Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with a start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on ignition system

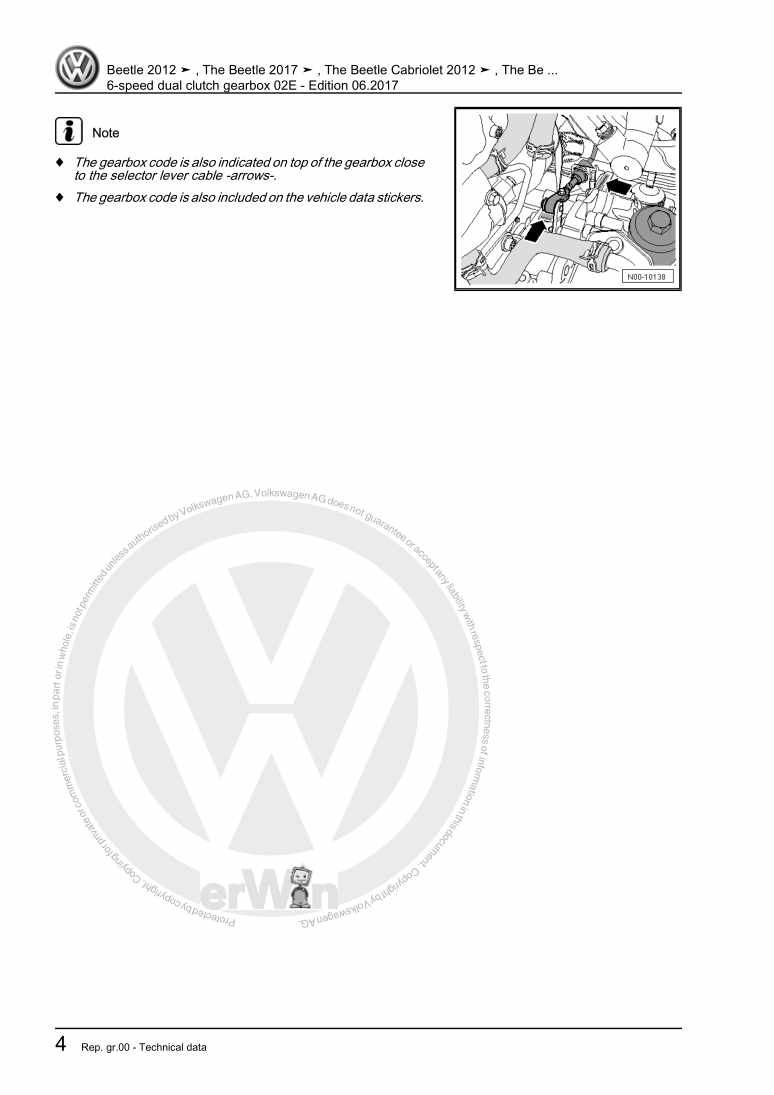

22 Identification

32.1 Engine number/engine data

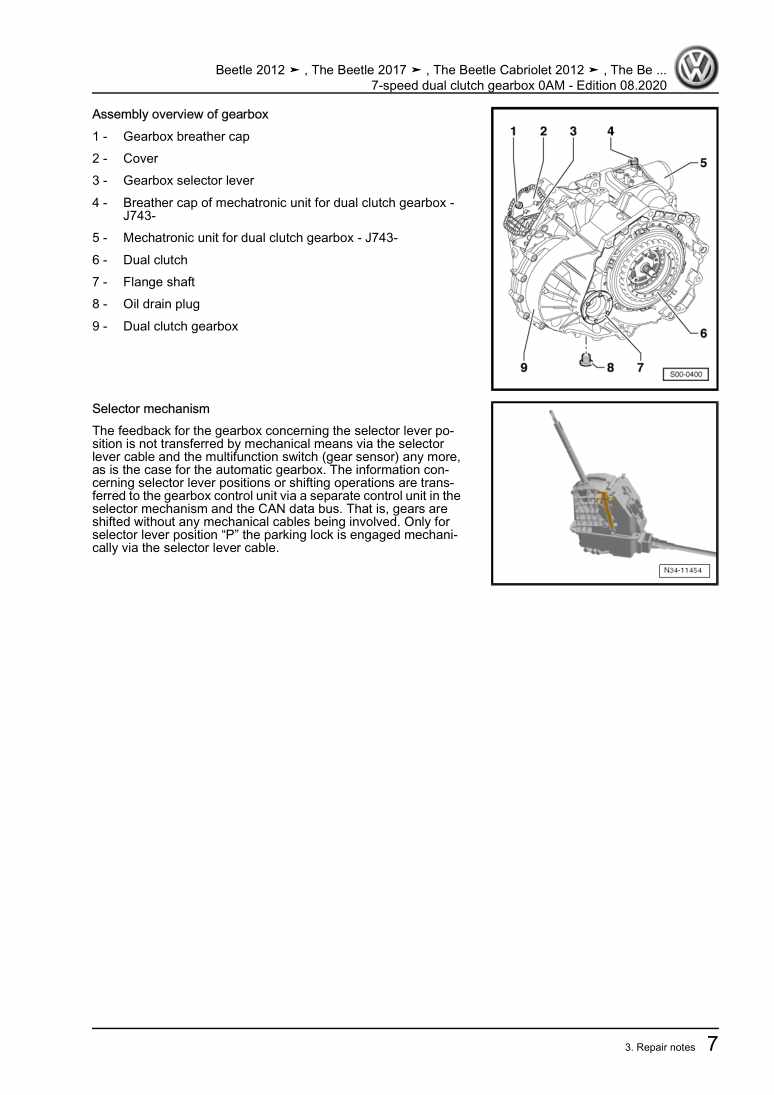

33 Repair notes

53.1 Rules for cleanliness

53.2 Foreign objects in engine

53.3 Contact corrosion

53.4 Routing and attachment of lines

63.5 Fitting radiator and condensers

63.6 Checking vacuum system

6Removing and installing engine

71 Removing and installing engine

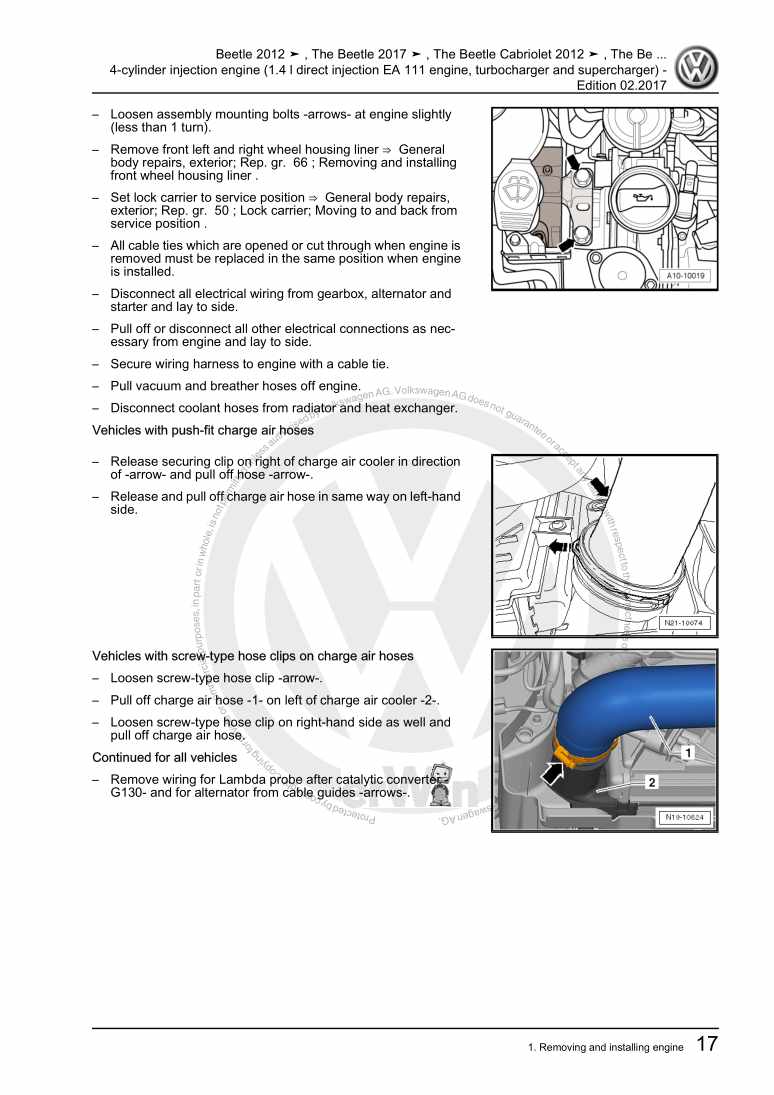

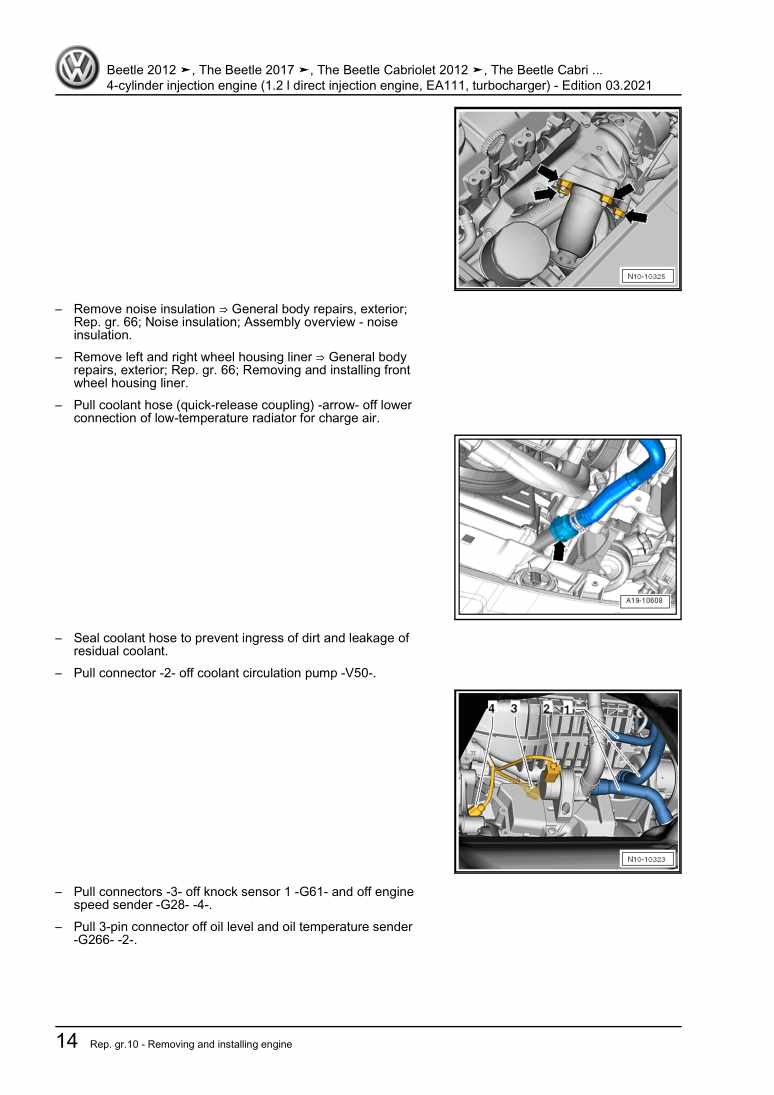

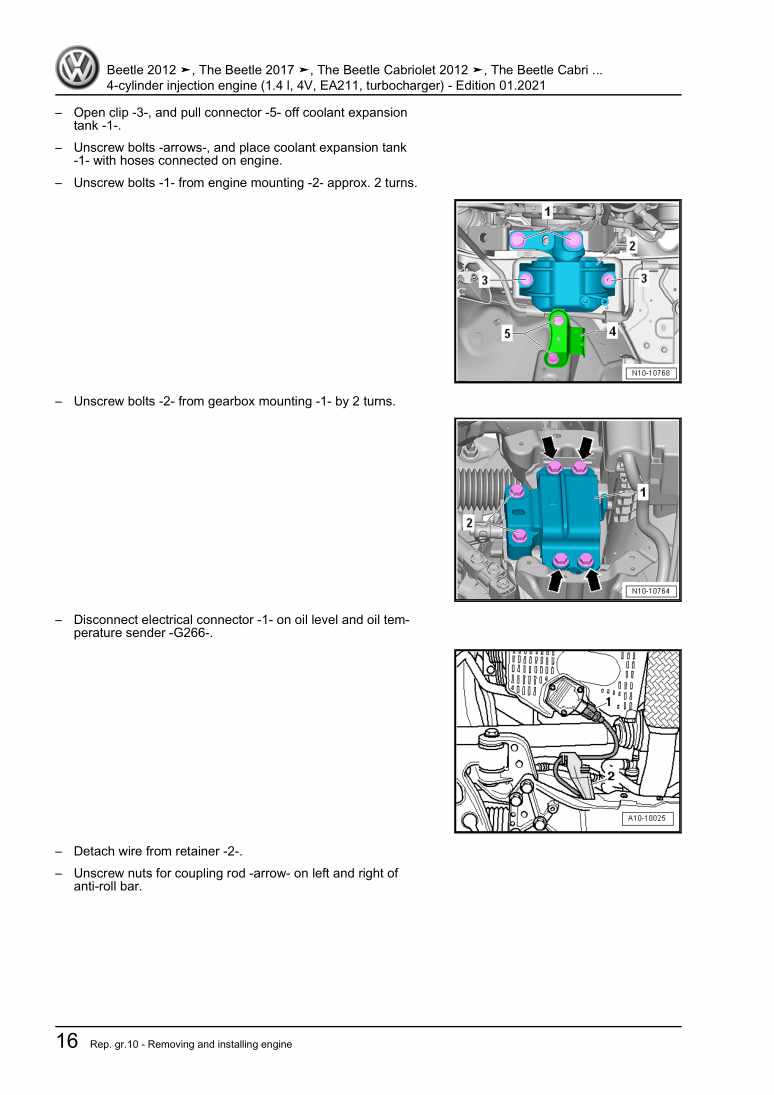

71.1 Removing engine

71.2 Separating engine and gearbox

151.3 Securing engine on engine and gearbox support

171.4 Installing engine

202 Assembly mountings

232.1 Assembly overview - assembly mountings

232.2 Removing and installing motor mounting

252.3 Removing and installing gearbox mounting

262.4 Removing and installing pendulum support

272.5 Supporting engine in installation position

272.6 Adjusting assembly mountings

352.7 Checking adjustment of assembly mountings (engine and gearbox mountings)

373 Motor cover

383.1 Removing and installing engine cover

38Crankshaft group

391 Cylinder block (pulley end)

391.1 Assembly overview - cylinder block (pulley end)

391.2 Removing and installing poly-V belt

401.3 Removing and installing tensioner for poly V-belt

421.4 Removing and installing vibration damper

421.5 Removing and installing bracket for ancillaries

481.6 Removing and installing engine support

502 Cylinder block, gearbox end

522.1 Assembly overview - cylinder block, gearbox end

522.2 Assembly overview - drive plate

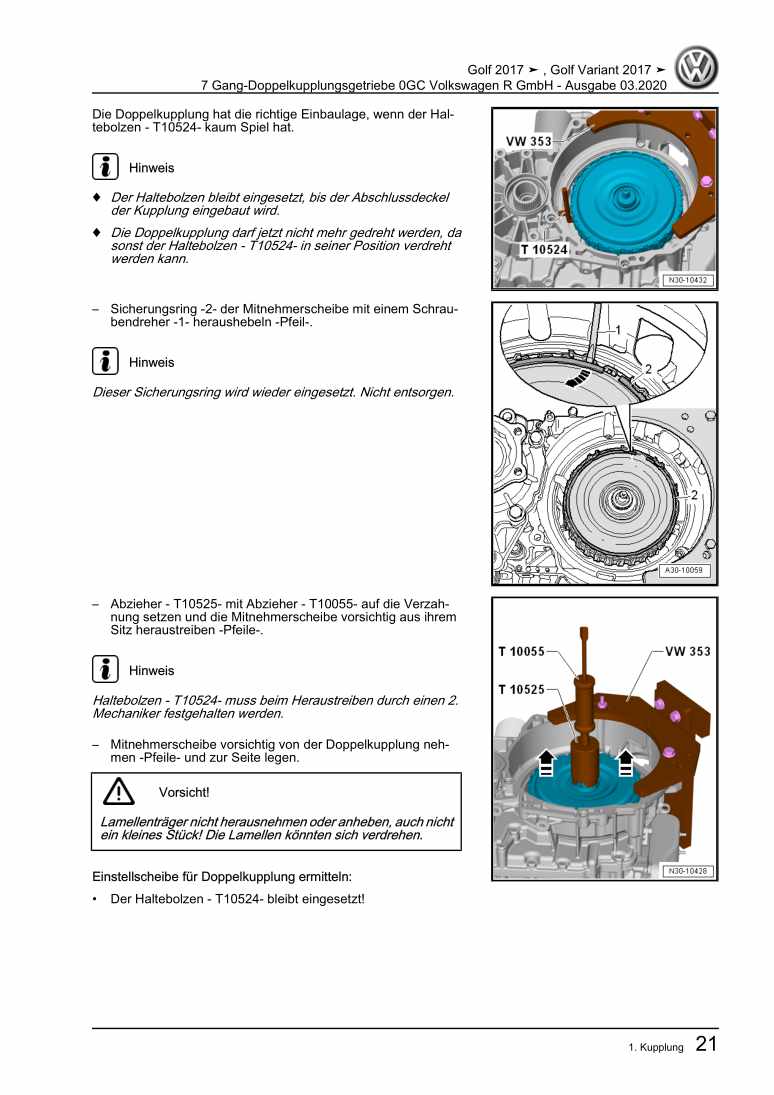

532.3 Removing and installing drive plate

542.4 Removing and installing flywheel

552.5 Removing and installing sealing flange on gearbox side

563 Crankshaft

603.1 Assembly overview - crankshaft

603.2 Crankshaft dimensions

613.3 Allocation of main bearing shells

623.4 Renewing needle bearing in crankshaft

633.5 Measuring axial clearance of crankshaft

663.6 Measuring radial clearance of crankshaft

673.7 Removing and installing sender wheel

674 Balancer shaft

694.1 Assembly overview - balance shaft

694.2 Removing and installing balance shaft

704.3 Renewing oil seal for balance shaft (inlet side)

745 Pistons and conrods

765.1 Assembly overview - pistons and conrods

765.2 Removing and installing pistons

775.3 Checking pistons and cylinder bores

795.4 Separating new conrod

805.5 Checking radial clearance of conrods

81Cylinder head, valve gear

821 Cylinder head

821.1 Assembly overview - cylinder head

821.2 Assembly overview - camshaft housing

851.3 Removing and installing cylinder head

861.4 Removing and installing vacuum pump

901.5 Checking compression

912 Cover for timing chain

942.1 Assembly overview - cover for timing chain

942.2 Removing and installing timing chain cover

962.3 Renewing seal for vibration damper

1023 Chain drive

1053.1 Assembly overview - camshaft timing chains

1053.2 Assembly overview - drive chain for balance shaft

1063.3 Removing and installing camshaft timing chain

1093.4 Removing and installing drive chain for balance shaft

1233.5 Checking chain elongation

1233.6 Checking valve timing

1244 Valve gear

1274.1 Assembly overview - valve gear

1274.2 Removing and installing camshaft

1304.3 Removing and installing camshaft control valve 1 N205

1434.4 Removing and installing valve stem seals

1445 Inlet and exhaust valves

1525.1 Checking valve guides

1525.2 Checking valves

1535.3 Valve dimensions

153Lubrication

1541 Sump, oil pump

1541.1 Assembly overview - sump/oil pump

1541.2 Engine oil:

1571.3 Removing and installing lower part of sump

1571.4 Removing and installing upper part of sump

1591.5 Removing and installing oil pump

1621.6 Removing and installing oil level and oil temperature sender G266

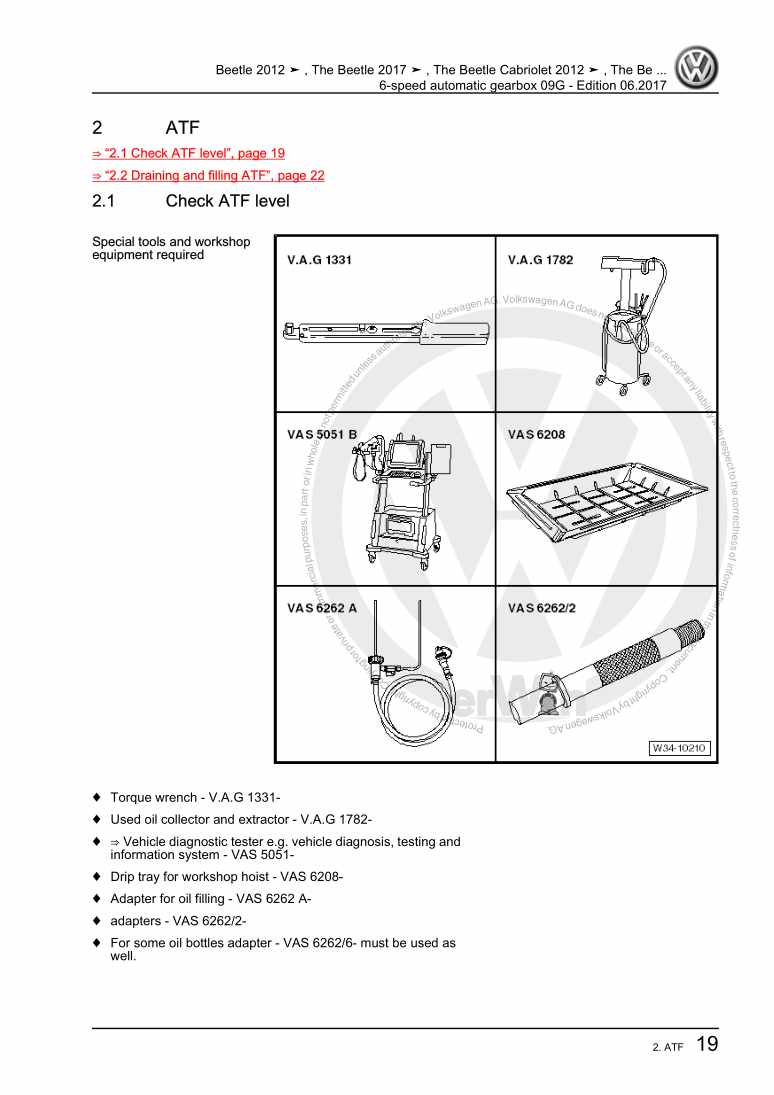

1642 Engine oil cooler

1662.1 Assembly overview - engine oil cooler

1662.2 Removing and installing engine oil cooler

1662.3 Removing and installing mechanical switching valve

1683 Crankcase ventilation

1693.1 Assembly overview - crankcase breather system

1693.2 Removing and installing oil separator

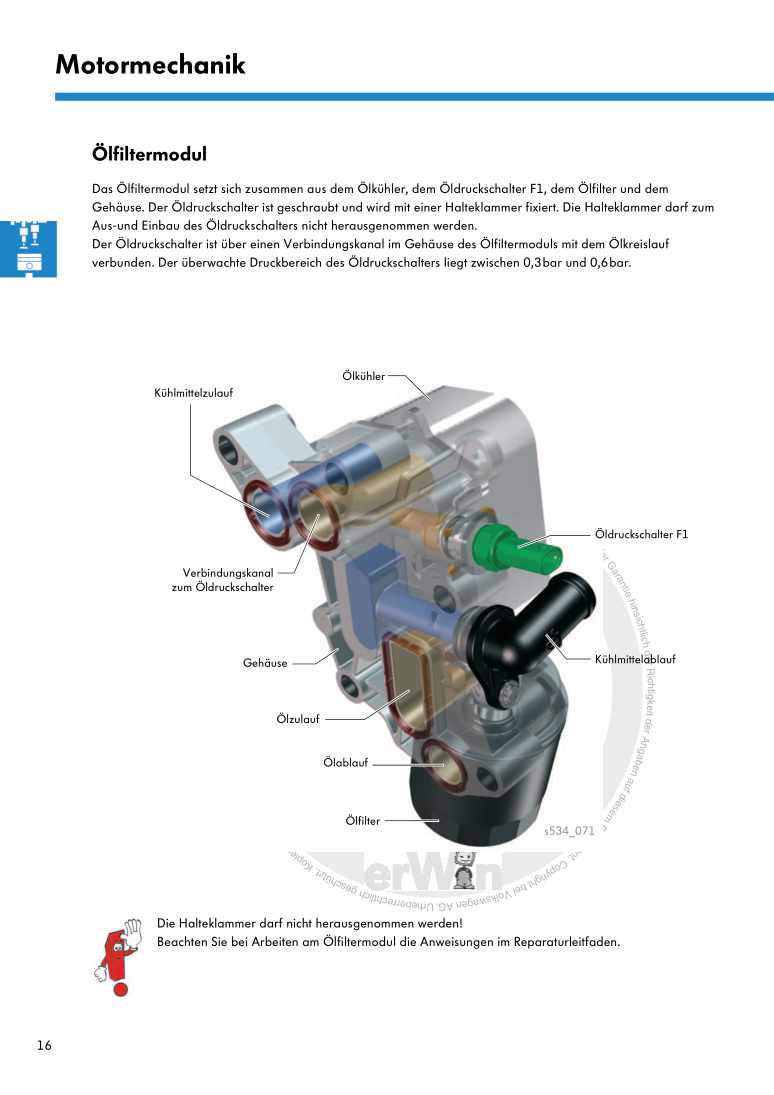

1704 Oil filter, oil pressure switch

1714.1 Assembly overview - oil filter

1714.2 Assembly overview - oil pressure switches/oil pressure control

1724.3 Removing and installing piston cooling jet control valve N522

1734.4 Removing and installing oil pressure switch F1

1734.5 Removing and installing oil pressure switch for reduced oil pressure F378

1744.6 Removing and installing stage 3 oil pressure switch F447

1754.7 Checking oil pressure

1774.8 Removing and installing oil pressure regulating valve N428

180Cooling

1821 Cooling system/coolant

1821.1 Connection diagram - coolant hoses

1821.2 Checking cooling system for leaks

1851.3 Draining and adding coolant

1872 Coolant pump, regulation of cooling system

1942.1 Assembly overview - coolant pump, thermostat

1942.2 Assembly overview - electric coolant pump

1962.3 Assembly overview - coolant temperature sender

1992.5 Removing and installing coolant pump

2012.6 Removing and installing coolant shut-off valve N82

2022.8 Removing and installing toothed belt for coolant pump

2062.9 Removing and installing thermostat housing

2082.10 Removing and installing coolant temperature sender G62

2112.11 Removing and installing radiator outlet coolant temperature sender G83

2123 Coolant pipes

2143.1 Assembly overview - coolant pipes

2143.2 Removing and installing coolant pipes

2143.3 Removing and installing upper coolant pipes

2154 Radiator, radiator fan

2184.1 Assembly overview - radiator/radiator fan

2184.2 Assembly overview - radiator cowl and radiator fan

2194.3 Removing and installing radiator

2194.4 Removing and installing radiator cowl

2204.5 Removing and installing radiator fan

2214.6 Removing and installing auxiliary radiator

221Turbocharging/supercharging

2241 Exhaust turbocharger

2241.1 Assembly overview - turbocharger

2241.2 Removing and installing turbocharger

2292 Charge air system

2362.1 Assembly overview - charge air system

2362.2 Removing and installing charge air cooler

2372.3 Removing and installing charge pressure sender G31

2382.4 Checking charge air system for leaks

238Mixture preparation - injection

2411 Injection system

2411.1 Overview of fitting locations - injection system

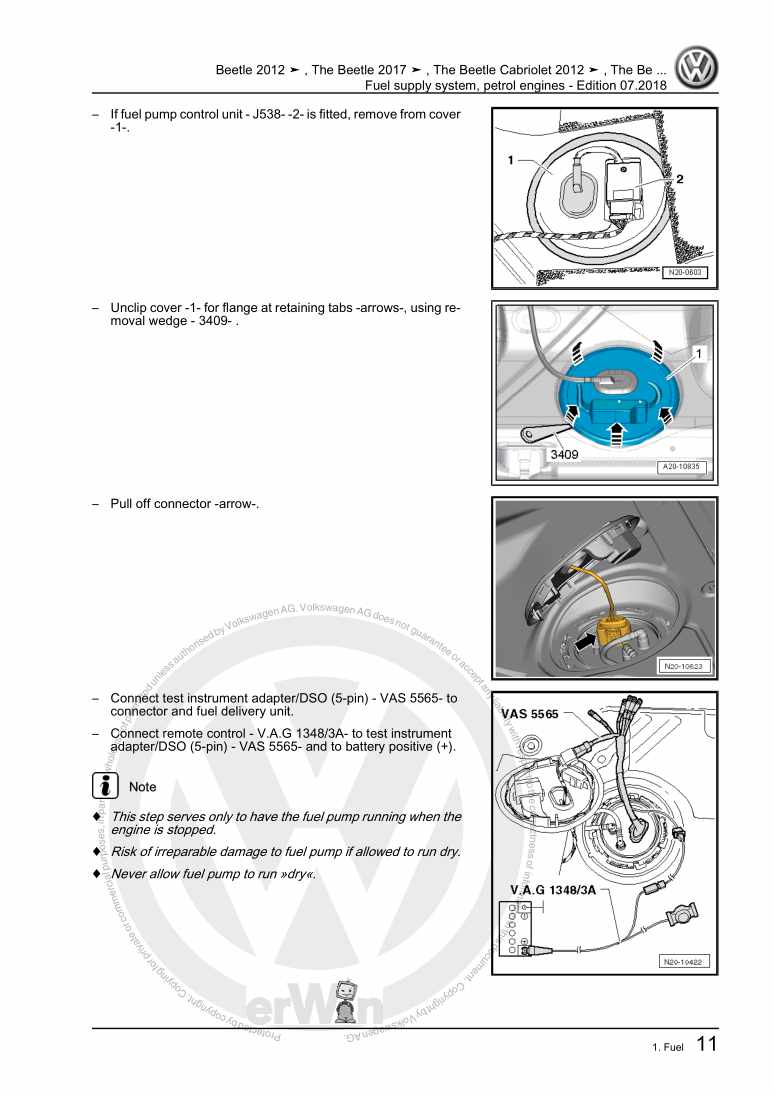

2411.2 Releasing high pressure in fuel system

2432 Injectors

2452.1 Assembly overview - fuel rail with injectors

2452.2 Removing and installing fuel rail

2472.3 Removing and installing injectors

2482.4 Renewing seals on injectors

2502.5 Cleaning injectors

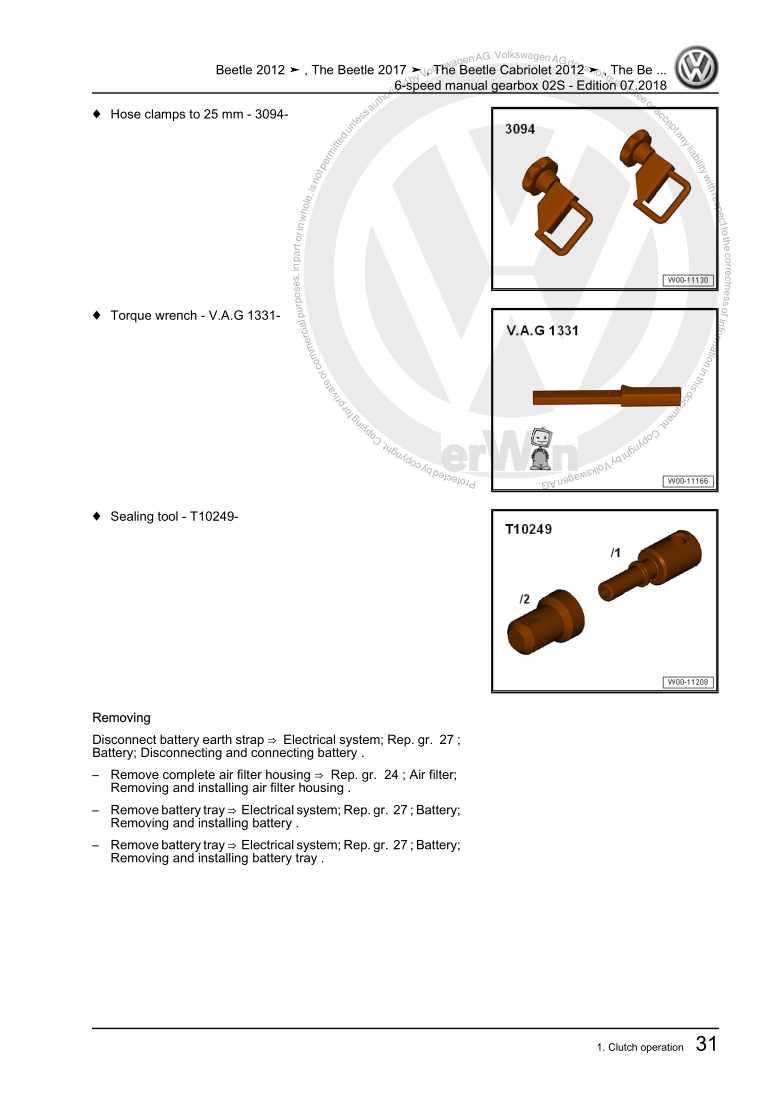

2523 Air filter

2543.1 Assembly overview - air filter housing

2543.2 Removing and installing air filter housing

2554 Intake manifold

2574.1 Assembly overview - intake manifold

2574.2 Removing and installing intake manifold

2584.3 Removing and installing throttle valve module J338

2624.4 Cleaning throttle valve module

2635 Senders and sensors

2655.3 Removing and installing fuel pressure sender G247

2665.4 Checking fuel pressure sender G247

2686 Engine (motor) control unit

2716.1 Removing and installing engine (motor) control unit J623

2717 High-pressure pump

2757.1 Assembly overview - high-pressure pump

2757.2 Removing and installing high-pressure pump

2768 Lambda probe

2808.1 Assembly overview - Lambda probe

2808.2 Removing and installing Lambda probe G39

2808.3 Removing and installing Lambda probe after catalytic converter G130

282Exhaust system

2831 Exhaust pipes and silencers

2831.1 Assembly overview - silencers

2831.2 Removing and installing rear silencer

2861.3 Aligning exhaust system free of stress

2891.4 Check exhaust system for leaks

2901.5 Installation position of clamp

2902 Exhaust gas cleaning

2922.1 Assembly overview - emission control

2922.2 Removing and installing catalytic converter

2923 Secondary air system

2963.1 Assembly overview - secondary air system

2963.2 Removing and installing secondary air pump motor V101

2973.3 Removing and installing secondary air inlet valve N112

297Ignition system

2991 Ignition system

2991.1 Assembly overview - ignition system

2991.2 Test data, spark plugs

3001.3 Removing and installing ignition coils with output stage

3001.4 Removing and installing knock sensor 1 G61

3021.5 Removing and installing Hall sender

3031.6 Removing and installing engine speed sender G28

303