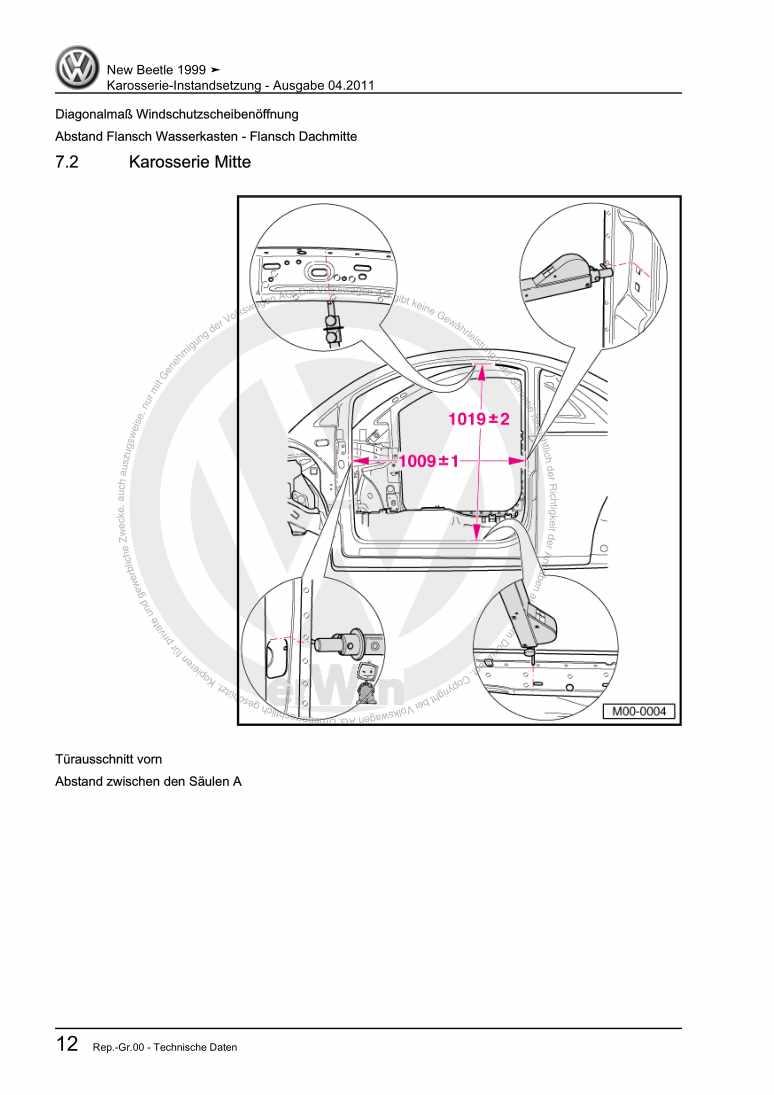

Technical data

11 Safety information

11.1 Safety measures when working on fuel system

11.2 Safety measures when working on vehicles with start/stop system

11.4 Safety measures when working on cooling system

21.5 Safety measures when working on exhaust system

21.6 Safety precautions when working on the SCR system

31.7 Safety regulations for working on glow plug system

41.8 Safety measures when working on subframe

42 Identification

52.1 Engine number/engine data

53 Repair notes

73.1 Rules for cleanliness

73.2 General information

73.3 General repair notes

83.4 Adapting learnt value for SCR system

93.5 Foreign objects in engine

93.6 Contact corrosion

103.7 Routing and attachment of lines

103.8 Installing radiators and condensers

103.9 Checking vacuum system

10Removing and installing engine

121 Removing and installing motor

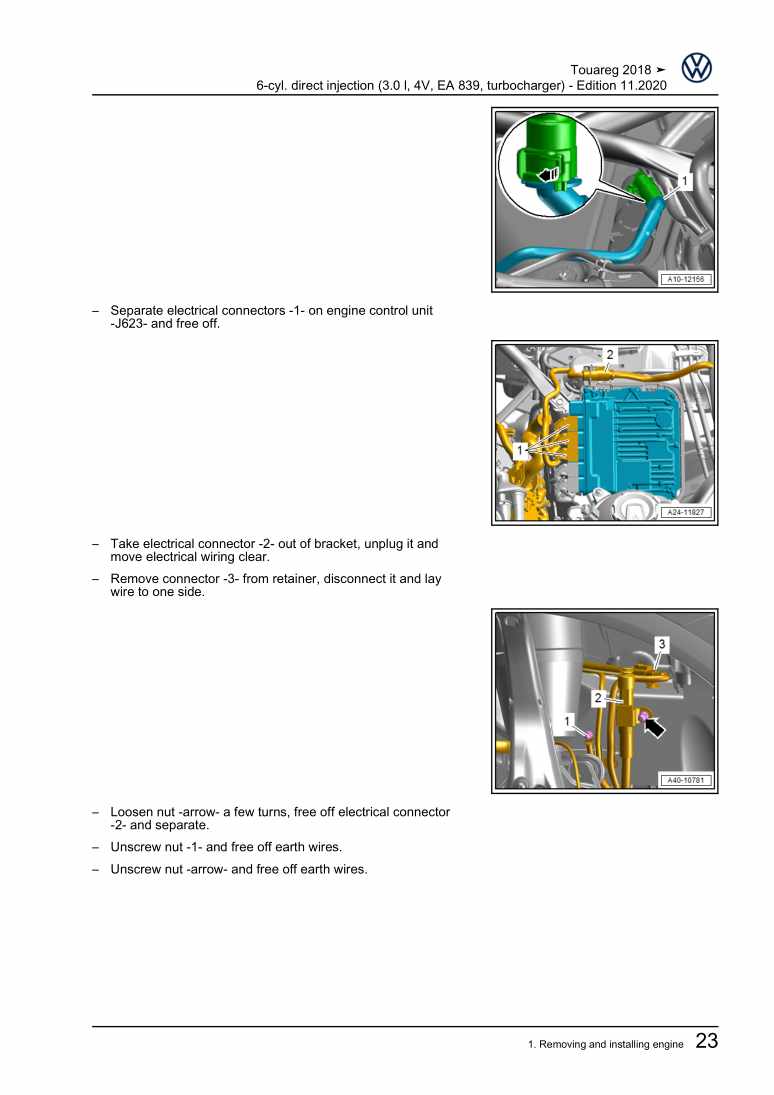

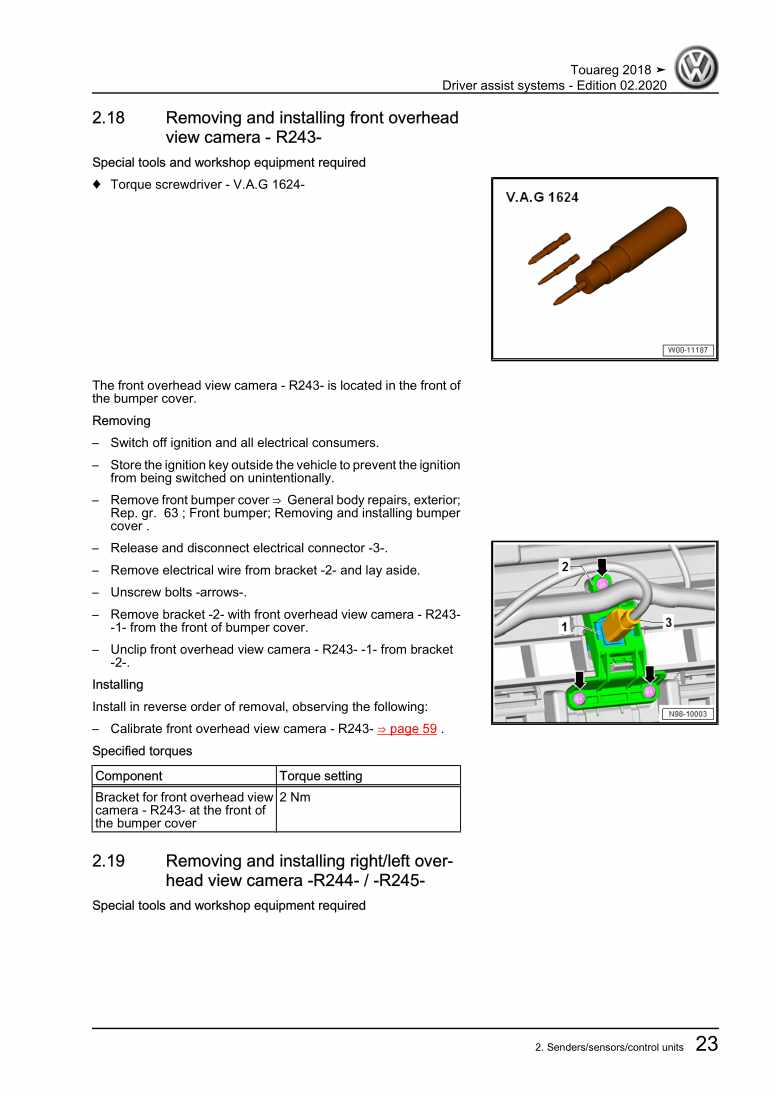

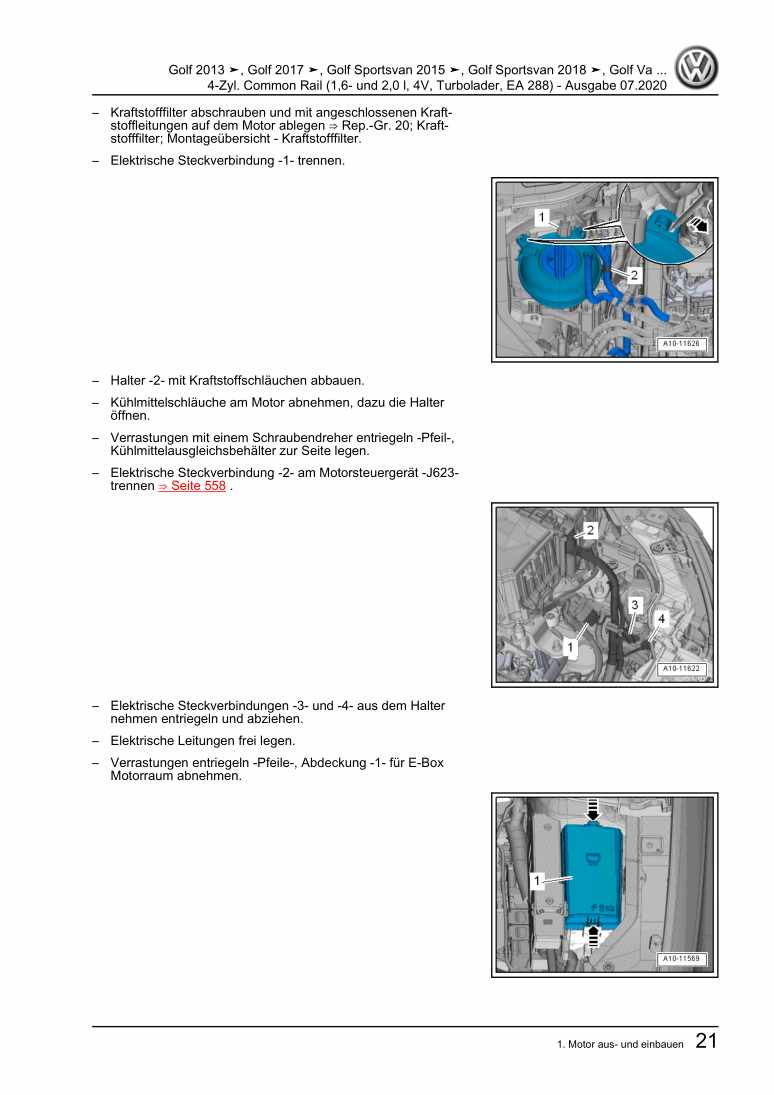

121.1 Removing motor

121.2 Separating engine and gearbox

341.3 Securing engine on engine and gearbox support

411.4 Installing engine

452 Assembly mountings

502.1 Assembly overview - assembly mountings

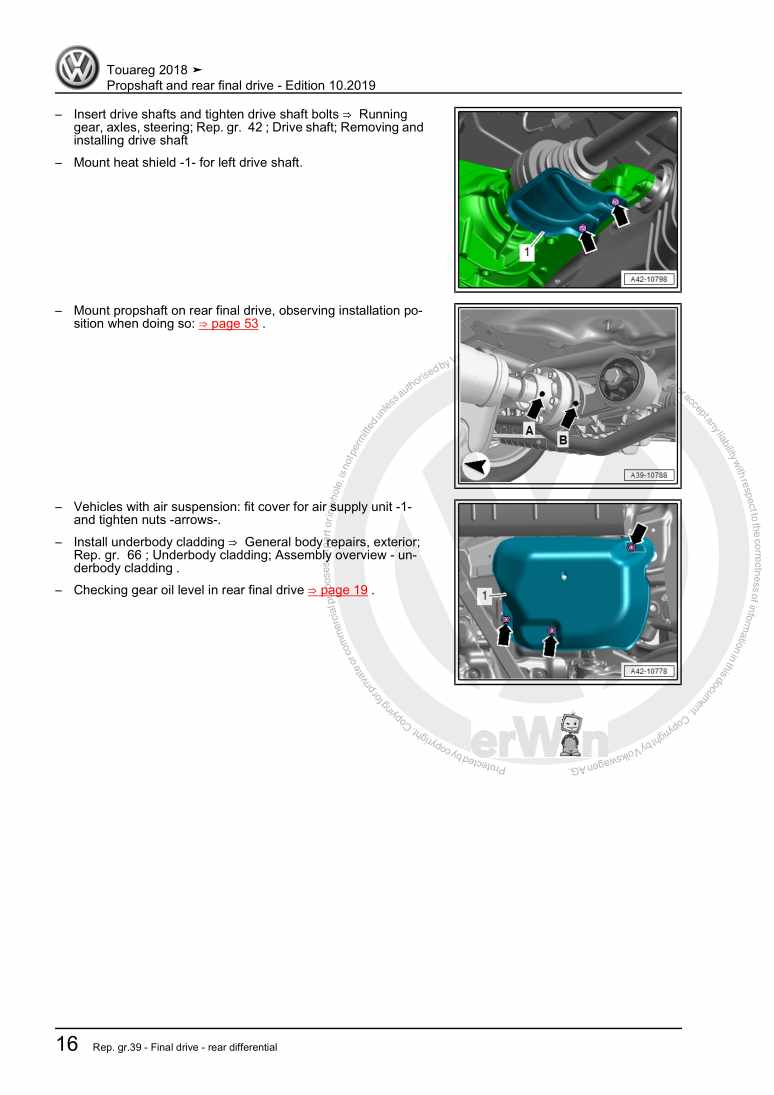

502.2 Removing and installing engine mounting

532.3 Removing and installing gearbox mountings

592.4 Supporting engine in installation position

603 Engine cover panel

643.1 Removing and installing engine cover

64Crankshaft group

681 Cylinder block (pulley end)

681.1 Assembly overview - cylinder block (pulley end)

681.2 Assembly overview - sealing flange, belt pulley end

711.3 Removing and installing poly-V belt

731.4 Removing and installing tensioner for poly V-belt

751.5 Removing and installing vibration damper

751.6 Removing and installing bracket for ancillaries

781.7 Removing and installing engine support

801.8 Renewing crankshaft oil seal - belt pulley end

811.9 Removing and installing sealing flange on pulley end

832 Cylinder block, gearbox end

882.1 Assembly overview - cylinder block, gearbox end

882.2 Removing and installing drive plate

882.3 Renewing crankshaft oil seal (gearbox end)

913 Crankshaft

943.1 Assembly overview - crankshaft

943.2 Crankshaft dimensions

963.3 Allocation of main bearing shells

973.4 Measuring axial clearance of crankshaft

983.5 Measuring radial clearance of crankshaft

993.6 Checking sender wheel

994 Balancer shaft

1014.1 Assembly overview - balance shaft

1014.2 Removing and installing balance shaft

1015 Pistons and conrods

1105.1 Assembly overview - pistons and conrods

1105.2 Removing and installing pistons

1145.3 Measuring piston projection at TDC

1155.4 Checking pistons and cylinder bores

1185.5 Checking radial clearance of conrods

120Cylinder head, valve gear

1211 Cylinder head

1211.1 Assembly overview - cylinder head

1211.2 Assembly overview - cylinder head cover

1241.3 Removing and installing cylinder head

1271.4 Removing and installing cylinder head cover

1361.5 Removing and installing injector seals

1421.6 Checking compression

1432 Cover for timing chain

1452.1 Assembly overview - cover for timing chain

1452.2 Removing and installing timing chain cover

1493 Chain drive

1623.1 Assembly overview - camshaft timing chains

1623.2 Assembly overview - drive chain for high pressure pump

1643.3 Assembly overview - drive chain for oil pump

1653.4 Assembly overview - intermediate drive

1653.5 Removing camshaft timing chain from camshafts

1663.6 Removing and installing camshaft timing chain

1793.7 Removing and installing drive chain for high-pressure pump

1913.8 Installing intermediate drive

1934 Valve gear

2024.1 Assembly overview - valve gear

2024.2 Measuring axial play of camshaft

2104.3 Measuring radial play of camshaft

2124.4 Removing and installing camshaft

2124.5 Checking hydraulic compensation elements

2284.6 Removing and installing valve stem seals

2305 Inlet and exhaust valves

2405.1 Reworking valve seats

2405.2 Checking valve guides

2405.3 Checking valves

2415.4 Valve dimensions

241Lubrication

2421 Sump, oil pump

2421.1 Assembly overview - sump/oil pump

2421.2 Engine oil:

2471.3 Removing and installing lower part of sump

2491.4 Removing and installing upper part of sump

2521.5 Removing and installing oil pump

2551.6 Removing and installing oil level and oil temperature sender G266

2582 Engine oil cooler

2592.1 Assembly overview - engine oil cooler

2592.2 Removing and installing engine oil cooler

2612.3 Removing and installing temperature regulator for engine oil cooler

2623 Crankcase ventilation

2643.1 Assembly overview - crankcase breather system

2643.2 Removing and installing oil separator

2654 Oil filter, oil pressure switch

2664.1 Assembly overview - oil filter

2664.2 Removing and installing oil pressure sender G10

2684.3 Checking oil pressure

2694.4 Removing and installing oil filter housing

2694.5 Removing and installing oil pressure regulating valve N428

2724.6 Removing and installing oil temperature sender 2 G664

272Cooling

2741 Cooling system/coolant

2741.1 Connection diagram - coolant hoses

2741.2 Checking cooling system for leaks

2781.3 Draining and adding coolant

2812 Coolant pump, regulation of cooling system

2922.1 Assembly overview - coolant pump

2922.2 Assembly overview - electric coolant pump

2942.3 Assembly overview - thermostat

2942.4 Assembly overview - coolant temperature sender

2962.5 Removing and installing electric coolant pump

2972.6 Removing and installing coolant pump

2992.7 Removing and installing thermostat housing

3012.8 Removing and installing thermostat

3032.9 Removing and installing coolant temperature sender G62

3032.11 Removing and installing coolant temperature sender 2 G802

3062.12 Removing and installing coolant valves

3073 Coolant pipes

3103.1 Assembly overview - coolant pipes

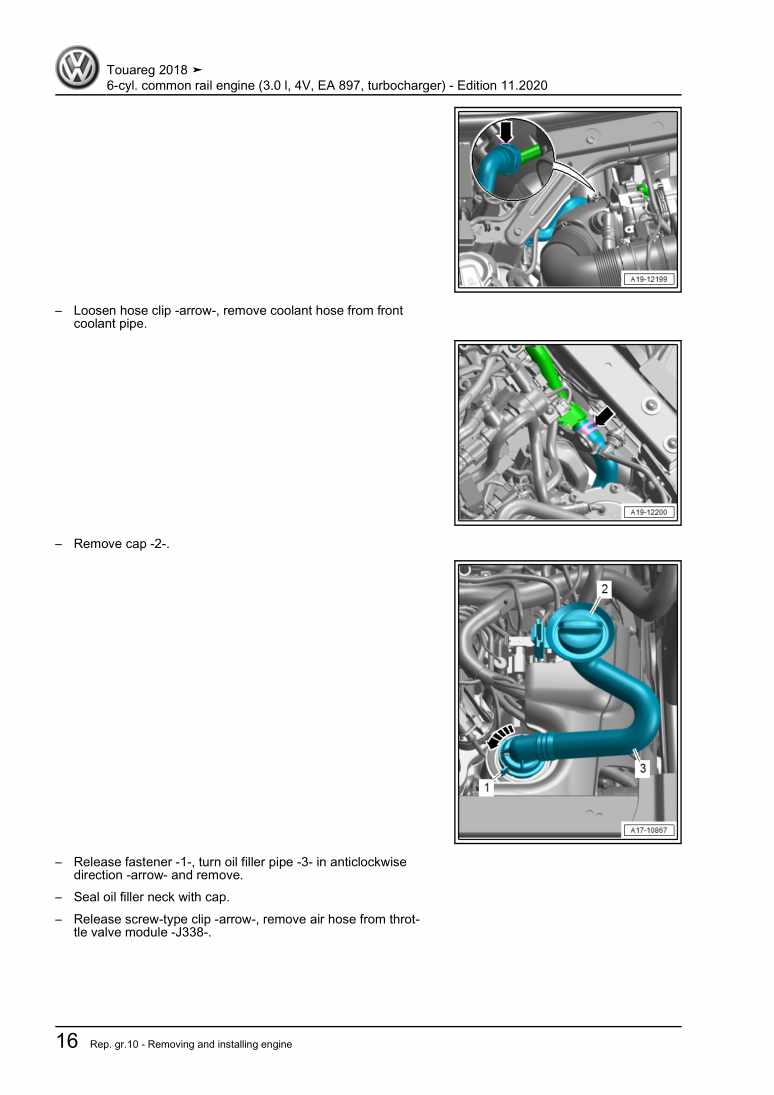

3103.2 Removing and installing coolant pipes

3154 Radiator, radiator fan

3284.1 Assembly overview - radiator/radiator fan

3284.2 Assembly overview - auxiliary radiator

3314.3 Removing and installing radiator

3324.4 Removing and installing radiator cowl

3384.5 Removing and installing radiator fan V7

3414.6 Removing and installing auxiliary radiator

341Turbocharging/supercharging

3441 Turbocharger

3441.1 Assembly overview - turbocharger

3441.2 Removing and installing turbocharger

3492 Charge air system

3542.1 Assembly overview - charge air system

3542.2 Assembly overview - charge-air hose connections

3552.3 Removing and installing charge air cooler

3562.4 Removing and installing charge pressure sender G31

3592.5 Checking charge air system for leaks

359Mixture preparation - injection

3641 Injection system

3641.1 Schematic overview - fuel system

3641.2 Overview of fitting locations - injection system

3651.3 Filling/bleeding fuel system

3721.4 Checking fuel system for leaks

3732 Vacuum system

3742.1 Connection diagram - vacuum system

3742.2 Checking vacuum system

3743 Injectors/high-pressure accumulator (rail)

3763.1 Assembly overview - injectors

3763.2 Testing injectors

3803.3 Adapting correction values for injectors

3813.4 Checking return flow rate of injectors with engine running

3823.5 Checking return flow rate of injectors at starter speed

3853.6 Testing jammed-open injectors

3883.7 Check pressure retention valve in fuel return line

3923.8 Removing and installing injectors

3933.9 Removing and installing high-pressure lines

3993.10 Removing and installing fuel rail

4014 Air filter

4064.1 Assembly overview - air filter housing

4064.2 Removing and installing air filter housing

4085 Intake manifold

4115.1 Assembly overview - intake manifold

4115.2 Removing and installing intake manifold upper part

4155.3 Removing and installing lower part of intake manifold

4205.4 Removing and installing intake manifold flap motor V157

4215.5 Removing and installing throttle valve module J338

4246 Senders and sensors

4266.1 Checking fuel pressure regulating valve N276

4266.2 Removing and installing fuel pressure regulating valve N276

4286.3 Removing and installing fuel pressure sender G247

4306.4 Removing and installing air mass meter G70

4336.5 Removing and installing pressure differential sender G505

4336.6 Removing and installing pressure differential sender 2 G524

4356.7 Removing and installing NOx sender G295

4366.8 Removing and installing NOx sender 2 G687

4386.9 Removing and installing particle sensor G784

4396.11 Removing and installing fuel temperature sender G81

4416.12 Removing and installing fuel pressure sender for low-pressure G410

4417 Engine control unit

4437.1 Assembly overview – motor control unit

4437.2 Removing and installing engine control unit J623

4438 High-pressure pump

4458.1 Assembly overview - high-pressure pump

4458.2 Removing and installing high-pressure pump

4489 Lambda probe

4549.1 Assembly overview - Lambda probe

4549.2 Removing and installing Lambda probe

456Exhaust system

4581 Exhaust pipes and silencers

4581.1 Assembly overview - silencers

4581.2 Removing and installing front exhaust pipe

4601.3 Separating exhaust pipes from silencers

4651.4 Removing and installing silencer

4661.5 Aligning exhaust system free of stress

4681.6 Checking exhaust system for leaks

4692 Emission control

4702.1 Assembly overview - emission control

4702.2 Removing and installing emission control module

4732.3 Removing and installing trap catalytic converter

4772.4 Removing and installing exhaust flap control unit J883

4793 SCR system (selective catalytic reduction)

4813.1 Assembly overview - tank for reducing agent

4813.2 Assembly overview - reducing agent supply line

4833.3 Assembly overview - control unit for reducing agent metering system

4843.4 Relieving pressure in SCR system

4853.5 Draining reducing agent tank

4863.6 Removing and installing reducing agent tank

4873.7 Removing and installing injector for reduction agent N474

4893.8 Assembly overview - injector for reducing agent

4913.9 Removing and installing control unit for reducing agent metering system J880

4923.10 Removing and installing reducing agent quality sensor G849

4934 Exhaust gas temperature regulation

4944.1 Assembly overview - exhaust gas temperature regulation

4944.2 Removing and installing exhaust gas temperature sender 1 G235

4954.3 Removing and installing exhaust gas temperature sender 2 G448

4974.4 Removing and installing exhaust gas temperature sender 3 G495

4984.5 Removing and installing exhaust gas temperature sender 4 G648

5005 Exhaust gas recirculation

5025.1 Assembly overview - exhaust gas recirculation

5025.2 Removing and installing exhaust gas recirculation valve

5075.3 Removing and installing exhaust gas recirculation cooler

5105.4 Removing and installing exhaust gas recirculation control motor 2 V339

5145.5 Removing and installing exhaust gas recirculation temperature sensor G98

5156 Exhaust manifold

5176.1 Assembly overview - exhaust manifold

5176.2 Removing and installing exhaust manifold

518Glow plug system

5231 Glow plug system

5231.1 Assembly overview - glow plug system

5231.2 Removing and installing glow plug

5251.3 Removing and installing automatic glow period control unit J179

5281.4 Removing and installing Hall sender G40

5291.5 Removing and installing engine speed sender G28

529