Technical data

11 Checklist for evaluating running gear of accident vehicles

12 General information

3Front suspension

41 Evaluating accident vehicles

42 Raising wheel suspension to unladen position

53 Overview - front axle

74 Assembly overview: subframe

94.1 Repairing thread in longitudinal member

114.2 Fixing position of subframe and brackets

114.3 Lowering subframe

134.4 Removing and installing subframe without steering rack

164.5 Removing and installing subframe with steering rack

204.6 Repairing subframe

255 Assembly overview: front wheel suspension, suspension link

385.1 Checking swivel joint

395.2 Removing and installing swivel joint

405.3 Removing and installing suspension link with mounting bracket

435.5 Renewing bonded rubber bush for suspension link

525.6 Renewing mounting bracket with suspension link bush

546 Assembly overview: wheel bearing

576.1 Removing and installing wheel bearing unit

586.2 Removing and installing wheel bearing housing

607 Assembly overview: anti-roll bar

677.1 Removing and installing anti-roll bar

678 Assembly overview: suspension strut

728.1 Removing and installing suspension strut

738.2 Repairing suspension strut

799 Assembly overview - subframe strut

829.1 Removing and installing subframe strut

8210 Removing and installing drive shafts

8410.1 Loosening and tightening twelve-point bolt for drive shaft connection

8410.2 Removing and installing drive shaft with constant velocity joint

8510.3 Removing and installing drive shafts with triple roller joint AAR2600i

8910.4 Removing and installing drive shafts with triple roller joint AAR3300i

9211 Repairing drive shafts - overview of drive shafts

9711.1 Heat shield for drive shafts

9812 Assembly overview: drive shaft with VL100 constant velocity joint

9912.1 Dismantling and assembling drive shaft with VL100 constant velocity joint

10112.2 Checking outer constant velocity joint

10512.3 Checking inner constant velocity joint

10613 Assembly overview: drive shaft with VL107 constant velocity joint

10913.1 Dismantling and assembling drive shaft with VL107 constant velocity joint

11114 Assembly overview: drive shaft with triple roller joint AAR2600i

11614.1 Dismantling and assembling drive shaft with triple roller joint AAR2600i

11715 Assembly overview: drive shaft with triple roller joint AAR3300i

12215.1 Dismantling and assembling drive shaft with triple roller joint AAR3300i

123Rear suspension

1291 Evaluating accident vehicles

1292 Rear axle in unladen position

1303 Overview - rear axle

1324 Assembly overview: subframe, transverse links track rod

1344.1 Fixing position of subframe

1364.2 Lowering rear axle

1374.3 Assembly overview: rear left vehicle level sender G76

1404.4 Removing and installing rear left vehicle level sender G76

1414.5 Removing and installing rear axle

1424.6 Subframe bracket

1484.7 Removing and installing upper transverse link

1494.8 Removing and installing lower transverse link

1514.9 Removing and installing track rod

1525 Assembly overview: wheel bearing housing, trailing arm

1555.1 Removing and installing wheel bearing housing

1565.2 Renewing bonded rubber bush for wheel bearing housing

1595.3 Removing and installing wheel bearing unit

1625.4 Removing and installing wheel bearing pre-seal

1655.5 Removing and installing trailing arm with mounting bracket

1675.6 Repairing trailing arm

1716 Assembly overview: shock absorber, coil spring

1756.1 Removing and installing coil spring

1756.2 Removing and installing shock absorbers

1776.3 Repairing shock absorber

1797 Assembly overview: anti-roll bar

1817.1 Removing and installing anti-roll bar

1818 Assembly overview - tie bars

1848.1 Removing and installing radius rods

184Self-levelling suspension

1861 Appraisal of accident vehicles

1862 Components of adaptive chassis control DCC and fitting locations

1872.1 Shock absorber damping adjustment button E387

1882.2 Removing and installing front left and right body acceleration senders G341/G342

1882.3 Renewing bracket for front left/right body acceleration sender G341/G342

1892.5 Removing and installing front left/right vehicle level sender G78/G289

1922.6 Assembly overview: rear left vehicle level sender G76 for adaptive chassis control DCC

1932.8 Removing and installing electronically controlled damping control unit J250

1952.9 Basic setting of adaptive chassis control DCC

1962.10 Cable routing left front axle

1972.11 Cable routing right front axle

1982.12 Cable routing rear axle

1993 Assembly overview: suspension strut for adaptive chassis control DCC

2003.1 Removing and installing suspension strut for adaptive chassis control DCC

2014 Assembly overview: shock absorber for adaptive chassis control DCC

2094.1 Removing and installing rear body acceleration sender G343

2104.2 Removing and installing shock absorber for adaptive chassis control DCC

2114.3 Repairing shock absorber for adaptive chassis control DCC

213Wheels, tyres, vehicle geometry

2161 Evaluating accident vehicles

2162 Specified torques for wheel bolts

2173 Position of anti-theft wheel bolts for steel wheels

2184 Fitting wheel and tyre

2194.1 General information

2194.2 Fittings instructions

2195 Tyre pressure monitor display

2215.1 General information

2215.2 System fault in the ABS system

2225.3 Perform basic settings

2226 Vehicle alignment check

2236.1 General information

2236.2 Prerequisites for testing

2256.3 Test preparations

2256.4 Wheel alignment specifications

2266.5 Overview - wheel alignment procedure

2276.6 Correcting front axle camber

2286.7 Adjusting camber on rear axle

2296.8 Adjusting toe at rear axle

2316.9 Adjusting front axle toe

2326.10 Basic setting of steering angle sensor G85

2336.11 Vehicle data sticker

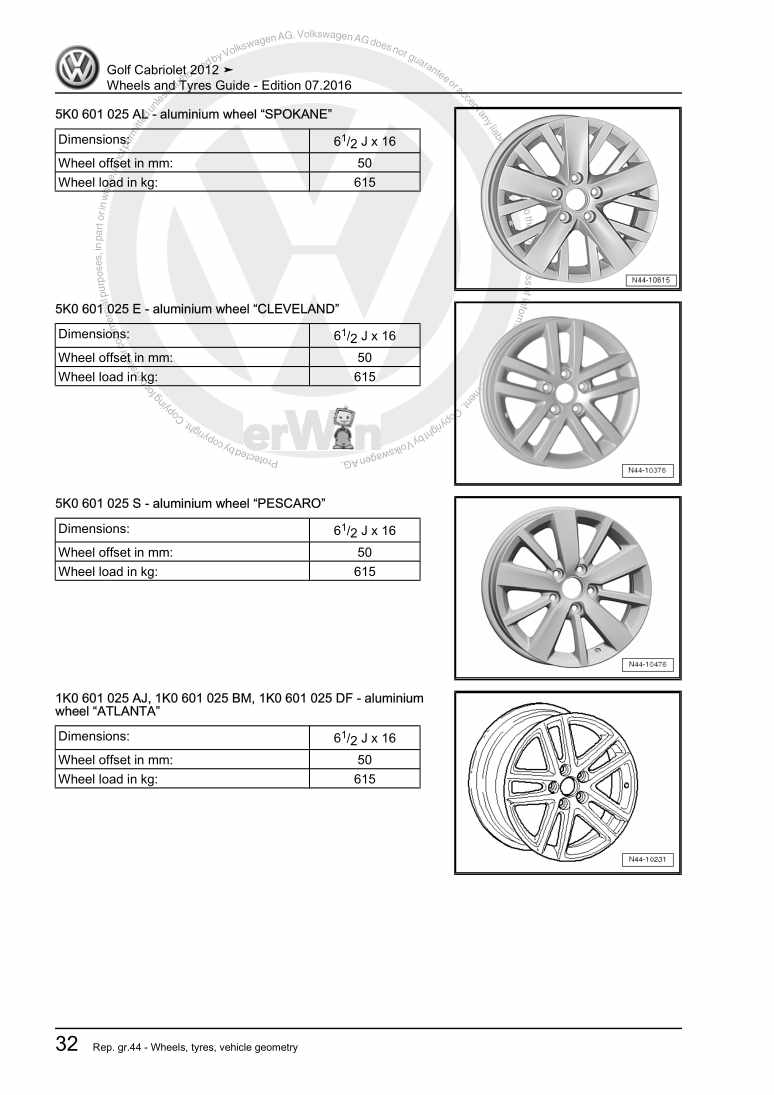

2337 Wheels, tyres

2347.1 Models with breakdown set

2347.2 Tyre sealant

2347.3 Removing a tyre

2347.4 Fitting a new tyre

2357.5 Tyre sealant disposal

2358 Instructions for changing or fitting wheels

2368.1 Fitting wheels

2379 Protecting wheel centring seat against corrosion

23810 Vibration due to wheels/tyres - causes and rectification

23910.1 Causes of rough running

23910.2 Balancing wheels

23910.3 Conducting a road test before balancing wheels

23910.4 Balancing wheels on stationary wheel balancing machine

24010.5 Vibration control system VAS 6230 A

24310.6 Finish balancer

24310.7 Radial and lateral runout of wheels and tyres

24410.9 Checking radial and lateral run-out on wheel rim

24510.10 Matching

24610.11 Flat spots caused by storage or handling

247Steering

2491 Evaluating accident vehicles

2492 General repair instructions

2502.1 Steering rack

2502.2 Gaskets and seals

2502.3 Nuts and bolts

2502.4 Electrical components

2512.5 Guided Fault Finding, vehicle self-diagnosis and Test Instruments

2513 Assembly overview - airbag and steering wheel

2523.1 Removing and installing airbag and steering wheel

2524.2 Handling and transporting steering column

2644.3 Checking steering column for damage

2655.1 Removing and installing steering column, left-hand drive, vehicle with knee airbag

2665.2 Handling and transporting steering column

2755.3 Checking steering column for damage

2766 Electromechanical steering rack, LHD vehicle

2776.1 Assembly overview - electromechanical steering rack, left-hand drive

2776.2 Removing and installing steering rack, left-hand drive vehicle

2787 Repairing electromechanical power steering rack

2867.1 Assembly overview: electromechanical steering rack

2867.2 Removing and installing track rod

2877.3 Removing and installing track rod ball joint

2907.4 Removing and installing boot

2917.5 Checking play, security and boots of track rod ends

2947.6 Checking and adjusting track rod length

2947.7 Allocation of track rod ball joints

295