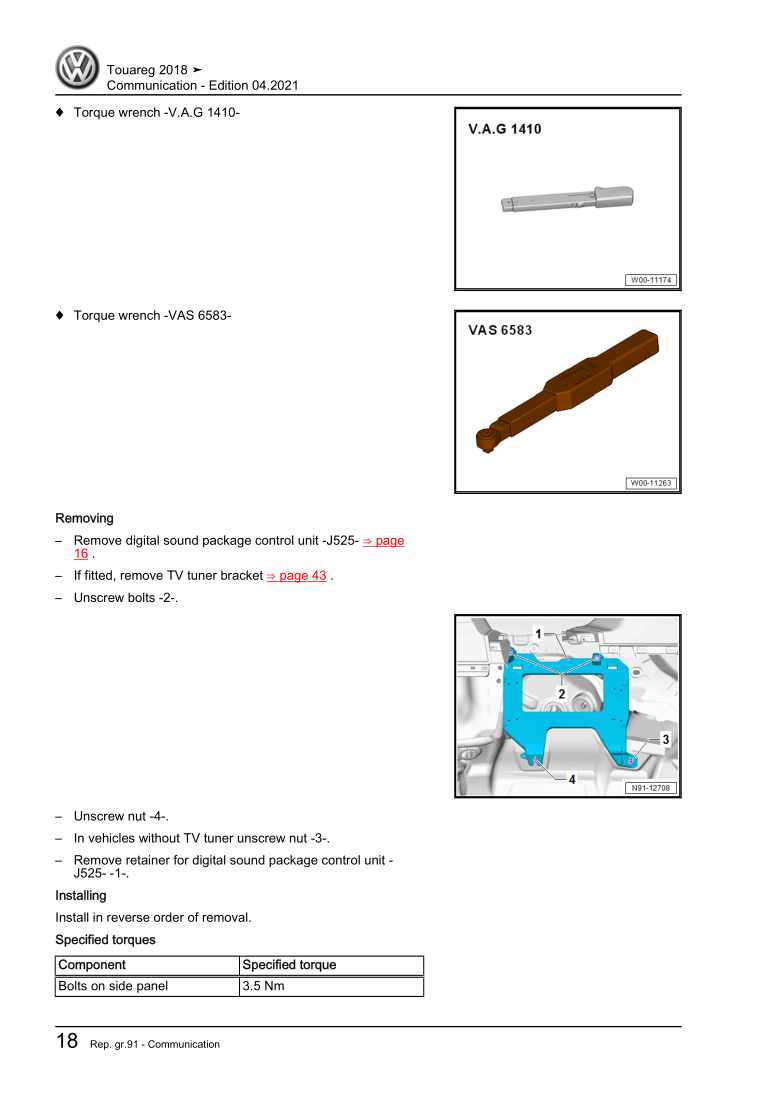

Technical data

11 Identification

11.1 Engine number/engine data

12 Safety information

22.1 Safety precautions when working on fuel system

22.2 Safety measures when working on vehicles with a start/stop system

22.4 Safety precautions when working on the cooling system

32.5 Safety precautions when working on exhaust system

32.6 Safety precautions when working on the SCR system

43 Repair notes

63.1 Identification labels

63.2 Using impact drivers

63.3 Rules for cleanliness

73.4 General notes

73.5 General repair notes

93.6 Foreign objects in engine

103.7 Contact corrosion

113.8 Routing and attachment of lines

113.9 Fitting radiator and condensers

113.10 Adapting after component replacement

12Removing and installing engine

131 Removing and installing engine

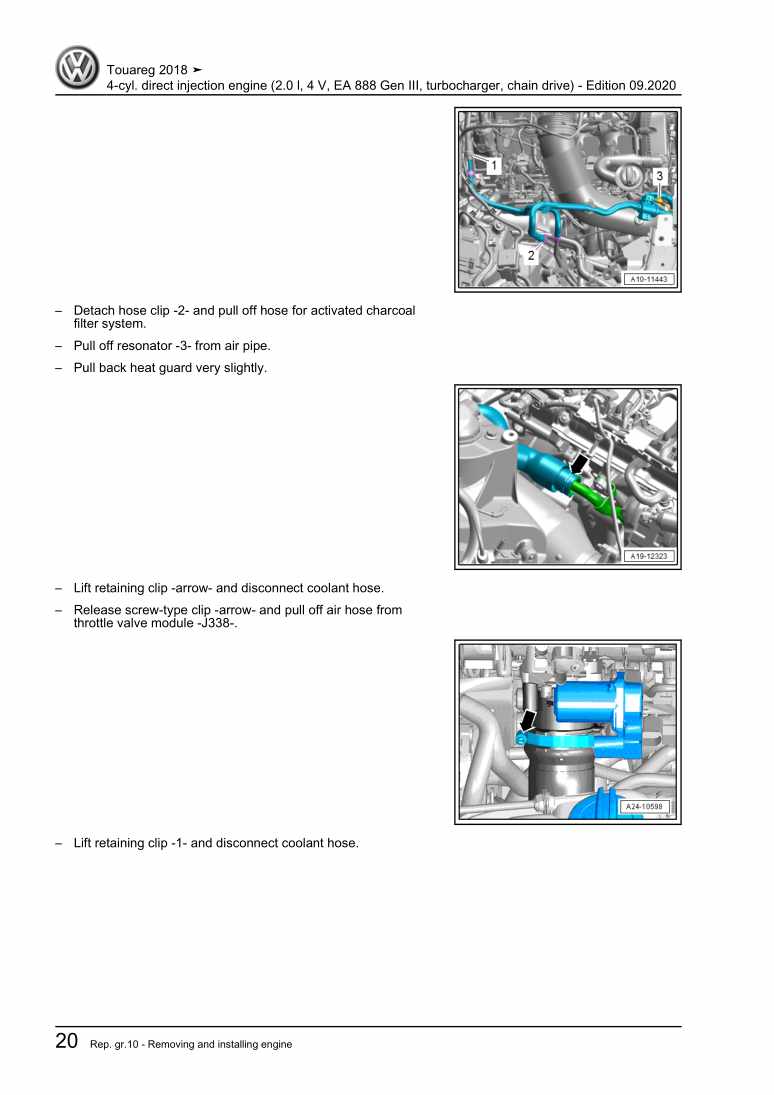

131.1 Removing engine

131.2 Separating engine and gearbox

361.3 Securing engine on engine and gearbox support

421.4 Installing engine

462 Assembly mountings

502.1 Assembly overview - assembly mountings

502.2 Removing and installing engine mounting

542.3 Removing and installing gearbox mounting

592.4 Supporting engine in installation position

602.5 Removing and installing power unit mounting senders

642.6 Removing and installing power unit mounting control unit J931

642.7 Calibrating electrohydraulic engine mounting

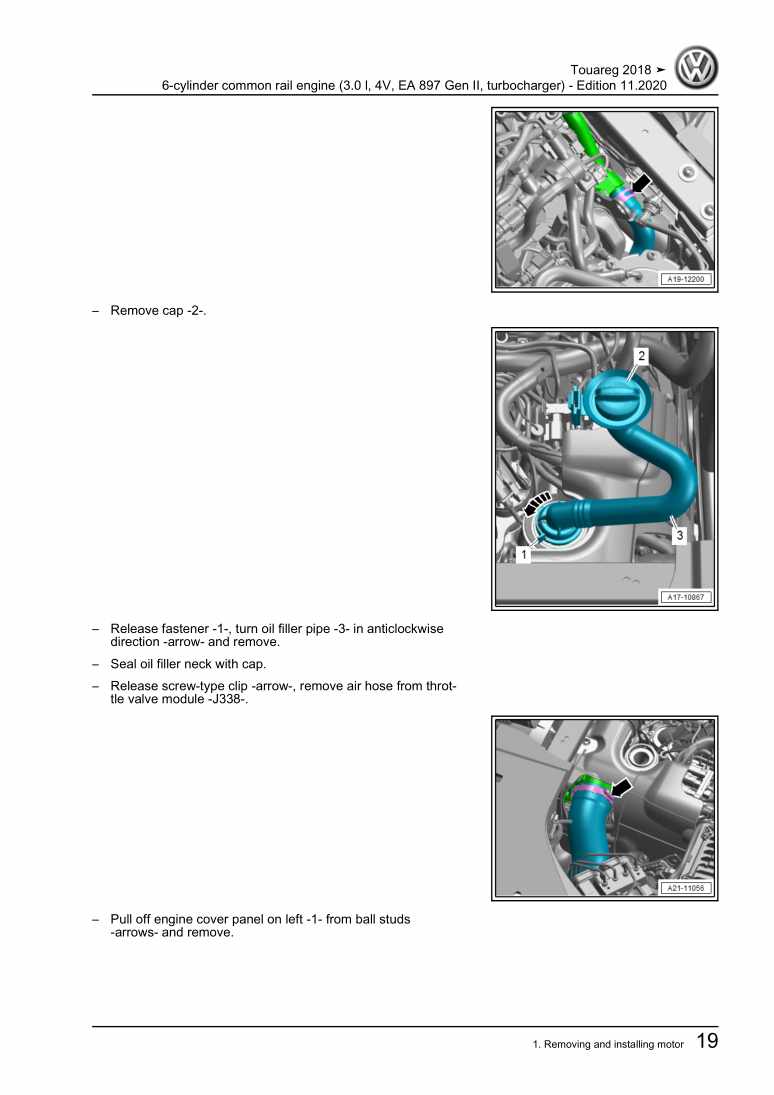

653 Engine cover panel

673.1 Removing and installing engine cover

67Crankshaft group

691 Cylinder block (pulley end)

691.1 Assembly overview - cylinder block (pulley end)

691.2 Assembly overview - sealing flange, belt pulley end

761.3 Removing and installing poly-V belt

791.4 Removing and installing tensioner for poly V-belt

831.5 Removing and installing vibration damper

861.6 Removing and installing bracket for ancillaries

931.7 Removing and installing engine support

971.8 Renewing crankshaft oil seal - belt pulley end

981.9 Removing and installing sealing flange on pulley end

992 Cylinder block, gearbox end

1052.1 Assembly overview - cylinder block, gearbox end

1052.2 Removing and installing drive plate

1052.3 Renewing crankshaft oil seal (gearbox end)

1083 Crankshaft

1113.1 Assembly overview - crankshaft

1113.2 Crankshaft dimensions

1143.3 Allocation of main bearing shells

1143.4 Measuring axial clearance of crankshaft

1153.5 Measuring radial clearance of crankshaft

1163.6 Checking sender wheel

1174 Balancer shaft

1194.1 Assembly overview - balance shaft

1194.2 Removing and installing balance shaft

1204.3 Renewing roller bearing

1285 Pistons and conrods

1315.1 Assembly overview - pistons and conrods

1315.2 Removing and installing pistons

1355.3 Measuring piston projection at TDC

1365.4 Checking pistons and cylinder bores

1385.5 Checking radial clearance of conrods

140Cylinder head, valve gear

1421 Cover for timing chain

1421.1 Assembly overview - cover for timing chain

1421.2 Removing and installing timing chain cover

1472 Chain drive

1582.1 Assembly overview - camshaft timing chains

1582.2 Assembly overview - drive chain

1602.3 Removing camshaft timing chain from camshafts

1622.4 Removing and installing camshaft timing chain

1742.5 Removing and installing drive chain for high-pressure pump

1852.6 Installing intermediate drive

1873 Cylinder head

1963.1 Assembly overview - cylinder head

1963.2 Assembly overview - cylinder head cover

1993.3 Removing and installing cylinder head

2023.4 Removing and installing cylinder head cover

2113.5 Removing and installing injector seals

2163.6 Checking compression

2174 Valve gear

2194.1 Assembly overview - valve gear

2194.2 Measuring axial play of camshaft

2284.3 Measuring radial play of camshaft

2304.4 Removing and installing camshaft

2314.5 Removing and installing valve stem seals

2475 Inlet and exhaust valves

2575.1 Reworking valve seats

2575.2 Checking valve guides

2575.3 Checking valves

2585.4 Valve dimensions

258Lubrication

2591 Sump, oil pump

2591.1 Assembly overview - sump/oil pump

2591.2 Engine oil:

2631.3 Removing and installing lower part of sump

2631.4 Removing and installing upper part of sump

2671.5 Removing and installing oil pump

2701.6 Removing and installing oil level and oil temperature sender G266

2722 Engine oil cooler

2742.1 Assembly overview - engine oil cooler

2742.2 Removing and installing engine oil cooler

2762.3 Removing and installing temperature regulator for engine oil cooler

2773 Oil filter, oil pressure switch

2793.1 Assembly overview - oil filter

2793.2 Removing and installing oil filter housing

2813.3 Removing and installing oil pressure sender G10

2833.4 Checking oil pressure

2843.5 Removing and installing oil pressure regulating valve N428

2853.6 Removing and installing oil temperature sender 2 G664

285Cooling

2881 Cooling system/coolant

2881.1 Connection diagram - coolant hoses

2881.2 Assembly overview – coolant expansion tank

2921.3 Checking cooling system for leaks

2931.4 Draining and adding coolant

2972 Coolant pump, regulation of cooling system

3062.1 Assembly overview - coolant pump

3062.2 Assembly overview - electric coolant pump

3072.3 Assembly overview - thermostat

3092.4 Assembly overview – coolant valves

3112.5 Assembly overview - coolant temperature sender

3142.6 Removing and installing electric coolant pump

3162.7 Removing and installing coolant pump

3192.8 Removing and installing map-controlled engine cooling thermostat F265

3222.10 Removing and installing coolant temperature sender G62

3232.12 Removing and installing coolant temperature sender 2 G802

3262.13 Removing and installing coolant temperature sender for charge air cooler G1130

3272.14 Removing and installing coolant valves

3293 Coolant pipes

3353.1 Assembly overview - coolant pipes

3353.2 Removing and installing coolant pipes

3403.3 Removing and installing coolant line

3604 Radiator, radiator fan

3624.1 Assembly overview - radiator/radiator fan

3624.2 Assembly overview – radiator cowl and radiator fan

3654.3 Assembly overview - radiator blind

3664.4 Assembly overview - auxiliary radiator

3674.5 Removing and installing radiator

3684.6 Removing and installing radiator blind

3724.7 Removing and installing radiator blind control motor V544

3734.8 Removing and installing water radiator for charge air cooling circuit

3754.9 Removing and installing radiator cowl

3774.10 Removing and installing radiator fan

3804.11 Removing and installing auxiliary radiator

381Turbocharging/supercharging

3841 Turbocharger

3841.1 Assembly overview - turbocharger

3841.2 Removing and installing turbocharger

3882 Charge air system

3922.1 Assembly overview - charge air system

3922.2 Assembly overview - charge-air hose connections

3942.3 Removing and installing charge air cooler

3952.4 Removing and installing charge pressure sender G31

3982.5 Removing and installing charge air temperature sender

3992.6 Checking charge air system for leaks

400Mixture preparation - injection

4051 Injection system

4051.1 Schematic overview - fuel system

4051.2 Overview of fitting locations - injection system

4061.3 Filling/bleeding fuel system

4131.4 Checking fuel system for leaks

4142 Vacuum system

4152.1 Connection diagram – vacuum system

4152.2 Checking vacuum system

4153 Air filter

4173.1 Assembly overview - air filter housing

4173.2 Removing and installing air filter housing

4194 Intake manifold

4234.1 Assembly overview – intake manifold

4234.2 Removing and installing intake manifold upper part

4264.3 Removing and installing lower part of intake manifold

4304.4 Removing and installing intake manifold flap control unit GX14

4314.5 Removing and installing throttle valve module GX3

4325 Injectors/high-pressure accumulator (rail)

4345.1 Assembly overview - injectors

4345.2 Testing injectors

4395.3 Adapting correction values for injectors

4395.4 Checking return flow rate of injectors with engine running

4405.5 Checking return flow rate of injectors at starter speed

4455.6 Removing and installing injectors

4505.7 Removing and installing high-pressure lines

4625.8 Removing and installing fuel rail

4646 Senders and sensors

4706.1 Removing and installing air mass meter G70

4706.2 Removing and installing fuel temperature sender G81

4716.3 Removing and installing fuel pressure sender G247

4726.4 Removing and installing fuel pressure sender for low-pressure G410

4746.5 Checking fuel pressure regulating valve N276

4756.6 Removing and installing fuel pressure regulating valve N276

4776.7 Removing and installing pressure differential sender

4806.8 Removing and installing NOx sender

4826.9 Removing and installing particle sensor G784

4867 High-pressure pump

4897.1 Assembly overview - high-pressure pump

4897.2 Removing and installing high-pressure pump

4918 Lambda probe

4968.1 Assembly overview - Lambda probe

4968.2 Removing and installing Lambda probe

4999 Engine control unit

5039.1 Assembly overview – engine/motor control unit

5039.2 Removing and installing engine control unit J623

503Exhaust system

5051 Exhaust pipes and silencers

5051.1 Assembly overview – silencers

5051.2 Removing and installing front exhaust pipe

5071.3 Separating exhaust pipes from silencers

5101.4 Removing and installing silencer

5121.5 Aligning exhaust system free of stress

5141.6 Checking exhaust system for leaks

5151.7 Installation position of clamp

5162 Emission control

5182.1 Assembly overview – emission control

5182.2 Removing and installing emission control module

5212.3 Removing and installing trap catalytic converter

5252.4 Removing and installing exhaust flap control unit J883

5273 SCR system (selective catalytic reduction)

5293.1 Assembly overview – reducing agent tank

5293.2 Assembly overview - injector for reducing agent

5323.3 Assembly overview - reducing agent supply line

5353.4 Relieving pressure in SCR system

5363.5 Disconnecting reducing agent supply line

5373.6 Draining reducing agent tank

5393.7 Removing and installing reducing agent tank

5413.8 Removing and installing injector for reduction agent N474

5433.9 Removing and installing injector 2 for reducing agent N758

5453.10 Removing and installing control unit for reducing agent metering system J880

5473.11 Removing and installing reducing agent quality sensor G849

5483.12 Removing and installing pump for reducing agent V437

5483.14 Removing and installing connection for SCR supply line

5534 Exhaust gas temperature regulation

5564.1 Assembly overview – exhaust gas temperature regulation

5564.2 Removing and installing exhaust gas temperature sender 1 G235

5574.3 Removing and installing exhaust gas temperature sender 2 G448

5594.4 Removing and installing exhaust gas temperature sender 3 G495

5604.5 Removing and installing exhaust gas temperature sender 4 G648

5615 Exhaust gas recirculation

5645.1 Assembly overview – exhaust gas recirculation

5645.2 Removing and installing exhaust gas recirculation cooler

5685.3 Removing and installing exhaust gas recirculation valve 2 GX6

5735.4 Removing and installing exhaust gas recirculation temperature sensor G98

5746 Exhaust manifold

5766.1 Assembly overview - exhaust manifold

5766.2 Removing and installing exhaust manifold

577Ignition system

5811 Glow plug system

5811.1 Assembly overview - glow plug system

5811.2 Removing and installing glow plug

5831.3 Removing and installing automatic glow period control unit J179

5871.4 Removing and installing Hall sender G40

5881.5 Removing and installing engine speed sender G28

589