Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with a start/stop system

21.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on SCR system

21.6 Safety precautions when working on exhaust system

42 Identification

52.1 Engine number/engine data

53 Repair notes

73.1 Rules for cleanliness

73.2 General information

73.3 General repair instructions

83.4 Adapting after component replacement

93.5 Foreign objects in engine

93.6 Contact corrosion

93.7 Routing and attachment of lines

103.8 Fitting radiator and condensers

103.9 Checking vacuum system

103.10 Nuts and bolts

113.11 Identification labels

113.12 Using impact drivers

113.13 Checking fuel system for leaks

124 Technical data

144.1 Coolant

15Removing and installing engine

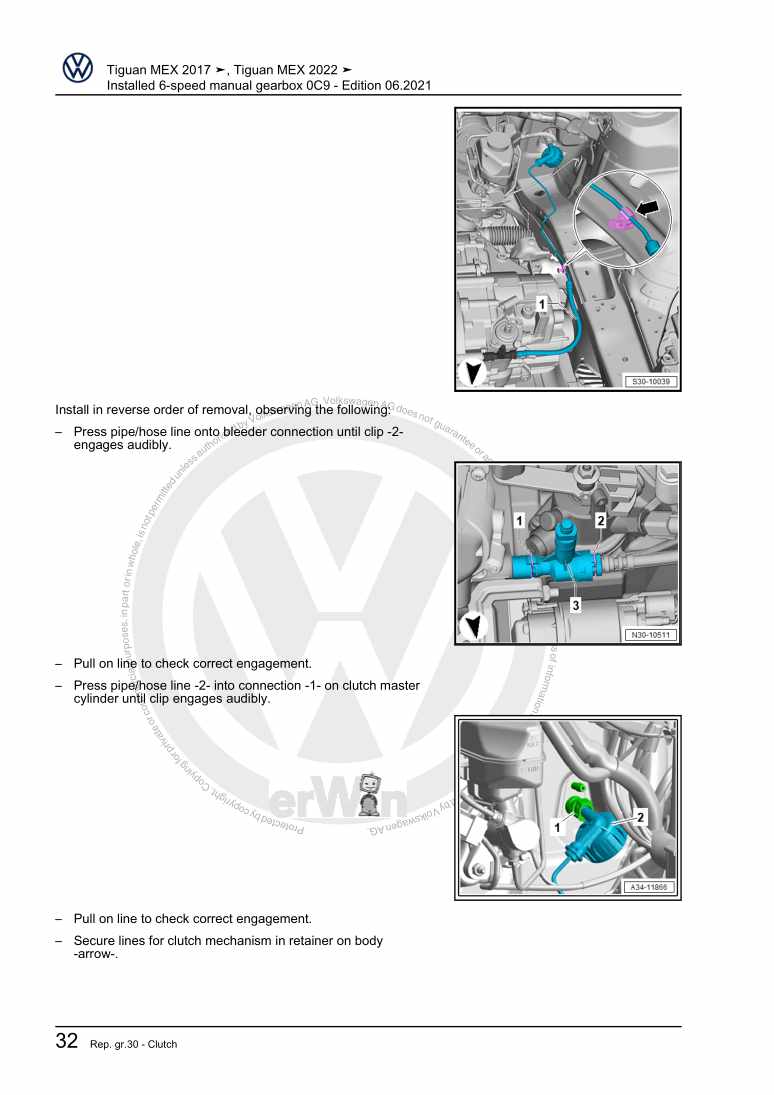

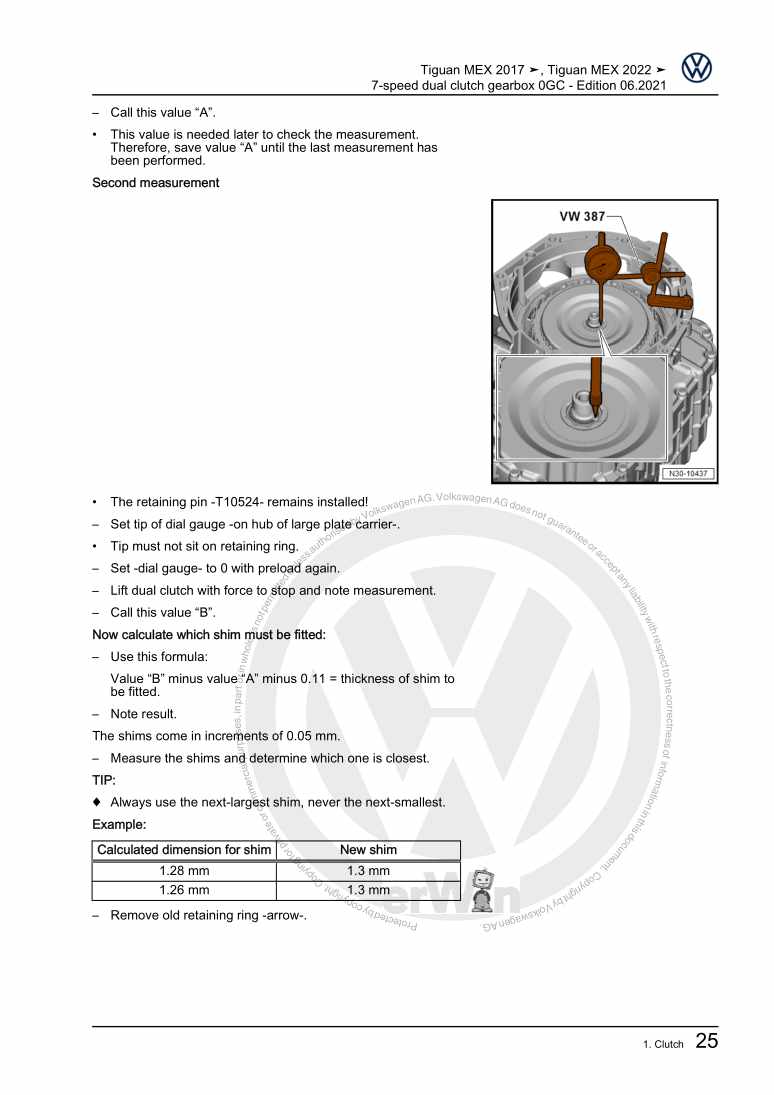

171 Removing and installing engine

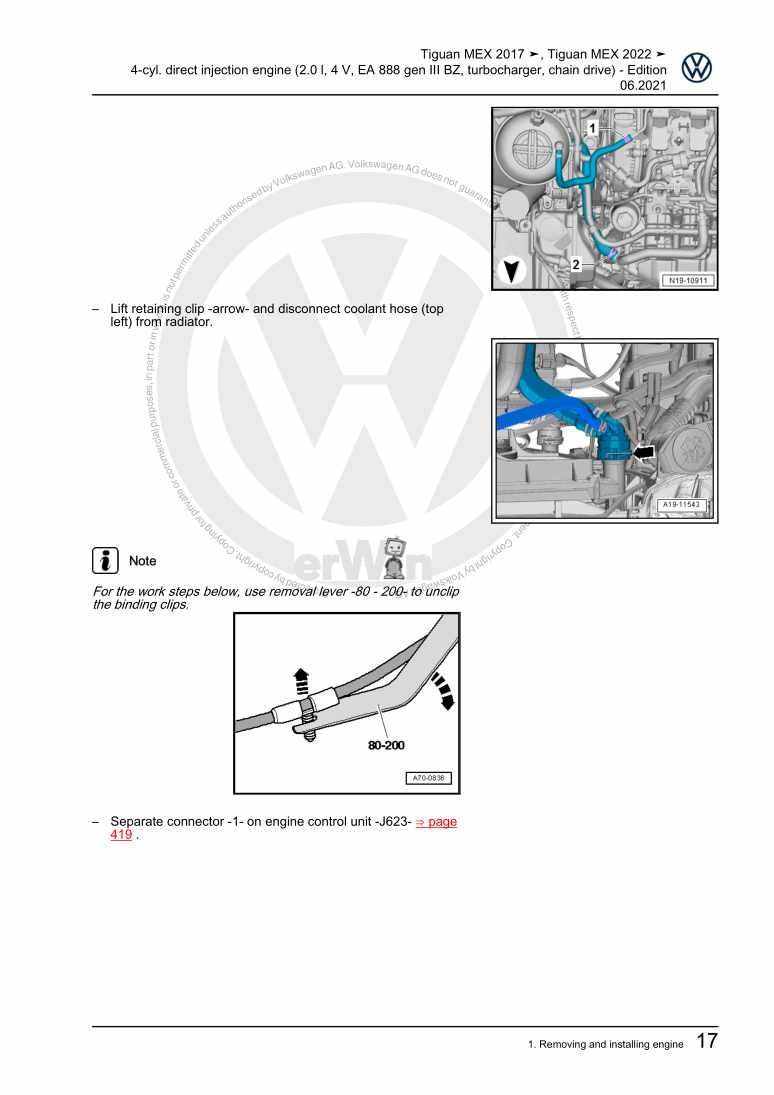

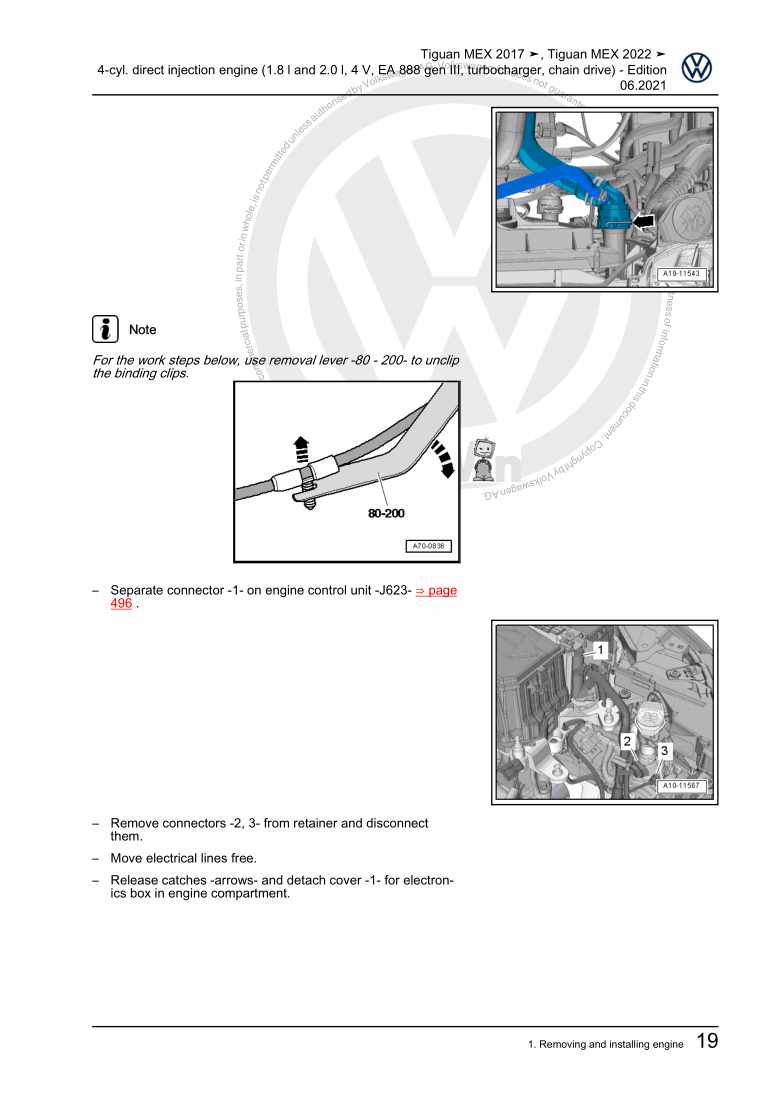

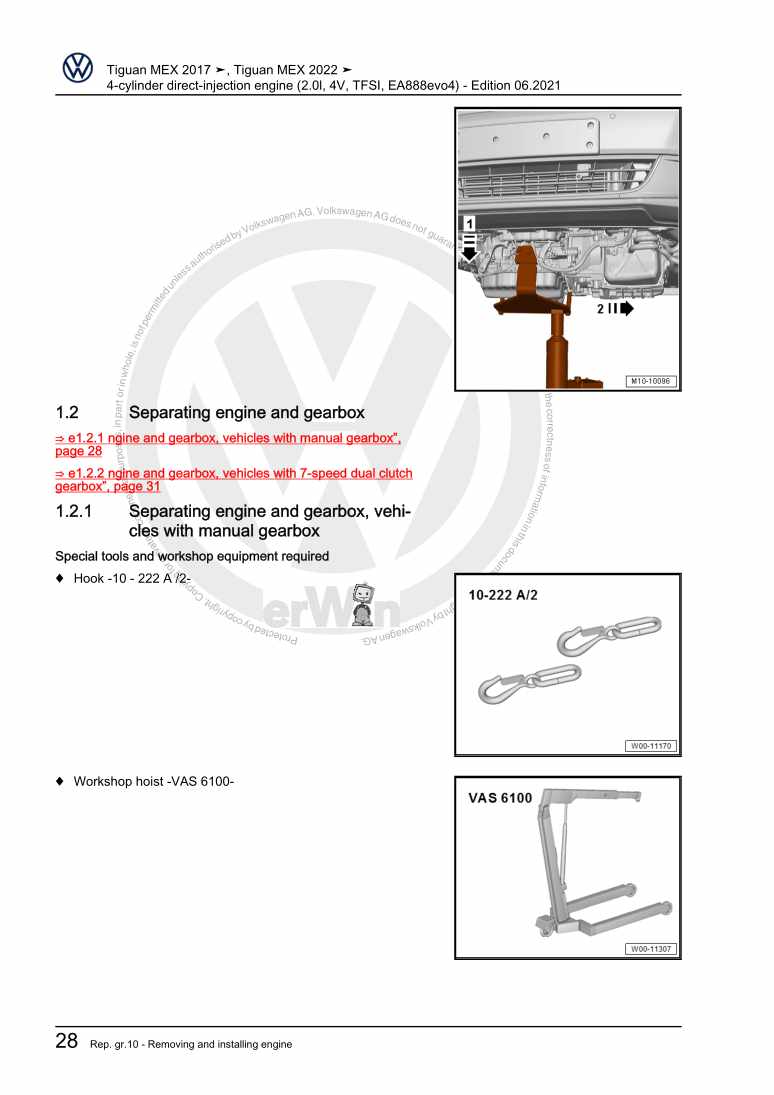

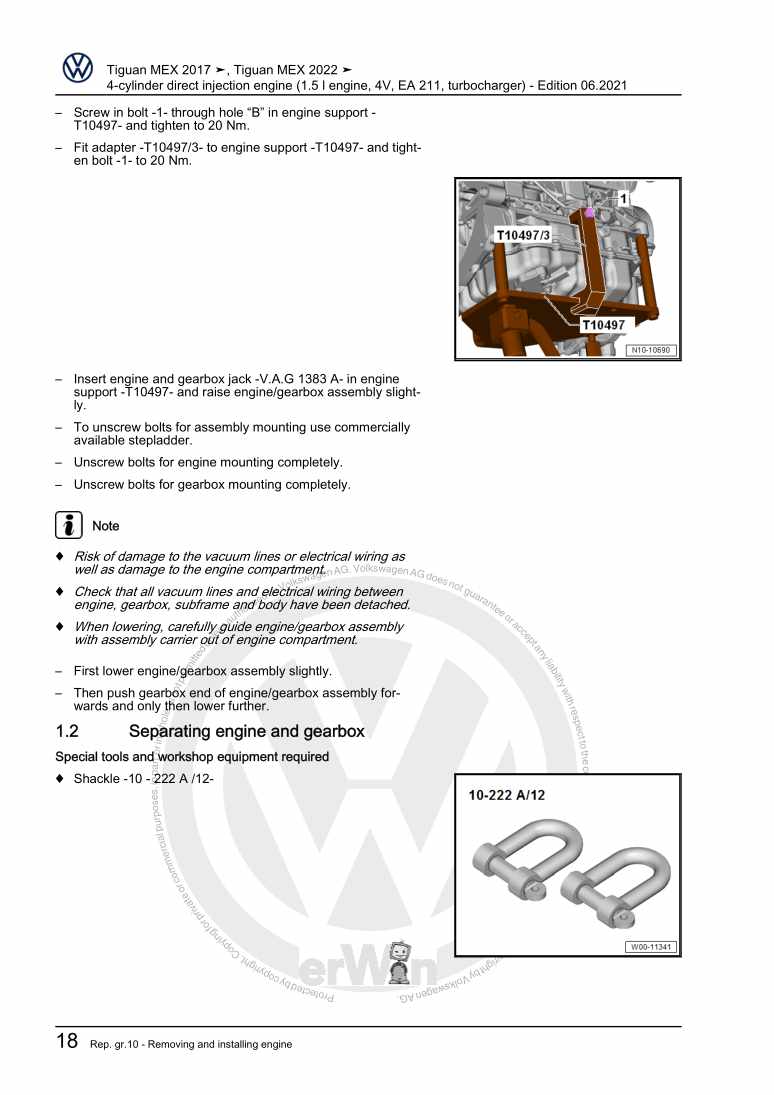

171.1 Removing engine

171.2 Separating engine and gearbox

311.3 Securing engine on engine and gearbox support

361.4 Installing engine

382 Assembly mountings

432.1 Assembly overview – assembly mountings

432.2 Removing and installing engine mounting

452.3 Removing and installing gearbox mounting

472.4 Removing and installing pendulum support

502.5 Supporting engine in installation position

502.6 Adjusting assembly mountings

562.7 Checking adjustment of assembly mountings

593 Engine cover panel

603.1 Removing and installing engine cover

60Crankshaft group

611 Cylinder block (pulley end)

611.1 Assembly overview - cylinder block (pulley end)

611.2 Assembly overview - sealing flange, belt pulley end

641.3 Removing and installing poly-V belt

651.4 Removing and installing tensioner for poly V-belt

661.5 Removing and installing vibration damper

671.6 Removing and installing bracket for ancillaries

681.7 Removing and installing engine support

701.8 Removing and installing sealing flange on pulley end

711.9 Renewing caps in cylinder block (pulley end)

752 Cylinder block, gearbox end

772.1 Assembly overview - cylinder block, gearbox end

772.2 Removing and installing flywheel

782.3 Removing and installing sealing flange on gearbox side

803 Crankshaft

1023.1 Assembly overview - crankshaft

1023.2 Crankshaft dimensions

1033.3 Measuring axial clearance of crankshaft

1043.4 Renewing needle bearing in crankshaft

1054 Pistons and conrods

1084.1 Assembly overview - pistons and conrods

1084.2 Removing and installing pistons

1114.3 Measuring piston projection at TDC

1134.4 Separating new conrod

1154.5 Checking pistons and cylinder bores

1164.6 Checking radial clearance of conrods

118Cylinder head, valve gear

1191 Cylinder head

1191.1 Assembly overview - cylinder head

1191.2 Assembly overview - cylinder head cover

1231.3 Removing and installing cylinder head

1251.4 Removing and installing cylinder head cover

1361.5 Removing and installing injector seals

1371.6 Removing and installing camshaft housing

1381.7 Checking compression

1452 Toothed belt drive

1482.1 Assembly overview - toothed belt cover

1482.2 Assembly overview - toothed belt

1482.3 Removing and installing toothed belt guard

1502.4 Removing and installing toothed belt

1552.5 Removing toothed belt from camshaft

1693 Valve gear

1753.1 Assembly overview - valve gear

1753.2 Measuring axial play of camshaft

1793.3 Removing and installing camshaft oil seal

1793.4 Removing and installing camshaft adjuster

1823.5 Removing and installing camshaft control valve 1 N205

1853.6 Checking hydraulic compensation elements

1863.7 Removing and installing valve stem oil seals

1873.8 Removing and installing control valve for the camshaft adjuster

1974 Inlet and exhaust valves

2014.1 Checking valve guides

2014.2 Checking valves

2024.3 Valve dimensions

202Lubrication

2031 Sump, oil pump

2031.1 Assembly overview - sump/oil pump

2031.2 Engine oil:

2091.3 Removing and installing sump

2091.4 Removing and installing lower part of sump

2131.5 Removing and installing upper part of sump

2171.6 Removing and installing oil pump

2221.7 Removing and installing oil level and oil temperature sender G266

2232 Engine oil cooler

2263 Oil filter, oil pressure switch

2273.1 Assembly overview - oil filter housing, oil pressure switch

2273.2 Removing and installing oil pressure switch F1

2293.3 Removing and installing oil pressure switch for reduced oil pressure F378

2313.4 Checking oil pressure

2333.5 Removing and installing oil filter housing

2343.6 Removing and installing oil pressure regulating valve N428

237Cooling

2381 Cooling system/coolant

2381.1 Connection diagram - coolant hoses

2381.2 Assembly overview – coolant expansion tank

2421.3 Checking cooling system for leaks

2431.4 Draining coolant

2471.5 Filling with coolant

2501.6 Checking filling quality

2621.7 Checking electric vacuum pump VAS 6096/2

2651.8 Flushing cooling system

2661.9 Flushing cooling system, quick reference guide

2891.10 Removing and installing coolant expansion tank

2902 Coolant pump, regulation of cooling system

2932.1 Assembly overview - coolant pump, thermostat

2932.2 Assembly overview - electric coolant pump

2972.3 Assembly overview - coolant temperature sender

3032.4 Removing and installing electric coolant pump

3062.5 Removing and installing coolant pump

3242.6 Removing and installing thermostat

3252.7 Checking thermostat

3292.8 Removing and installing coolant valve for cylinder head N489

3292.9 Removing and installing coolant temperature sender G62

3302.10 Removing and installing radiator outlet coolant temperature sender G83

3313 Coolant pipes

3343.1 Assembly overview - coolant pipes

3343.2 Removing and installing coolant pipes

3364 Radiator, radiator fan

3554.1 Assembly overview - radiator/radiator fan

3554.2 Assembly overview – radiator cowl and radiator fan

3584.3 Removing and installing radiator

3604.4 Removing and installing water radiator for charge air cooling circuit

3624.5 Removing and installing radiator cowl

3674.6 Removing and installing radiator fan

370Turbocharging/supercharging

3721 Turbocharger

3721.1 Assembly overview - turbocharger

3721.2 Removing and installing turbocharger

3811.3 Renewing vacuum unit for turbocharger

3991.4 Removing and installing connection for turbocharger

4082 Charge air system

4102.1 Assembly overview - charge air system

4102.2 Assembly overview - charge-air hose connections

4122.3 Removing and installing charge pressure sender G31

4132.4 Checking charge air system for leaks

4142.5 Removing and installing air intake pipe

4172.6 Checking charge air cooler for leaks

418Mixture preparation - injection

4241 Injection system

4241.1 Schematic overview - fuel system

4241.2 Overview of fitting locations - injection system

4251.3 Filling/bleeding fuel system

4331.4 Checking fuel system for leaks

4342 Vacuum system

4352.1 Connection diagram – vacuum system

4352.2 Checking vacuum system

4363 Injectors/high-pressure accumulator (rail)

4373.1 Assembly overview - injectors

4373.2 Assembly overview - fuel rail

4393.3 Adapting correction values for injectors

4403.4 Testing injectors

4413.5 Checking return flow rate of injectors with engine running

4423.6 Checking return flow rate of injectors at starter speed

4453.7 Checking open injectors

4473.8 Removing and installing injectors

4503.9 Removing and installing high-pressure lines

4533.10 Removing and installing fuel rail

4574 Air filter

4614.1 Assembly overview - air filter housing

4614.2 Removing and installing air filter housing

4634.3 Removing and installing air guide on lock carrier

4655 Intake manifold

4665.1 Assembly overview – intake manifold

4665.2 Removing and installing intake manifold

4695.3 Removing and installing throttle valve module J338

4746 Senders and sensors

4776.1 Removing and installing fuel pressure regulating valve N276

4776.2 Checking fuel pressure regulating valve N276

4846.3 Removing and installing fuel pressure sender G247

4866.4 Removing and installing air mass meter G70/intake air temperature sender G42

4876.5 Removing and installing pressure differential sender G505

4896.6 Removing and installing exhaust gas pressure sensor 1 G450

4926.9 Removing and installing fuel temperature sender G81

4946.10 Removing and installing control unit for NOx sender GX30

4967 Engine control unit

5017.1 Assembly overview – engine/motor control unit

5017.2 Removing and installing engine control unit J623

5017.3 Removing and installing engine (motor) control unit J623 with protective housing

5038 High-pressure pump

5098.1 Assembly overview - high-pressure pump

5098.2 Removing and installing high-pressure pump

5109 Lambda probe

5149.1 Assembly overview - Lambda probe

5149.2 Removing and installing Lambda probe

516Exhaust system

5201 Exhaust pipes and silencers

5201.1 Assembly overview – silencers

5201.2 Assembly overview - front exhaust pipe

5201.3 Removing and installing front exhaust pipe

5221.4 Removing and installing silencer

5231.5 Removing and installing front exhaust pipe bracket

5251.6 Aligning exhaust system free of stress

5261.7 Checking exhaust system for leaks

5271.8 Installation position of clamp

5271.9 Align end exhaust pipes

5292 Emission control

5302.1 Assembly overview – emission control

5302.2 Removing and installing catalytic converter

5342.3 Removing and installing particulate filter

5362.4 Removing and installing emission control module

5362.5 Removing and installing exhaust flap control unit J883

5473 SCR system (selective catalytic reduction)

5493.1 Assembly overview – reducing agent tank

5493.2 Assembly overview - reducing agent supply line

5513.3 Assembly overview - delivery module for reducing agent

5523.4 Removing and installing reducing agent tank

5533.5 Removing and installing front section of reducing agent supply line

5563.6 Removing and installing delivery module for reducing agent

5633.7 Removing and installing injector for reduction agent N474

5653.8 Removing and installing control unit for reducing-agent heater J891

5683.9 Assembly overview - injector for reducing agent

5683.10 Draining reducing agent tank

5703.11 Removing and installing rear section of reducing agent supply line

5733.12 Removing and installing filler pipe for reducing agent tank

5743.13 Disconnecting reducing agent supply line

5763.14 SCR - resetting learnt values

5794 Exhaust gas temperature regulation

5814.1 Assembly overview – exhaust gas temperature regulation

5814.2 Removing and installing exhaust gas temperature sender 1 G235

5834.3 Removing and installing exhaust gas temperature sender 2 G448

5884.4 Removing and installing exhaust gas temperature sender 3 G495

5904.5 Removing and installing exhaust gas temperature sender 4 G648

5925 Exhaust gas recirculation

5955.1 Assembly overview – exhaust gas recirculation

5955.2 Assembly overview - exhaust gas recirculation valve 1 GX5

6005.3 Removing and installing exhaust gas recirculation cooler

6015.4 Removing and installing exhaust gas recirculation valve 1 GX5

6095.5 Removing and installing exhaust gas recirculation valve 2 GX6

6105.6 Removing and installing exhaust gas recirculation temperature sensor G98

6115.7 Checking exhaust gas recirculation cooler for leaks

615Glow plug system

6211 Glow plug system

6211.1 Assembly overview – glow plug system

6211.2 Removing and installing glow plug

6231.3 Removing and installing automatic glow period control unit J179

6261.4 Removing and installing Hall sender G40

6271.5 Removing and installing engine speed sender G28

627