Technical data

11 Technical data

11.1 Engine number

11.2 Engine data

1Removing and installing engine

31 Removing and installing engine

31.1 Removing engine

31.2 Notes on installing

151.3 Specified torques

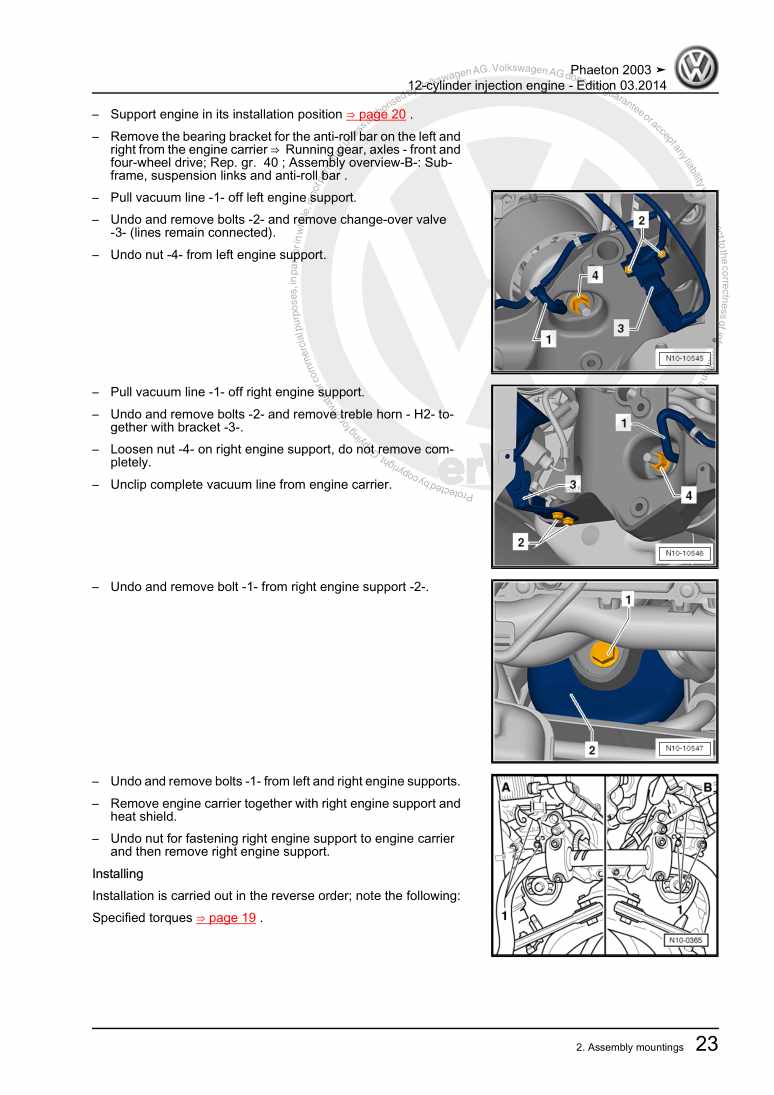

161.4 Front engine mounting

16Crankshaft group

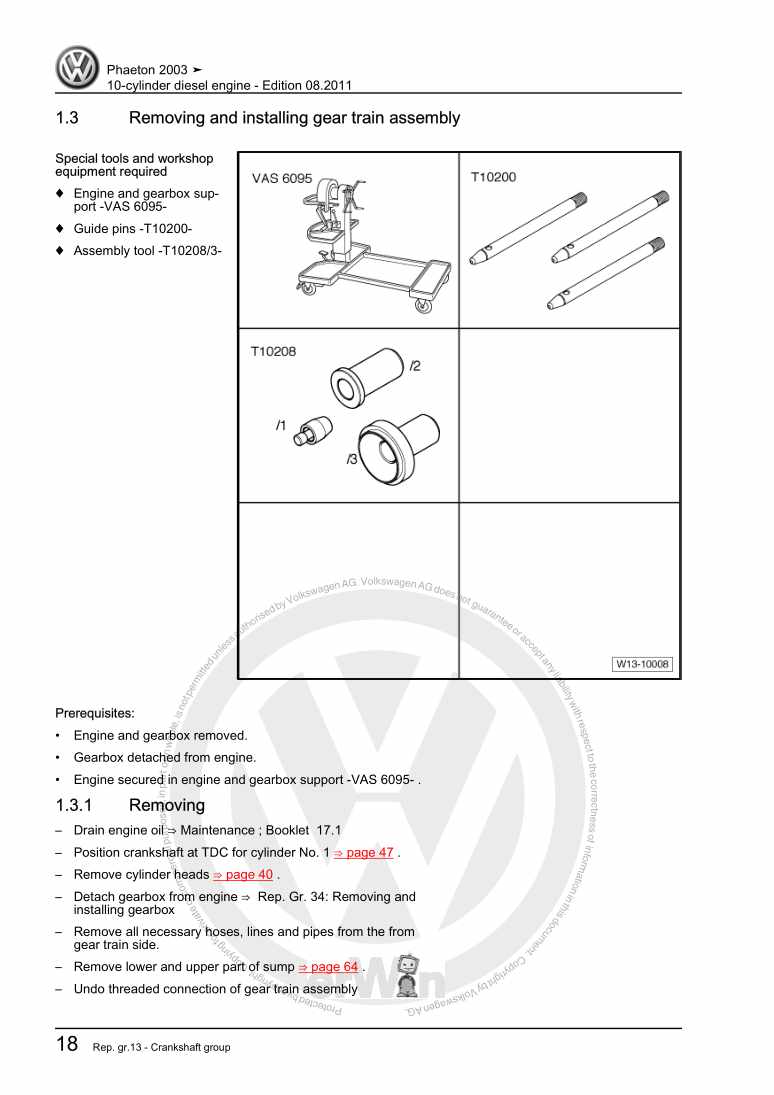

181 Dismantling and assembling engine

181.1 Assembly overview - poly V-belt drive

201.2 Removing and installing poly V-belt

231.3 Renewing crankshaft oil seal - belt pulley end

241.4 Removing and installing front sealing flange

261.5 Assembly overview - drive plate/dual-mass flywheel

291.6 Removing and installing dual-mass flywheel

301.7 Extracting and driving in needle roller bearing for dual-mass flywheel

311.8 Removing and installing drive plate

321.9 Renewing crankshaft oil seal on timing chain end

331.10 Assembly overview - timing chain covers

351.11 Removing and installing timing chain covers

361.12 Assembly overview - balancer shaft

431.13 Removing and installing balancer shaft

442 Chain drive (engine code BMK)

472.1 Assembly overview - drive chain for valve gear

472.2 Removing and installing drive chain for valve gear

482.3 Assembly overview - chain for balancer shaft and oil pump

492.4 Removing and installing chain for balancer shaft and oil pump

513 Chain drive (engine codes CARA, CEXA, CEXB)

553.1 Assembly overview - drive chain for valve gear

553.2 Removing and installing drive chain for valve gear

563.3 Assembly overview - chain for balancer shaft and oil pump

573.4 Removing and installing chain for balancer shaft and oil pump

594 Removing and installing crankshaft

634.1 Assembly overview - crankshaft

634.2 Crankshaft dimensions

654.3 Measuring axial clearance

654.4 Measuring radial clearance

665 Pistons and conrods

675.1 Assembly overview - pistons and conrods

675.2 Checking piston projection at TDC

705.3 Piston and cylinder dimensions

715.4 Checking radial clearance of conrods

71Cylinder head, valve gear

721 Cylinder head

721.1 Assembly overview - cylinder head

721.2 Assembly overview - cylinder head cover

751.3 Removing and installing cylinder head cover

781.4 Removing and installing cylinder head

841.5 Checking compression

911.6 Assembly overview - vacuum pump

932 Valve gear

952.1 Assembly overview - valve gear

952.2 Checking axial clearance of camshafts

962.3 Renewing camshaft oil seal

972.4 Removing and installing camshafts

1002.5 Renewing valve stem seals

1042.6 Checking hydraulic valve compensation elements

1082.7 Valve dimensions

1102.8 Checking valve guides

1103 Chain drive for camshafts

1123.1 Camshaft timing chains (engine code BMK)

1123.2 Camshaft timing chains (engine codes CARA, CEXA, CEXB)

131Lubrication

1511 Engine oil

1511.1 Oil capacities

1511.2 Checking engine oil level

1512 Parts of lubrication system

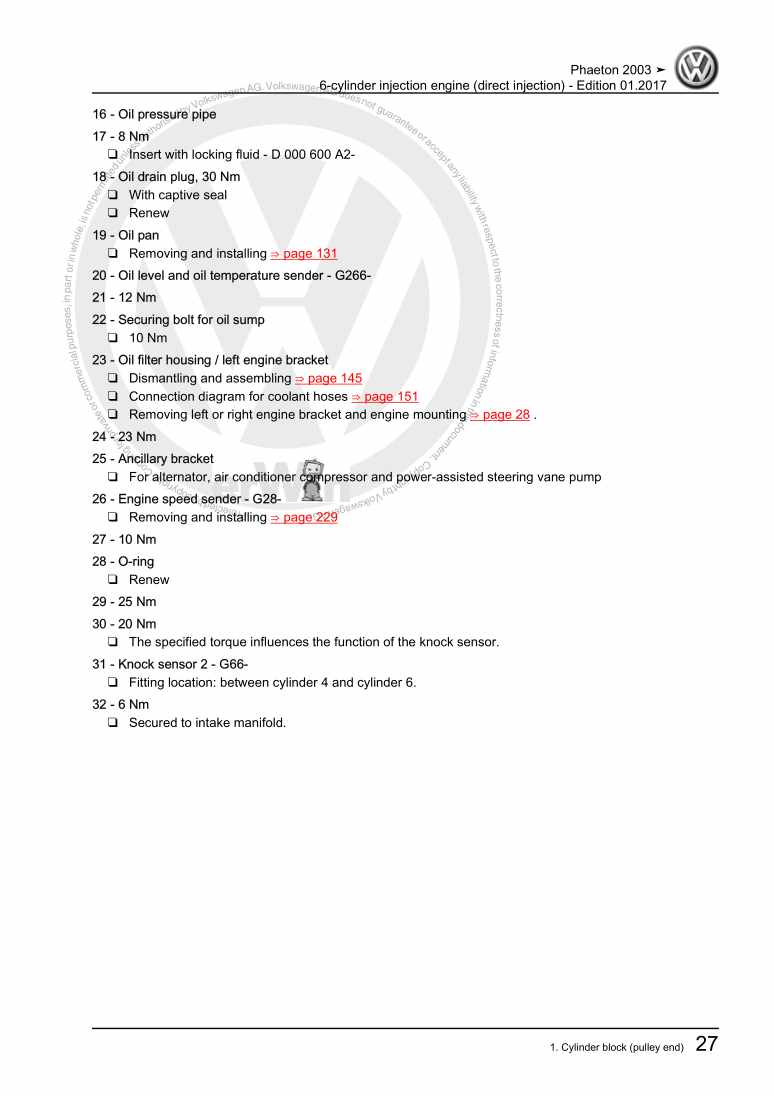

1522.1 Assembly overview - oil pump, lower part of sump

1522.2 Removing and installing lower part of sump

1532.3 Removing and installing oil pump

1552.4 Assembly overview - upper part of sump

1562.5 Removing and installing upper part of sump

1573 Oil cooler, pressure control valve and oil filter housing

1613.1 Assembly overview - oil cooler, pressure control valve, and oil filter housing

1613.2 Removing and installing oil cooler

1623.3 Removing and installing oil filter housing

1633.7 Checking oil pressure and oil pressure switch

167Cooling

1701 Parts of cooling system

1701.1 Assembly overview - radiator

1701.2 Removing and installing fan support

1711.3 Assembly overview - fans

1721.4 Checking cooling system for leaks

1731.5 Draining and filling coolant

1731.6 Assembly overview - coolant pump and thermostat

1771.7 Removing and installing coolant pump

1771.8 Removing and installing continued coolant circulation pump V51

1781.9 Removing and installing hose connection with thermostat

1791.10 Assembly overview - pump for exhaust gas recirculation cooler V400

1801.11 Removing and installing pump for exhaust gas recirculation cooler V400

1811.12 Assembly overview - coolant pipes

1821.13 Removing and installing coolant pipes

1851.14 Removing and installing coolant temperature sender G62

192Turbocharging/supercharging

1941 Charge air system with turbocharger

1941.1 Rules for cleanliness

1941.2 Assembly overview - turbocharger (engine code BMK)

1941.3 Removing and installing turbocharger (engine code BMK)

1961.4 Assembly overview - turbocharger (engine codes CARA, CEXA und CEXB)

1981.5 Removing and installing turbocharger (engine codes CARA, CEXA und CEXB)

2001.6 Removing and installing turbocharger 1 control unit J724

2041.7 Assembly overview - parts of charge air cooling

2131.8 Removing and installing charge air cooler

214Mixture preparation - injection

2161 Diesel direct injection system

2171.1 Safety precautions

2181.2 Rules for cleanliness and instructions for working on fuel system

2181.3 Schematic overview of fuel system (engine code BMK)

2191.4 Schematic overview of fuel system (engine codes CARA, CEXA und CEXB)

2211.5 Assembly overview - fuel system (engine code BMK)

2231.6 Assembly overview - fuel system (engine codes CARA, CEXA und CEXB)

2251.7 Assembly overview - intake manifold

2281.8 Removing and installing intake manifold upper part

2321.9 Removing and installing intake manifold flap motor V157 or intake manifold flap 2 motor V275

2361.10 Removing and installing lower parts of intake manifold (engine code BMK)

2431.12 Removing and installing injectors (piezo injectors)

2531.13 Checking fuel pressure regulating valve N276

2591.14 Removing and installing fuel pressure regulating valve N276

2591.15 Removing and installing fuel pressure sender G247

2611.16 Checking return flow rate of injectors (piezo injectors) with engine running

2621.17 Checking return flow rate of injectors (piezo injectors) at starting speed

2651.18 Checking for injectors sticking open (piezo injectors)

2661.19 Installing high-pressure lines

2671.20 Checking pressure retention valve in fuel return

2701.21 Assembly overview - toothed belt for high-pressure pump (engine code BMK)

2711.23 Assembly overview - high-pressure pump (engine code BMK)

2771.24 Removing and installing high-pressure pump (engine code BMK)

2801.29 Bleeding fuel system

2941.30 Assembly overview - air filter

2952 Engine control unit

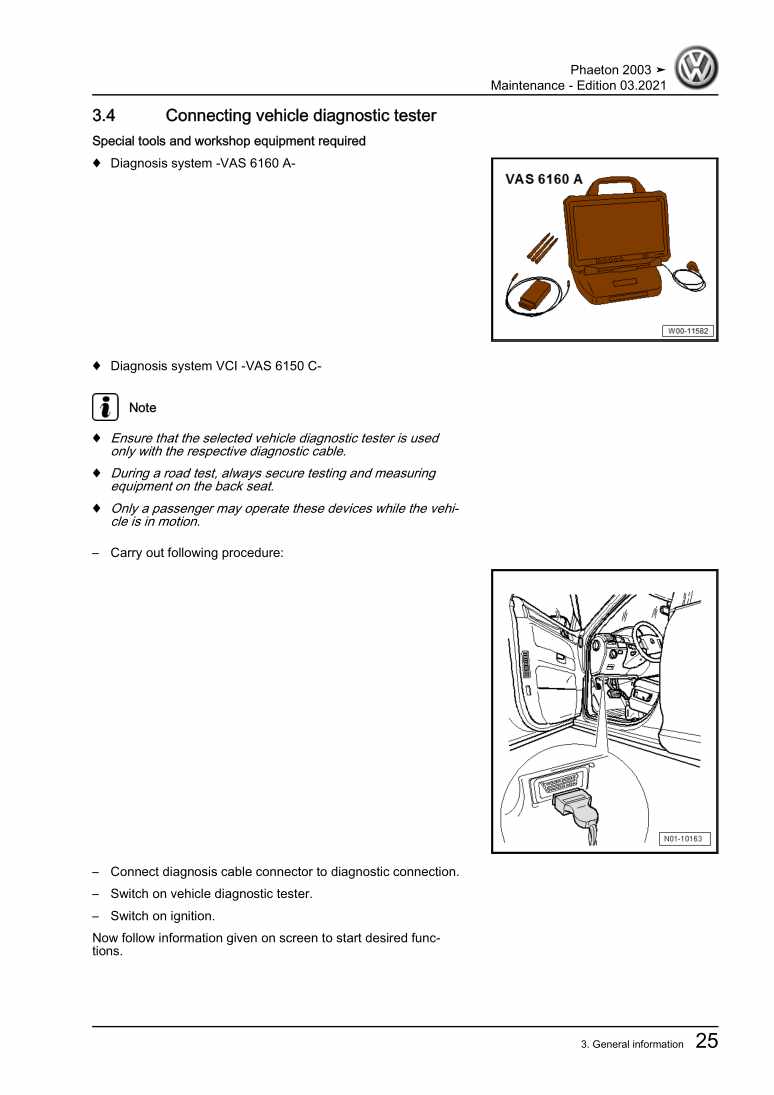

2982.1 Reading and clearing engine control unit fault memory

2982.2 Adapting functions and components

2992.3 Removing and installing engine control unit

3002.4 Fitting locations

300Exhaust system

3031 Parts of the exhaust system

3031.1 Assembly overview - exhaust system

3031.2 Assembly overview - front exhaust pipe and catalytic converter

3061.3 Assembly overview - exhaust manifold and intermediate pipes

3072 Exhaust gas recirculation system, engine code BMK

3082.1 Assembly overview - exhaust gas recirculation system

3082.2 Checking mechanical exhaust gas recirculation valve

3092.3 Removing and installing mechanical exhaust gas recirculation valve

3102.4 Removing and installing exhaust gas recirculation cooler

3103 Exhaust gas recirculation, engine codes CARA, CEXA, CEXB

3123.1 Assembly overview - exhaust gas recirculation system

3123.2 Removing and installing exhaust gas recirculation control motor V338

3133.3 Removing and installing exhaust gas recirculation cooler

3143.4 Removing and installing exhaust gas recirculation temperature sensor G98

316Glow plug system

3181 Glow plug system

3181.1 Glow plug characteristics

3181.2 Removing, installing and checking ceramic glow pin plugs

3181.3 Removing and installing metal glow plugs

3201.4 Checking metal glow plugs

321