Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety precautions when working on charge air system

21.3 Safety regulations for working on fuel supply

21.4 Safety precautions when working on the SCR system

31.6 Safety measures when working on vehicles with a start/stop system

41.7 Safety precautions when working on fuel system

42 Identification

52.1 Engine number/engine data

53 Repair instructions

73.1 Rules for cleanliness when working on fuel supply system

73.2 Rules for cleanliness and instructions for working on fuel system

73.3 Rules for cleanliness during work on fuel system

93.4 Rules for cleanliness when working on the SCR system

93.5 General notes on the lubrication system

103.6 General notes on cooling system

103.7 General notes on fuel system

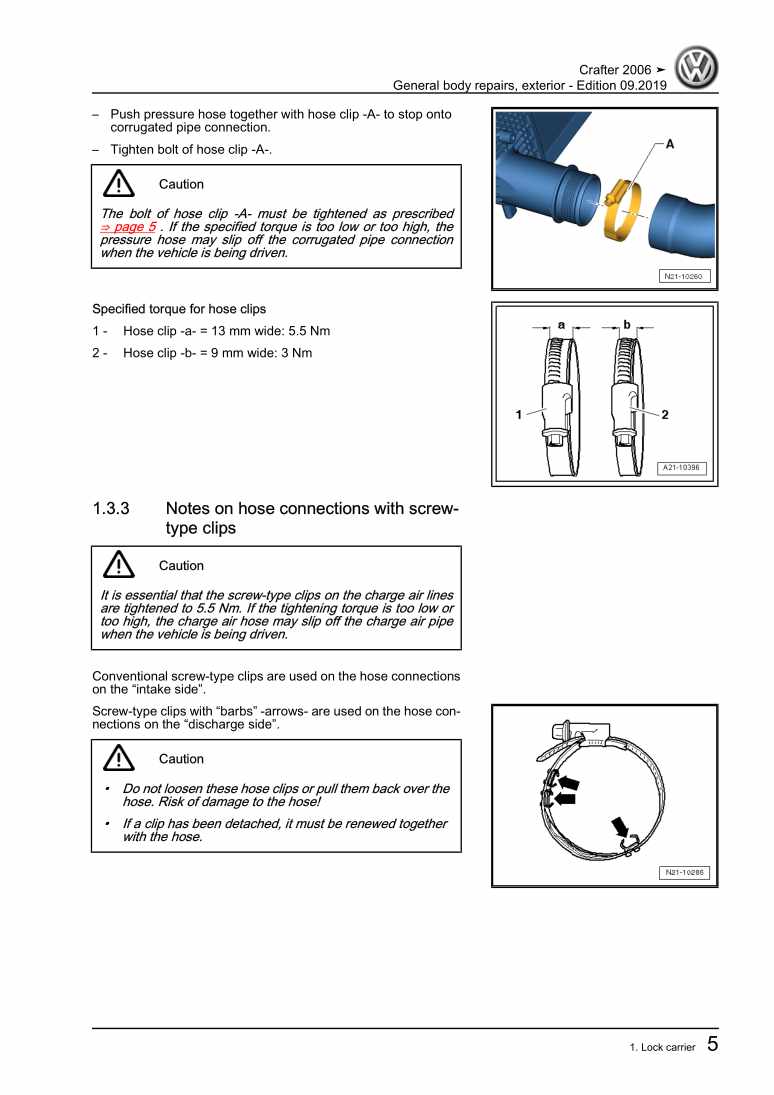

113.8 Notes on hose connections with screw-type clips

12Removing and installing engine

141 Removing and installing engine

141.1 Removing engine

141.2 Securing engine on engine and gearbox support

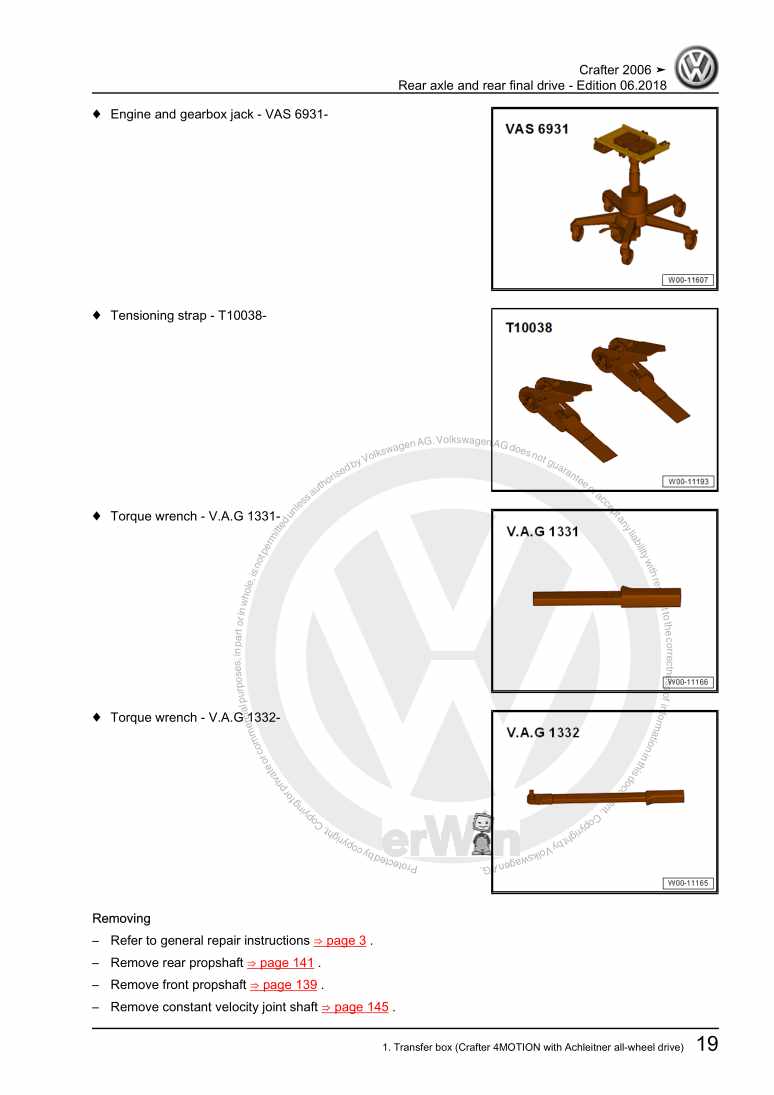

241.3 Removing engine, Crafter 4MOTION with Achleitner four-wheel drive

251.4 Installing engine

362 Assembly mountings

382.1 Assembly overview - assembly mountings

382.2 Supporting engine in installation position

40Crankshaft group

431 Cylinder block (pulley end)

431.1 Assembly overview - poly V-belt drive

431.2 Assembly overview - cylinder block (pulley end)

471.3 Assembly overview - sealing flange, belt pulley end

491.4 Removing and installing poly-V belt

501.5 Removing and installing tensioner for poly V-belt

531.6 Removing and installing poly V-belt for viscous fan

541.7 Removing and installing vibration damper

571.8 Removing and installing bracket for ancillaries

581.9 Removing and installing bracket with belt pulley

601.10 Renewing crankshaft oil seal - belt pulley end

611.11 Removing and installing sealing flange on pulley end

642 Cylinder block, gearbox end

692.1 Assembly overview - cylinder block, gearbox end

692.2 Removing and installing flywheel

702.3 Removing and installing sealing flange on gearbox side

713 Crankshaft

833.1 Assembly overview - crankshaft

833.2 Renewing needle bearing in crankshaft

843.3 Crankshaft dimensions

863.4 Measuring axial clearance of crankshaft

873.5 Measuring radial clearance of crankshaft

884 Auxiliary drive

894.1 Assembly overview - ancillary drive

894.2 Retrofitting auxiliary drive (genuine parts set)

974.3 Removing and installing poly V-belt for auxiliary drive

1015 Pistons and conrods

1035.1 Assembly overview - pistons and conrods

1035.2 Measuring piston projection at TDC

1055.3 Checking pistons and cylinder bores

1075.4 Separating new conrod

1105.5 Checking radial clearance of conrods

1105.6 Installation position of bearing shells

111Cylinder head, valve gear

1121 Cylinder head

1121.1 Assembly overview - cylinder head

1121.2 Assembly overview - cylinder head cover

1161.3 Removing and installing cylinder head

1181.4 Removing and installing cylinder head cover

1301.5 Removing and installing injector seals

1361.6 Removing and installing vacuum pump

1371.7 Checking compression

1392 Fully enclosing toothed belt guard

1412.1 Assembly overview - fully enclosing toothed belt guard

1412.2 Removing and installing upper toothed belt guard (fully enclosing)

1432.3 Removing and installing lower toothed belt guard (fully enclosed)

1442.4 Removing and installing rear toothed belt guard (fully enclosing)

1463 Toothed belt drive

1503.1 Assembly overview - toothed belt

1503.2 Removing and installing toothed belt

1524 Valve gear

1674.1 Assembly overview - valve gear

1674.2 Removing and installing valve stem seals

1694.3 Renewing valve stem seals with cylinder head removed

1744.4 Removing and installing camshaft

1774.5 Measuring axial play of camshaft

1864.6 Measuring radial play of camshaft

1874.7 Removing and installing camshaft oil seal

1874.8 Checking hydraulic compensation elements

1925 Inlet and exhaust valves

1945.1 Reworking valve seats

1945.2 Checking valve guides

1945.3 Checking valves

1955.4 Valve dimensions

195Lubrication

1961 Sump, oil pump

1961.1 Assembly overview - sump/oil pump

1961.2 Removing and installing oil sump

1991.3 Removing and installing oil pump

2031.4 Engine oil:

2041.5 Removing and installing oil level and oil temperature sender G266

2041.6 Measuring oil consumption

2052 Oil filter, oil pressure switch

2062.1 Assembly overview - oil filter housing with engine oil cooler

2062.2 Removing and installing engine oil cooler

2082.3 Removing and installing oil filter housing

2102.4 Removing and installing oil pressure switch F1

2122.5 Checking oil pressure switch F1

2132.6 Checking oil pressure

2153 Oil circuit

2173.1 Removing and installing oil supply line, single turbo

2173.2 Removing and installing oil supply line, bi-turbo

218Cooling

2231 Cooling system/coolant

2231.1 Connection diagram - coolant hoses

2231.2 Draining and adding coolant

2331.3 Checking cooling system for leaks

2422 Coolant pump, regulation of cooling system

2452.1 Assembly overview - coolant pump, thermostat

2452.2 Assembly overview - electric coolant pump

2452.3 Removing and installing coolant pump

2462.4 Removing and installing 4/2-way valve with thermostat

2482.5 Removing and installing coolant temperature sender G62

2512.6 Removing and installing radiator outlet coolant temperature sender G83

2522.7 Removing and installing coolant flange

2532.8 Removing and installing Y-thermostat

2552.9 Removing and installing coolant circulation pump V50

2572.10 Removing and installing 3/2-way valve, Euro 6 vehicles

2583 Coolant pipes/coolant hoses

2603.1 Assembly overview - coolant pipe/coolant hose

2603.2 Removing and installing coolant pipe with coolant hose

2614 Radiator, radiator fan

2654.1 Assembly overview - radiator/radiator fan

2654.2 Assembly overview - viscous fan

2664.3 Removing and installing viscous fan

2684.4 Removing and installing cowling

2714.5 Removing and installing radiator

272Turbocharging/supercharging

2761 Turbocharger

2761.1 Assembly overview - turbocharger, single turbo

2761.2 Assembly overview - turbocharger, bi-turbo

2791.3 Removing and installing turbocharger, single turbo

2821.4 Removing and installing turbocharger, bi-turbo

2881.6 Assembly overview - turbocharger, bi-turbo, dismantling

3031.7 Renewing gasket between bi-turbo turbine housings

3061.8 Removing and installing regulating flap potentiometer G584

3101.9 Renewing vacuum unit for turbocharger

3172 Charge air system

3242.1 Assembly overview - charge air system

3242.2 Removing and installing charge air cooler

3262.5 Removing and installing charge pressure control solenoid valve N75

3282.6 Removing and installing exhaust gas flap valve N220

3292.7 Removing and installing charge air pipe

3302.8 Checking charge air system for leaks

332Mixture preparation - injection

3361 Injection system

3361.1 Schematic overview - fuel system

3361.2 Overview of fitting locations - injection system

3381.3 Checking fuel system for leaks

3452 Vacuum system

3462.1 Connection diagram - vacuum system

3463 Intake manifold

3493.1 Assembly overview – intake manifold

3493.2 Removing and installing intake manifold

3503.3 Removing and installing throttle valve module J338

3544 Air filter

3564.1 Assembly overview - air filter housing

3564.2 Removing and installing air filter housing

3575 Injectors/high-pressure accumulator (rail)

3585.1 Assembly overview - injectors

3585.2 Removing and installing injectors

3615.3 Adapting correction values for injectors

3665.4 Testing injectors

3675.5 Testing jammed-open injectors

3675.6 Checking return flow rate of injectors with engine running

3695.7 Checking return flow rate of injectors at starter speed

3725.8 Removing and installing fuel rail

3745.9 Removing and installing high-pressure lines

3776 Senders and sensors

3816.1 Removing and installing fuel pressure regulating valve N276

3816.2 Checking fuel pressure regulating valve N276

3836.3 Removing and installing fuel pressure sender G247

3846.4 Removing and installing air mass meter G70

3877 Engine control unit

3897.1 Removing and installing engine control unit J623

3897.2 Removing and installing engine (motor) control unit J623 with protective housing

3908 High-pressure pump

3928.1 Assembly overview - high-pressure pump

3928.2 Removing and installing high-pressure pump

3948.3 Initial fuel filling after installation of the high-pressure pump

3978.4 Checking high-pressure pump

3989 Lambda probe

4019.1 Removing and installing Lambda probe

401Exhaust system

4051 Exhaust pipes and silencers

4051.1 Assembly overview – silencers

4051.5 Checking exhaust system for leaks

4091.6 Removing and installing rear silencer

4092 Emission control

4182.1 Assembly overview – emission control

4182.2 Removing and installing particulate filter

4203 SCR system (selective catalytic reduction)

4283.1 Assembly overview – reducing agent tank

4283.2 Removing and installing reducing agent tank

4303.3 Removing and installing reducing agent supply line

4323.4 Removing and installing injector for reduction agent N474

4353.5 Removing and installing control unit for reducing-agent heater J891

4363.6 Removing and installing delivery unit for reducing agent metering system GX19

4373.7 Draining reducing agent tank

4413.8 Removing and installing filler neck for reducing agent

4443.9 Removing and installing NOx sender G295/control unit for NOx sender J583

4453.10 Removing and installing NOx sender 2 G687/control unit for NOx sender 2 J881

4473.11 Removing and installing exhaust gas temperature sender 2 G448

4504 Exhaust gas recirculation

4534.1 Assembly overview – exhaust gas recirculation

4534.2 Removing and installing exhaust gas recirculation valve N18

4544.3 Removing and installing exhaust gas recirculation cooler

4554.4 Checking exhaust gas recirculation cooler for leaks

4584.5 Removing and installing pump for exhaust gas recirculation cooler V400

4624.6 Removing and installing exhaust gas recirculation temperature sensor G98

463Glow plug system

4651 Glow plug system

4651.1 Removing and installing glow plug

4651.2 Checking glow plug system

4671.3 Removing and installing Hall sender G40

4671.4 Removing and installing engine speed sender G28

469