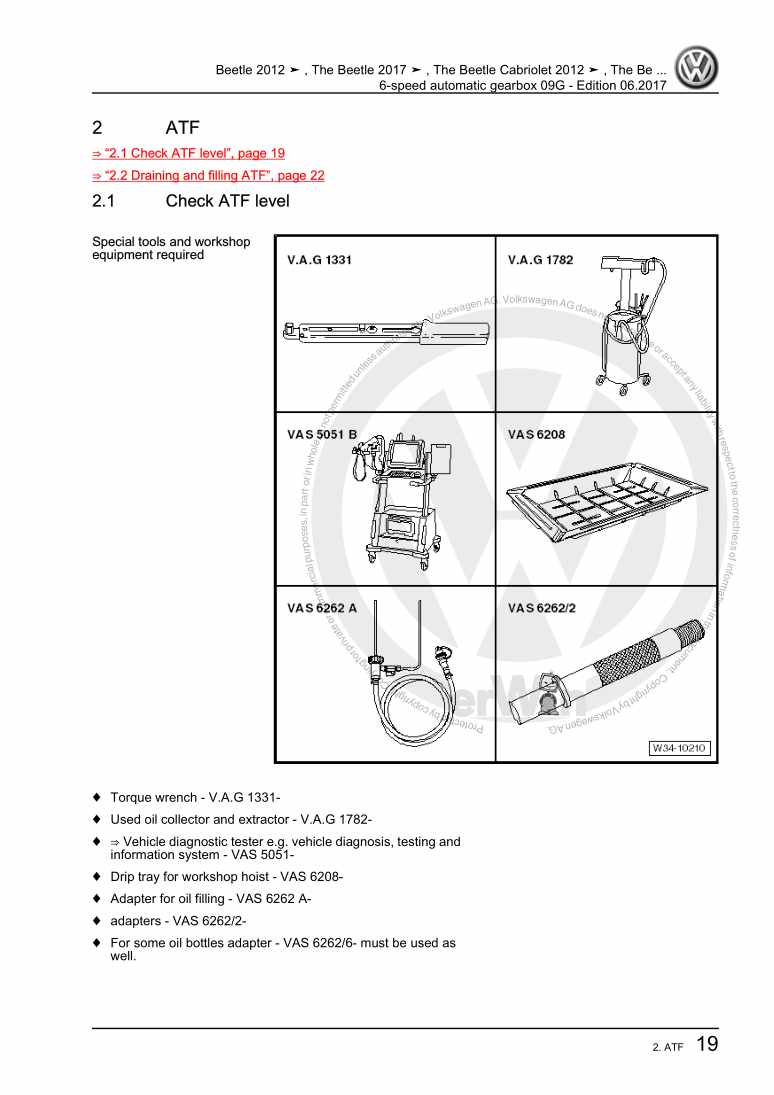

Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with a start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on ignition system

22 Identification

32.1 Engine number/engine data

33 Repair instructions

53.1 Rules for cleanliness

53.2 Foreign objects in engine

53.3 Contact corrosion

53.4 Routing and attachment of lines

53.5 Fitting radiator and condensers

6Removing and installing engine

71 Removing and installing engine

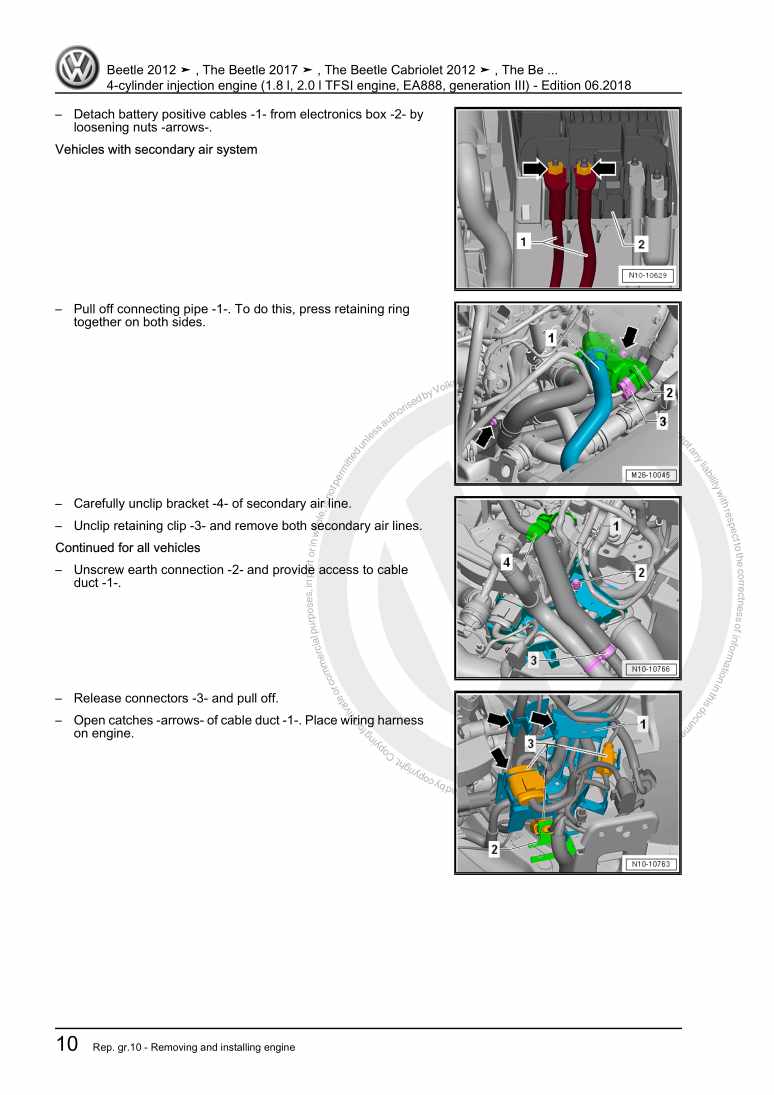

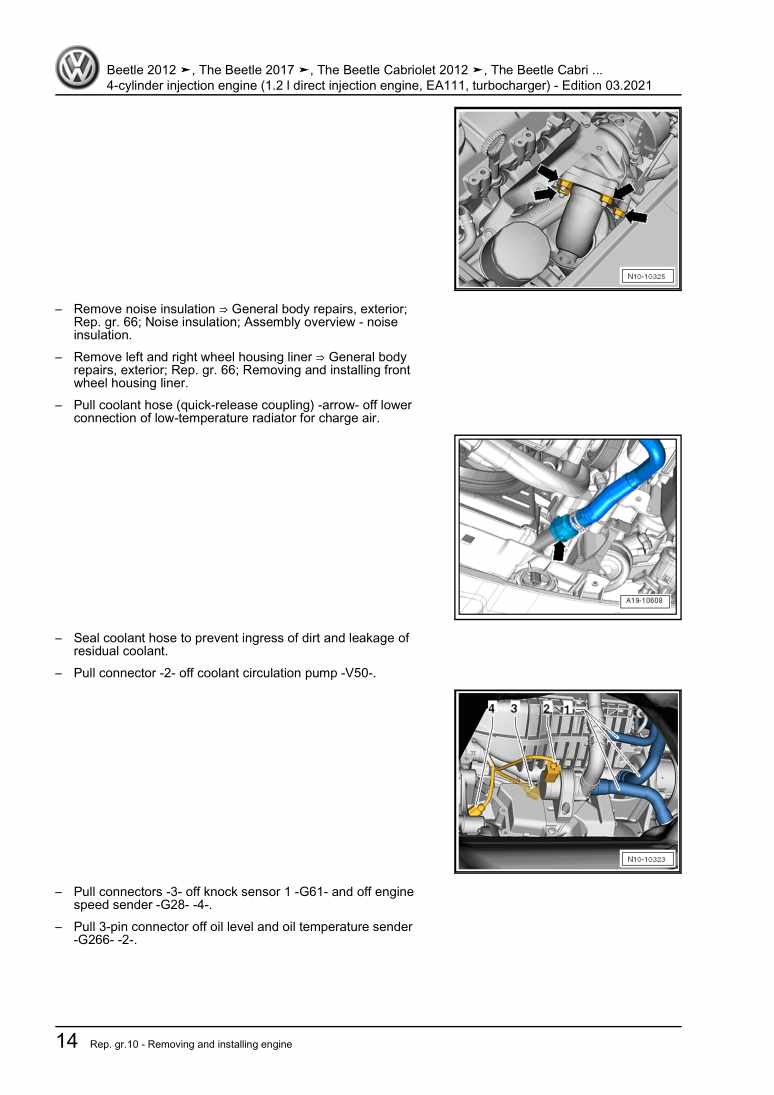

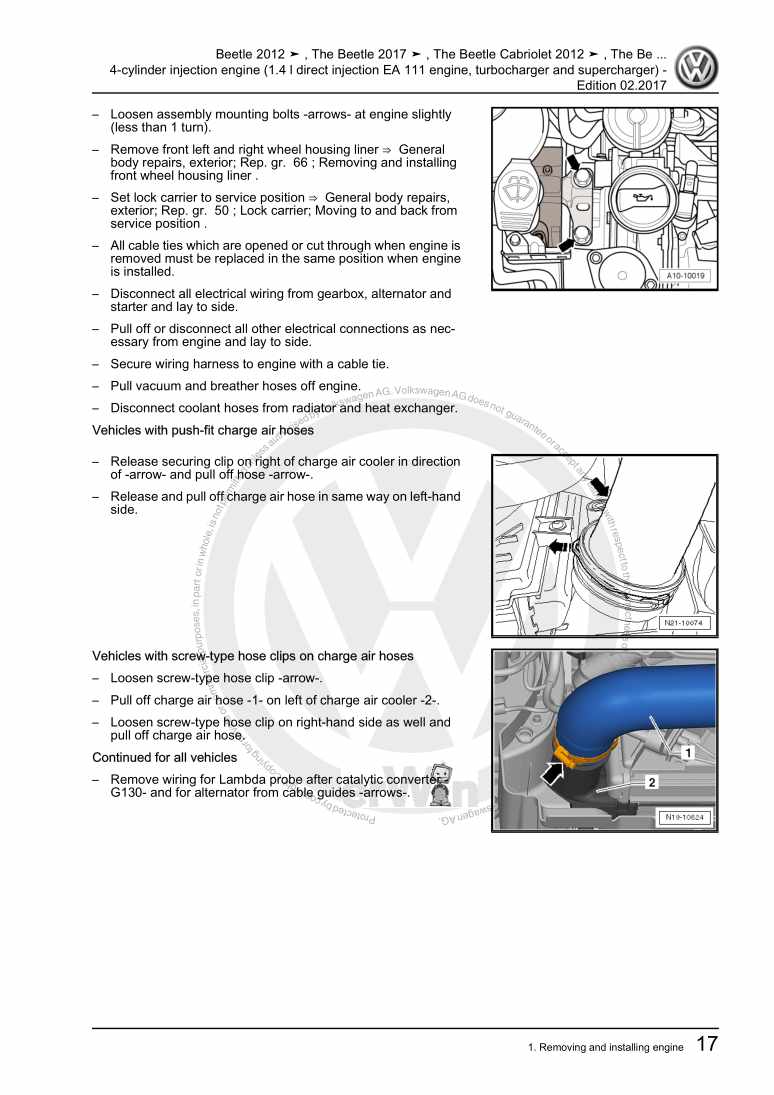

71.1 Removing engine

71.2 Separating engine and gearbox

201.3 Securing engine on engine and gearbox support

221.4 Installing engine

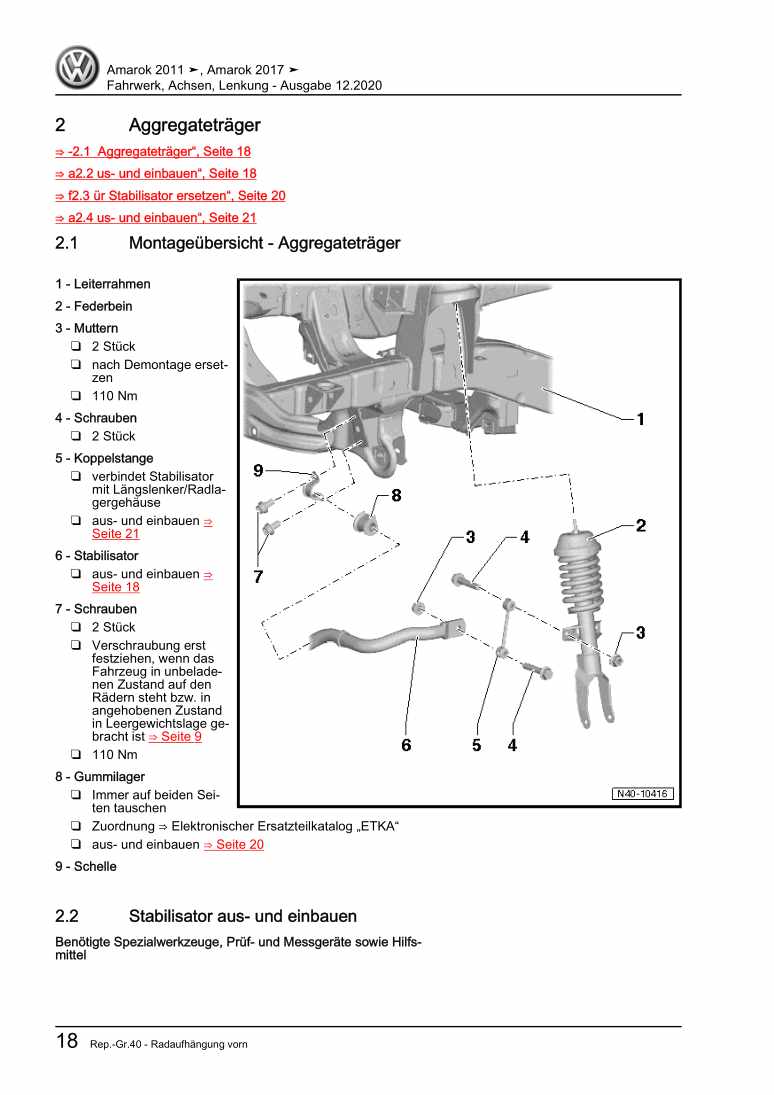

232 Assembly mountings

272.1 Assembly overview - assembly mountings

272.2 Removing and installing engine mounting

302.3 Removing and installing gearbox mounting

322.4 Removing and installing pendulum support

332.5 Supporting engine in installation position

342.6 Adjusting assembly mountings

432.7 Checking adjustment of assembly mountings

45Crankshaft group

461 Cylinder block (pulley end)

461.1 Assembly overview - poly V-belt drive

461.2 Assembly overview - sealing flange, belt pulley end

501.3 Removing and installing poly-V belt

521.4 Removing and installing tensioner for poly V-belt

561.5 Removing and installing vibration damper

571.6 Removing and installing engine support

581.7 Renewing crankshaft oil seal - belt pulley end

611.8 Removing and installing sealing flange on pulley end

642 Cylinder block, gearbox end

672.1 Assembly overview - cylinder block, gearbox end

672.2 Removing and installing flywheel

682.3 Removing and installing sealing flange on gearbox side

693 Crankshaft

803.1 Crankshaft dimensions

803.2 Renewing needle bearing in crankshaft

803.3 Measuring axial clearance of crankshaft

834 Pistons and conrods

854.1 Assembly overview - pistons and conrods

854.2 Removing and installing pistons

884.3 Checking pistons and cylinder bores

894.4 Separating new conrod

914.5 Checking radial clearance of conrods

924.6 Removing and installing oil spray jets

92Cylinder head, valve gear

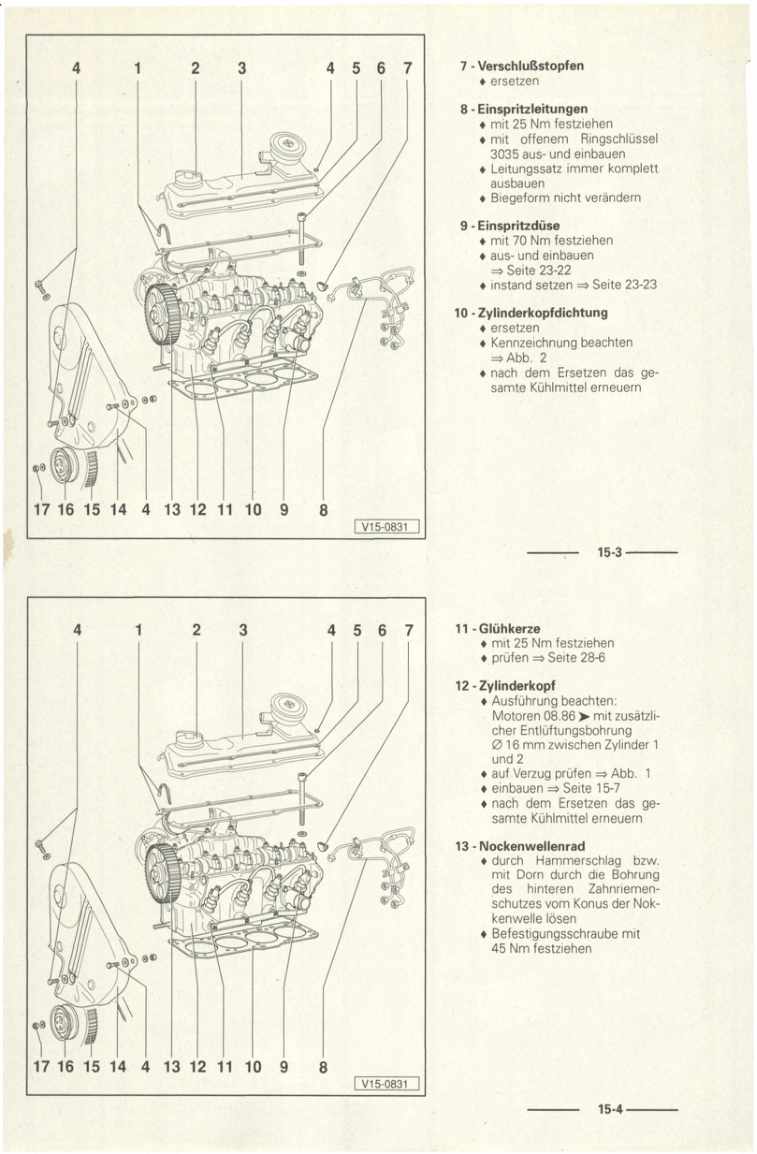

951 Cylinder head

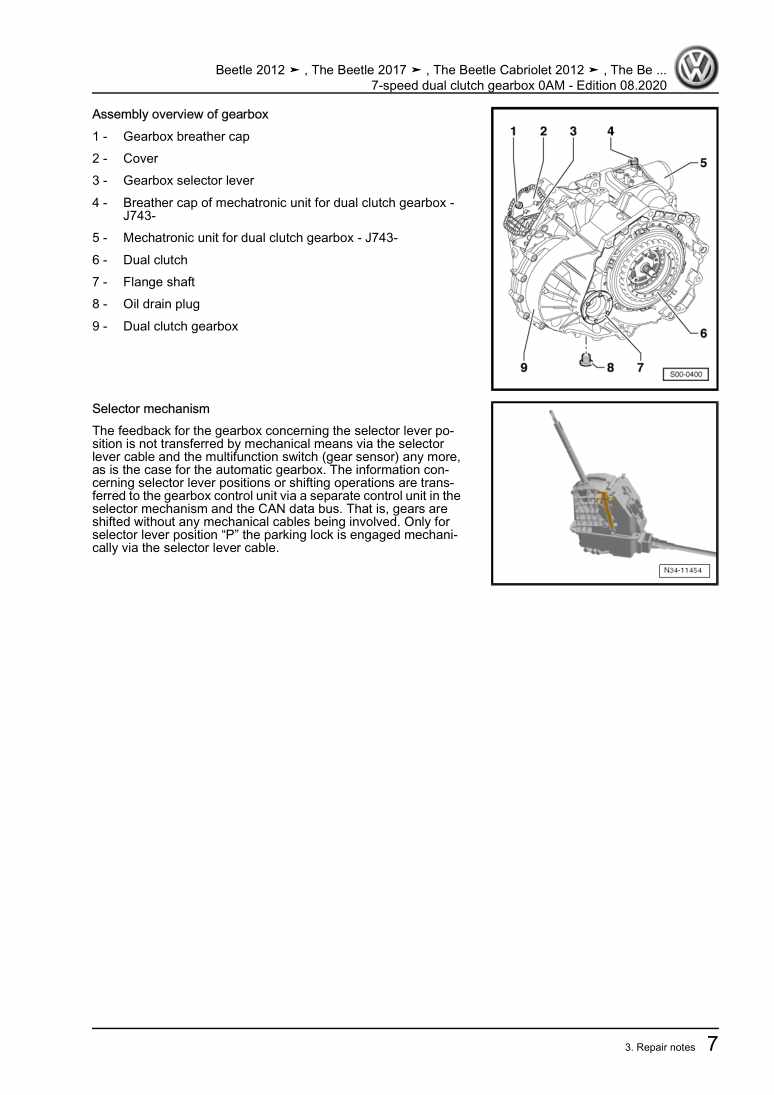

951.1 Assembly overview - cylinder head

951.2 Assembly overview - camshaft housing

971.3 Removing and installing cylinder head

991.4 Removing and installing camshaft housing

1041.5 Checking compression

1092 Toothed belt drive

1122.1 Assembly overview - toothed belt cover

1122.2 Assembly overview - toothed belt

1122.3 Removing and installing toothed belt guard

1142.4 Removing and installing toothed belt

1152.5 Checking valve timing

1222.6 Adjusting valve timing

1282.7 Removing toothed belt from camshaft

1373 Valve gear

1423.1 Assembly overview - valve gear

1423.2 Measuring axial play of camshaft

1433.3 Removing and installing camshaft oil seal

1443.4 Removing and installing camshaft adjuster

1503.5 Removing and installing camshaft control valve 1 N205

1623.6 Removing and installing exhaust camshaft control valve 1 N318

1633.7 Removing and installing valve stem seals

1644 Inlet and exhaust valves

1754.1 Checking valve guides

1754.2 Checking valves

1764.3 Valve dimensions

176Lubrication

1771 Sump, oil pump

1771.1 Assembly overview - sump/oil pump

1771.2 Engine oil:

1811.3 Removing and installing lower part of sump

1811.4 Removing and installing upper part of sump

1861.5 Removing and installing oil pump

1931.6 Removing and installing oil level and oil temperature sender G266

1942 Engine oil cooler

1962.1 Assembly overview - engine oil cooler

1962.2 Removing and installing engine oil cooler

1963 Crankcase ventilation

1983.1 Assembly overview - crankcase breather system

1983.2 Removing and installing oil separator

1994 Oil filter, oil pressure switch

2034.1 Assembly overview - oil filter/oil pressure switch

2034.2 Removing and installing oil pressure switch F1

2044.3 Removing and installing oil pressure switch for reduced oil pressure F378

2054.4 Checking oil pressure

2064.5 Removing and installing oil pressure regulating valve N428

208Cooling

2091 Cooling system/coolant

2091.1 Connection diagram - coolant hoses

2091.2 Assembly overview - engine preheater

2101.3 Checking cooling system for leaks

2111.4 Draining and adding coolant

2141.5 Removing and installing engine preheating element Z97

2232 Coolant pump, regulation of cooling system

2262.1 Assembly overview - coolant pump, thermostat

2262.2 Assembly overview - electric coolant pump

2292.3 Assembly overview - coolant temperature sender

2302.4 Removing and installing electric coolant pump

2312.5 Removing and installing coolant pump

2332.6 Removing and installing thermostat

2392.7 Removing and installing toothed belt pulley for coolant pump

2422.8 Removing and installing coolant temperature sender G62

2442.9 Removing and installing radiator outlet coolant temperature sender G83

2453 Coolant pipes

2473.1 Assembly overview - coolant pipes

2473.2 Removing and installing coolant pipes

2474 Radiator, radiator fan

2524.1 Assembly overview - radiator/radiator fan

2524.2 Assembly overview – radiator cowl and radiator fan

2544.3 Removing and installing radiator

2554.4 Removing and installing water radiator for charge air cooling circuit

2574.5 Removing and installing radiator cowl

2604.6 Removing and installing radiator fan V7

2624.7 Removing and installing radiator fan 2 V177

263Turbocharging/supercharging

2641 Turbocharger

2641.1 Assembly overview - turbocharger

2641.2 Removing and installing turbocharger

2681.3 Removing and installing charge pressure positioner V465

2742 Charge air system

2792.1 Assembly overview - charge air system

2792.2 Removing and installing charge air cooler

2822.3 Removing and installing charge pressure sender GX26

2852.4 Checking charge air system for leaks

2852.5 Removing and installing air pipe

287Mixture preparation - injection

2891 Injectors

2891.1 Assembly overview - fuel rail with injectors

2891.2 Removing and installing fuel rail

2911.3 Removing and installing injectors

2911.4 Cleaning injectors

2972 Air filter

2992.1 Assembly overview - air filter housing

2992.2 Removing and installing air filter housing

3002.3 Removing and installing resonator for intake air

3013 Intake manifold

3033.1 Assembly overview – intake manifold

3033.2 Removing and installing intake manifold

3053.3 Removing and installing throttle valve module GX3

3093.4 Cleaning throttle valve module GX3

3104 Senders and sensors

3124.1 Removing and installing fuel pressure sender G247

3124.2 Checking fuel pressure sender G247

3134.3 Removing and installing intake manifold sender GX9

3155 Engine control unit

3175.1 Removing and installing engine control unit J623

3176 High-pressure pump

3226.1 Assembly overview - high-pressure pump

3226.2 Removing and installing high-pressure pump

3266.3 Removing and installing high-pressure pipe

3287 Lambda probe

3317.1 Assembly overview - Lambda probe

3317.2 Removing and installing Lambda probe

332Exhaust system

3361 Exhaust pipes and silencers

3361.1 Assembly overview – silencers

3361.2 Separating exhaust pipes from silencers

3391.3 Removing and installing rear silencer

3411.4 Aligning exhaust system free of stress

3421.5 Checking exhaust system for leaks

3431.6 Installation position of clamp

3432 Emission control

3462.1 Assembly overview – emission control

3462.2 Removing and installing catalytic converter

348Ignition system

3541 Ignition system

3541.1 Assembly overview - ignition system

3541.2 Test data, spark plugs

3561.3 Removing and installing ignition coils with output stage

3561.4 Removing and installing knock sensor 1 G61

3591.5 Removing and installing Hall sender

3591.6 Removing and installing engine speed sender G28

360