Technical data

11 Checklist for evaluating running gear of accident vehicles

12 General information

3Front suspension

41 Appraisal of accident vehicles

42 Servicing front suspension

52.1 Overview - front axle

52.2 Raising wheel suspension to unladen position

63 Subframe, anti-roll bar, suspension links

83.1 Assembly overview: subframe, anti-roll bar, suspension links

83.2 Repairing thread in longitudinal member

113.3 Fixing position of subframe

113.4 Lowering subframe

133.5 Removing and installing subframe without steering rack

173.6 Removing and installing subframe with steering rack

213.7 Repairing subframe

263.8 Checking swivel joint

383.9 Removing and installing swivel joint

383.10 Removing and installing suspension link with mounting bracket

423.12 Renewing bonded rubber bush for suspension link

503.13 Renewing mounting bracket with suspension link bush

523.14 Removing and installing anti-roll bar

544 Assembly overview - wheel bearings

604.1 Removing and installing wheel bearing unit

624.2 Removing and installing wheel bearing housing

645 Assembly overview: suspension strut

695.1 Removing and installing suspension strut

705.2 Repairing suspension strut

766 Removing and installing drive shafts

796.1 Loosening and tightening twelve-point head bolt, with ribbing, securing drive shaft

796.3 Removing and installing drive shaft with constant velocity joint

826.5 Removing and installing right drive shaft with (push-on) constant velocity slip joint

906.7 Removing and installing drive shafts with triple roller joint AAR3300i (pushed into gearbox)

1027 Repairing drive shaft - overview of drive shafts

1077.1 Heat shields for drive shafts

1088 Assembly overview: drive shaft with VL107 constant velocity joint (bolt-on)

1098.1 Dismantling and assembling drive shaft with VL107 constant velocity joint

1118.2 Checking outer constant velocity joint

1158.3 Checking inner constant velocity joint

1169 Assembly overview: drive shaft with VL107 constant velocity slip joint

1189.2 Checking outer constant velocity joint

12410 Assembly overview: drive shaft with triple roller joint AAR3300i

12610.1 Dismantling and assembling drive shaft with triple roller joint AAR3300i

128Rear suspension

1401 Appraisal of accident vehicles

1402 Repairing rear suspension (front-wheel drive)

1412.1 Overview - rear axle

1412.2 Rear axle in unladen position

1433 Assembly overview: subframe up to model year 2010 (front-wheel drive)

1453.1 Removing and installing rear axle

1453.2 Repairing subframe

1494 Assembly overview: transverse link, track rod up to model year 2010 (front-wheel drive)

1544.1 Assembly overview: rear left vehicle level sender G76 , front-wheel drive

1574.2 Removing and installing rear left vehicle level sender G76

1574.3 Removing and installing upper transverse link

1584.4 Removing and installing lower transverse link

1604.5 Removing and installing track rod

1625 Allocation of track rods to trailing arms (front- and four-wheel drive)

1656.1 Assembly overview: rear left vehicle level sender G76 (front-wheel drive)

1696.2 Removing and installing rear left vehicle level sender G76

1696.3 Removing and installing rear axle

1706.4 Removing and installing upper transverse link

1736.5 Removing and installing lower transverse link

1756.6 Removing and installing track rod

1777 Assembly overview: wheel bearing housing, trailing arm (front-wheel drive)

1807.1 Removing and installing wheel bearing housing

1817.2 Renewing bonded rubber bush for wheel bearing housing

1857.3 Removing and installing wheel bearing/wheel hub unit

1877.4 Removing and installing trailing arm with mounting bracket

1907.5 Repairing trailing arm

1948 Assembly overview: shock absorber, coil spring (front-wheel drive)

1978.1 Removing and installing coil spring

1978.2 Removing and installing shock absorbers

1998.3 Repairing shock absorber

2019 Assembly overview: anti-roll bar (front-wheel drive)

2039.1 Removing and installing anti-roll bar

20310 Repairing rear suspension (four-wheel drive)

20610.1 Overview - rear axle

20610.2 Rear axle in unladen position

20811 Assembly overview: subframe, final drive (four-wheel drive)

21011.1 Removing and installing rear axle

21011.2 Repairing subframe, up to Week 21/2012

21511.3 Repairing subframe, as of Week 22/2012

22312 Assembly overview: transverse link, track rod (four-wheel drive)

23712.1 Overview - rear left vehicle level sender G76

24012.2 Removing and installing rear left vehicle level sender G76

24012.3 Removing and installing upper transverse link

24112.4 Removing and installing lower transverse link

24312.5 Removing and installing track rod

24513 Assembly overview: wheel bearing housing, trailing arm (four-wheel drive)

24913.1 Removing and installing wheel bearing housing

25113.2 Renewing bonded rubber bush for wheel bearing housing

25413.3 Removing and installing wheel bearing/wheel hub unit

25713.4 Removing and installing trailing arm with mounting bracket

25813.5 Repairing trailing arm

26114 Assembly overview: shock absorber, coil spring (four-wheel drive)

26414.1 Removing and installing coil spring

26414.2 Removing and installing shock absorbers

26614.3 Repairing shock absorber

26815 Assembly overview: anti-roll bar (four-wheel drive)

27015.1 Removing and installing anti-roll bar

27016 Assembly overview: drive shaft

27316.1 Loosening and tightening twelve-point head bolt, with ribbing, securing drive shaft

27416.3 Removing and installing drive shaft

27716.4 Dismantling and assembling drive shaft

28116.5 Checking inner constant velocity joint

285Self-levelling suspension

2871 Appraisal of accident vehicles

2872 Components of adaptive chassis control DCC and fitting locations

2882.1 Shock absorber damping adjustment button E387

2892.2 Removing and installing front left body acceleration sender G341

2892.3 Removing and installing front right body acceleration sender G342

2902.4 Renewing bracket for front left/right body acceleration sender G341/G342

2912.6 Removing and installing front left/right vehicle level sender G78/G289

2942.11 Removing and installing electronically controlled damping control unit J250

2992.12 Basic setting of adaptive chassis control DCC

2992.13 Cable routing left front axle

3002.14 Cable routing right front axle

3012.15 Cable routing rear axle

3023 Assembly overview: suspension strut for adaptive chassis control DCC

3033.1 Removing and installing suspension strut for adaptive chassis control DCC

3054 Assembly overview: shock absorber for adaptive chassis control DCC (front-wheel drive)

3134.1 Removing and installing rear body acceleration sender G343 (front-wheel drive)

3144.3 Repairing shock absorber for adaptive chassis control DCC (front-wheel drive)

3175 Assembly overview: shock absorber for adaptive chassis control DCC (four-wheel drive)

3205.1 Removing and installing rear body acceleration sender G343 (four-wheel drive)

321Wheels, tyres, vehicle geometry

3271 Appraisal of accident vehicles

3272 Torque settings for wheels

3283 Vehicle alignment check

3293.1 General information

3293.2 Conditions for testing

3313.3 Test preparations

3313.4 Wheel alignment specifications

3323.5 Overview - wheel alignment procedure

3333.6 Correcting front axle camber

3343.7 Adjusting camber on rear axle

3363.8 Adjusting toe at rear axle

3373.9 Adjusting front axle toe

3383.10 Basic setting of steering angle sensor G85

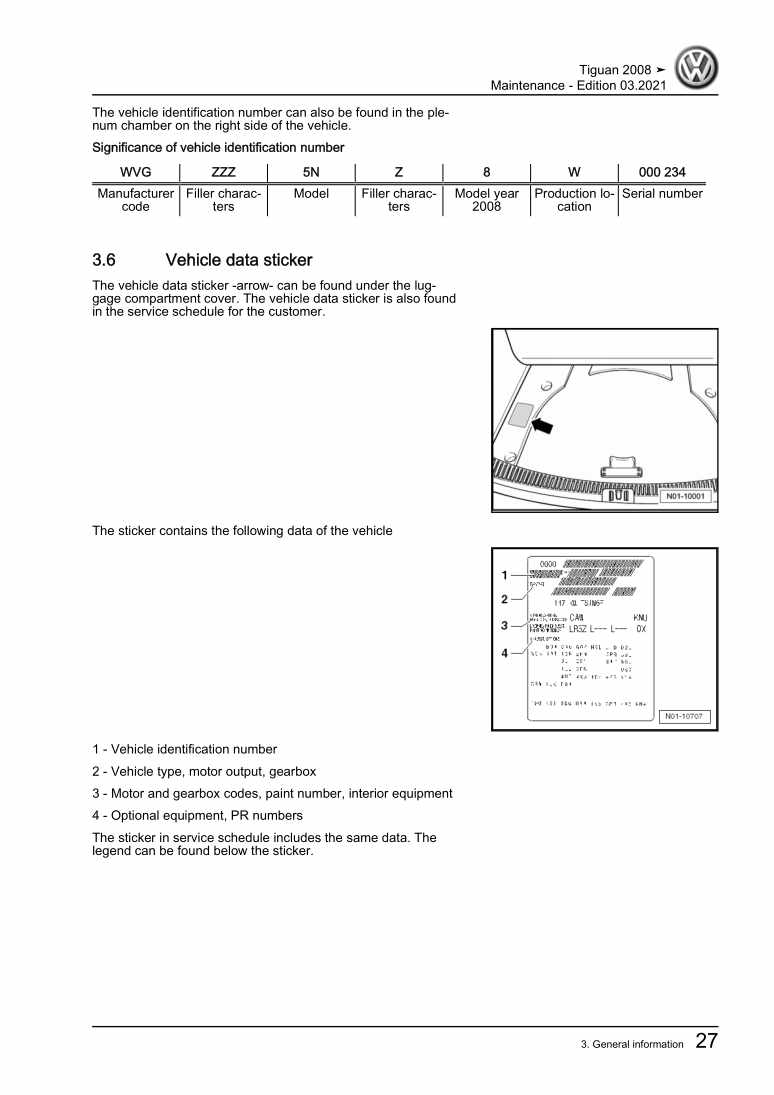

3393.11 Vehicle data sticker

3394 Front camera for driver assist systems R242

3404.1 Adjusting front camera for driver assistance system R242

340Steering

3481 Appraisal of accident vehicles

3482 General repair instructions

3492.1 Steering rack

3492.2 Gaskets and seals

3492.3 Nuts and bolts

3492.4 Electrical components

3502.5 Guided Fault Finding, vehicle self-diagnosis and Test Instruments

3503 Steering column and steering wheel

3513.1 Assembly overview: steering column, left-hand drive

3513.2 Assembly overview: steering column, right-hand drive

3523.3 Removing and installing steering wheel

3523.4 Removing and installing steering column

3553.6 Handling and transporting steering column

3603.7 Checking steering column for damage

3623.8 Removing and installing mounting bracket, RHD

3624 Electromechanical steering rack

3644.1 Assembly overview - electromechanical steering rack, left-hand drive

3644.4 Removing and installing steering rack, left-hand drive vehicle

3694.5 Removing and installing steering rack, right-hand drive vehicle

3785 Differentiating between 2nd and 3rd generation steering racks

3886 Repairing electromechanical steering rack, left-hand drive vehicles

3896.1 Assembly overview: electromechanical steering rack, LHD vehicle

3896.2 Renewing bonded rubber bushes for power-assisted steering rack

3906.3 Removing and installing boot

3926.4 Checking play, security and boots of track rod ends

3946.5 Removing and installing track rod

3947 Repairing electromechanical steering rack, right-hand drive vehicles

3987.1 Assembly overview: electromechanical steering rack, RHD vehicle

3987.2 Removing and installing boot

3997.3 Checking play, security and boots of track rod ends

4017.4 Removing and installing track rod

401