Technical data

11 Checklist for evaluating running gear of accident vehicles

12 General information

3Front suspension

41 Appraisal of accident vehicles

42 Raising wheel suspension to unladen position

53 Overview - front axle

74 Assembly overview: subframe, anti-roll bar, suspension links

84.1 Assembly overview: front left vehicle level sender G78

124.2 Removing and installing front left vehicle level sender G78

124.3 Repairing thread in longitudinal member

134.4 Fixing position of subframe and brackets

144.5 Lowering subframe

154.6 Removing and installing subframe without steering rack

194.7 Removing and installing subframe with steering rack

234.8 Repairing subframe

284.9 Checking swivel joint

404.10 Removing and installing swivel joint

404.11 Removing and installing suspension link with mounting bracket

444.13 Renewing bonded rubber bush for suspension link

534.14 Renewing mounting bracket with suspension link bush

564.15 Removing and installing anti-roll bar

575 Assembly overview: wheel bearing

645.1 Removing and installing wheel bearing unit

655.2 Removing and installing wheel bearing housing

686 Assembly overview: suspension strut

746.1 Removing and installing suspension strut

756.2 Repairing suspension strut

827 Removing and installing drive shafts

857.1 Loosening and tightening drive shaft hexagon bolt

857.2 Loosening and tightening twelve-point head bolt, with ribbing, securing drive shaft

867.4 Removing and installing drive shaft with constant velocity joint

897.6 Removing and installing right drive shaft with (push-on) constant velocity slip joint

977.7 Removing and installing drive shafts with triple roller joint AAR2600i

1037.8 Removing and installing drive shafts with triple roller joint AAR3300i

1077.9 Removing and installing intermediate shaft

1118 Repairing drive shaft - overview of drive shafts

1138.1 Heat shields for drive shafts

1159 Assembly overview: drive shaft with VL90 or VL100 constant velocity joint

1169.1 Dismantling and assembling drive shaft with VL90 or VL100 constant velocity joint

1189.2 Checking outer constant velocity joint

1229.3 Checking inner constant velocity joint

12310 Assembly overview: drive shaft with VL107 constant velocity joint (bolt-on)

12610.1 Dismantling and assembling drive shaft with VL107 constant velocity joint

12910.2 Repairing intermediate shaft

13311 Assembly overview: drive shaft with VL107 constant velocity slip joint (push-on)

13611.1 Dismantling and assembling drive shaft with VL107 (push-on) constant velocity slip joint

13711.2 Checking outer constant velocity joint

14012 Assembly overview: drive shaft with triple roller joint AAR2600i

14212.1 Dismantling and assembling drive shaft with triple roller joint AAR2600i

14413 Assembly overview: drive shaft with triple roller joint AAR3300i

14913.1 Dismantling and assembling drive shaft with triple roller joint AAR3300i

151Rear suspension

1561 Appraisal of accident vehicles

1562 Rear axle in unladen position

1573 Overview - rear axle

1604 Assembly overview: subframe, transverse links track rod

1614.1 Fixing position of subframe

1634.2 Lowering rear axle

1644.4 Removing and installing rear axle

1694.5 Removing and installing upper transverse link

1744.6 Removing and installing lower transverse link

1754.7 Removing and installing track rod

1775 Assembly overview: wheel bearing housing, trailing arm

1805.1 Removing and installing wheel bearing housing

1815.2 Renewing bonded rubber bush for wheel bearing housing

1845.3 Removing and installing wheel bearing/wheel hub unit

1875.4 Removing and installing wheel bearing pre-seal

1905.5 Removing and installing trailing arm with mounting bracket

1925.6 Repairing trailing arm

1966 Assembly overview: shock absorber, coil spring

2006.1 Removing and installing coil spring

2006.2 Removing and installing shock absorbers

2026.3 Repairing shock absorber

2047 Assembly overview: anti-roll bar

2067.1 Removing and installing anti-roll bar

2068 Assembly overview: subframe attachments, Touran BlueMotion

209Self-levelling suspension

2101 Evaluating accident vehicles

2102 Components of adaptive chassis control DCC and fitting locations

2112.1 Shock absorber damping adjustment button E387

2122.2 Removing and installing front left and right body acceleration senders G341/G342

2122.3 Renewing bracket for front left/right body acceleration sender G341/G342

2132.5 Removing and installing front left/right vehicle level sender G78/G289

2162.6 Assembly overview: rear left vehicle level sender G76 for adaptive chassis control DCC

2172.8 Removing and installing electronically controlled damping control unit J250

2192.10 Basic setting of adaptive chassis control DCC

2202.11 Cable routing left front axle

2202.12 Cable routing right front axle

2222.13 Cable routing rear axle

2233 Assembly overview: suspension strut for adaptive chassis control DCC

2243.1 Removing and installing suspension strut for adaptive chassis control DCC

2264 Assembly overview: shock absorber for adaptive chassis control DCC

2354.1 Removing and installing rear body acceleration sender G343

2364.2 Removing and installing shock absorber for adaptive chassis control DCC

2374.3 Repairing shock absorber for adaptive chassis control DCC

239Wheels, tyres, vehicle geometry

2421 Appraisal of accident vehicles

2422 Specified torques for wheel bolts

2433 Fitting wheel and tyre

2443.1 General information

2443.2 Fittings instructions

2444 Removing and fitting tyres (wheels with tyre pressure monitoring)

2464.2 Wheel change

2464.3 Pressing tyre off wheel rim

2474.4 Removing tyre from wheel

2484.5 Fitting tyre to wheel rim

2485 Removing and fitting tyres with run-flat properties to wheel rims

2505.1 Safety information

2505.2 Fittings instructions

2505.3 Pressing tyre off wheel rim

2515.4 Removing tyre from wheel

2525.5 Fitting tyre to wheel rim

2536 Tyre pressure monitor display

2566.1 System fault in the ABS system

2566.2 Perform basic settings

2577 Tyre pressure monitor

2587.1 Button behaviour

2587.2 Assembly overview: tyre pressure sensor

2597.3 Removing and installing tyre pressure sensor

2608 Vehicle alignment check

2628.1 General information

2628.2 Test requirements

2648.3 Test preparations

2648.4 Wheel alignment specifications

2658.5 Overview - wheel alignment procedure

2678.6 Correcting front axle camber

2688.7 Adjusting camber on rear axle

2698.8 Adjusting toe at rear axle

2718.9 Adjusting front axle toe

2728.10 Basic setting of steering angle sensor G85

2738.11 Vehicle data sticker

2739 Wheels, tyres

2749.1 Models with breakdown set

2749.2 Tyre sealant

2749.3 Removing a tyre

2749.4 Fitting a new tyre

2759.5 Tyre sealant disposal

27510 Instructions for changing or fitting wheels

27610.1 Fitting wheels

27711 Protecting wheel centring seat against corrosion

27812 Vibration due to wheels/tyres - causes and rectification

27912.1 Causes of rough running

27912.2 Balancing wheels

27912.3 Conducting a road test before balancing wheels

27912.4 Balancing wheels on stationary wheel balancing machine

28012.5 Vibration control system VAS 6230 A

28312.6 Finish balancer

28312.7 Radial and lateral runout of wheels and tyres

28412.9 Checking radial and lateral run-out on wheel rim

28512.10 Matching

28612.11 Flat spots caused by storage or handling

28713 Front camera for driver assist systems R242

28913.1 Adjusting front camera for driver assistance system R242

289Steering

2971 Appraisal of accident vehicles

2972 General repair instructions

2982.1 Steering rack

2982.2 Gaskets and seals

2982.3 Nuts and bolts

2982.4 Electrical components

2992.5 Guided fault-finding, vehicle self-diagnosis and test instruments

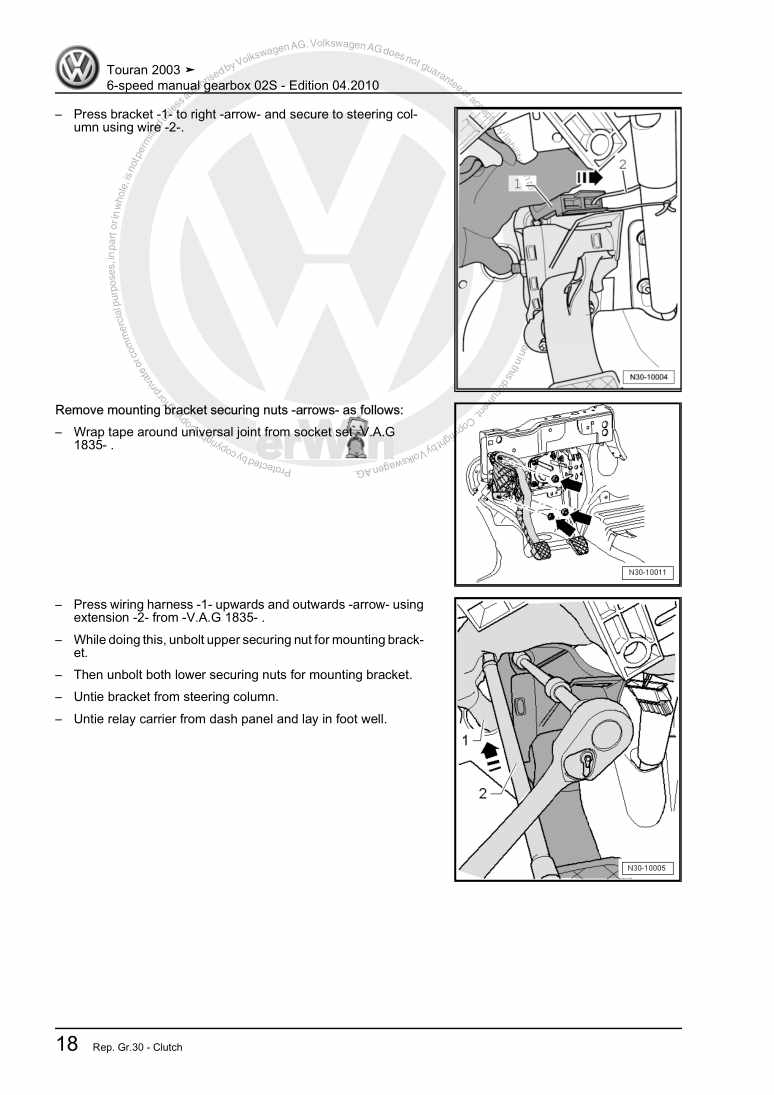

2993 Assembly overview - steering columns up to model year 2010

3003.1 Removing and installing steering rack to model year 2010

3003.2 Removing and installing steering column to model year 2010

3033.3 After the following work, basic settings for steering angle sender G85 must be checked:

3083.4 Handling and transporting steering column, to model year 2010

3093.5 Checking steering column for damage

3103.6 Removing and installing mounting bracket with strut, to model year 2010

3104 Steering wheel, steering column, from model year 2011

3134.1 Assembly overview - airbag steering wheel, from model year 2011

3134.2 Removing and installing airbag and steering wheel

3134.3 Assembly overview - steering column, left-hand drive, from model year 2011

3154.4 Removing and installing steering column, left-hand drive, from model year 2011

3164.5 Assembly overview - steering column, right-hand drive, from model year 2011 . .

3214.7 Handling and transporting steering column, from model year 2011

3284.8 Checking steering column for damage

3295 Electromechanical steering rack, left-hand drive up to model year 2008

3307 Electromechanical steering rack, left-hand drive from model year 2011

3487.2 Removing and installing steering rack, left-hand drive vehicle (APA) from model year 2011

3498 Electromechanical steering rack, right-hand drive up to model year 2008

3579 Electromechanical steering rack, left-hand drive from model year 2009

36810 Differentiating between 1st and 2nd generation steering racks

37611 Differentiating between 2nd and 3rd generation steering racks

37712 Exchanging 1st generation steering rack for 2nd generation steering rack

37813 Repairing electromechanical 1st generation steering rack

37913.1 Removing and installing boot

37913.2 Removing and installing track rod

38114 Repairing electromechanical 2nd and 3rd generation steering racks

38514.1 Assembly overview: electromechanical steering rack

38514.2 Removing and installing boot

38614.3 Checking play, security and boots of track rod ends

38814.4 Removing and installing track rod

38815 Repairing electromechanical steering rack, left-hand drive (APA)

39215.1 Assembly overview: electromechanical steering rack, LHD vehicle

39215.2 Renewing bonded rubber bushes for power-assisted steering rack

39315.3 Removing and installing track rod

39515.4 Removing and installing track rod ball joint

39915.5 Removing and installing boot

40015.6 Checking play, security and boots of track rod ends

40315.7 Allocation of track rod ball joints

403