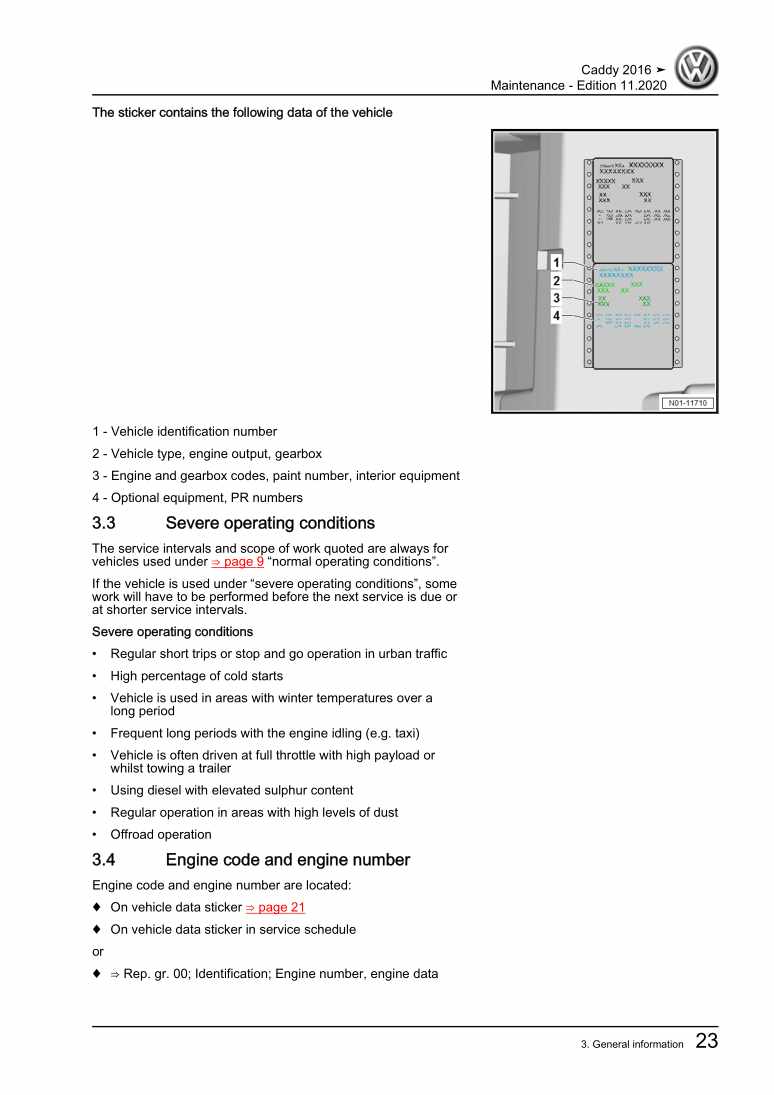

Technical data

11 Identification

11.1 Engine number/engine data

12 Safety information

22.1 Safety regulations for working on fuel supply

22.2 Safety precautions when working on fuel system

22.3 Safety precautions when working on the cooling system

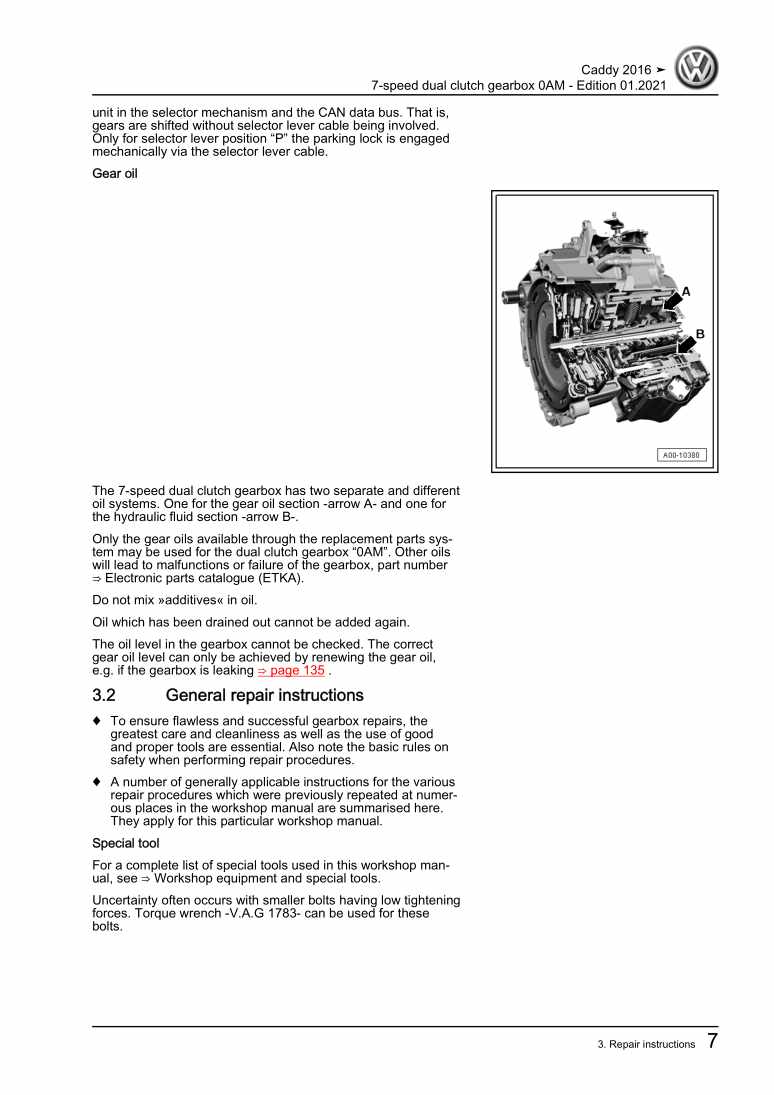

33 Repair instructions

53.1 Rules for cleanliness

53.2 General repair instructions

6Removing and installing engine

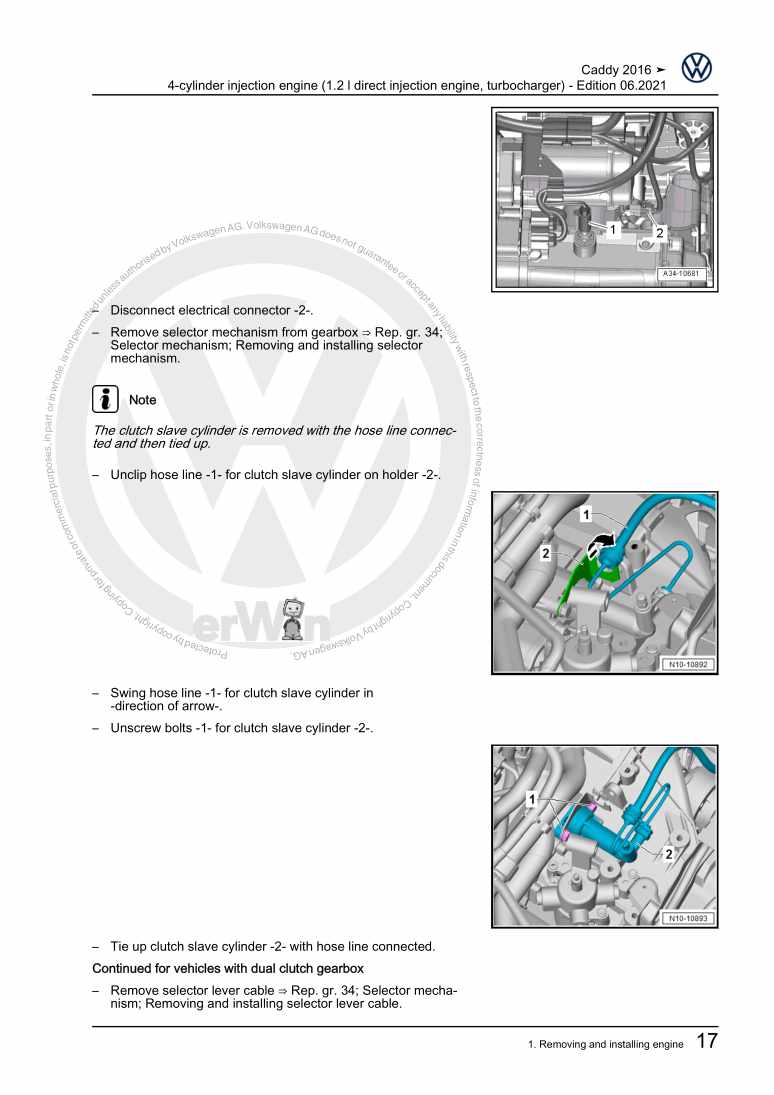

81 Removing and installing engine

81.1 Removing engine

81.2 Separating engine and gearbox

231.3 Securing engine on engine and gearbox support

281.4 Installing engine

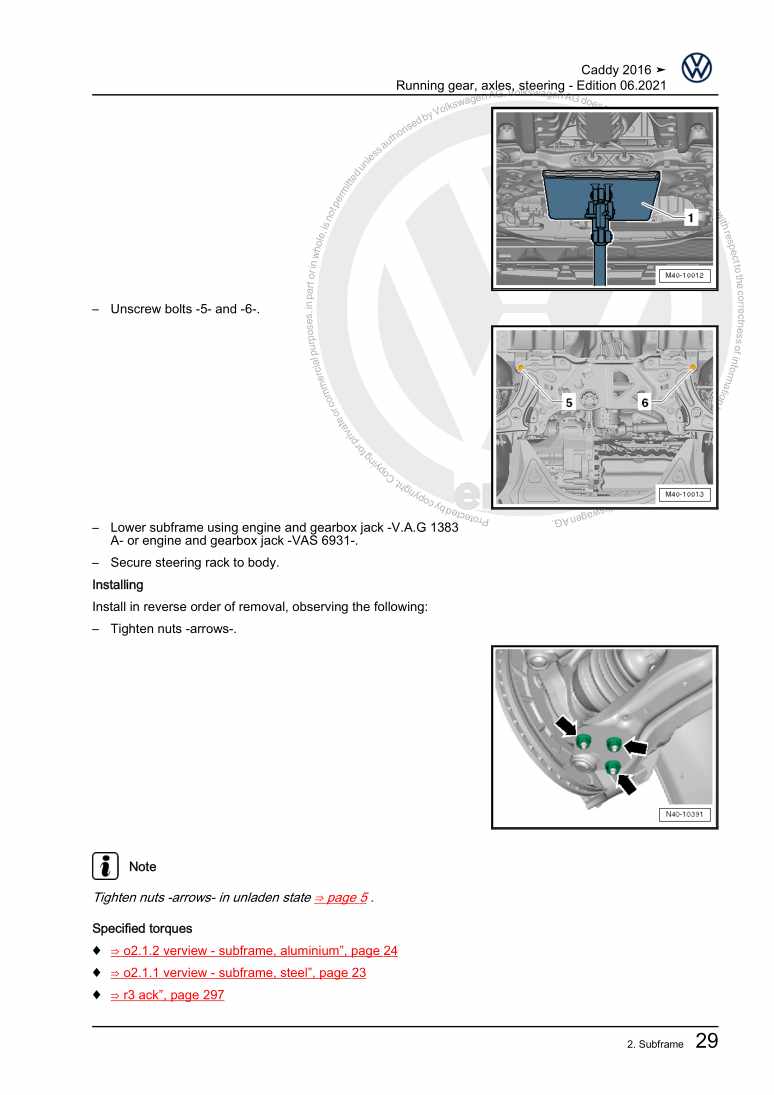

292 Assembly mountings

342.1 Assembly overview - assembly mountings

342.2 Removing and installing engine mounting

382.3 Supporting engine in installation position

412.4 Adjusting assembly mountings

433 Engine cover panel

493.1 Removing and installing engine cover

49Crankshaft group

511 Cylinder block (pulley end)

511.1 Assembly overview - poly V-belt drive

511.2 Assembly overview - cylinder block (pulley end)

531.3 Assembly overview - sealing flange, belt pulley end

561.4 Removing and installing poly-V belt

571.5 Removing and installing tensioner for poly V-belt

601.6 Removing and installing bracket for ancillaries

621.7 Removing and installing vibration damper

651.8 Removing and installing engine bracket

661.9 Renewing crankshaft oil seal - belt pulley end

701.10 Removing and installing sealing flange on pulley end

722 Cylinder block, gearbox end

782.1 Assembly overview - cylinder block, gearbox end

782.2 Removing and installing flywheel

792.3 Removing and installing sealing flange on gearbox side

803 Crankshaft

913.1 Assembly overview - crankshaft

913.2 Crankshaft dimensions

923.3 Measuring axial clearance of crankshaft

933.4 Measuring radial clearance of crankshaft

943.5 Renewing needle bearing in crankshaft

944 Pistons and conrods

974.1 Assembly overview - pistons and conrods

974.2 Measuring piston projection at TDC

1004.3 Checking pistons and cylinder bores

1014.4 Separating new conrod

1044.5 Checking radial clearance of conrods

1044.6 Removing and installing oil spray jets

105Cylinder head, valve gear

1071 Cylinder head

1071.1 Assembly overview - cylinder head

1071.2 Assembly overview - cylinder head cover

1111.3 Removing and installing cylinder head

1131.4 Removing and installing cylinder head cover

1301.5 Removing and installing injector seals

1331.6 Removing and installing vacuum pump

1361.7 Checking compression

1372 Fully enclosing toothed belt guard

1402.1 Assembly overview - fully enclosing toothed belt guard

1402.2 Removing and installing upper toothed belt guard (fully enclosing)

1422.3 Removing and installing lower toothed belt guard (fully enclosed)

1432.4 Removing and installing rear toothed belt guard (fully enclosing)

1443 Toothed belt drive

1493.1 Assembly overview - toothed belt

1493.2 Removing and installing toothed belt

1524 Valve gear

1704.1 Assembly overview - valve gear

1704.2 Measuring axial play of camshaft

1734.3 Measuring radial play of camshaft

1754.4 Removing and installing camshaft

1754.5 Removing and installing camshaft oil seal

1854.6 Checking hydraulic compensation elements

1914.7 Removing and installing valve stem seals

1925 Inlet and exhaust valves

2015.1 Reworking valve seats

2015.2 Checking valve guides

2015.3 Checking valves

2025.4 Valve dimensions

203Lubrication

2041 Sump, oil pump

2041.1 Assembly overview - sump/oil pump

2041.2 Engine oil:

2071.3 Removing and installing oil sump

2081.4 Removing and installing oil pump

2131.5 Removing and installing oil level and oil temperature sender G266

2142 Engine oil cooler

2162.1 Removing and installing engine oil cooler

2162.2 Checking engine oil cooler for leaks

2203 Oil filter, oil pressure switch

2233.1 Assembly overview - oil filter housing, oil pressure switch

2233.2 Removing and installing oil pressure switch F1

2253.3 Checking oil pressure and oil pressure switch

2263.4 Removing and installing oil filter housing

2284 Oil circuit

2334.1 Assembly overview - oil circuit

2334.2 Removing and installing oil supply line

233Cooling

2401 Cooling system/coolant

2401.1 Connection diagram - coolant hoses

2401.2 Checking cooling system for leaks

2411.3 Draining and adding coolant

2442 Coolant pump, regulation of cooling system

2542.1 Assembly overview - coolant pump, thermostat

2542.2 Removing and installing coolant circulation pump 2 V178

2542.3 Removing and installing coolant pump

2572.4 Removing and installing 4/2-way valve with thermostat

2582.5 Removing and installing coolant temperature sender G62

2612.6 Removing and installing radiator outlet coolant temperature sender G83

2623 Coolant pipes

2653.1 Assembly overview - coolant pipes

2653.2 Removing and installing coolant pipes

2673.3 Removing and installing upper coolant pipes

2774 Radiator, radiator fan

2794.1 Assembly overview - radiator/radiator fan

2794.2 Removing and installing radiator

2814.3 Removing and installing radiator cowl with radiator fan

2824.4 Removing and installing radiator fan VX57

2834.5 Removing and installing radiator fan 2 V177

284Turbocharging/supercharging

2861 Turbocharger

2861.1 Assembly overview - turbocharger

2861.2 Removing and installing turbocharger

2901.3 Renewing vacuum unit for turbocharger

2972 Charge air system

3062.1 Assembly overview - charge air system

3062.2 Assembly overview - charge-air hose connections

3082.3 Removing and installing charge air cooler

3102.4 Removing and installing air pipe

3122.6 Checking charge air system for leaks

315Mixture preparation - injection

3191 Injection system

3191.1 Schematic overview - fuel system

3191.2 Overview of fitting locations - injection system

3211.3 Filling/bleeding fuel system

3311.4 Checking fuel system for leaks

3322 Vacuum system

3342.1 Connection diagram – vacuum system

3342.2 Checking vacuum system

3352.3 Removing and installing charge pressure control solenoid valve N75

3443 Injectors/high-pressure accumulator (rail)

3473.1 Assembly overview - injectors

3473.2 Adapting correction values for injectors

3503.3 Testing injectors

3513.4 Checking return flow rate of injectors with engine running

3513.5 Checking return flow rate of injectors at starter speed

3543.6 Testing jammed-open injectors

3563.7 Removing and installing injectors

3583.8 Removing and installing high-pressure lines

3633.9 Removing and installing fuel rail

3694 Air filter

3754.1 Assembly overview - air filter housing

3754.2 Removing and installing air filter housing

3775 Intake manifold

3805.1 Assembly overview – intake manifold

3805.2 Removing and installing intake manifold

3825.3 Removing and installing throttle valve module GX3

3866 Senders and sensors

3896.1 Removing and installing exhaust gas pressure sensor 1 G450

3896.2 Removing and installing air mass meter G70

3906.3 Checking fuel pressure regulating valve N276

3916.4 Removing and installing fuel pressure regulating valve N276

3926.5 Removing and installing fuel pressure sender G247

3967 Engine control unit

3997.1 Removing and installing engine control unit J623

3997.2 Removing and installing engine (motor) control unit J623 with protective housing

4018 High-pressure pump

4058.1 Assembly overview - high-pressure pump

4058.2 Removing and installing high-pressure pump

4078.3 Checking high-pressure pump

4119 Lambda probe

4149.1 Removing and installing Lambda probe

414Exhaust system

4161 Exhaust pipes and silencers

4161.1 Assembly overview – silencers

4161.2 Separating exhaust pipes from silencers

4171.3 Aligning exhaust system free of stress

4191.4 Installation position of clamp

4202 Emission control

4222.1 Assembly overview – emission control

4222.2 Removing and installing particulate filter

4253 Exhaust gas temperature regulation

4363.1 Assembly overview – exhaust gas temperature regulation

4363.2 Removing and installing exhaust gas temperature sender 1 G235

4373.3 Removing and installing exhaust gas temperature sender 3 G495

4383.4 Removing and installing exhaust gas temperature sender 4 G648

4404 Exhaust gas recirculation

4434.1 Assembly overview – exhaust gas recirculation

4434.2 Removing and installing exhaust gas recirculation cooler

4454.3 Checking changeover for exhaust gas recirculation cooler

4484.4 Checking exhaust gas recirculation cooler for leaks

4494.5 Cleaning exhaust gas recirculation system

449Glow plug system

4591 Glow plug system

4591.1 Removing and installing glow plug

4591.2 Removing and installing automatic glow period control unit J179

4611.3 Removing and installing engine speed sender G28

4611.4 Removing and installing Hall sender G40

462