Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with start/stop system

21.4 Safety precautions when working on the cooling system

31.5 Safety precautions when working on exhaust system

32 Identification

52.1 Motor number/motor data

53 Repair instructions

73.1 Rules for cleanliness

73.2 Foreign objects in engine

73.3 Contact corrosion

73.4 Routing and attachment of lines

83.5 Fitting radiator and condensers

84 Technical data

104.1 Coolant

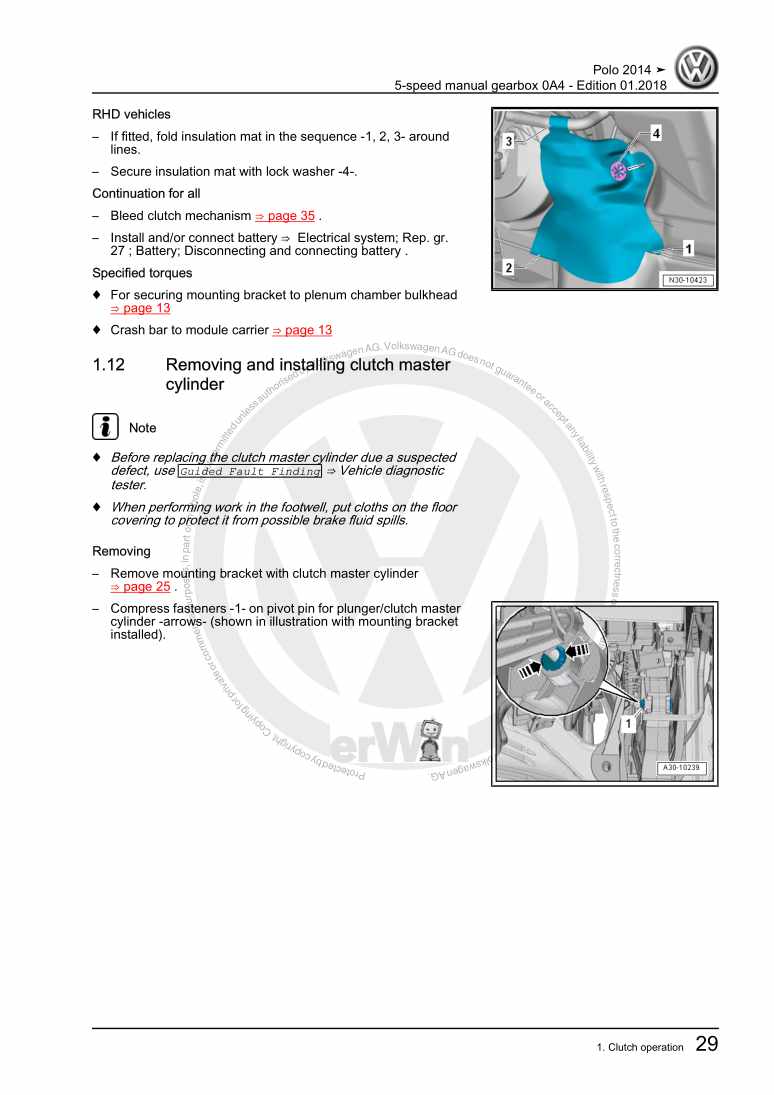

11Removing and installing engine

131 Removing and installing engine

131.1 Removing engine

131.2 Separating engine and gearbox

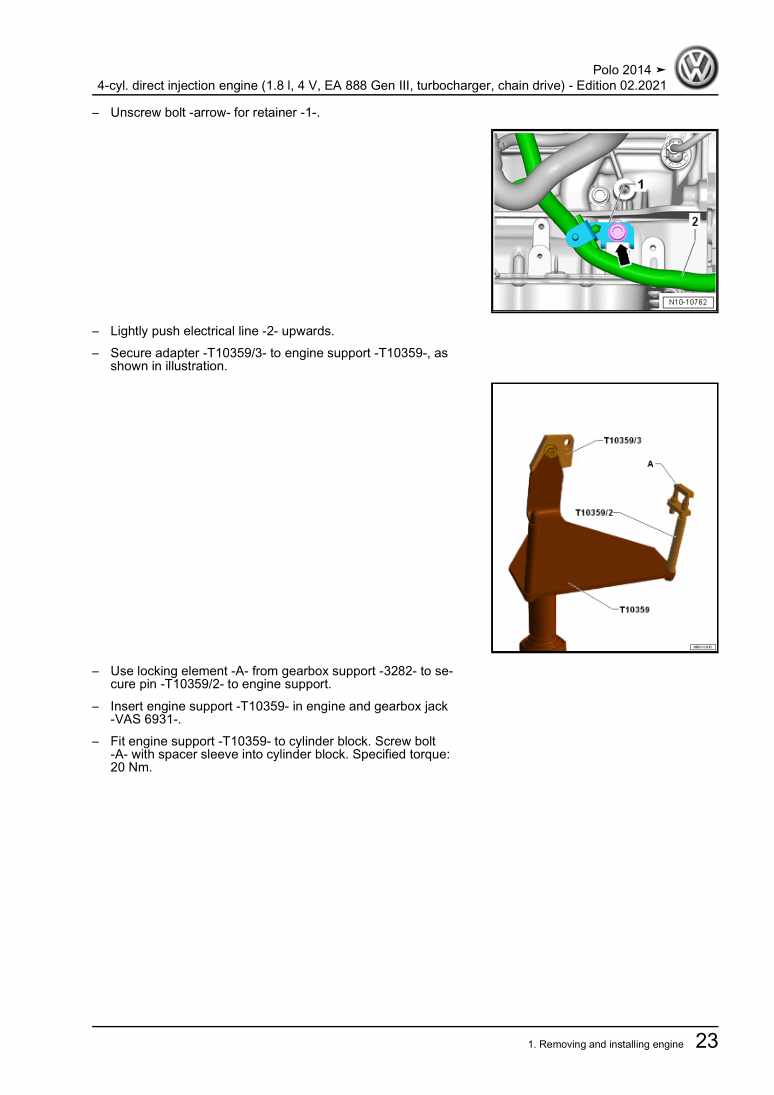

211.3 Securing engine on engine and gearbox support

261.4 Installing engine

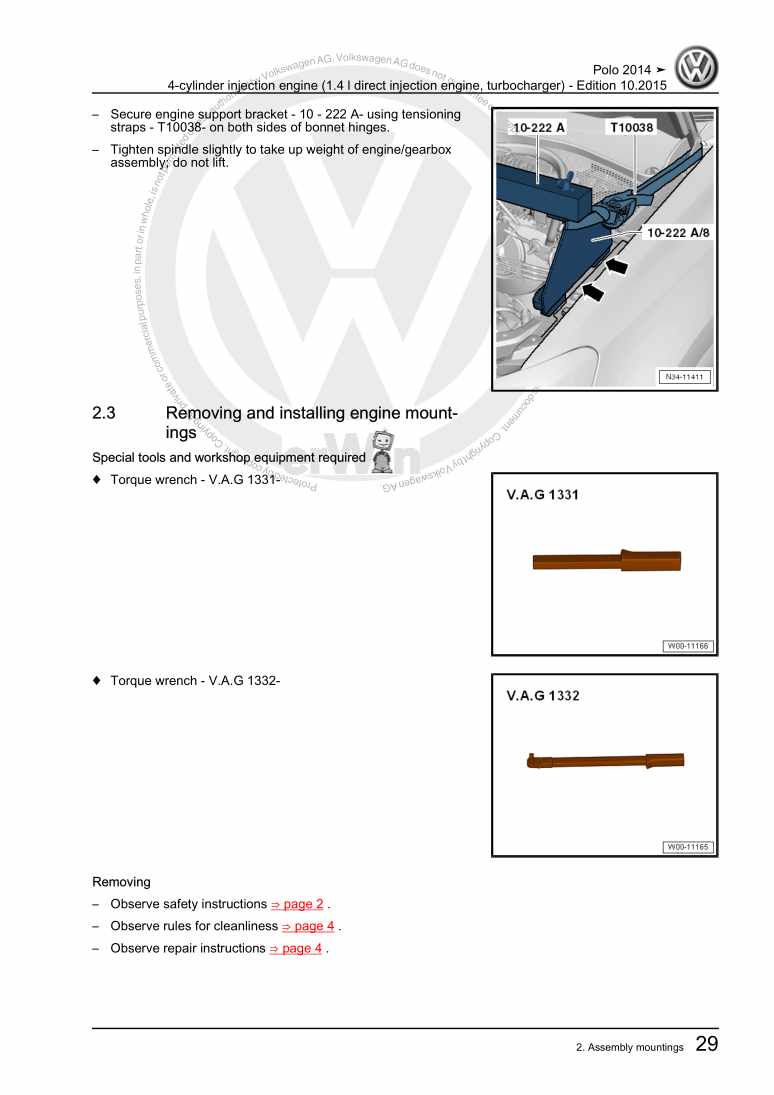

282 Assembly mountings

322.1 Assembly overview - assembly mountings

322.2 Supporting engine in installation position

342.3 Removing and installing engine mounting

362.4 Removing and installing gearbox mounting

372.5 Removing and installing pendulum support

383 Engine cover panel

403.1 Removing and installing engine cover

40Crankshaft group

411 Cylinder block (pulley end)

411.1 Assembly overview - poly V-belt drive

411.2 Assembly overview - sealing flange, belt pulley end

431.3 Removing and installing poly-V belt

441.4 Removing and installing tensioner for poly V-belt

451.5 Removing and installing vibration damper

461.6 Removing and installing bracket for ancillaries

471.7 Removing and installing engine support

491.8 Removing and installing sealing flange on pulley end

512 Cylinder block, gearbox end

542.1 Assembly overview - cylinder block, gearbox end

542.2 Removing and installing flywheel

552.3 Removing and installing sealing flange on gearbox side

583 Crankshaft

713.1 Assembly overview - crankshaft

713.2 Crankshaft dimensions

733.3 Measuring axial clearance of crankshaft

733.4 Renewing needle bearing in crankshaft

744 Pistons and conrods

774.1 Assembly overview - pistons and conrods

774.2 Removing and installing pistons

814.3 Measuring piston projection at TDC

824.4 Checking pistons and cylinder bores

854.5 Checking radial clearance of conrods

87Cylinder head, valve gear

881 Cylinder head

881.1 Assembly overview - cylinder head

881.2 Assembly overview - cylinder head cover

921.3 Removing and installing cylinder head cover

931.4 Removing and installing cylinder head

951.5 Removing and installing injector seals

1031.6 Checking compression

1041.7 Removing and installing camshaft housing

1062 Toothed belt drive

1112.1 Assembly overview - toothed belt cover

1112.2 Assembly overview - toothed belt

1112.3 Removing and installing toothed belt guard

1132.4 Removing toothed belt from camshaft

1152.5 Removing and installing toothed belt

1193 Valve gear

1343.1 Assembly overview - valve gear

1343.2 Measuring axial play of camshaft

1363.3 Removing and installing camshaft oil seal

1373.4 Checking hydraulic compensation elements

1393.5 Removing and installing valve stem seals

1404 Inlet and exhaust valves

1494.1 Checking valve guides

1494.2 Checking valves

1504.3 Valve dimensions

150Lubrication

1511 Sump, oil pump

1511.1 Assembly overview - sump/oil pump

1511.2 Engine oil:

1531.3 Removing and installing oil sump

1531.4 Removing and installing oil pump

1601.5 Removing and installing oil level and oil temperature sender G266

1642 Engine oil cooler

1663 Oil filter, oil pressure switch

1673.1 Assembly overview - oil filter housing, oil pressure switch

1673.2 Removing and installing oil pressure switch F1

1683.3 Checking oil pressure

1693.4 Removing and installing oil filter housing

1703.5 Removing and installing oil pressure regulating valve N428

174Cooling

1761 Cooling system/coolant

1761.1 Connection diagram - coolant hoses

1761.2 Checking cooling system for leaks

1771.3 Draining coolant

1811.4 Filling with coolant

1821.5 Checking filling quality of cooling system

1951.6 Checking electric vacuum pump VAS 6096/2

1971.7 Flushing cooling system

1982 Coolant pump, regulation of cooling system

2232.1 Assembly overview - coolant pump, thermostat

2232.2 Assembly overview - coolant temperature sender

2252.3 Assembly overview - electric coolant pump

2262.4 Removing and installing coolant pump

2272.5 Removing and installing thermostat

2292.6 Removing and installing coolant valve for cylinder head N489

2302.7 Checking thermostat

2312.8 Removing and installing coolant temperature sender G62

2312.9 Removing and installing electric coolant pump

2333 Coolant pipes

2383.1 Assembly overview - coolant pipes

2384 Radiator, radiator fan

2394.1 Assembly overview - radiator/radiator fan

2394.2 Assembly overview – radiator cowl and radiator fan

2414.3 Removing and installing radiator

2424.4 Removing and installing radiator cowl

2484.5 Removing and installing radiator fan

249Turbocharging/supercharging

2521 Turbocharger

2521.1 Assembly overview - turbocharger

2521.2 Removing and installing turbocharger

2571.3 Renewing vacuum unit for turbocharger

2652 Charge air system

2762.1 Assembly overview - charge air system

2762.2 Removing and installing charge air cooler

2782.3 Removing and installing bracket for charge air cooler

2792.4 Removing and installing charge air temperature sender

2802.5 Removing and installing charge pressure sender G31

2812.6 Checking charge air system for leaks

2822.7 Checking charge air cooler for leaks

285Mixture preparation - injection

2911 Injection system

2911.1 Overview of fitting locations - injection system

2911.2 Schematic overview - fuel system

2951.3 Filling/bleeding fuel system

2961.4 Checking fuel system for leaks

2972 Vacuum system

2982.1 Connection diagram – vacuum system

2982.2 Checking vacuum system

2983 Injectors/high-pressure accumulator (rail)

3003.1 Assembly overview - injectors

3003.2 Assembly overview - fuel rail

3023.3 Removing and installing injectors

3033.4 Removing and installing high-pressure lines

3083.5 Testing jammed-open injectors

3113.6 Checking return flow rate of injectors with engine running

3133.7 Removing and installing fuel rail

3154 Air filter

3194.1 Assembly overview - air filter housing

3194.2 Removing and installing air filter housing

3215 Intake manifold

3235.1 Assembly overview – intake manifold

3235.2 Removing and installing throttle valve module J338

3235.3 Removing and installing intake manifold

3256 Senders and sensors

3316.1 Removing and installing fuel temperature sender G81

3316.2 Removing and installing air mass meter G70

3316.3 Removing and installing fuel pressure regulating valve N276

3336.4 Removing and installing fuel pressure sender G247

3346.5 Removing and installing pressure differential sender G505

3366.6 Removing and installing exhaust gas pressure sensor 1 G450

3377 Engine control unit

3397.1 Assembly overview – engine/motor control unit

3397.2 Removing and installing engine control unit J623

3407.3 Removing and installing engine (motor) control unit J623 with protective housing

3418 High-pressure pump

3438.1 Assembly overview - high-pressure pump

3438.2 Removing and installing high-pressure pump

3459 Lambda probe

3519.1 Assembly overview - Lambda probe

3519.2 Removing and installing Lambda probe

352Exhaust system

3571 Exhaust pipes and silencers

3571.1 Assembly overview – silencers

3571.2 Separating exhaust pipes from silencers

3581.3 Removing and installing silencer

3601.4 Removing and installing front exhaust pipe

3611.5 Aligning exhaust system free of stress

3631.6 Installation position of clamp

3641.7 Align end exhaust pipes

3651.8 Checking exhaust system for leaks

3652 Emission control

3662.1 Assembly overview – emission control

3662.2 Removing and installing emission control module

3692.3 Removing and installing particulate filter

3752.4 Removing and installing exhaust flap control unit J883

3783 Exhaust gas temperature regulation

3803.1 Assembly overview – exhaust gas temperature regulation

3803.2 Removing and installing exhaust gas temperature sender

3824 Exhaust gas recirculation

3874.1 Assembly overview – exhaust gas recirculation

3874.2 Removing and installing exhaust gas recirculation cooler

3934.3 Removing and installing exhaust gas recirculation control motor V338

3994.4 Removing and installing exhaust gas recirculation control motor 2 V339

4014.5 Checking exhaust gas recirculation cooler for leaks

403Glow plug system

4041 Glow plug system

4041.1 Assembly overview – glow plug system

4041.2 Removing and installing glow plug

4051.3 Removing and installing automatic glow period control unit J179

4091.4 Removing and installing knock sensor 1 G61

4091.5 Removing and installing Hall sender G40

4101.6 Removing and installing engine speed sender G28

411