Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with start/stop system

21.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on the SCR system

21.6 Safety precautions when working on ignition system

31.7 Safety precautions when working on exhaust system

32 Identification

42.1 Engine number/engine data

43 Repair instructions

53.1 Rules for cleanliness

53.2 General information

53.3 Foreign objects in engine

63.4 Contact corrosion

63.5 Routing and attachment of lines

63.6 Checking vacuum system

6Removing and installing engine

81 Removing and installing motor

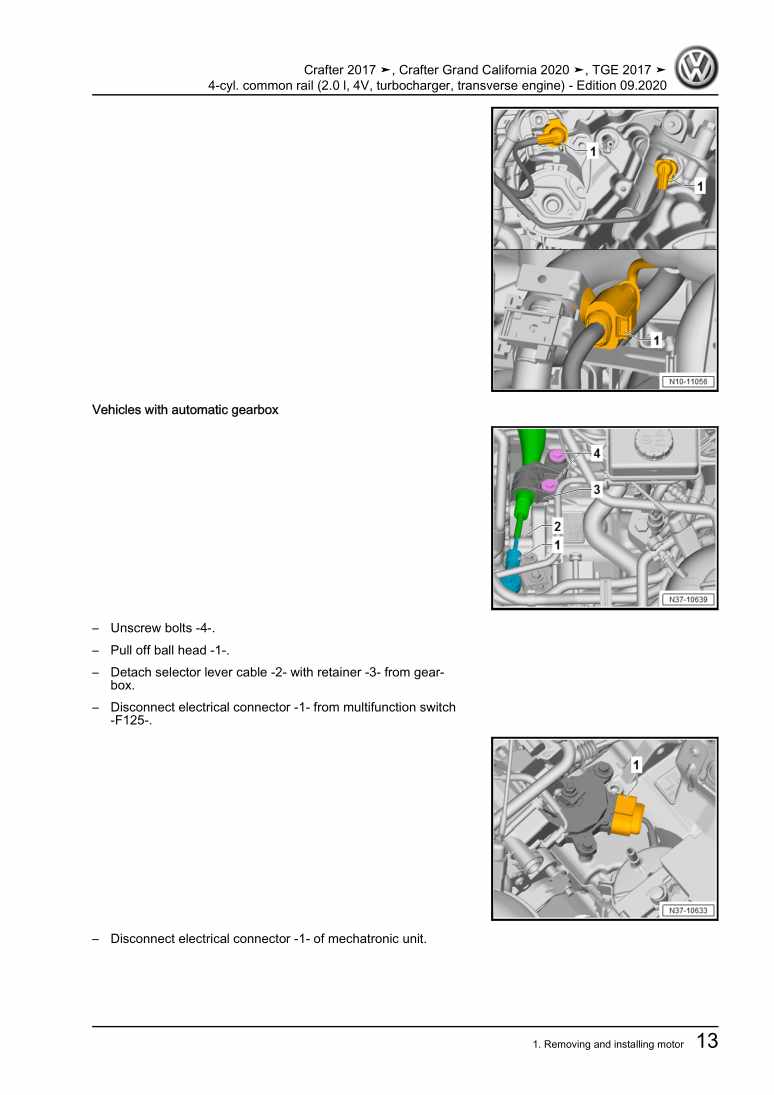

81.1 Removing motor

81.2 Separating engine and gearbox

161.3 Securing engine on engine and gearbox support

171.4 Installing engine

192 Assembly mountings

232.1 Assembly overview - assembly mountings

232.2 Removing and installing engine mounting

252.3 Removing and installing gearbox mountings

272.4 Removing and installing engine mounting

282.5 Supporting engine in installation position

30Crankshaft group

351 Cylinder block (pulley end)

351.1 Assembly overview - cylinder block (pulley end)

351.2 Assembly overview - sealing flange, belt pulley end

371.3 Removing and installing poly-V belt

391.4 Removing and installing tensioner for poly V-belt

431.5 Removing and installing vibration damper

441.6 Removing and installing bracket for ancillaries

461.7 Removing and installing engine support

481.8 Removing and installing sealing flange on pulley end

512 Cylinder block, gearbox end

542.1 Assembly overview - cylinder block, gearbox end

542.2 Assembly overview - drive plate

562.3 Removing and installing drive plate

572.4 Removing and installing flywheel

582.5 Removing and installing sealing flange on gearbox side

603 Crankshaft

703.1 Assembly overview - crankshaft

703.2 Crankshaft dimensions

723.3 Renewing needle bearing in crankshaft

723.4 Measuring axial clearance of crankshaft

743.5 Measuring radial clearance of crankshaft

754 Auxiliary drive

764.1 Assembly overview - ancillary drive

764.2 Removing and installing 2nd alternator

784.3 Removing and installing 2nd air conditioner compressor

794.4 Removing and installing bracket for auxiliary drive

835 Pistons and conrods

865.1 Assembly overview - pistons and conrods

865.2 Removing and installing pistons

885.3 Measuring piston projection at TDC

905.4 Checking pistons and cylinder bores

925.5 Separating new conrod

955.6 Checking radial clearance of conrods

955.7 Removing and installing oil spray jets

96Cylinder head, valve gear

981 Cylinder head

981.1 Assembly overview - cylinder head

981.2 Assembly overview - camshaft housing

1011.3 Assembly overview - cylinder head cover

1031.4 Removing and installing cylinder head

1051.5 Removing and installing cylinder head cover

1141.6 Removing and installing injector seals

1151.7 Removing and installing camshaft housing

1171.8 Checking compression

1212 Toothed belt drive

1232.1 Assembly overview - toothed belt cover

1232.2 Assembly overview - toothed belt

1232.3 Removing and installing toothed belt guard

1252.4 Removing and installing toothed belt

1302.5 Removing toothed belt from camshaft

1453 Valve gear

1533.1 Assembly overview - valve gear

1533.2 Measuring axial play of camshaft

1553.3 Removing and installing camshaft oil seal

1563.4 Checking hydraulic compensation elements

1583.5 Removing and installing valve stem seals

1583.6 Removing and installing toothed belt pulley

1714 Inlet and exhaust valves

1734.1 Checking valve guides

1734.2 Checking valves

1744.3 Valve dimensions

174Lubrication

1751 Sump, oil pump

1751.1 Assembly overview - sump/oil pump

1751.2 Engine oil:

1781.3 Removing and installing sump

1781.4 Removing and installing oil pump

1811.5 Removing and installing oil level and oil temperature sender G266

1821.6 Removing and installing toothed belt for oil pump

1832 Engine oil cooler

1843 Oil filter, oil pressure switch

1853.1 Assembly overview - oil filter housing, oil pressure switch

1853.2 Removing and installing oil pressure switch F1

1873.3 Removing and installing oil pressure switch for reduced oil pressure F378

1883.4 Checking oil pressure

1923.5 Removing and installing oil filter housing

1923.6 Removing and installing oil pressure regulating valve N428

1953.7 Measuring oil consumption

1964 Oil circuit

1974.1 Assembly overview - oil circuit

1974.2 Removing and installing oil supply line

1994.3 Removing and installing oil return line for turbocharger

202Cooling

2061 Cooling system/coolant

2061.1 Assembly overview – coolant expansion tank

2061.2 Connection diagram - coolant hoses

2061.3 Checking cooling system for leaks

2081.4 Draining and adding coolant

2101.5 Removing and installing coolant expansion tank

2272 Coolant pump, regulation of cooling system

2302.1 Assembly overview - coolant pump, thermostat

2302.2 Assembly overview - electric coolant pump

2322.3 Assembly overview - coolant temperature sender

2332.4 Removing and installing pump for exhaust gas recirculation cooler V400

2332.5 Removing and installing charge air cooling pump V188

2362.6 Removing and installing auxiliary pump for heating V488

2372.7 Removing and installing coolant pump

2402.8 Removing and installing thermostat

2412.9 Checking thermostat

2422.10 Removing and installing coolant valve for cylinder head N489

2422.11 Removing and installing coolant temperature sender G62

2432.12 Removing and installing radiator outlet coolant temperature sender G83

2462.13 Removing and installing coolant temperature sender 3 G812

2472.14 Removing and installing shut-off valve

2483 Coolant pipes

2513.1 Assembly overview - coolant pipes

2513.2 Removing and installing coolant pipes

2514 Radiator, radiator fan

2554.1 Assembly overview - radiator/radiator fan

2554.2 Assembly overview - radiator cowl and radiator fan

2564.3 Removing and installing radiator

2574.4 Removing and installing radiator cowl with radiator fan

2614.5 Removing and installing radiator fan V7

2634.6 Removing and installing radiator fan 2 V177

2644.7 Removing and installing auxiliary radiator

2644.8 Removing and installing viscous fan

2674.9 Removing and installing bracket for viscous fan

269Turbocharging/supercharging

2701 Turbocharger

2701.1 Assembly overview - turbocharger

2701.2 Removing and installing turbocharger

2761.3 Renewing vacuum unit for turbocharger

2841.5 Removing and installing upper connecting pipe, vehicles with bi-turbo

2991.6 Removing and installing lower connecting pipe, vehicles with bi-turbo

3001.7 Renewing turbine housing, vehicles with bi-turbo

3022 Charge air system

3072.1 Assembly overview - charge air system

3072.2 Removing and installing charge air cooler

3092.3 Removing and installing charge pressure sender 2 G447

3132.4 Checking charge air system for leaks

3142.5 Detaching and securing charge air cooler

3162.6 Removing and installing bracket for charge air cooler

3182.7 Checking charge air cooler for leaks

319Mixture preparation - injection

3231 Injection system

3231.1 Filling/bleeding fuel system

3231.2 Checking fuel system for leaks

3242 Vacuum system

3252.1 Connection diagram - vacuum system

3252.2 Assembly overview - vacuum system

3282.3 Assembly overview - vacuum pipes

3292.4 Checking vacuum system

3302.5 Removing and installing solenoid valves N75/N274/N529/N316

3312.6 Removing and installing vacuum pipes

3333 Injectors/high-pressure accumulator (rail)

3353.1 Assembly overview - injectors

3353.2 Assembly overview - fuel rail

3373.3 Adapting correction values for injectors

3393.4 Testing injectors

3393.5 Testing jammed-open injectors

3403.6 Checking return flow rate of injectors with engine running

3423.7 Checking return flow rate of injectors at starter speed

3443.8 Removing and installing injectors

3463.9 Removing and installing high-pressure lines

3493.10 Removing and installing fuel rail

3544 Air filter

3574.1 Assembly overview - air filter housing

3574.2 Removing and installing air filter housing

3575 Intake manifold

3595.1 Assembly overview - intake manifold

3595.2 Removing and installing intake manifold

3615.3 Removing and installing throttle valve module GX3

3635.4 Removing and installing vacuum unit for intake manifold

3646 Senders and sensors

3666.1 Removing and installing fuel pressure regulating valve N276

3666.2 Checking fuel pressure regulating valve N276

3686.3 Removing and installing fuel pressure sender G247

3696.4 Removing and installing air mass meter G70

3716.5 Removing and installing pressure differential sender G505

3726.8 Removing and installing fuel temperature sender G81

3756.9 Removing and installing control unit for NOx sender J583/NOx sender G295

3766.11 Removing and installing control unit for NOx sender 2 J881/NOx sender 2 G687

3796.13 Removing and installing intake manifold sender GX9

3827 Engine control unit

3837.1 Removing and installing engine control unit J623

3838 High-pressure pump

3858.1 Assembly overview - high-pressure pump

3858.2 Removing and installing high-pressure pump

3868.3 Checking high-pressure pump

3919 Lambda probe

3949.1 Assembly overview - Lambda probe

3949.2 Removing and installing Lambda probe 1 before catalytic converter GX10

395Exhaust system

3971 Exhaust pipes and silencers

3971.1 Assembly overview - silencers

3971.2 Removing and installing front silencer

3971.3 Aligning exhaust system free of stress

3991.4 Checking exhaust system for leaks

3991.5 Installation position of clamp

4002 Emission control

4012.1 Assembly overview - emission control

4012.2 Removing and installing catalytic converter

4032.3 Removing and installing particulate filter

4063 SCR system (selective catalytic reduction)

4103.1 Assembly overview - tank for reducing agent

4103.2 Assembly overview - delivery module for reducing agent

4113.3 Removing and installing reducing agent tank VX85

4123.4 Removing and installing delivery unit for reducing agent metering system GX19

4163.5 Removing and installing injector for reduction agent N474

4183.6 Removing and installing control unit for reducing-agent heater J891

4213.7 Draining reducing agent tank VX85

4213.8 Removing and installing filler pipe for reducing agent tank VX85

4243.9 Disconnecting reducing agent supply line

4273.10 SCR - resetting learnt values

4294 Exhaust gas temperature regulation

4304.1 Assembly overview - exhaust gas temperature regulation

4304.2 Removing and installing exhaust gas temperature sender 1 G235

4304.3 Removing and installing exhaust gas temperature sender 2 G448

4324.4 Removing and installing exhaust gas temperature sender 3 G495

4345 Exhaust gas recirculation

4365.1 Assembly overview - exhaust gas recirculation

4365.2 Removing and installing exhaust gas recirculation cooler

4385.3 Removing and installing exhaust gas recirculation pipes

4415.4 Removing and installing temperature sensor 2 for exhaust gas recirculation G690

4445.5 Checking exhaust gas recirculation cooler for leaks

4455.6 Removing and installing temperature sensor 3 for exhaust gas recirculation G949

4485.7 Removing and installing bracket for exhaust gas recirculation cooler

450Glow plug system

4581 Glow plug system

4581.1 Assembly overview - glow plug system

4581.2 Removing and installing glow plug

4591.3 Checking glow plug

4631.4 Removing and installing automatic glow period control unit J179

4631.5 Removing and installing knock sensor 1 G61

4641.6 Removing and installing knock sensor 2 G66

4671.7 Removing and installing Hall sender G40

4691.8 Removing and installing engine speed sender G28

470