Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on ignition system

21.6 Safety precautions when working on exhaust system

32 Identification

42.1 Engine number/engine data

43 Repair instructions

63.1 Rules for cleanliness

63.2 General information

73.3 Foreign objects in engine

73.4 Contact corrosion

83.5 Routing and attachment of lines

83.6 Fitting radiator and condensers

83.7 Checking vacuum system

8Removing and installing engine

101 Removing and installing engine

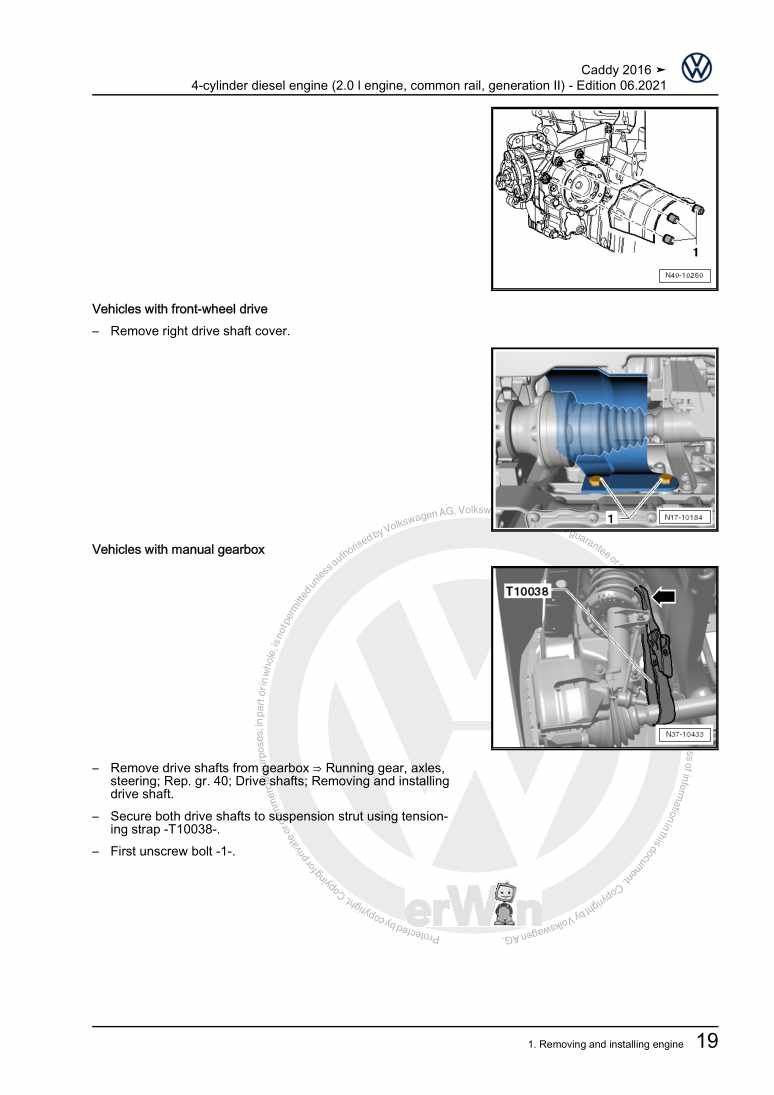

101.1 Removing engine

101.2 Separating engine and gearbox

221.3 Securing engine on engine and gearbox support

261.4 Installing engine

282 Assembly mountings

332.1 Assembly overview - assembly mountings

332.2 Removing and installing engine mounting

352.3 Removing and installing gearbox mounting

382.4 Removing and installing pendulum support

392.5 Supporting engine in installation position

422.6 Adjusting assembly mountings

442.7 Checking adjustment of assembly mountings

483 Engine cover panel

503.1 Removing and installing engine cover

50Crankshaft group

511 Cylinder block (pulley end)

511.1 Assembly overview - poly V-belt drive

511.2 Assembly overview - cylinder block (pulley end)

531.3 Assembly overview - sealing flange, belt pulley end

561.4 Removing and installing poly-V belt

571.5 Removing and installing tensioner for poly V-belt

591.6 Removing and installing vibration damper

601.7 Removing and installing bracket for ancillaries

611.8 Removing and installing engine support

641.9 Renewing crankshaft oil seal - belt pulley end

661.10 Removing and installing sealing flange on pulley end

682 Cylinder block, gearbox end

732.1 Assembly overview - cylinder block, gearbox end

732.2 Removing and installing flywheel

742.3 Removing and installing sealing flange on gearbox side

753 Crankshaft

863.1 Assembly overview - crankshaft

863.2 Crankshaft dimensions

873.3 Renewing needle bearing in crankshaft

883.4 Measuring axial clearance of crankshaft

904 Pistons and conrods

924.1 Assembly overview - pistons and conrods

924.2 Removing and installing pistons

954.3 Measuring piston projection at TDC

964.4 Checking pistons and cylinder bores

984.5 Separating new conrod

1004.6 Checking radial clearance of conrods

1014.7 Removing and installing oil spray jets

101Cylinder head, valve gear

1031 Cylinder head

1031.1 Assembly overview - cylinder head

1031.2 Assembly overview - cylinder head cover

1071.3 Removing and installing cylinder head

1091.4 Removing and installing cylinder head cover

1251.5 Removing and installing injector seals

1321.6 Removing and installing vacuum pump

1331.7 Checking compression

1352 Fully enclosing toothed belt guard

1372.1 Assembly overview - fully enclosing toothed belt guard

1372.2 Removing and installing upper toothed belt guard (fully enclosing)

1392.3 Removing and installing lower toothed belt guard (fully enclosed)

1402.4 Removing and installing rear toothed belt guard (fully enclosing)

1413 Toothed belt drive

1463.1 Assembly overview - toothed belt

1463.2 Removing and installing toothed belt

1494 Valve gear

1654.1 Assembly overview - valve gear

1654.2 Measuring axial play of camshaft

1684.3 Measuring radial play of camshaft

1694.4 Removing and installing camshaft oil seal

1694.5 Removing and installing camshaft

1724.6 Checking hydraulic compensation elements

1814.7 Removing and installing valve stem seals

1825 Inlet and exhaust valves

1925.1 Reworking valve seats

1925.2 Checking valve guides

1925.3 Checking valves

1935.4 Valve dimensions

193Lubrication

1941 Sump, oil pump

1941.1 Assembly overview - sump/oil pump

1941.2 Engine oil:

1971.3 Removing and installing oil sump

1981.4 Removing and installing oil pump

2021.5 Removing and installing oil level and oil temperature sender G266

2042 Engine oil cooler

2062.1 Assembly overview - engine oil cooler

2062.2 Removing and installing engine oil cooler

2063 Oil filter, oil pressure switch

2113.1 Assembly overview - oil filter housing, oil pressure switch

2113.2 Removing and installing oil filter housing

2123.3 Removing and installing oil pressure switch F1

2153.4 Checking oil pressure and oil pressure switch

2174 Oil circuit

2194.1 Assembly overview - oil circuit

2194.2 Removing and installing oil return line for turbocharger

220Cooling

2261 Cooling system/coolant

2261.1 Connection diagram - coolant hoses

2261.2 Checking cooling system for leaks

2281.3 Draining and adding coolant

2332 Coolant pump, regulation of cooling system

2432.1 Assembly overview - coolant pump, thermostat

2432.2 Removing and installing coolant circulation pump 2 V178

2432.3 Removing and installing coolant pump

2462.4 Removing and installing 4/2-way valve with thermostat

2472.5 Removing and installing coolant temperature sender G62

2492.6 Removing and installing radiator outlet coolant temperature sender G83

2513 Coolant pipes

2543.1 Assembly overview - coolant pipes

2543.2 Removing and installing coolant pipes

2564 Radiator, radiator fan

2644.1 Assembly overview - radiator, radiator fan

2644.2 Assembly overview – radiator cowl and radiator fan

2654.3 Removing and installing radiator

2664.4 Removing and installing radiator cowl with radiator fan

2674.5 Removing and installing radiator fan VX57

2684.6 Removing and installing radiator fan 2 V177

269Turbocharging/supercharging

2711 Turbocharger

2711.1 Assembly overview - turbocharger

2711.2 Removing and installing turbocharger

2742 Charge air system

2792.1 Assembly overview - charge air system

2792.2 Assembly overview - charge-air hose connections

2812.3 Removing and installing charge air cooler

2822.5 Checking charge air system for leaks

2852.6 Removing and installing air pipe

289Mixture preparation - injection

2921 Injection system

2921.1 Schematic overview - fuel system

2921.2 Overview of fitting locations - injection system

2941.3 Assembly overview - fuel system

2971.4 Filling/bleeding fuel system

3001.5 Checking fuel system for leaks

3012 Vacuum system

3022.1 Connection diagram – vacuum system

3022.2 Checking vacuum system

3033 Injectors/high-pressure accumulator (rail)

3153.1 Assembly overview - injectors

3153.2 Assembly overview - fuel rail

3163.3 Adapting correction values for injectors

3163.4 Testing injectors

3173.5 Checking return flow rate of injectors with engine running

3183.6 Checking return flow rate of injectors at starter speed

3213.7 Testing jammed-open injectors

3233.8 Check pressure retention valve in fuel return line

3243.9 Removing and installing injectors

3263.10 Removing and installing high-pressure lines

3323.11 Removing and installing fuel rail

3364 Air filter

3404.1 Assembly overview - air filter housing

3404.2 Removing and installing air filter housing

3425 Intake manifold

3455.1 Assembly overview – intake manifold

3455.2 Removing and installing intake manifold

3475.3 Removing and installing throttle valve module GX3

3516 Senders and sensors

3526.1 Removing and installing fuel pressure regulating valve N276

3526.2 Checking fuel pressure regulating valve N276

3546.3 Removing and installing fuel pressure sender G247

3566.4 Removing and installing air mass meter G70

3586.5 Removing and installing pressure differential sender G505

3597 Engine control unit

3607.1 Removing and installing engine (motor) control unit J623 with protective housing

3608 High-pressure pump

3638.1 Assembly overview - high-pressure pump

3638.2 Removing and installing high-pressure pump

3638.3 Checking high-pressure pump

3679 Lambda probe

3709.1 Removing and installing Lambda probe

370Exhaust system

3721 Exhaust pipes and silencers

3721.1 Assembly overview – silencers

3721.2 Separating exhaust pipes from silencers

3731.3 Aligning exhaust system free of stress

3741.4 Checking exhaust system for leaks

3761.5 Installation position of clamp

3762 Emission control

3792.1 Assembly overview – emission control

3792.2 Removing and installing particulate filter

3813 Exhaust gas temperature regulation

3883.1 Assembly overview – exhaust gas temperature regulation

3883.2 Removing and installing exhaust gas temperature sender 1 G235

3893.3 Removing and installing exhaust gas temperature sender 3 G495

3913.4 Removing and installing exhaust gas temperature sender 4 G648

3934 Exhaust gas recirculation

3954.1 Assembly overview – exhaust gas recirculation

3954.2 Removing and installing exhaust gas recirculation cooler

3974.3 Checking exhaust gas recirculation cooler for leaks

3994.4 Checking changeover for exhaust gas recirculation cooler

3994.5 Cleaning exhaust gas recirculation system

400Glow plug system

4101 Glow plug system

4101.1 Removing and installing glow plug

4101.2 Checking glow plug

4121.3 Removing and installing automatic glow period control unit J179

4121.4 Removing and installing Hall sender G40

4131.5 Removing and installing engine speed sender G28

414