Technical data

11 Safety information

11.1 Safety precautions when working on exhaust system

11.2 Safety regulations for working on fuel supply

11.3 Safety measures when working on vehicles with a start/stop system

21.5 Safety precautions when working on ignition system

21.6 Safety precautions when working on cooling system

31.7 Safety precautions when working on exhaust system

32 Identification

42.1 Engine number/engine data

43 Repair instructions

63.1 Rules for cleanliness

63.2 Adapting after component replacement

63.3 General information

73.4 General repair instructions

73.5 Foreign objects in engine

83.6 Contact corrosion

93.7 Routing and attachment of lines

93.8 Fitting radiators and condensers

93.9 Checking vacuum system

93.10 Nuts and bolts

103.11 Identification labels

103.12 Using impact drivers

103.13 Checking fuel system for leaks

11Removing and installing engine

121 Removing and installing engine

121.1 Removing engine

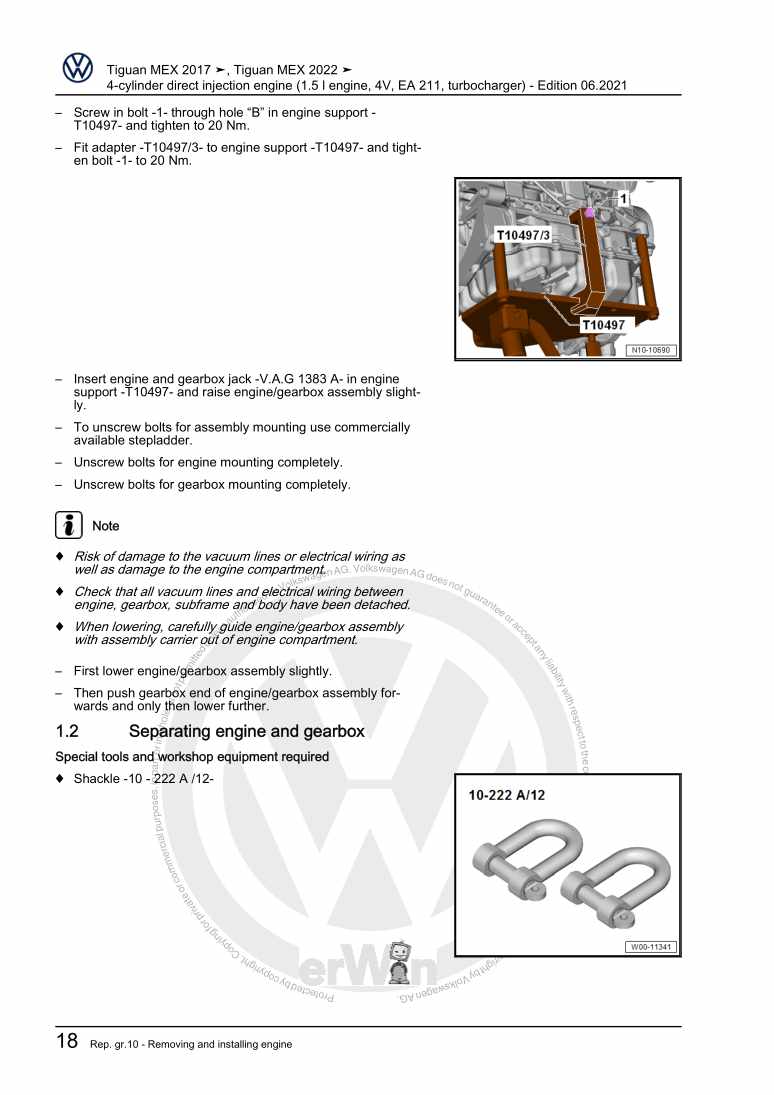

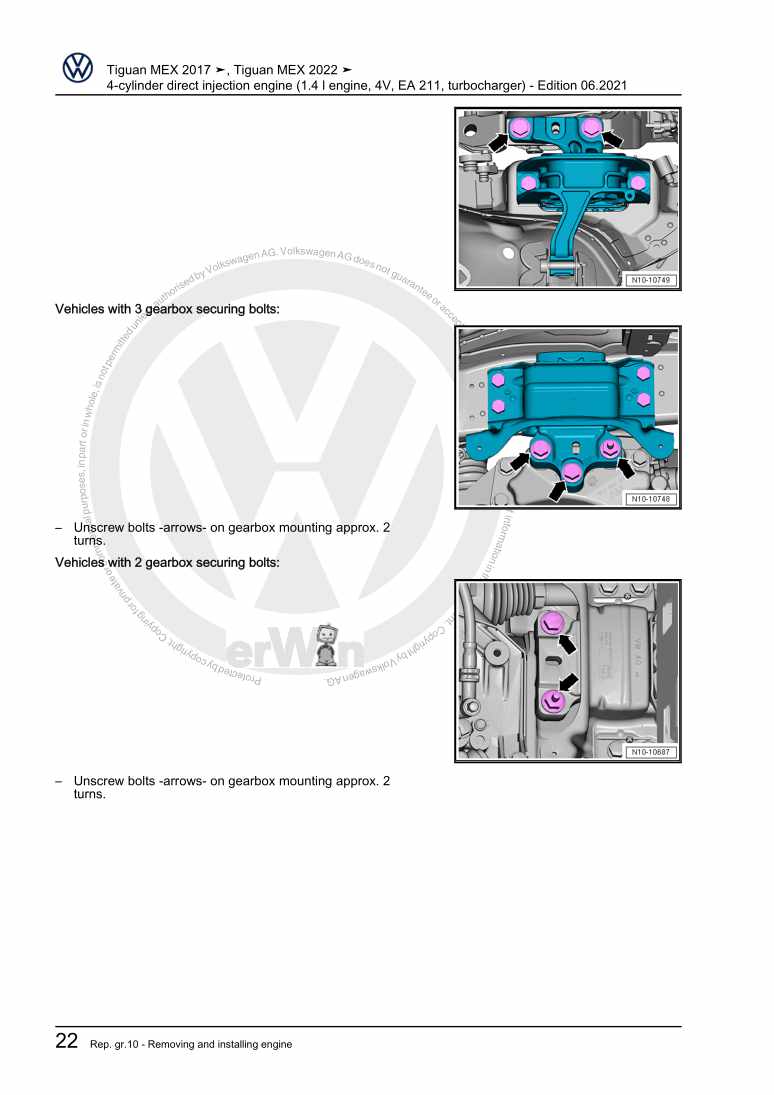

121.2 Separating engine and gearbox

281.3 Securing engine on engine and gearbox support

331.4 Installing engine

362 Assembly mountings

402.1 Assembly overview - assembly mountings

402.2 Removing and installing engine mounting

432.3 Removing and installing gearbox mounting

442.4 Removing and installing pendulum support

462.5 Supporting engine in installation position

462.6 Checking adjustment of assembly mountings

502.7 Adjusting assembly mountings

513 Engine cover panel

543.1 Removing and installing engine cover

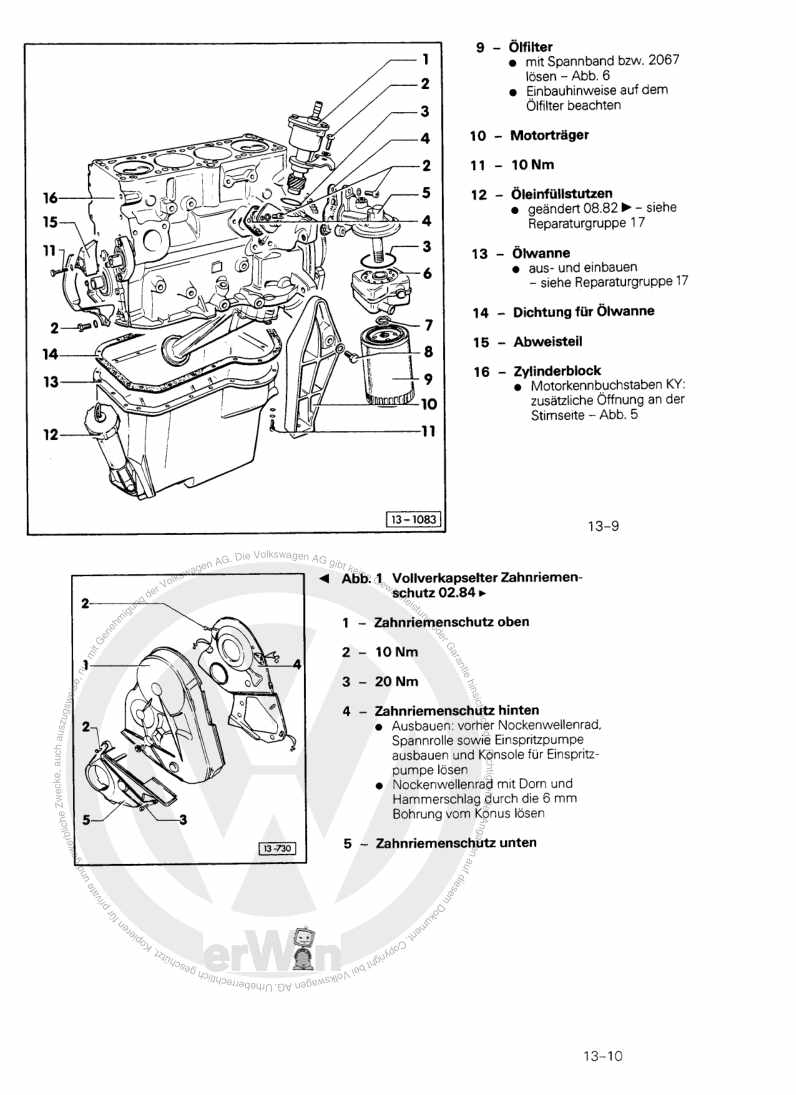

54Crankshaft group

551 Cylinder block (pulley end)

551.1 Assembly overview - cylinder block (pulley end)

551.2 Removing and installing poly-V belt

581.3 Removing and installing tensioner for poly V-belt

591.4 Removing and installing vibration damper

591.5 Removing and installing bracket for ancillaries

681.6 Removing and installing engine support

711.7 Renewing crankshaft oil seal - belt pulley end

732 Cylinder block, gearbox end

762.1 Assembly overview - cylinder block, gearbox end

762.2 Removing and installing flywheel

782.3 Removing and installing sealing flange on gearbox side

793 Crankshaft

843.1 Assembly overview - crankshaft

843.2 Crankshaft dimensions

873.3 Allocation of main bearing shells

873.4 Renewing needle bearing in crankshaft

893.5 Measuring axial clearance of crankshaft

923.6 Measuring radial clearance of crankshaft

933.7 Removing and installing crankshaft

943.8 Removing and installing sender wheel

964 Balancer shaft

974.1 Assembly overview - balance shaft

974.2 Removing and installing balance shaft

994.3 Renewing oil seal for balance shaft (inlet side)

1045 Pistons and conrods

1065.1 Assembly overview - pistons and conrods

1065.2 Removing and installing pistons

1115.3 Removing and installing oil spray jets

1145.4 Checking pistons and cylinder bores

1165.5 Separating new conrod

1185.6 Checking radial clearance of conrods

118Cylinder head, valve gear

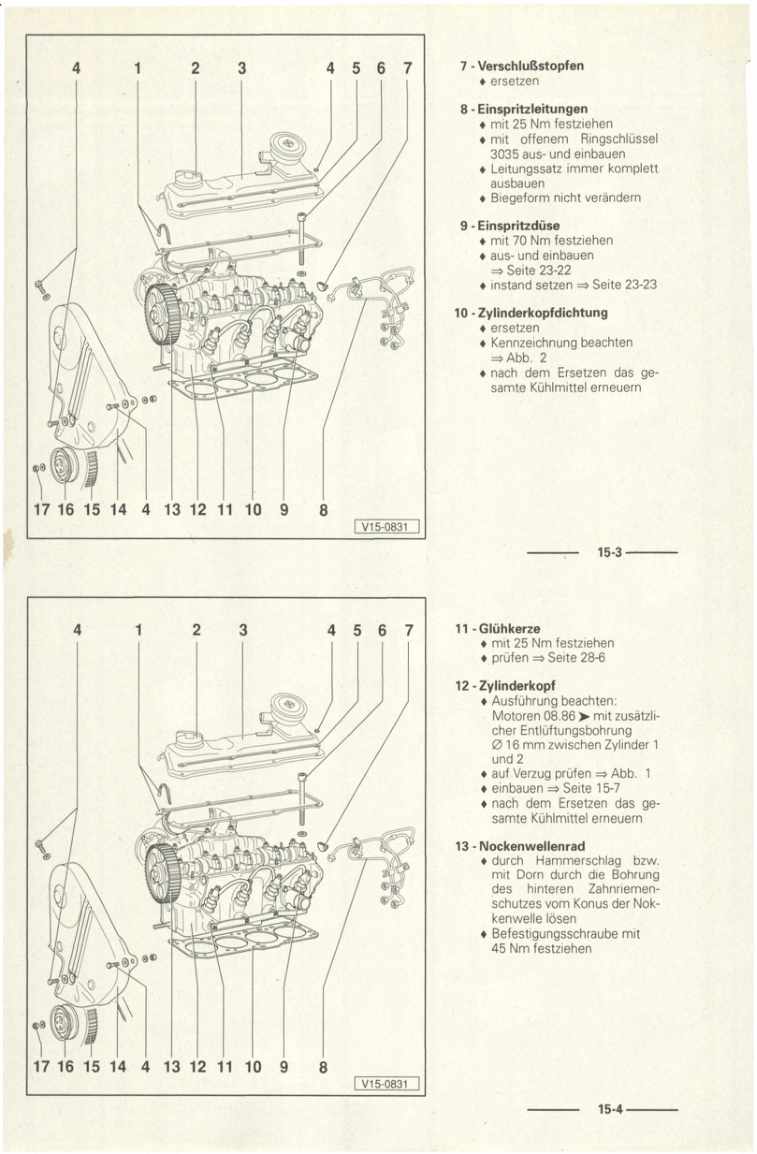

1201 Cylinder head

1201.1 Assembly overview - cylinder head

1201.2 Assembly overview - vacuum pump

1241.3 Removing and installing cylinder head

1251.4 Removing and installing vacuum pump

1341.5 Checking compression

1352 Cover for timing chain

1382.1 Assembly overview - cover for timing chain

1382.2 Removing and installing timing chain cover

1413 Chain drive

1473.1 Assembly overview - camshaft timing chains

1473.2 Assembly overview - drive chain for balance shaft

1503.3 Removing and installing bearing saddle

1533.4 Removing and installing camshaft timing chain

1583.5 Checking timing chain

1683.6 Removing and installing drive chain for balance shaft

1694 Valve gear

1744.1 Assembly overview - valve gear

1744.2 Removing and installing camshaft

1784.3 Installing ball for sliding piece

1874.4 Removing and installing actuators for camshaft adjustment

1884.5 Removing and installing camshaft control valve 1 N205

1894.6 Removing and installing exhaust camshaft control valve 1 N318

1904.7 Removing and installing valve stem oil seals

1905 Inlet and exhaust valves

2035.1 Checking valve guides

2035.2 Checking valves

2045.3 Valve dimensions

204Lubrication

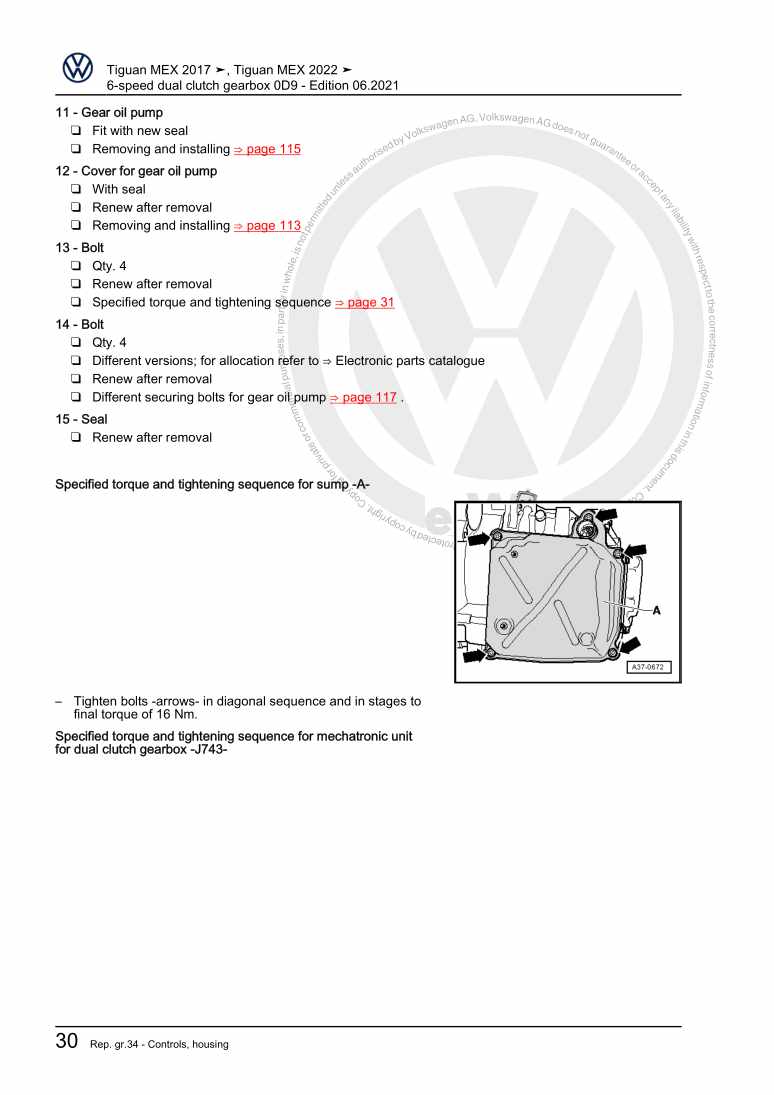

2051 Sump, oil pump

2051.1 Assembly overview - sump/oil pump

2051.2 Engine oil:

2081.3 Removing and installing lower part of sump

2081.4 Removing and installing oil pump

2091.5 Removing and installing upper part of sump

2101.6 Removing and installing oil level and oil temperature sender G266

2152 Engine oil cooler

2162.1 Assembly overview - engine oil cooler

2162.2 Removing and installing engine oil cooler

2162.3 Removing and installing mechanical switching valve

2173 Crankcase ventilation

2183.1 Assembly overview - crankcase breather system

2183.2 Removing and installing oil separator

2193.3 Removing and installing crankcase pressure sensor G1068

2204 Oil filter, oil pressure switch

2224.1 Assembly overview - oil filter

2224.2 Assembly overview - oil pressure switches/oil pressure control

2224.3 Removing and installing oil pressure switch F22

2244.4 Removing and installing oil pressure switch for reduced oil pressure F378

2244.5 Removing and installing stage 2 oil pressure switch F446

2254.6 Removing and installing oil pressure regulating valve N428

2264.7 Removing and installing piston cooling jet control valve N522

2274.8 Checking oil pressure

227Cooling

2311 Cooling system/coolant

2311.1 Connection diagram - coolant hoses

2311.2 Checking cooling system for leaks

2321.3 Draining and adding coolant

2362 Coolant pump, regulation of cooling system

2452.1 Assembly overview - coolant pump, thermostat

2452.2 Assembly overview - electric coolant pump

2472.3 Assembly overview – coolant valves

2482.4 Assembly overview - coolant temperature sender

2492.5 Removing and installing electric coolant pump

2502.6 Removing and installing coolant pump

2532.7 Removing and installing toothed belt for coolant pump

2542.8 Removing and installing actuator for engine temperature regulation N493

2562.9 Removing and installing coolant temperature sender G62

2592.10 Removing and installing radiator outlet coolant temperature sender G83

2602.11 Removing and installing coolant valves

2603 Coolant pipes

2633.1 Assembly overview - coolant pipes

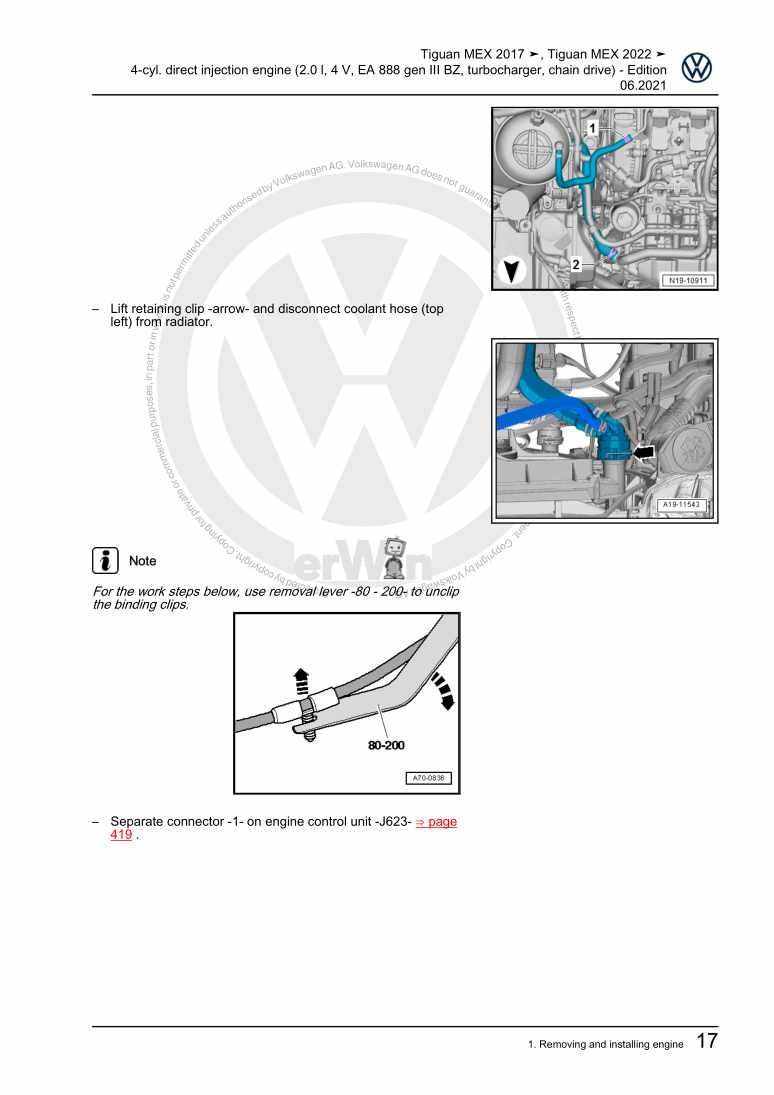

2633.2 Removing and installing coolant pipes

2644 Radiator, radiator fan

2714.1 Assembly overview - radiator/radiator fan

2714.2 Assembly overview – radiator cowl and radiator fan

2724.3 Assembly overview - auxiliary radiator

2734.4 Removing and installing radiator

2744.5 Removing and installing radiator cowl

2764.6 Removing and installing radiator fan

2774.7 Removing and installing auxiliary radiator

278Turbocharging/supercharging

2811 Turbocharger

2811.1 Assembly overview - turbocharger

2811.2 Removing and installing turbocharger

2861.3 Removing and installing charge pressure control module GX34

2921.4 Removing and installing turbocharger air recirculation valve

2942 Charge air system

2962.1 Assembly overview - charge air system

2962.2 Assembly overview - charge-air hose connections

2972.3 Removing and installing charge air cooler

2992.4 Removing and installing charge pressure sender G31

3012.5 Removing and installing air intake pipe

3022.6 Checking charge air system for leaks

305Mixture preparation - injection

3081 Injection system

3081.1 Overview of fitting locations - injection system

3082 Vacuum system

3152.1 Connection diagram – vacuum system

3152.2 Checking vacuum system

3153 Injectors

3173.1 Assembly overview - fuel rail with injectors

3173.2 Removing and installing fuel rail

3183.3 Removing and installing injectors

3203.4 Cleaning injectors

3254 Air filter

3274.1 Assembly overview - air filter housing

3274.2 Removing and installing air filter housing

3294.3 Removing and installing air guide on lock carrier

3305 Intake manifold

3325.1 Assembly overview – intake manifold

3325.2 Removing and installing intake manifold

3345.3 Removing and installing throttle valve module GX3

3385.4 Cleaning throttle valve module GX3

3395.5 Removing and installing intake manifold flap valve N316

3405.6 Checking intake manifold change-over

3406 Senders and sensors

3436.2 Control unit for structure-borne sound and actuator for structure-borne sound

3446.3 Removing and installing intake manifold pressure sender G71

3456.4 Removing and installing fuel pressure sender G247

3456.5 Checking fuel pressure sender G247

3466.6 Removing and installing pressure differential sender for particulate filter G1037

3497 Engine control unit

3517.1 Assembly overview – engine/motor control unit

3517.2 Removing and installing engine control unit J623

3518 High-pressure pump

3538.1 Assembly overview - high-pressure pump

3538.2 Removing and installing high-pressure pump

3568.3 Removing and installing high-pressure pipe

3589 Lambda probe

3609.1 Assembly overview - Lambda probe

3609.2 Removing and installing Lambda probe

362Exhaust system

3651 Exhaust pipes and silencers

3651.1 Assembly overview – silencers

3651.2 Removing and installing silencer

3661.3 Aligning exhaust system free of stress

3681.4 Checking exhaust system for leaks

3691.5 Installation position of clamp

3692 Emission control

3712.1 Assembly overview – emission control

3712.3 Removing and installing bracket for catalytic converter

3752.4 Removing and installing catalytic converter

3783 Exhaust gas temperature regulation

3883.1 Assembly overview – exhaust gas temperature regulation

3883.2 Removing and installing parts of exhaust gas temperature regulation

390Ignition system

3921 Ignition system

3921.1 Assembly overview - ignition system

3921.2 Removing and installing ignition coils

3941.3 Removing and installing knock sensor 1 G61

3961.4 Removing and installing Hall sender

3971.5 Removing and installing engine speed sender G28

399