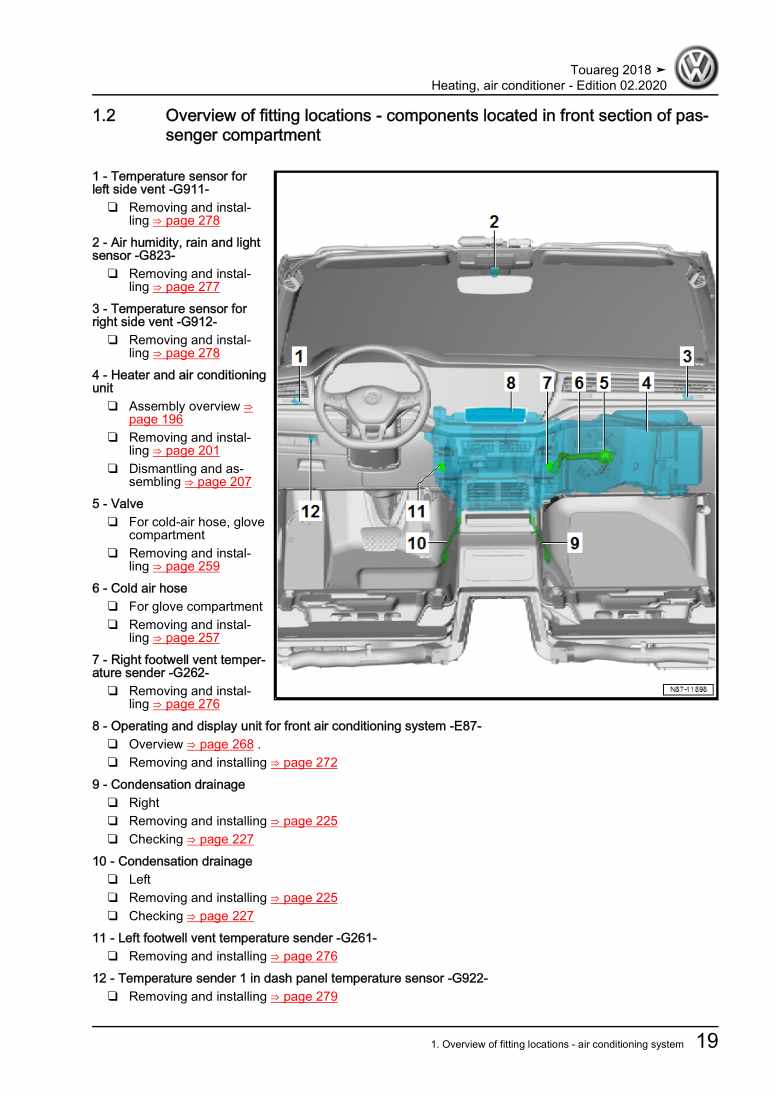

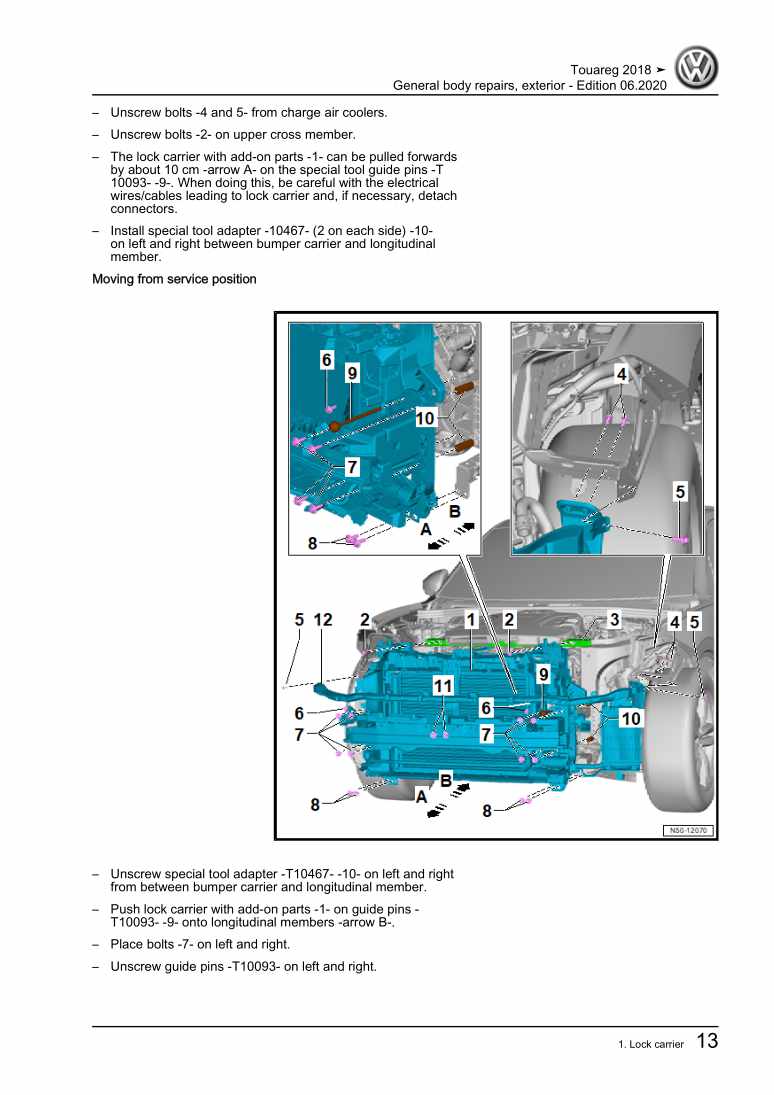

Technical data

11 Safety information

11.1 Safety precautions when working on high-voltage system

11.2 Safety precautions when working in the vicinity of high-voltage components

21.3 Safety regulations for working on fuel supply

21.4 Safety measures when working on vehicles with a start/stop system

31.6 Safety precautions when working on subframe

31.7 Safety precautions when working on ignition system

31.8 Safety precautions when working on the cooling system

41.9 Safety precautions when working on exhaust system

42 Identification

52.1 Engine number/engine data

52.2 Numbering of cylinders

63 Repair instructions

73.1 Rules for cleanliness

73.2 Foreign objects in engine

73.3 Contact corrosion

73.4 Routing and attachment of lines

83.5 Fitting radiator and condensers

83.6 Checking fuel system for leaks

84 Hazard classification of high-voltage system

9Removing and installing engine

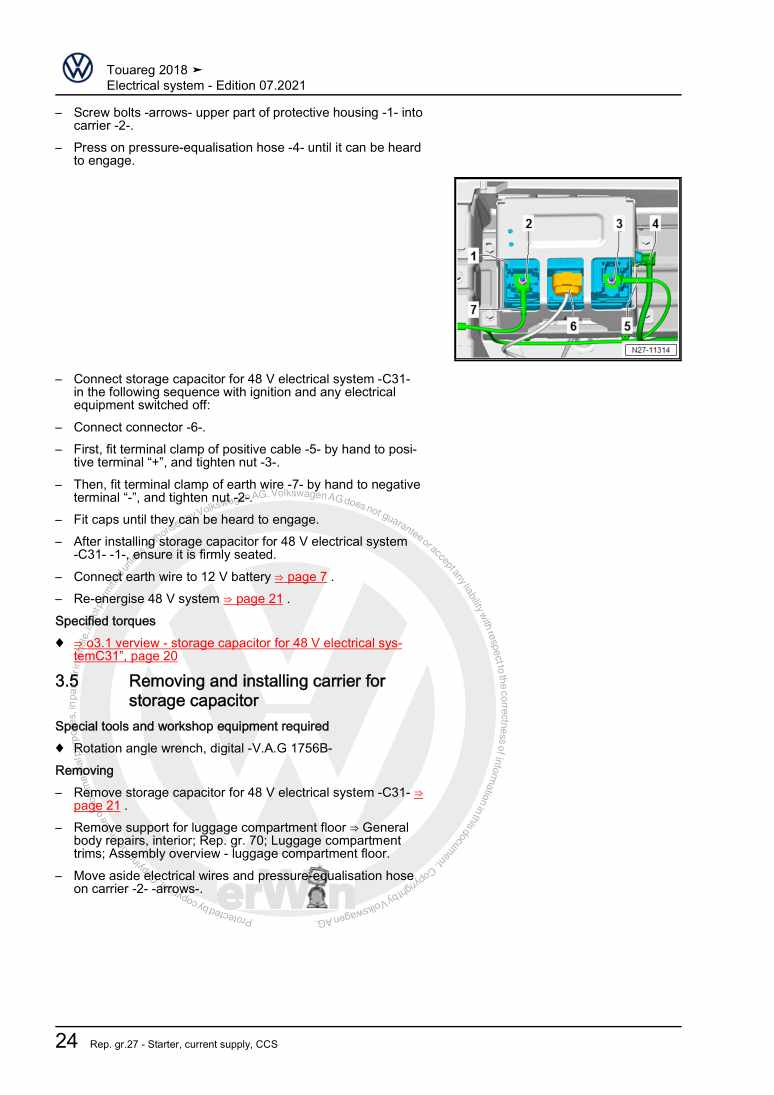

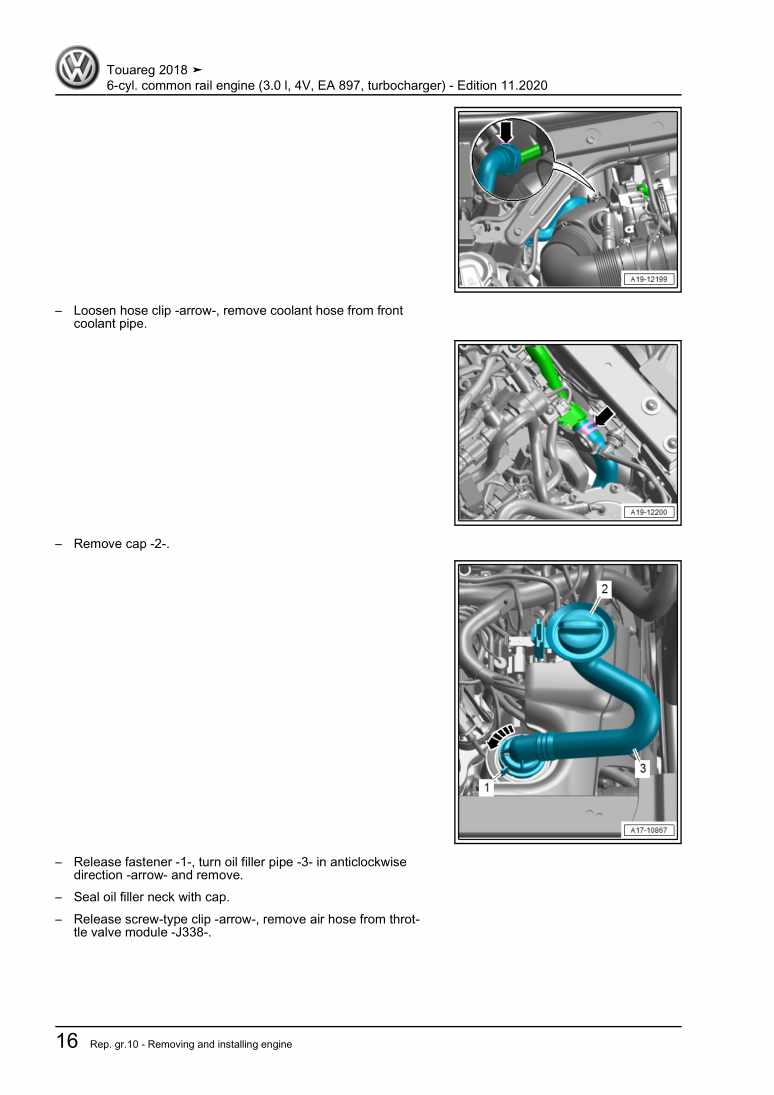

161 Removing and installing engine

161.1 Removing engine

161.2 Separating engine and gearbox

491.3 Removing engine from scissor-type assembly platform

571.4 Securing engine on engine and gearbox support

581.5 Installing engine

612 Assembly mountings

682.1 Assembly overview – assembly mountings

682.2 Supporting engine in installation position

742.3 Removing and installing engine mounting

752.4 Removing and installing gearbox mounting

792.5 Removing and installing power unit mounting senders

842.6 Calibrating electrohydraulic engine mounting

843 Engine cover panel

863.1 Removing and installing engine cover

86Crankshaft group

871 Cylinder block (pulley end)

871.1 Assembly overview - cylinder block (pulley end)

871.2 Assembly overview - sealing flange, belt pulley end

931.3 Removing and installing poly-V belt

951.4 Removing and installing tensioner for poly V-belt

991.5 Removing and installing vibration damper

1011.6 Removing and installing bracket for ancillaries

1061.7 Removing and installing engine support

1071.8 Renewing crankshaft oil seal - belt pulley end

1081.9 Removing and installing sealing flange on pulley end

1102 Cylinder block, gearbox end

1152.1 Assembly overview - cylinder block, gearbox end

1152.2 Removing and installing drive plate

1152.3 Renewing crankshaft oil seal (gearbox end)

1173 Crankshaft

1203.1 Assembly overview - crankshaft

1203.2 Crankshaft dimensions

1233.3 Allocation of main bearing shells

1233.4 Measuring axial clearance of crankshaft

1253.5 Measuring radial clearance of crankshaft

1263.6 Removing and installing sender wheel

1263.7 Checking sender wheel

1273.8 Removing and installing crankshaft

1284 Balancer shaft

1324.1 Assembly overview - balance shaft

1324.2 Removing and installing balance shaft

1325 Pistons and conrods

1385.1 Assembly overview - pistons and conrods

1385.2 Removing and installing pistons

1435.3 Removing and installing oil spray jets

1475.4 Checking pistons and cylinder bores

1485.5 Checking radial clearance of conrods

150Cylinder head, valve gear

1521 Cylinder head

1521.1 Assembly overview - cylinder head

1521.2 Assembly overview - camshaft housing

1561.3 Removing and installing cylinder head

1591.4 Removing and installing camshaft housing

1681.5 Checking compression

1812 Cover for timing chain

1832.1 Assembly overview - cover for timing chain

1832.2 Removing and installing timing chain cover

1863 Chain drive

1973.1 Assembly overview - camshaft timing chains

1973.2 Assembly overview - drive chain for oil pump

2013.3 Removing camshaft timing chain from camshafts

2023.4 Removing and installing camshaft timing chain

2283.5 Removing and installing chain tensioner

2294 Valve gear

2334.1 Assembly overview - valve gear

2334.2 Measuring axial play of camshaft

2364.3 Measuring radial play of camshaft

2374.4 Removing and installing camshaft

2384.5 Removing and installing cam actuators

2404.6 Removing and installing camshaft control valve 1 N205

2434.7 Removing and installing valve stem seals

2435 Inlet and exhaust valves

2585.1 Checking valve guides

2585.2 Checking valves

2595.3 Valve dimensions

259Lubrication

2601 Sump, oil pump

2601.1 Assembly overview - sump/oil pump

2601.2 Engine oil:

2651.3 Removing and installing lower part of sump

2661.4 Removing and installing upper part of sump

2691.5 Removing and installing oil baffle plate

2761.6 Removing and installing oil pump

2781.7 Removing and installing oil level and oil temperature sender G266

2802 Engine oil cooler

2812.1 Assembly overview - engine oil cooler

2812.2 Removing and installing engine oil cooler

2812.3 Removing and installing spray nozzle valve

2843 Crankcase ventilation

2863.1 Assembly overview - crankcase breather system

2863.2 Removing and installing crankcase breather module

2874 Oil filter, oil pressure switch

2894.1 Assembly overview - oil filter

2894.2 Assembly overview - oil pressure switches/oil pressure control

2914.3 Removing and installing oil pressure switch F22

2924.4 Removing and installingoil temperature sender G8

2934.5 Checking oil pressure

2944.6 Removing and installing oil filter housing

2954.7 Removing and installing oil pressure regulating valve N428

2974.8 Removing and installing oil pressure sender G10

298Cooling

3001 Cooling system/coolant

3001.1 Connection diagram - coolant hoses

3001.2 Overview of fitting locations – cooling system

3081.3 Assembly overview – coolant expansion tank

3111.4 Checking cooling system for leaks

3131.5 Draining and adding coolant

3231.6 Removing and installing coolant expansion tank

3492 Coolant pump, regulation of cooling system

3552.1 Assembly overview - coolant pump, thermostat

3552.2 Assembly overview - electric coolant pump

3572.3 Assembly overview - coolant temperature sender

3592.4 Assembly overview – coolant valves

3632.5 Removing and installing electric coolant pump

3652.6 Removing and installing coolant pump

3712.7 Removing and installing map-controlled engine cooling thermostat F265

3722.8 Removing and installing coolant temperature sender G62

3742.9 Removing and installing engine outlet coolant temperature sender G82

3752.10 Removing and installing radiator outlet coolant temperature sender G83

3772.12 Removing and installing coolant valves

3812.13 Removing and installing coolant temperature sender for high-voltage system

3873 Coolant pipes

3973.1 Assembly overview - coolant pipes

3973.2 Removing and installing coolant pipes

3994 Radiator, radiator fan

4074.1 Assembly overview – radiator, radiator fan

4074.2 Removing and installing radiator

4124.3 Removing and installing radiator cowl

4174.4 Removing and installing radiator fan V7

4224.5 Removing and installing radiator for high-voltage system coolant circuit

4224.6 Removing and installing air ducts

425Turbocharging/supercharging

4301 Turbocharger

4301.1 Assembly overview - turbocharger

4301.2 Removing and installing turbocharger

4351.3 Renewing vacuum unit for turbocharger

4411.4 Removing and installing temperature sender for engine cover panel G765

4472 Charge air system

4482.1 Assembly overview - charge air system

4482.2 Assembly overview - charge-air hose connections

4532.3 Removing and installing air pipe

4542.4 Removing and installing pressure pipe

4572.5 Removing and installing charge air cooler

4612.6 Removing and installing charge pressure sender G31

4642.7 Removing and installing overrun air recirculation valve

4652.8 Checking charge air system for leaks

465Mixture preparation - injection

4681 Injection system

4681.1 Overview of fitting locations - injection system

4681.2 Checking fuel system for leaks

4782 Vacuum system

4792.1 Connection diagram – vacuum system

4792.2 Checking vacuum system

4793 Injectors

4813.1 Assembly overview - fuel rail with injectors

4813.2 Removing and installing fuel rail

4833.3 Removing and installing injectors

4853.4 Cleaning injectors

4914 Air filter

4944.1 Assembly overview - air filter housing

4944.2 Removing and installing air filter housing

4955 Intake manifold

4975.1 Assembly overview – intake manifold

4975.2 Removing and installing intake manifold

4985.3 Removing and installing throttle valve module J338

5015.4 Cleaning throttle valve module

5036 Senders and sensors

5056.2 Assembly overview - pressure differential sender, models with particulate filter

5066.3 Removing and installing actuator for structure-borne sound R214

5076.4 Removing and installing control unit for structure-borne sound J869

5086.5 Removing and installing intake manifold sender GX9

5086.6 Removing and installing fuel pressure sender G247

5096.7 Removing and installing fuel pressure sender for low-pressure G410

5107 Engine control unit

5147.1 Assembly overview – engine/motor control unit

5147.2 Removing and installing engine control unit J623

5148 High-pressure pump

5168.1 Assembly overview - high-pressure pump

5168.2 Removing and installing high-pressure pump

5208.3 Removing and installing high-pressure pipe

5239 Lambda probe

5279.1 Assembly overview - Lambda probe

5279.2 Removing and installing Lambda probe

528Exhaust system

5331 Exhaust pipes and silencers

5331.1 Assembly overview – silencers

5331.2 Removing and installing front silencer

5401.3 Separating exhaust pipes from silencers

5431.4 Removing and installing silencer

5441.5 Aligning exhaust system free of stress

5451.6 Checking exhaust system for leaks

5462 Emission control

5472.1 Assembly overview – emission control

5472.2 Removing and installing catalytic converter

5502.3 Removing and installing particulate filter

5513 Exhaust gas temperature regulation

5543.1 Removing and installing exhaust gas temperature sender 3 G495

554Ignition system

5561 Ignition system

5561.1 Assembly overview - ignition system

5561.2 Removing and installing ignition coils with output stage

5581.3 Removing and installing knock sensor 1 G61

5621.4 Removing and installing Hall sender

5631.5 Removing and installing engine speed sender G28

564Electric drive systems

5661 High-voltage components

5661.1 Overview of fitting locations - high-voltage components

5662 Warning stickers

5692.1 Checking warning stickers

5693 High-voltage battery unit

5733.1 Assembly overview – high-voltage battery

5733.2 Visual inspection of high-voltage battery 1 AX2

5753.3 Diagnosing high-voltage battery 1 AX2

5763.4 Searching for leaks from high-voltage battery

5773.5 Removing and installing high-voltage battery 1 AX2

5843.6 Removing and installing battery regulation control unit J840

5933.7 Removing and installing switching unit for high-voltage battery SX6

5944 High-voltage battery components

5974.1 Assembly overview – high-voltage battery

5974.2 Overview of fitting locations - battery modules

6024.3 Overview of fitting locations – battery connectors

6034.4 Marking battery modules

6044.5 Removing battery module

6054.6 Installing battery module

6195 Power and control electronics for electric drive

6355.1 Overview of fitting locations - power and control electronics for electric drive

6355.2 Removing and installing power and control electronics for electric drive

6386 Electric drive motor

6446.1 Assembly overview – electric drive motor

6446.2 Removing and installing three-phase current drive VX54

6486.3 Removing and installing centring sleeve

6486.4 Removing and installing drive motor temperature sender G712

6506.5 Removing and installing drive motor rotor position sender 1 G713

6516.6 Removing and installing torsion damper

6526.7 Removing and installing actuator for disengagement clutch V606

6546.8 Removing and installing coolant connection

6576.9 Transporting three-phase current drive

6586.10 Checking ease of movement of disengagement clutch

6597 High-voltage cables

6617.1 Overview of fitting locations - high-voltage cables

6617.2 Removing and installing high-voltage wiring harness for high-voltage battery

6687.3 Removing and installing high-voltage wiring harness for drive motor

6737.5 Removing and installing high-voltage cable for high-voltage heater (PTC)

6818 De-energising high-voltage system

6899 Re-energising high-voltage system

69110 Potential equalisation lines

69210.1 General notes - potential equalisation lines

69210.2 Overview of fitting locations - potential equalisation lines

69210.3 Removing and installing potential equalisation line

69411 Charging socket

69811.1 Assembly overview – charging socket

69811.2 Removing and installing high-voltage battery charging socket 1 UX4

69911.3 Removing and installing module for battery charge selector buttons EX32

70412 Charging unit for high-voltage battery

70512.1 Assembly overview – charging unit for high-voltage battery

70512.2 Removing and installing charging unit 1 for high-voltage battery AX4

70512.3 Removing and installing bracket for charging unit 1 for high-voltage battery AX4

710