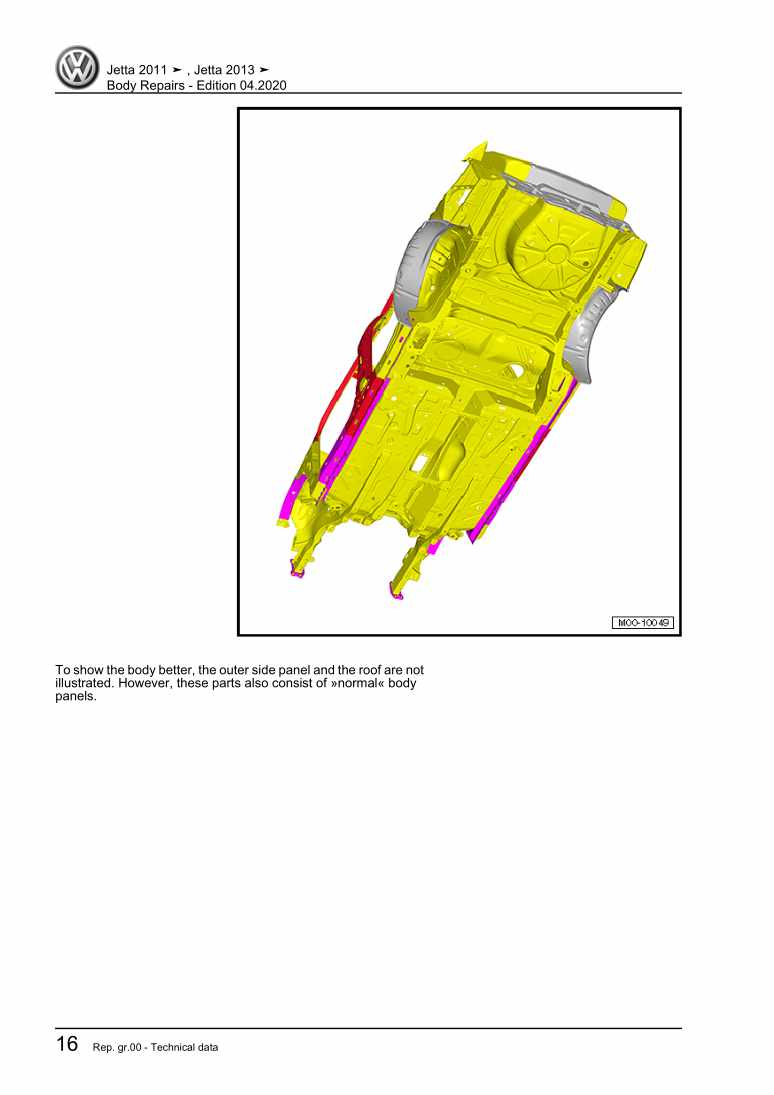

Technical data

11 Checklist for evaluating running gear of accident vehicles

12 General information

3Front suspension

41 Evaluating accident vehicles

42 Raising wheel suspension to unladen position

53 Overview - front axle

74 Assembly overview: subframe

94.1 Repairing thread in longitudinal member

104.2 Fixing position of subframe

104.3 Lowering subframe

134.4 Removing and installing subframe without steering rack

174.5 Removing and installing subframe with hydraulic steering rack

204.6 Removing and installing subframe with electromechanical steering rack

274.7 Repairing subframe

315 Assembly overview: front wheel suspension, suspension link

415.1 Checking swivel joint

425.2 Removing and installing swivel joint

435.3 Removing and installing suspension link

475.5 Renewing front bonded rubber bush for suspension link

535.6 Renewing rear bonded rubber bush for suspension link

556 Assembly overview: wheel bearing

586.1 Removing and installing wheel bearing unit

596.2 Removing and installing wheel bearing housing

627 Assembly overview: anti-roll bar

697.1 Removing and installing anti-roll bar

698 Assembly overview: suspension strut

748.1 Removing and installing suspension strut

758.2 Repairing suspension strut

819 Removing and installing drive shafts

849.1 Loosening and tightening twelve-point head bolt, with ribbing, securing drive shaft

849.3 Removing and installing drive shaft with constant velocity joint

879.4 Removing and installing right drive shaft with (push-on) constant velocity slip joint

909.5 Removing and installing drive shafts with triple roller joint AAR2600i

969.6 Removing and installing drive shafts with triple roller joint AAR3300i

10010 Repairing drive shafts - overview of drive shafts

10510.1 Heat shield for drive shafts

10611 Assembly overview: drive shaft with VL100 constant velocity joint

10711.1 Dismantling and assembling drive shaft with VL100 constant velocity joint

10911.2 Checking outer constant velocity joint

11311.3 Checking inner constant velocity joint

11412 Assembly overview: drive shaft with VL107 constant velocity joint

11712.1 Dismantling and assembling drive shaft with VL107 constant velocity joint

11913 Assembly overview: drive shaft with VL107 constant velocity slip joint (push-on)

12413.1 Dismantling and assembling drive shaft with VL107 (push-on) constant velocity slip joint

12514 Assembly overview: drive shaft with triple roller joint AAR2600i

12914.1 Dismantling and assembling drive shaft with triple roller joint AAR2600i

13115 Assembly overview: drive shaft with triple roller joint AAR3300i

13615.1 Dismantling and assembling drive shaft with triple roller joint AAR3300i

138Rear suspension

1441 Evaluating accident vehicles

1442 Rear axle in unladen position (torsion beam rear axle)

1453 Overview of rear axle (torsion beam rear axle)

1474 Assembly overview: axle beam, subframe, cross piece (torsion beam rear axle)

1494.1 Removing and installing axle assembly

1504.2 Removing and installing bonded rubber bush for axle beam

1544.3 Removing and installing cross piece

1584.4 Removing and installing bonded rubber bush for cross piece

1605 Assembly overview - plate for axle beam, torsion beam rear axle

1635.1 Removing plate for axle beam

1635.2 Installing plate for axle beam

1646 Assembly overview: wheel suspension (torsion beam rear axle)

1706.1 Removing and installing coil spring

1717 Assembly overview: shock absorbers (torsion beam rear axle)

1737.1 Removing and installing shock absorbers

1748 Assembly overview: wheel bearings, drum brake (torsion beam rear axle)

1768.1 Removing and installing wheel hub with wheel bearing, vehicles with drum brakes

1779 Assembly overview: wheel bearings, disc brake (torsion beam rear axle)

18110 Rear axle in unladen position (multi-link rear suspension)

18511 Overview of rear axle (multi-link rear suspension)

18812.1 Assembly overview: rear left vehicle level sender G76

19112.2 Removing and installing rear left vehicle level sender G76

19112.3 Fixing position of subframe

19212.4 Lowering rear axle

19312.5 Removing and installing rear axle

19612.6 Removing and installing upper transverse link

19912.7 Removing and installing lower transverse link

20112.8 Removing and installing track rod

20313.1 Removing and installing wheel bearing housing

20713.2 Renewing bonded rubber bush for wheel bearing housing

21013.3 Removing and installing wheel bearing/wheel hub unit

21313.4 Removing and installing trailing arm with mounting bracket

21613.5 Repairing trailing arm

22014 Assembly overview: shock absorber, coil spring (multi-link rear suspension)

22414.1 Removing and installing coil spring

22414.2 Removing and installing shock absorbers

22614.3 Repairing shock absorber

22815 Assembly overview: anti-roll bar (multi-link rear suspension)

23015.1 Removing and installing anti-roll bar

23016 Assembly overview: subframe attachments, BlueMotion vehicles

23316.1 Removing and installing shield for rear axle

234Wheels, tyres, vehicle geometry

2361 Evaluating accident vehicles

2362 Specified torque for fitting wheels

2373 Fitting wheel and tyre

2383.1 General information

2383.2 Fittings instructions

2384 Removing and fitting tyres (wheels with tyre pressure monitoring)

2404.2 Wheel change

2404.3 Fittings instructions

2414.4 Pressing tyre off wheel rim

2424.5 Removing tyre from wheel

2434.6 Fitting tyre to wheel rim

2435 Removing and fitting tyres with run-flat properties to wheel rims

2455.1 Safety information

2455.2 Fittings instructions

2455.3 Pressing tyre off wheel rim

2465.4 Removing tyre from wheel

2475.5 Fitting tyre to wheel rim

2486 Tyre pressure monitor display

2516.1 General information

2517 Tyre Pressure Monitoring System (TPMS)

2537.1 Assembly overview: tyre pressure sensor

2537.2 Removing and installing tyre pressure sensor

2548 Vehicle alignment check

2558.1 General information for vehicles with torsion beam rear axle

2558.2 General information for vehicles with multi-link rear suspension

2578.3 Conditions for testing

2588.4 Checking trailing arm of axle beam (torsion beam rear axle) using VAS 241 001

2598.5 Checking trailing arm of axle beam (torsion beam rear axle) using VAS 801

2618.6 Test preparations

2648.7 Vehicle alignment specifications for vehicles with torsion beam rear axle

2648.8 Vehicle alignment specifications for vehicles with multi-link rear suspension

2668.9 Transverse vehicle inclination “zero position”

2688.10 Overview - wheel alignment procedure

2688.11 Correcting front axle camber

2698.12 Checking torsion beam rear axle camber

2718.13 Adjusting multi-link rear suspension camber

2718.14 Checking torsion beam rear axle toe

2728.15 Adjusting multi-link rear suspension toe

2738.16 Adjusting front axle toe

2738.17 Basic setting of steering angle sensor G85

2748.18 Vehicle data sticker

2749 Wheels, tyres

2769.1 Models with breakdown set

2769.2 Removing a tyre

2769.3 Fitting a new tyre

2769.4 Tyre sealant disposal

27710 Instructions for changing or fitting wheels

27810.1 Fitting wheels

27911 Protecting wheel centring seat against corrosion

28012 Vibration due to wheels/tyres - causes and rectification

28112.1 Causes of rough running

28112.2 Balancing wheels

28112.3 Conducting a road test before balancing wheels

28112.4 Balancing wheels on stationary wheel balancing machine

28212.5 Vibration control system VAS 6230 A

28412.6 Finish balancer

28412.7 Radial and lateral runout of wheels and tyres

28512.9 Checking radial and lateral run-out on wheel rim

28612.10 Matching

28712.11 Flat spots caused by storage or handling

288Steering

2901 Evaluating accident vehicles

2902 General repair instructions

2912.1 Steering rack

2912.2 Gaskets and seals

2912.3 Nuts and bolts

2912.4 Electrical components

2922.5 Guided Fault Finding, vehicle self-diagnosis and Test Instruments

2923 Assembly overview - airbag and steering wheel

2933.1 Removing and installing airbag and steering wheel

2934 Assembly overview: steering column, left-hand drive

2964.1 Removing and installing steering column

2964.2 Handling and transporting steering column

3044.3 Checking steering column for damage

3055 Assembly overview: steering column, right-hand drive

3075.1 Removing and installing steering column, right-hand drive vehicle

3075.2 Handling and transporting steering column

3165.3 Checking steering column for damage

3176 Electromechanical steering rack, LHD vehicle

3186.1 Assembly overview - electromechanical steering rack for LHD vehicle

3186.2 Removing and installing steering rack, left-hand drive vehicle

3207 Electromechanical steering rack, RHD vehicle

3287.1 Assembly overview - electromechanical steering rack for RHD vehicle

3287.2 Removing and installing steering rack, right-hand drive vehicle

3298 Repairing electromechanical steering rack

3368.1 Assembly overview: electromechanical steering rack

3368.2 Removing and installing track rod

3378.3 Removing and installing track rod ball joint

3408.4 Removing and installing boot

3418.5 Checking play, security and boots of track rod ends

3448.6 Checking and adjusting track rod length

3448.7 Allocation of track rod ball joints

3459 Assembly overview: hydraulic power steering

3469.1 Removing and installing power-assisted steering rack

34710 Repairing hydraulic power-assisted steering rack

35310.1 Assembly overview: power-assisted steering rack

35310.2 Removing and installing track rod

35410.3 Removing and installing track rod ball joint

35710.4 Removing and installing boot

35810.5 Checking play, security and boots of track rod ends

36010.6 Checking and adjusting left track rod length

36010.7 Allocation of track rod ball joints

36111 Vane pump, 4-cylinder petrol engine

36211.1 Assembly overview: vane pump, 4-cylinder petrol engine

36211.2 Removing and installing vane pump, 4-cylinder petrol engine

36312 Vane pump, 5-cylinder petrol engine

36612.1 Checking vane pump delivery pressure, 5-cylinder petrol engine

36612.2 Assembly overview: vane pump, 5-cylinder petrol engine

36912.3 Removing and installing vane pump, 5-cylinder petrol engine

37013 Assembly overview: hydraulic lines, 4-cylinder petrol engine

37414 Assembly overview: hydraulic lines, 5-cylinder petrol engine

37615 Assembly overview: power steering reservoir, 4-cylinder petrol engine

37816 Assembly overview: power steering reservoir, 5-cylinder petrol engine

37917 Checking power steering fluid level

38018 Bleeding steering system and checking for leaks

38118.1 Bleeding steering system

38118.2 Check steering system for leaks

381