Technical data

11 Safety information

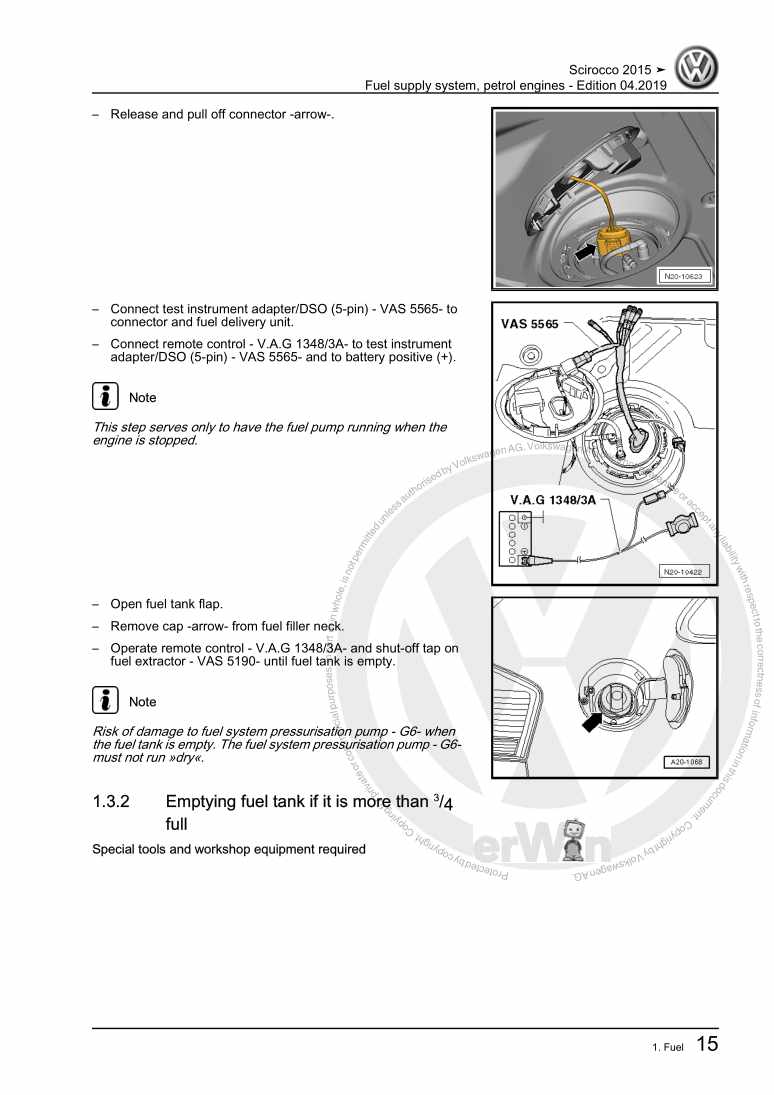

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with start/stop system

11.4 Safety precautions when working on ignition system

21.5 Safety precautions when working on the cooling system

22 Identification

32.1 Engine number/engine data

33 Repair instructions

53.1 Rules for cleanliness

53.2 Foreign objects in engine

53.3 Contact corrosion

53.4 Routing and attachment of lines

53.5 Fitting radiator and condensers

63.6 Checking vacuum system

6Removing and installing engine

71 Removing and installing engine

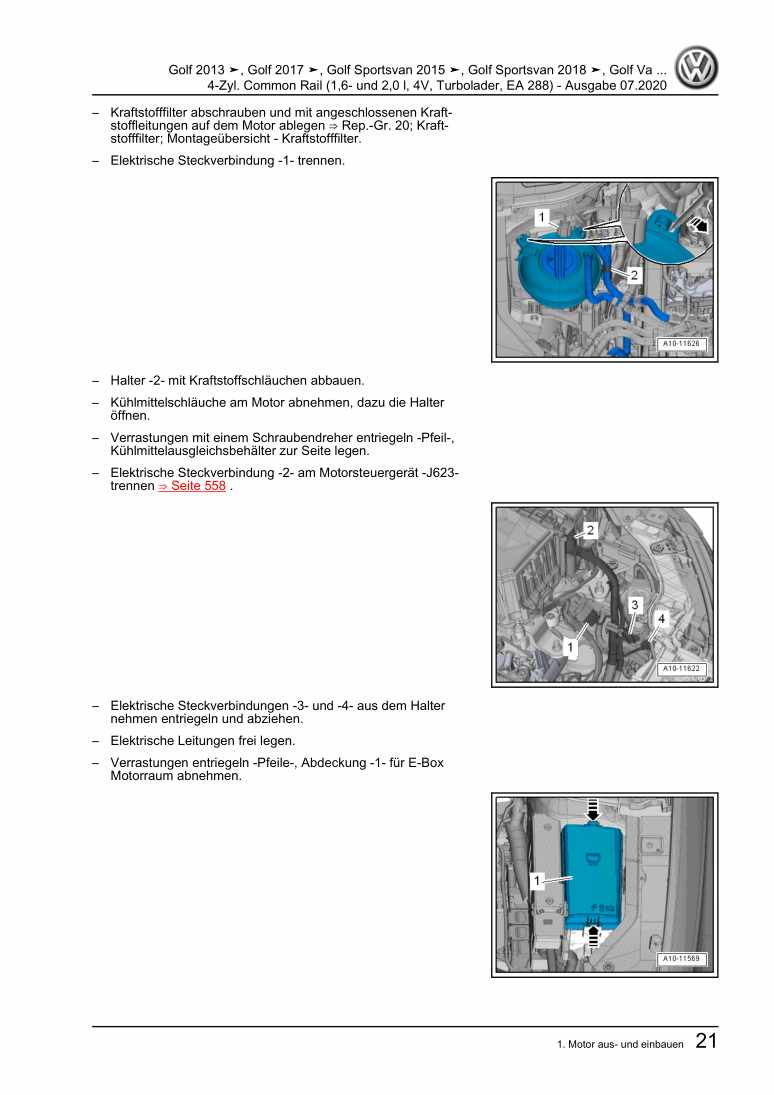

71.1 Removing engine

71.2 Separating engine and gearbox

191.3 Securing engine on engine and gearbox support

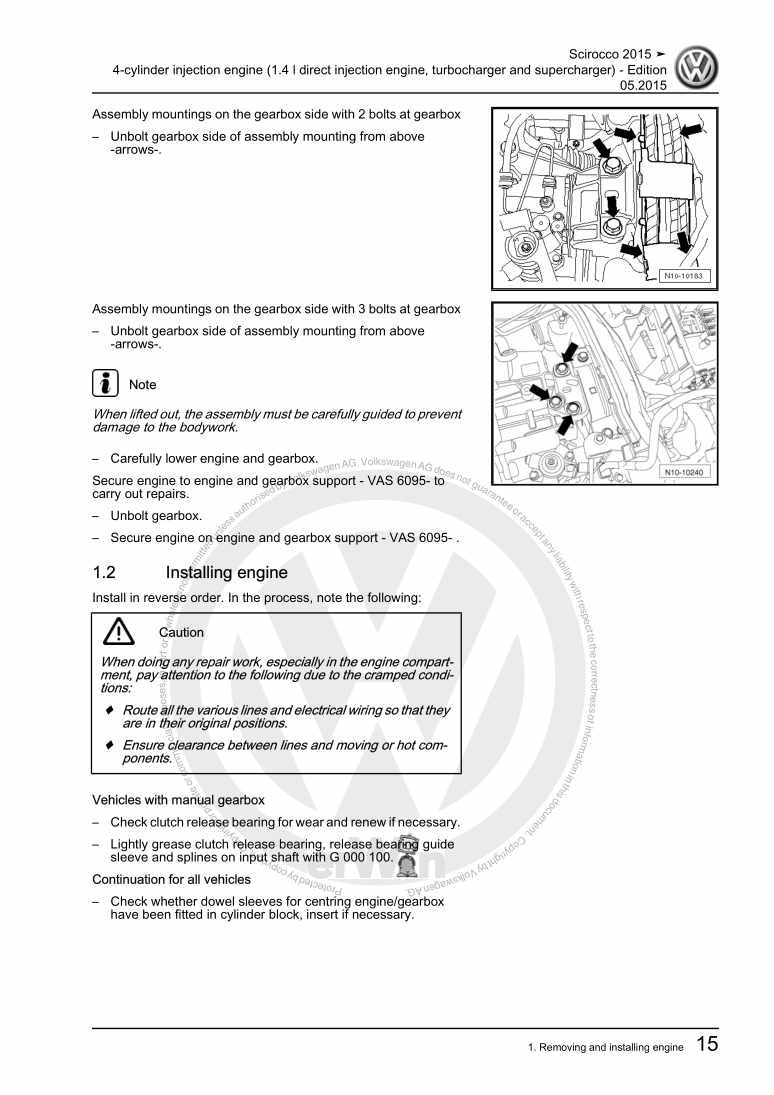

201.4 Installing engine

222 Assembly mountings

252.1 Assembly overview - assembly mountings

252.2 Supporting engine in installation position

272.3 Removing and installing engine mounting

312.4 Removing and installing gearbox mounting

322.5 Removing and installing pendulum support

342.6 Checking adjustment of assembly mountings

352.7 Adjusting assembly mountings

353 Engine cover panel

383.1 Removing and installing engine cover

38Crankshaft group

391 Cylinder block (pulley end)

391.1 Assembly overview - cylinder block (pulley end)

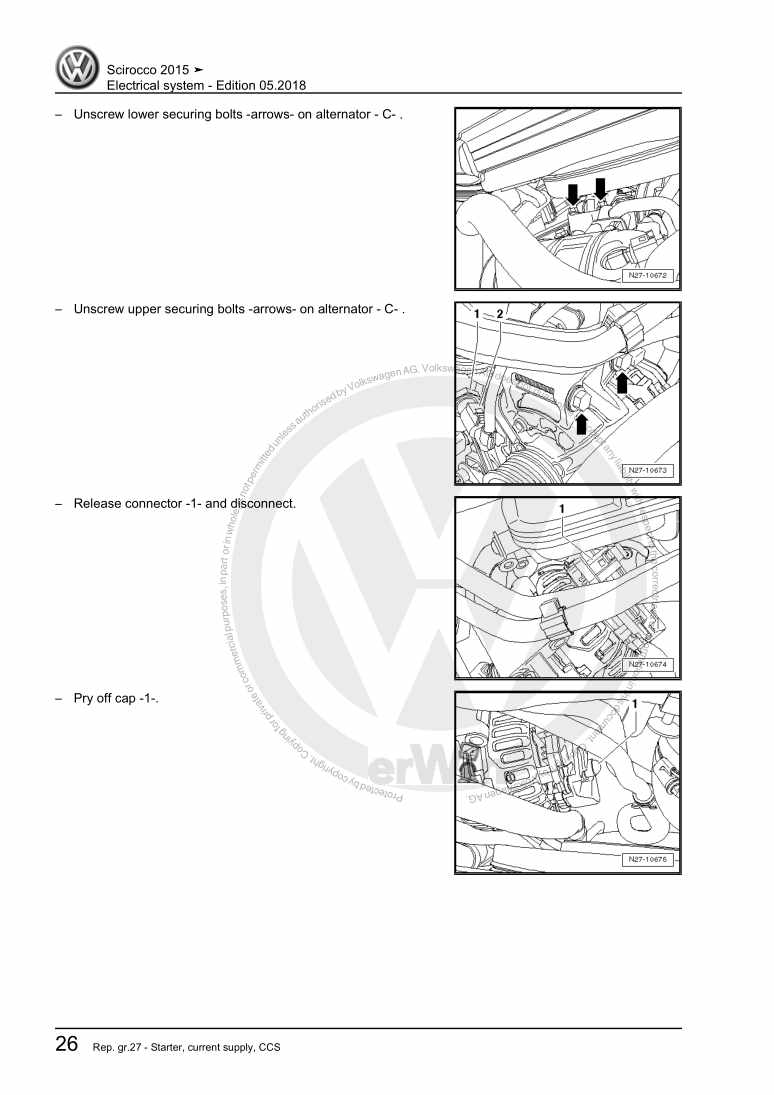

391.2 Removing and installing poly-V belt

421.3 Removing and installing tensioner for poly V-belt

431.4 Removing and installing bracket for ancillaries

461.5 Removing and installing vibration damper

481.6 Removing and installing engine support

562 Cylinder block, gearbox end

582.1 Assembly overview - cylinder block, gearbox end

582.2 Removing and installing flywheel

592.3 Removing and installing sealing flange on gearbox side

613 Crankshaft

703.1 Assembly overview - crankshaft

703.2 Crankshaft dimensions

723.3 Allocation of main bearing shells

723.4 Renewing needle bearing in crankshaft

743.5 Measuring axial clearance of crankshaft

763.6 Measuring radial clearance of crankshaft

773.7 Removing and installing sender wheel

784 Balancer shaft

804.1 Assembly overview - balance shaft

804.2 Removing and installing balance shaft

835 Pistons and conrods

915.1 Assembly overview - pistons and conrods

915.2 Removing and installing pistons

955.3 Removing and installing oil spray jets

975.4 Checking pistons and cylinder bores

985.5 Separating new conrod

1015.6 Checking radial clearance of conrods

101Cylinder head, valve gear

1031 Cylinder head

1031.1 Assembly overview - cylinder head

1031.2 Renewing oil non-return valve in cylinder head

1071.3 Removing and installing cylinder head

1081.4 Checking compression

1251.5 Removing and installing vacuum pump

1272 Cover for timing chain

1292.1 Assembly overview - cover for timing chain

1292.2 Removing and installing upper timing chain cover

1312.3 Removing and installing timing chain cover (bottom)

1342.4 Renewing seal for vibration damper

1393 Chain drive

1433.1 Assembly overview - camshaft timing chains

1433.2 Removing and installing camshaft timing chain

1443.3 Removing and installing drive chain for balance shaft

1613.4 Checking valve timing

1624 Valve gear

1654.1 Assembly overview - valve gear

1654.2 Removing and installing camshaft

1684.3 Removing and installing camshaft control valve 1 N205

1874.4 Measuring axial play of camshaft

1874.5 Renewing valve stem seals

1885 Inlet and exhaust valves

2015.1 Checking valve guides

201Lubrication

2031 Sump, oil pump

2031.1 Assembly overview - sump/oil pump

2031.2 Removing and installing lower part of sump

2061.3 Removing and installing oil pump

2091.4 Removing and installing upper part of sump

2111.5 Engine oil:

2162 Engine oil cooler

2182.1 Removing and installing engine oil cooler

2183 Crankcase ventilation

2203.1 Removing and installing oil separator

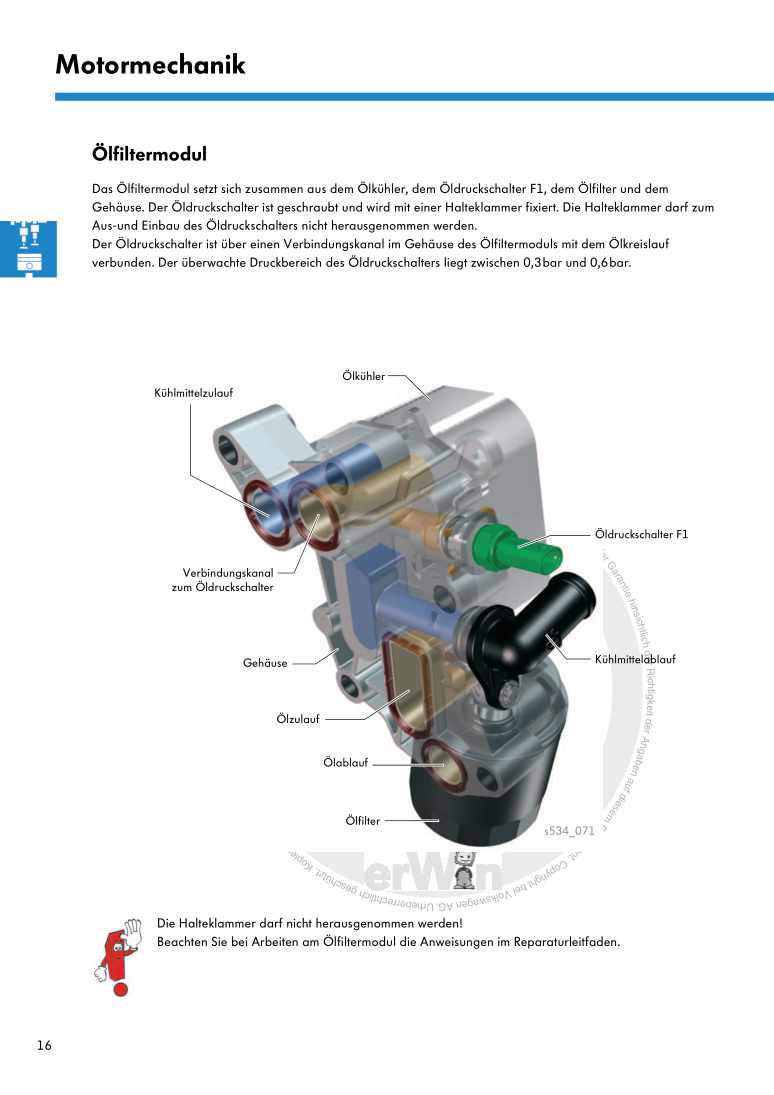

2204 Oil filter, oil pressure switch

2214.1 Assembly overview - oil filter/oil pressure switch

2214.2 Removing and installing oil pressure regulating valve N428

2234.3 Removing and installing oil pressure switch F1

2234.4 Removing and installing oil pressure switch for reduced oil pressure F378

2254.5 Checking oil pressure

226Cooling

2301 Cooling system/coolant

2301.1 Connection diagram - coolant hoses

2301.2 Draining and adding coolant

2311.3 Checking cooling system for leaks

2372 Coolant pump, regulation of cooling system

2422.1 Assembly overview - coolant pump, thermostat

2422.2 Assembly overview - electric coolant pump

2452.3 Removing and installing electric coolant pump

2462.4 Removing and installing coolant pump with thermostat housing

2482.5 Removing and installing coolant pump on thermostat housing

2502.6 Removing and installing thermostat

2532.7 Removing and installing toothed belt for coolant pump

2562.8 Renewing oil seal for coolant pump drive

2592.9 Removing and installing coolant temperature sender G62

2613 Coolant pipes

2643.1 Assembly overview - coolant pipes

2643.2 Removing and installing lower coolant pipes

2643.3 Removing and installing upper coolant pipes

2664 Radiator, radiator fan

2704.1 Assembly overview - radiator/radiator fan

2704.2 Removing and installing radiator

2704.3 Removing and installing radiator cowl

2714.4 Removing and installing radiator fan V7 and radiator fan 2 V177

273Turbocharging/supercharging

2751 Turbocharger

2751.1 Assembly overview - turbocharger

2751.2 Removing and installing turbocharger

2801.3 Checking vacuum unit for turbocharger

2871.4 Renewing vacuum unit for turbocharger

2892 Charge air system

2902.1 Schematic overview - charge air system

2902.2 Assembly overview - charge air system

2912.3 Assembly overview - charge-air hose connections

2922.4 Removing and installing charge air cooler

2932.5 Checking charge air system for leaks

295Mixture preparation - injection

2991 Injection system

2991.1 Overview of fitting locations - injection system

2992 Injectors

3062.1 Assembly overview - fuel rail with injectors

3062.2 Removing and installing injectors

3082.3 Renewing seals on injectors

3122.4 Cleaning injectors

3143 Air filter

3173.1 Assembly overview - air filter housing

3173.2 Removing and installing air filter housing

3194 Intake manifold

3204.1 Assembly overview – intake manifold

3204.2 Removing and installing intake manifold with fuel rail

3224.3 Removing and installing fuel rail

3294.4 Removing and installing throttle valve module J338

3304.5 Cleaning throttle valve module

3324.6 Checking intake manifold change-over

3335 Senders and sensors

3365.2 Removing and installing air mass meter G70

3365.3 Removing and installing fuel pressure sender G247

3375.4 Checking fuel pressure sender G247

3396 Engine (motor) control unit

3446.1 Removing and installing engine control unit J623

3447 High-pressure pump

3507.1 Assembly overview - high-pressure pump

3507.2 Removing and installing high-pressure pump

352Exhaust system

3551 Exhaust pipes and silencers

3551.1 Assembly overview – silencers

3551.2 Separating exhaust pipes from silencers

3571.3 Aligning exhaust system free of stress

3591.4 Installation position of clamp

3601.5 Checking exhaust system for leaks

3612 Emission control

3622.1 Assembly overview – emission control

3622.2 Removing and installing catalytic converter

3643 Exhaust manifold

367Ignition system

3681 Ignition system

3681.1 Assembly overview - ignition system

3681.2 Removing and installing ignition coils with output stage

3691.3 Removing and installing knock sensor 1 G61

3701.4 Removing and installing engine speed sender G28

3711.5 Test data, spark plugs

372