Technical data

11 Safety information

11.1 Safety precautions when working on a high-voltage system

11.2 Safety precautions when working in the vicinity of high-voltage components

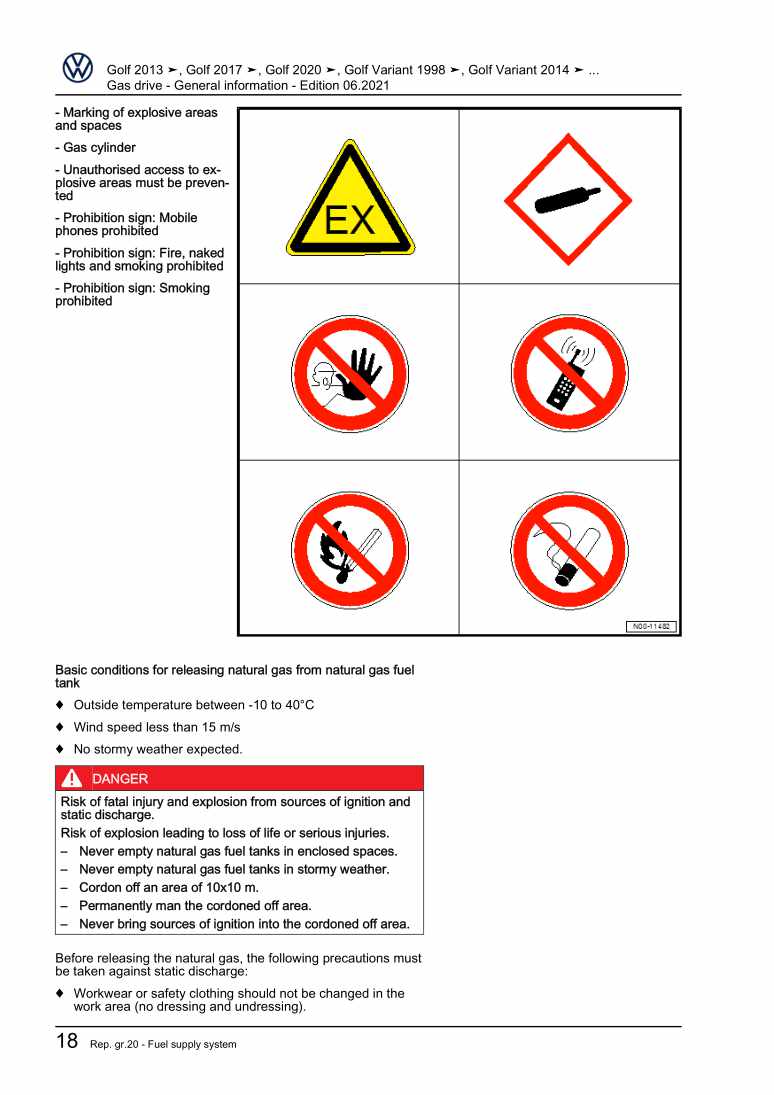

21.3 Safety regulations for working on fuel supply

21.5 Safety precautions when working on ignition system

31.6 Safety precautions when working on the cooling system

32 Identification

42.1 Engine number/engine data

43 Repair notes

63.1 Rules for cleanliness

63.2 Foreign objects in engine

63.3 Contact corrosion

63.4 Pipe/wire routing and attachment

73.5 Fitting radiator and condensers

73.6 Checking vacuum system

74 Classification of dangers of the high-voltage system

8Removing and installing engine

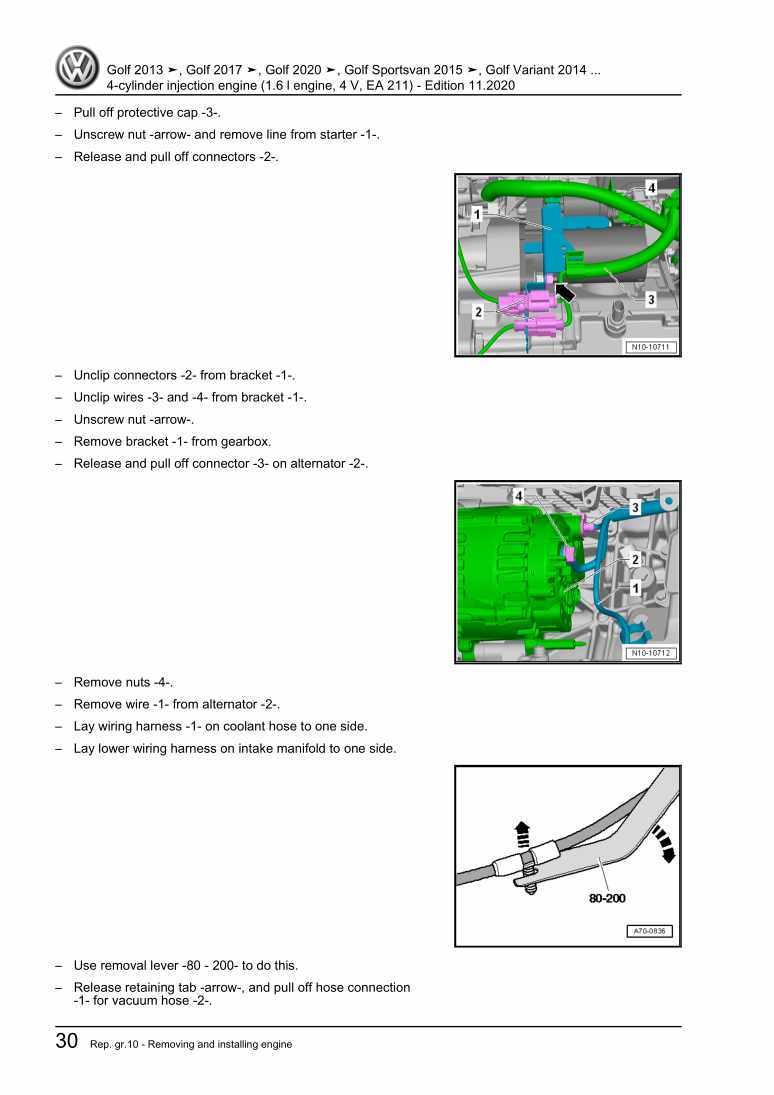

151 Removing and installing engine

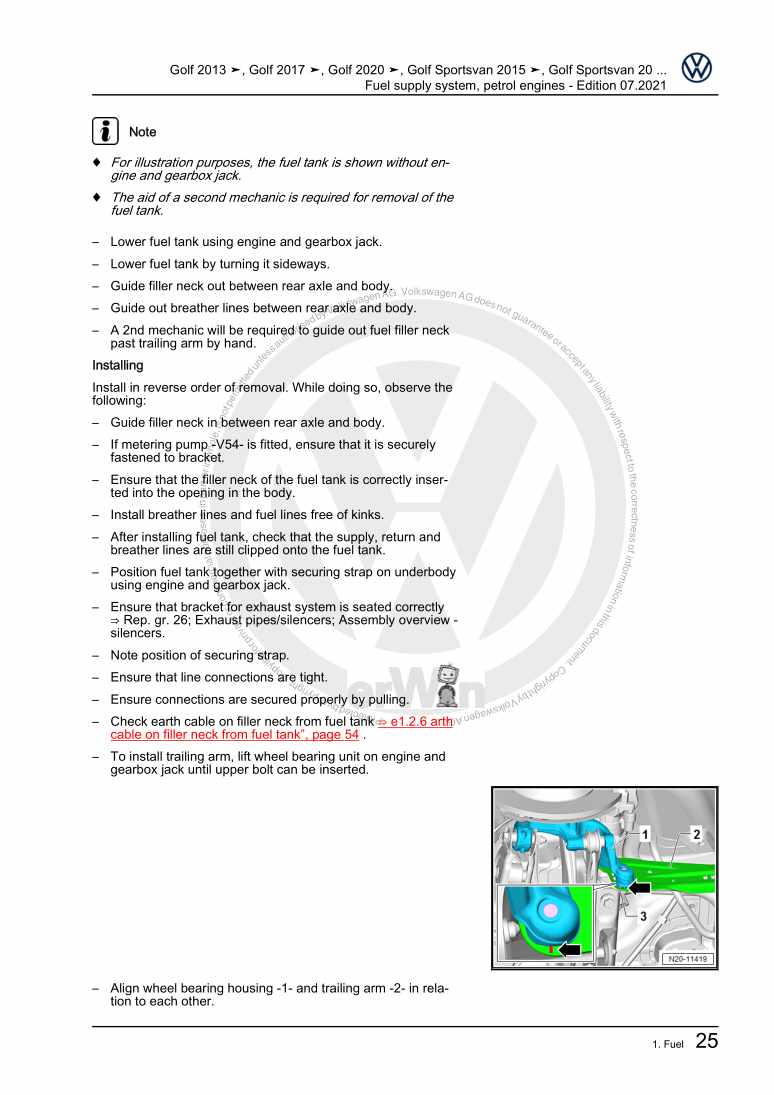

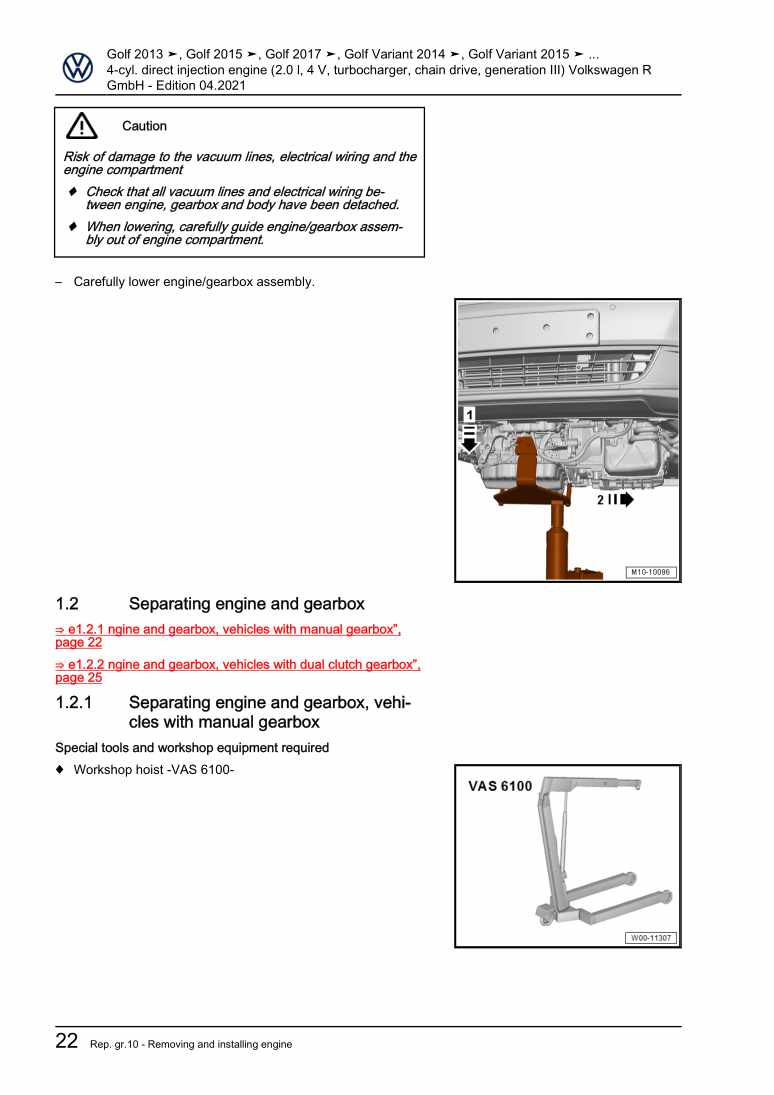

151.1 Removing engine

151.2 Separating engine and gearbox

251.3 Securing engine on engine and gearbox support

271.4 Installing engine

292 Assembly mounting

342.1 Assembly overview - assembly mountings

342.2 Supporting engine in installation position

352.3 Removing and installing motor mounting

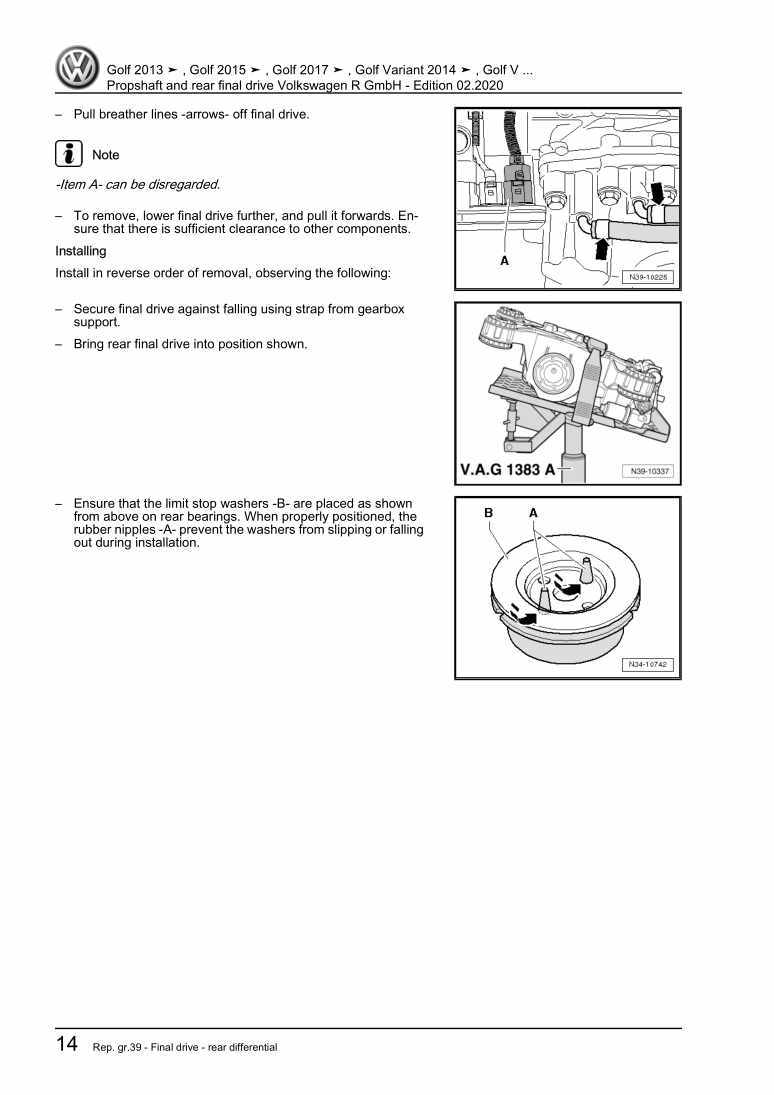

392.4 Removing and installing gearbox mounting

432.5 Removing and installing pendulum support

432.6 Checking adjustment of assembly mountings (engine and gearbox mountings)

442.7 Adjusting assembly mountings

453 Motor cover

473.1 Removing and installing engine cover

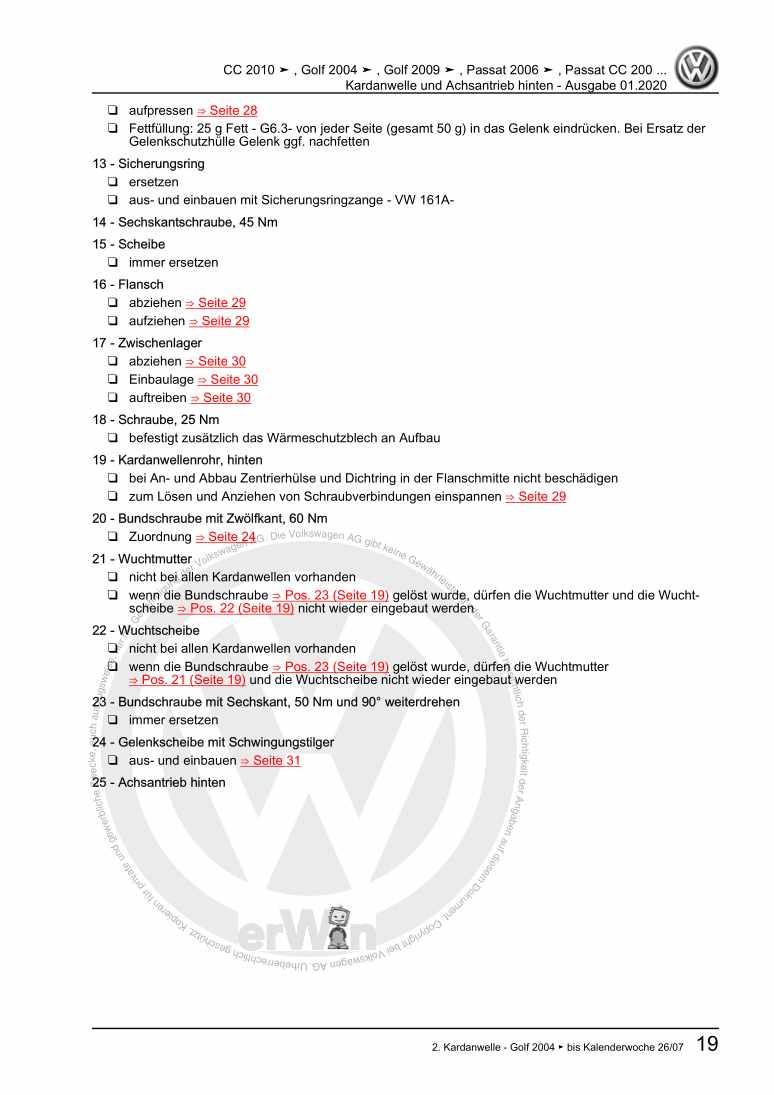

47Crankshaft group

481 Cylinder block (pulley end)

481.1 Assembly overview - sealing flange, vibration damper

481.2 Removing and installing engine support

491.3 Removing and installing vibration damper

501.4 Renewing crankshaft oil seal - belt pulley end

511.5 Removing and installing sealing flange on pulley end

532 Cylinder block, gearbox end

562.1 Assembly overview - cylinder block, gearbox end

562.2 Removing and installing flywheel

572.3 Removing and installing sealing flange on gearbox side

583 Camshaft

683.1 Crankshaft dimensions

683.2 Measuring axial clearance of crankshaft

683.3 Renewing needle bearing in crankshaft

694 Pistons and conrods

724.1 Assembly overview - pistons and conrods

724.2 Removing and installing pistons

744.3 Removing and installing oil spray jets

754.4 Checking pistons and cylinder bores

764.5 Checking radial clearance of conrods

77Cylinder head, valve gear

791 Cylinder head

791.1 Assembly overview - cylinder head

791.2 Assembly overview - camshaft housing

811.3 Removing and installing cylinder head

821.4 Removing and installing camshaft housing

861.5 Checking compression

952 Toothed belt drive

972.1 Assembly overview - toothed belt cover

972.2 Assembly overview - toothed belt

982.3 Removing toothed belt from camshaft

1002.4 Removing and installing toothed belt

1123 Valve gear

1273.1 Assembly overview - valve gear

1273.2 Removing and installing inlet camshaft control valve 1 N205

1283.3 Measuring axial play of camshaft

1283.4 Removing and installing camshaft oil seal

1293.5 Removing and installing valve stem seals

1344 Inlet and exhaust valves

1424.1 Checking valve guides

1424.2 Checking valves

1424.3 Valve dimensions

143Lubrication

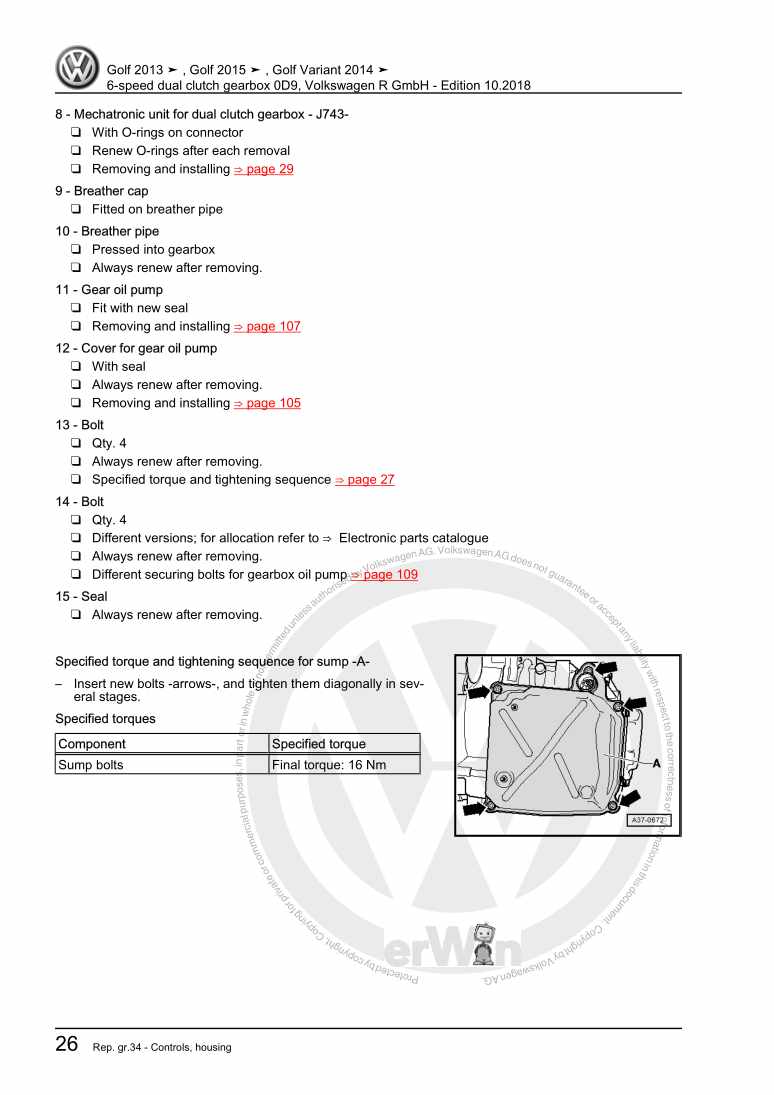

1441 Sump, oil pump

1441.1 Assembly overview - sump/oil pump

1441.2 Engine oil:

1481.3 Removing and installing lower part of sump

1491.4 Removing and installing upper part of sump

1531.5 Removing and installing oil pump

1561.6 Removing and installing oil level and oil temperature sender G266

1572 Engine oil cooler

1592.1 Assembly overview - engine oil cooler

1592.2 Removing and installing engine oil cooler

1593 Crankcase ventilation

1613.1 Assembly overview - crankcase breather system

1613.2 Removing and installing oil separator

1624 Oil filter, oil pressure switch

1644.1 Assembly overview - oil filter/oil pressure switch

1644.2 Removing and installing oil pressure switch F22

1654.3 Removing and installing oil pressure switch for reduced oil pressure F378

1664.4 Removing and installing oil pressure regulating valve N428

1684.5 Checking oil pressure

169Cooling

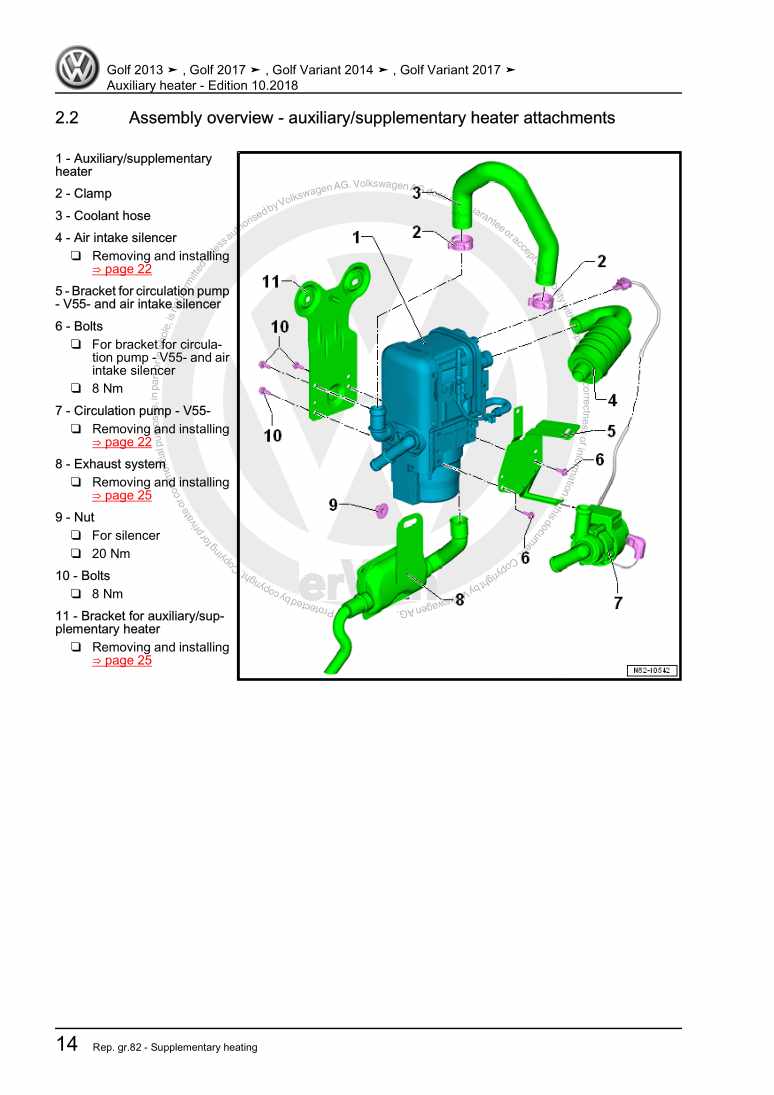

1711 Cooling system/coolant

1711.1 Connection diagram - coolant hoses

1711.2 Coolant hose schematic diagram, high-voltage system

1731.3 Checking cooling system for leaks

1741.4 Checking cooling system of high-voltage system for leaks

1761.5 Draining and adding coolant

1851.6 Draining and adding coolant, high-voltage system

1911.7 Checking filling quality of cooling system, high-voltage system

1982 Coolant pump, regulation of cooling system

2012.1 Assembly overview - coolant pump, thermostat

2012.2 Assembly overview - electric coolant pump

2042.3 Assembly overview - coolant temperature sender

2052.4 Removing and installing electric coolant pump

2052.5 Removing and installing coolant pump

2112.6 Removing and installing thermostat

2142.7 Removing and installing toothed belt pulley for coolant pump

2182.8 Removing and installing coolant temperature sender G62

2192.9 Removing and installing radiator outlet coolant temperature sender G83

2202.10 Removing and installing coolant valves

2212.11 Removing and installing coolant temperature sender for heater G241

2272.12 Removing and installing engine temperature sender 2 G652

2282.13 Overview of fitting locations - electric coolant pumps

2292.14 Assembly overview - coolant valves

2313 Coolant pipes

2323.1 Assembly overview - coolant pipes

2323.2 Removing and installing coolant pipes

2324 Radiator, radiator fan

2384.1 Assembly overview - radiator, radiator fan

2384.2 Assembly overview - radiator cowl and radiator fan

2404.3 Removing and installing radiator

2404.4 Removing and installing radiator cowling

2444.5 Removing and installing radiator fan V7

245Turbocharging/supercharging

2471 Exhaust turbocharger

2471.1 Assembly overview - turbocharger

2471.2 Removing and installing turbocharger

2481.3 Removing and installing charge pressure positioner V465

2552 Charge air system

2562.1 Assembly overview - charge air system

2562.2 Assembly overview - charge-air hose connections

2572.3 Removing and installing charge pressure sender GX26

2582.4 Removing and installing charge air cooler

2582.5 Checking charge air system for leaks

259Mixture preparation - injection

2611 Injection system

2611.1 Overview of fitting locations - injection system

2611.2 Releasing high pressure in fuel system

2662 Injectors

2682.1 Assembly overview - fuel rail with injectors

2682.2 Removing and installing fuel rail

2692.3 Removing and installing injectors

2692.4 Cleaning injectors

2753 Air filter

2763.1 Assembly overview - air filter housing

2763.2 Removing and installing air filter housing

2774 Intake manifold

2784.1 Assembly overview - intake manifold

2784.2 Removing and installing intake manifold

2794.3 Removing and installing throttle valve module GX3

2824.4 Cleaning throttle valve module GX3

2845 Senders and sensors

2865.1 Removing and installing intake manifold sender GX9

2865.2 Removing and installing fuel pressure sender G247

2865.3 Checking fuel pressure sender G247

2876 Engine (motor) control unit

2906.1 Removing and installing engine (motor) control unit J623

2907 High-pressure pump

2947.1 Assembly overview - high-pressure pump

2947.2 Removing and installing high-pressure pump

2957.3 Removing and installing high-pressure pipe

2968 Lambda probe

2988.1 Assembly overview - Lambda probe

298Exhaust system

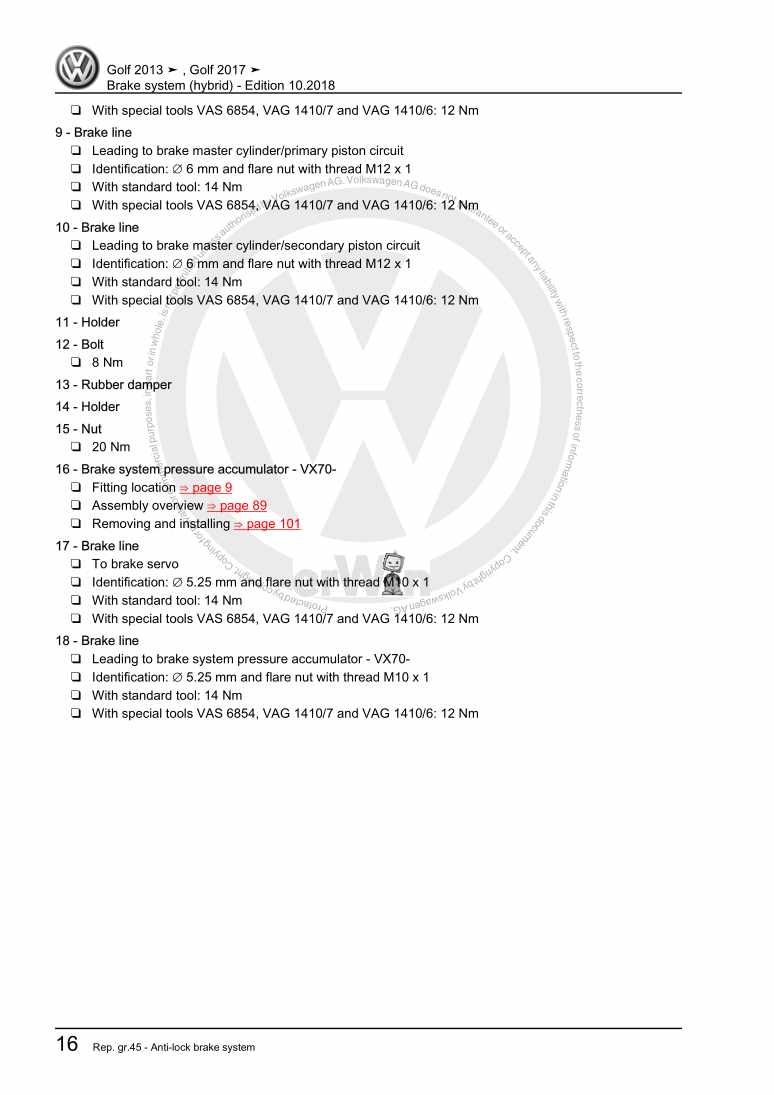

3011 Exhaust pipes, silencers

3011.1 Assembly overview - silencers

3011.2 Removing and installing silencer

3011.3 Aligning exhaust system free of stress

3021.4 Check exhaust system for leaks

3022 Exhaust gas cleaning

3032.1 Assembly overview - emission control

3032.2 Removing and installing catalytic converter

304Ignition system

3081 Ignition system

3081.1 Assembly overview - ignition system

3081.2 Test data, spark plugs

3091.3 Removing and installing ignition coils with output stage

3091.4 Removing and installing knock sensor 1 G61

3111.5 Removing and installing Hall sender G40

3121.6 Removing and installing engine speed sender G28

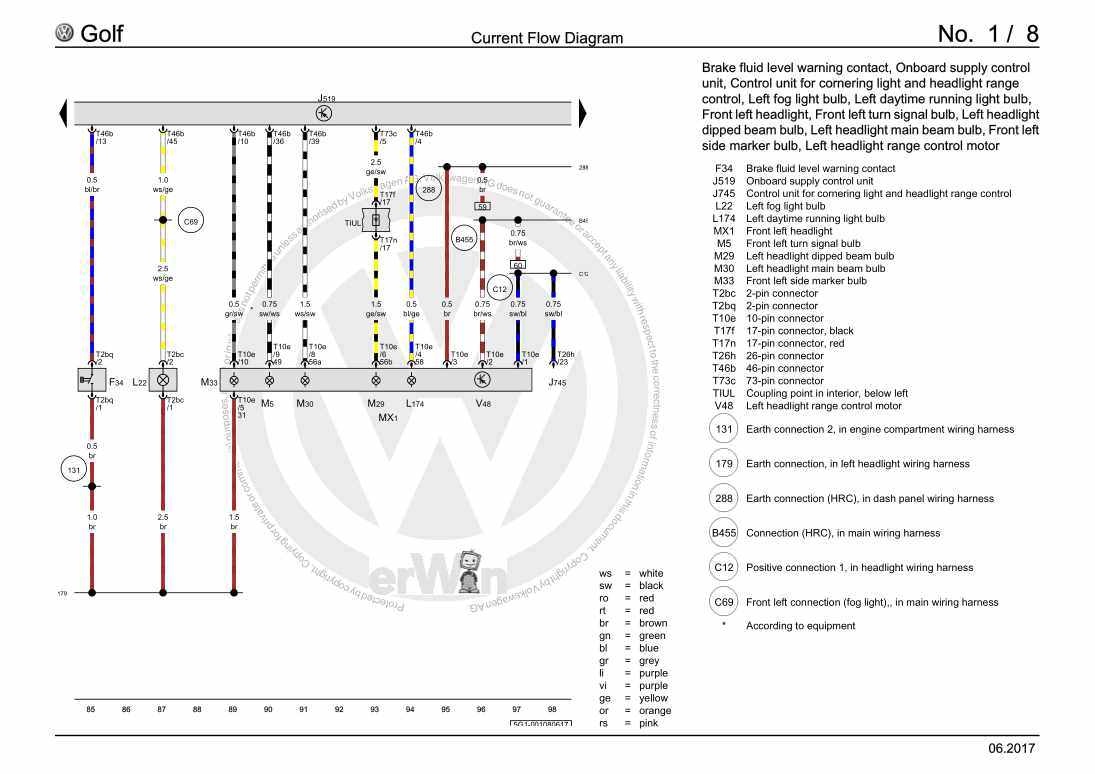

314Electric drive systems

3161 Warning stickers

3161.1 Checking warning stickers

3162 High-voltage components

3212.1 Overview of fitting locations - high-voltage components

3212.2 Testing high-voltage components and high-voltage cables

3223 High-voltage battery unit

3233.1 Assembly overview - high-voltage battery

3233.2 Visual inspection of high-voltage battery 1 AX2

3243.3 Removing and installing high-voltage battery 1 AX2

3243.4 Raising high-voltage battery 1 AX2

3303.5 Removing and installing battery regulation control unit J840

3314 Power and control electronics for electric drive

3334.1 Assembly overview - power and control electronics for electric drive

3334.3 Removing and installing power and control electronics for electric drive

3364.4 Removing and installing bracket for power and control electronics for electric drive JX1

3404.5 Removing and installing high-voltage system fuse 3 S353

3415 Charging unit for high-voltage battery

3445.1 Assembly overview - charging unit for high-voltage battery

3445.2 Removing and installing charging unit 1 for high-voltage battery AX4

3456 Electric drive motor

3496.1 Removing and installing three-phase current drive VX54

3496.2 Removing and installing drive motor temperature sender G712

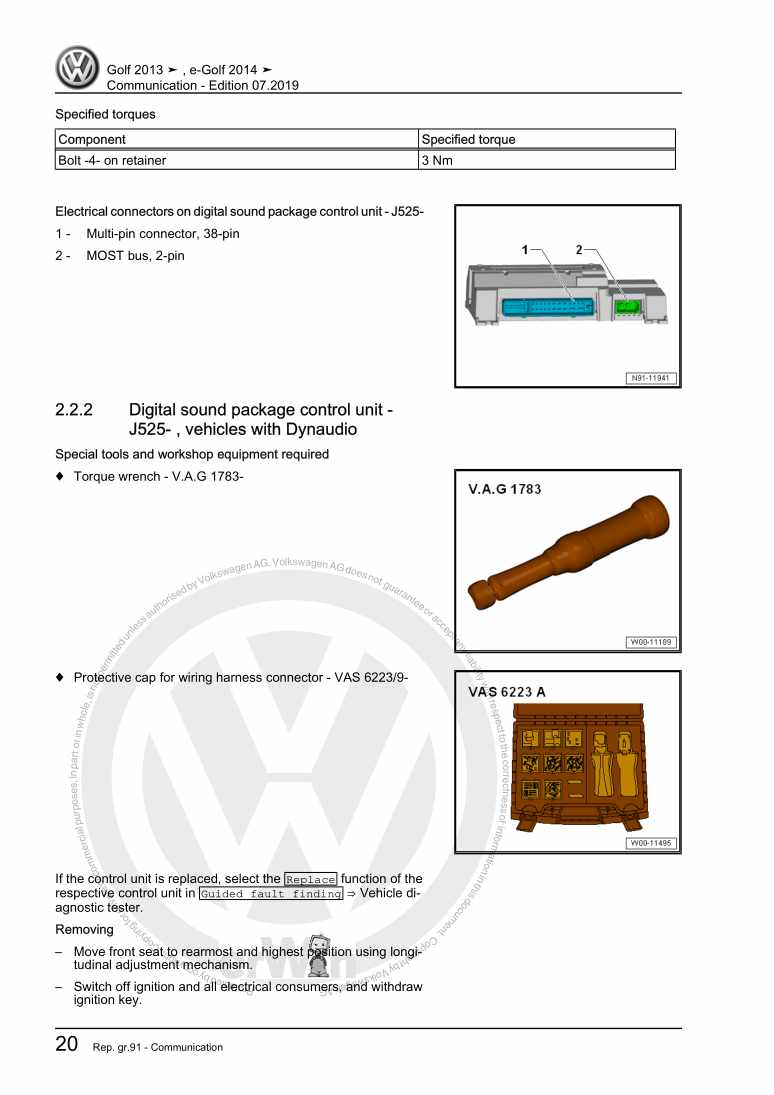

3496.3 Removing and installing drive motor rotor position sender 1 G713

3497 High-voltage cables

3507.1 Overview of fitting locations - high-voltage cables

3507.2 Removing and installing high-voltage wiring harness for high-voltage battery

3537.3 Removing and installing high-voltage wiring harness for drive motor

3577.5 Removing and installing high-voltage cable for high-voltage heater (PTC)

3618 Charging socket

3648.1 Assembly overview - charging socket

3648.2 Removing and installing high-voltage battery charging socket 1 UX4

3658.3 Emergency release charging connector

3668.4 Removing and installing button and display module

3689 De-energising high-voltage system

36910 Re-energising high-voltage system

37111 Potential equalisation lines

37211.1 General notes - potential equalisation lines

37211.2 Overview of fitting locations - potential equalisation lines

37211.3 Removing and installing potential equalisation line for high-voltage battery 1 AX2

375