Technical data

11 Identification

11.1 Engine number/engine data

12 Safety information

32.1 Safety precautions during work on fuel system

32.2 Safety measures when working on vehicles with a start/stop system

32.4 Safety precautions when working on the cooling system

42.5 Safety precautions when working on the SCR system

52.6 Safety precautions when working on exhaust system

63 Repair instructions

73.1 Rules for cleanliness

73.2 Adapting learnt value for SCR system

73.3 Foreign objects in engine

73.4 Contact corrosion

83.5 Routing and attachment of lines

83.6 Fitting radiator and condensers

8Removing and installing engine

91 Removing and installing engine

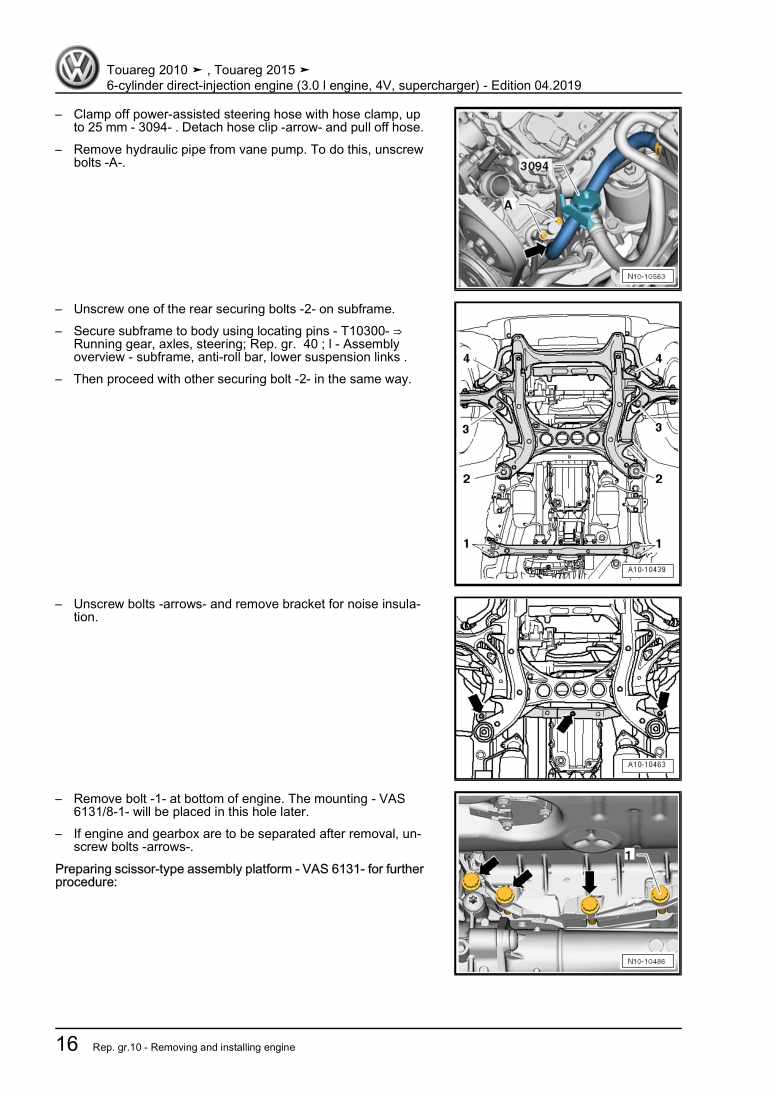

91.1 Removing engine

91.2 Separating engine and gearbox

251.3 Securing engine on engine and gearbox support

351.4 Installing engine

392 Assembly mountings

442.1 Assembly overview – assembly mountings

442.2 Removing and installing engine mounting

462.3 Removing and installing engine mounting

482.4 Supporting engine in installation position

503 Engine cover panel

533.1 Removing and installing engine cover

53Crankshaft group

541 Cylinder block (pulley end)

541.1 Assembly overview - poly V-belt drive

541.2 Assembly overview - sealing flange, belt pulley end

581.3 Removing and installing poly-V belt

641.4 Removing and installing tensioner for poly V-belt

661.5 Removing and installing vibration damper

661.6 Removing and installing bracket for ancillaries

671.7 Renewing crankshaft oil seal - belt pulley end

671.8 Removing and installing sealing flange on pulley end

691.9 Removing and installing cover for sealing flange (pulley end)

732 Cylinder block, gearbox end

752.1 Assembly overview - drive plate

752.2 Removing and installing drive plate

752.3 Removing and installing sender wheel

772.4 Checking sender wheel

772.5 Renewing crankshaft oil seal (gearbox end)

783 Crankshaft

813.1 Assembly overview - crankshaft

813.2 Crankshaft dimensions

833.3 Allocation of main bearing shells

843.4 Measuring axial clearance of crankshaft

853.5 Measuring radial clearance of crankshaft

864 Balancer shaft

874.1 Assembly overview - balance shaft

874.2 Renewing roller bearing for balance shaft

874.3 Removing and installing balance shaft

895 Pistons and conrods

925.1 Assembly overview - pistons and conrods

925.2 Measuring piston projection at “TDC”

965.3 Checking pistons and cylinder bores

985.4 Checking radial clearance of conrods

100Cylinder head, valve gear

1011 Cylinder head

1011.1 Assembly overview - cylinder head

1011.2 Assembly overview - cylinder head cover

1051.3 Removing and installing cylinder head

1081.4 Removing and installing cylinder head cover

1151.5 Removing and installing injector seals

1211.6 Checking compression

1212 Cover for timing chain

1242.1 Assembly overview - cover for timing chain

1242.2 Removing and installing timing chain cover

1283 Chain drive

1373.1 Assembly overview - camshaft timing chains

1373.2 Assembly overview - drive chain for oil pump and high-pressure pump

1393.3 Removing and installing camshaft timing chain

1403.4 Removing camshaft timing chain from camshafts

1533.5 Removing and installing drive chain for oil pump and high-pressure pump

1644 Valve gear

1684.1 Assembly overview - valve gear

1684.2 Measuring axial play of camshaft

1714.3 Measuring radial play of camshaft

1724.4 Removing and installing camshaft

1734.5 Checking hydraulic compensation elements

2054.6 Removing and installing valve stem oil seals

2075 Inlet and exhaust valves

2175.1 Reworking valve seats

2175.2 Checking valve guides

2175.3 Checking valves

2185.4 Valve dimensions

218Lubrication

2201 Sump, oil pump

2201.1 Assembly overview - sump/oil pump

2201.2 Engine oil:

2251.3 Removing and installing lower part of sump

2271.4 Removing and installing upper part of sump

2321.5 Removing and installing oil pump

2361.6 Removing and installing oil level and oil temperature sender

2382 Oil filter, oil pressure switch

2402.1 Assembly overview - oil filter housing, oil pressure switch

2402.2 Removing and installing oil filter housing

2422.3 Removing and installing oil pressure regulating valve N428

2442.4 Checking oil pressure and oil pressure switch

2442.5 Removing and installing oil pressure switch

2463 Engine oil cooler

2483.1 Assembly overview - engine oil cooler

2483.2 Removing and installing engine oil cooler

2493.3 Removing and installing mounting plate for engine oil cooler/coolant shut-off valve

2503.4 Removing and installing temperature regulator for engine oil cooler

251Cooling

2531 Cooling system/coolant

2531.1 Connection diagram - coolant hoses

2531.2 Checking cooling system for leaks

2551.3 Draining and adding coolant

2571.4 Draining cooling system

2651.5 Checking filling quality

2672 Coolant pump, regulation of cooling system

2692.1 Assembly overview - coolant pump

2692.2 Assembly overview - coolant shut-off valve

2702.3 Assembly overview - coolant temperature sender

2702.4 Removing and installing coolant pump

2712.5 Removing and installing thermostat

2722.6 Removing and installing coolant temperature sender G62

2732.7 Removing and installing radiator outlet coolant temperature sender G83

2732.9 Removing and installing coolant shut-off valve

2763 Coolant pipes

2773.1 Assembly overview - coolant pipes

2773.2 Removing and installing coolant pipes

2814 Radiator, radiator fan

2914.1 Assembly overview - radiator/radiator fan

2914.2 Removing and installing radiator cowl with radiator fan

2924.3 Removing and installing radiator module

2934.4 Dismantling radiator module

297Turbocharging/supercharging

2991 Turbocharger

2991.1 Assembly overview - turbocharger

2991.2 Removing and installing turbocharger

3021.3 Removing and installing turbocharger 1 control unit J724

3092 Charge air system

3242.1 Assembly overview - charge air system

3242.2 Assembly overview - charge-air hose connections

3252.3 Removing and installing charge air cooler

3272.4 Removing and installing charge pressure sender G31

3292.5 Removing and installing air intake pipe

3302.6 Checking charge air system for leaks

333Mixture preparation - injection

3411 Injection system

3411.1 Schematic overview - fuel system

3411.2 Overview of fitting locations - injection system

3441.3 Filling/bleeding fuel system

3491.4 Checking fuel system for leaks

3492 Vacuum system

3502.1 Connection diagram – vacuum system

3503 Injectors/high-pressure accumulator (rail)

3513.1 Assembly overview - injectors

3513.2 Adapting correction values for injectors

3543.3 Checking return flow rate of injectors with engine running

3543.4 Checking return flow rate of injectors at starter speed

3563.5 Checking open injectors

3593.6 Checking restrictor in fuel return line

3613.7 Removing and installing injectors

3623.8 Removing and installing high-pressure lines

3674 Air filter

3704.1 Assembly overview - air filter housing

3704.2 Removing and installing air filter housing

3705 Intake manifold

3735.1 Assembly overview – intake manifold

3735.2 Removing and installing intake manifold

3765.3 Removing and installing intake manifold flap motor V157

3815.4 Removing and installing throttle valve module J338

3836 Senders and sensors

3856.1 Removing and installing fuel pressure regulating valve N276

3856.2 Removing and installing fuel pressure sender G247

3876.3 Removing and installing air mass meter G70

3906.4 Removing and installing pressure differential sender G505

3916.5 Removing and installing NOx sender G295

3926.6 Removing and installing NOx sender 2 G687

3936.7 Removing and installing particle sensor G784

3947 Engine control unit

3967.1 Removing and installing engine (motor) control unit J623 with protective housing

3968 High-pressure pump

3988.1 Assembly overview - high-pressure pump

3988.2 Removing and installing high-pressure pump

4009 Lambda probe

4079.1 Assembly overview - Lambda probe

4079.2 Removing and installing Lambda probe 1 before catalytic converter GX10

413Exhaust system

4151 Exhaust pipes and silencers

4151.1 Assembly overview – silencers

4151.2 Replacing tail pipes

4171.3 Aligning exhaust system free of stress

4181.4 Checking exhaust system for leaks

4192 Emission control

4202.1 Assembly overview – emission control

4202.2 Removing and installing catalytic converter

4272.3 Removing and installing particulate filter

4292.4 Removing and installing reduction catalytic converter

4333 SCR system (selective catalytic reduction)

4343.1 Assembly overview – reducing agent tank

4343.2 Assembly overview - delivery module for reducing agent

4343.3 Assembly overview - reducing agent supply line

4363.4 Draining reducing agent tank

4383.5 Removing and installing reducing agent tank

4423.6 Removing and installing reducing agent supply line

4453.7 Removing and installing injector for reduction agent N474

4483.8 Removing and installing pump for reducing agent V437

4523.9 Removing and installing heater element (heater cup)

4543.10 Disconnecting reducing agent supply line

4574 Exhaust manifold

4614.1 Assembly overview - exhaust manifold

4614.2 Removing and installing exhaust manifold

4625 Exhaust gas temperature regulation

4675.1 Assembly overview – exhaust gas temperature regulation

4675.2 Removing and installing parts of exhaust gas temperature regulation

4746 Exhaust gas recirculation

4836.1 Assembly overview – exhaust gas recirculation

4836.2 Removing and installing exhaust gas recirculation control motor V338

4876.3 Removing and installing exhaust gas recirculation cooler

4886.4 Removing and installing exhaust gas recirculation temperature sensor G98

489Glow plug system

4911 Glow plug system

4911.1 Assembly overview – glow plug system

4911.2 Removing and installing glow plug

4911.3 Removing and installing engine speed sender G28

4931.4 Removing and installing Hall sender G40

493