Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety measures when working on vehicles with start/stop system

11.4 Safety precautions when working on the cooling system

21.5 Safety precautions when working on SCR system

21.6 Safety precautions when working on ignition system

31.7 Safety precautions when working on exhaust system

32 Identification

52.1 Engine number/engine data

53 Repair notes

73.1 Rules for cleanliness

73.2 General information

73.3 General repair instructions

83.4 Foreign objects in engine

83.5 Contact corrosion

83.6 Routing and attachment of lines

93.7 Fitting radiators and condensers

93.8 Checking vacuum system

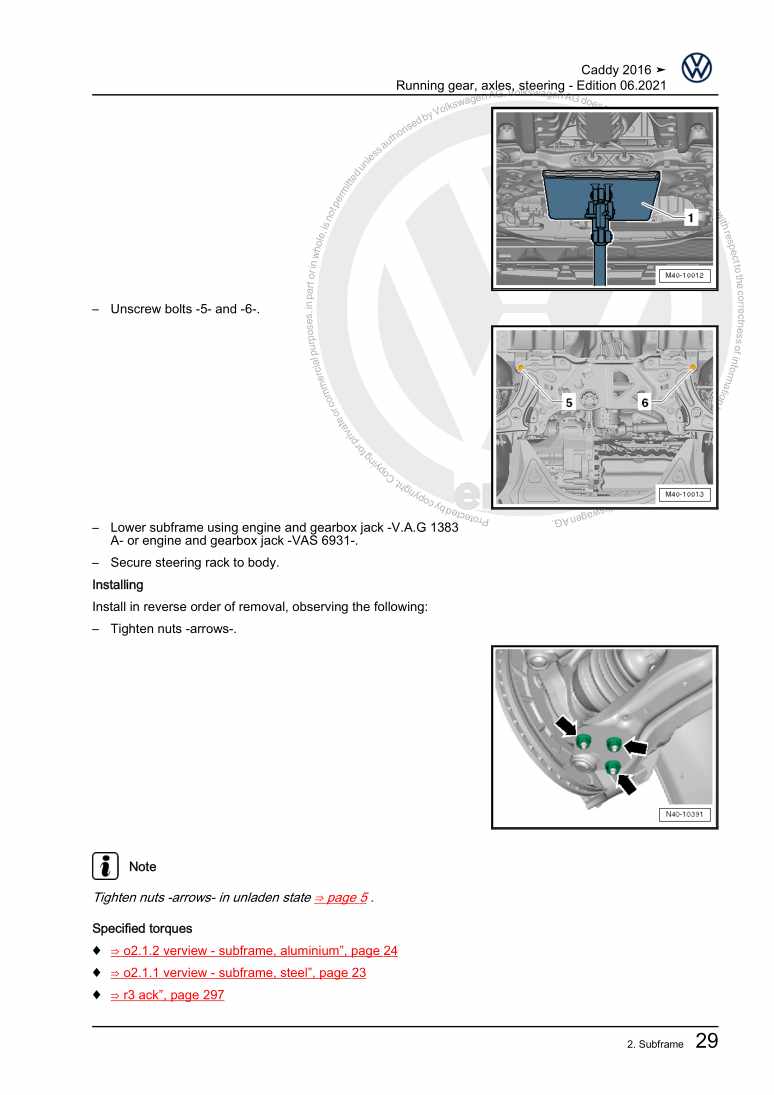

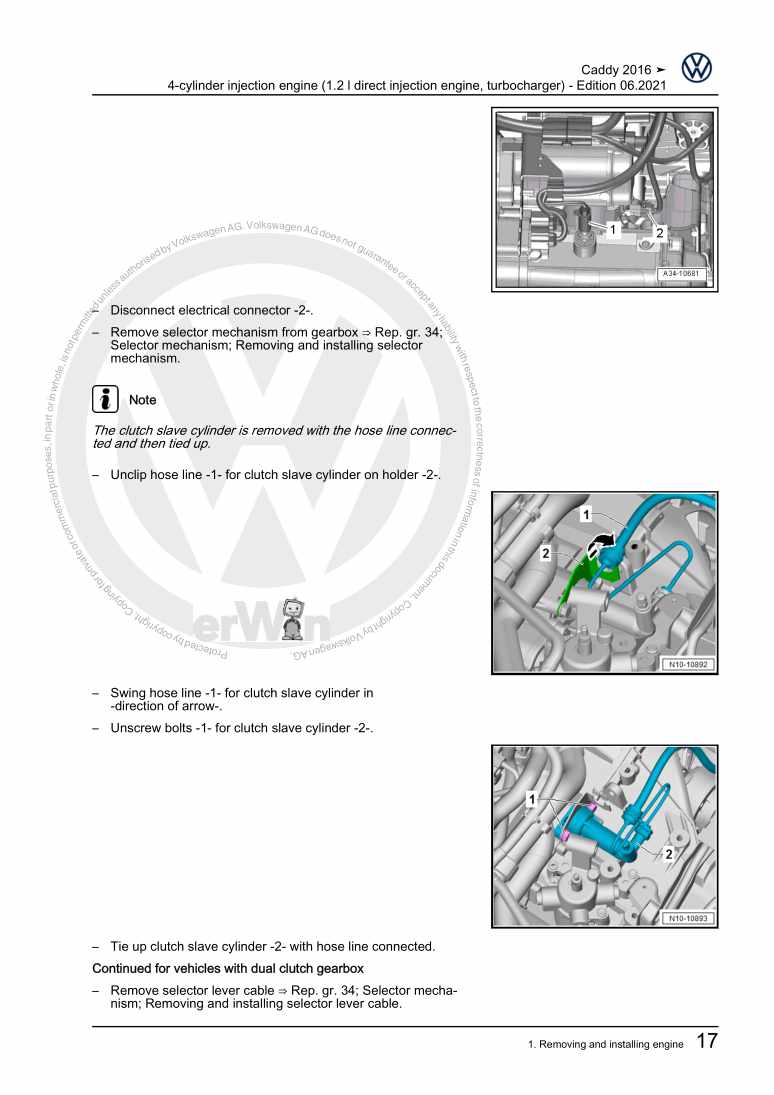

9Removing and installing engine

101 Removing and installing engine

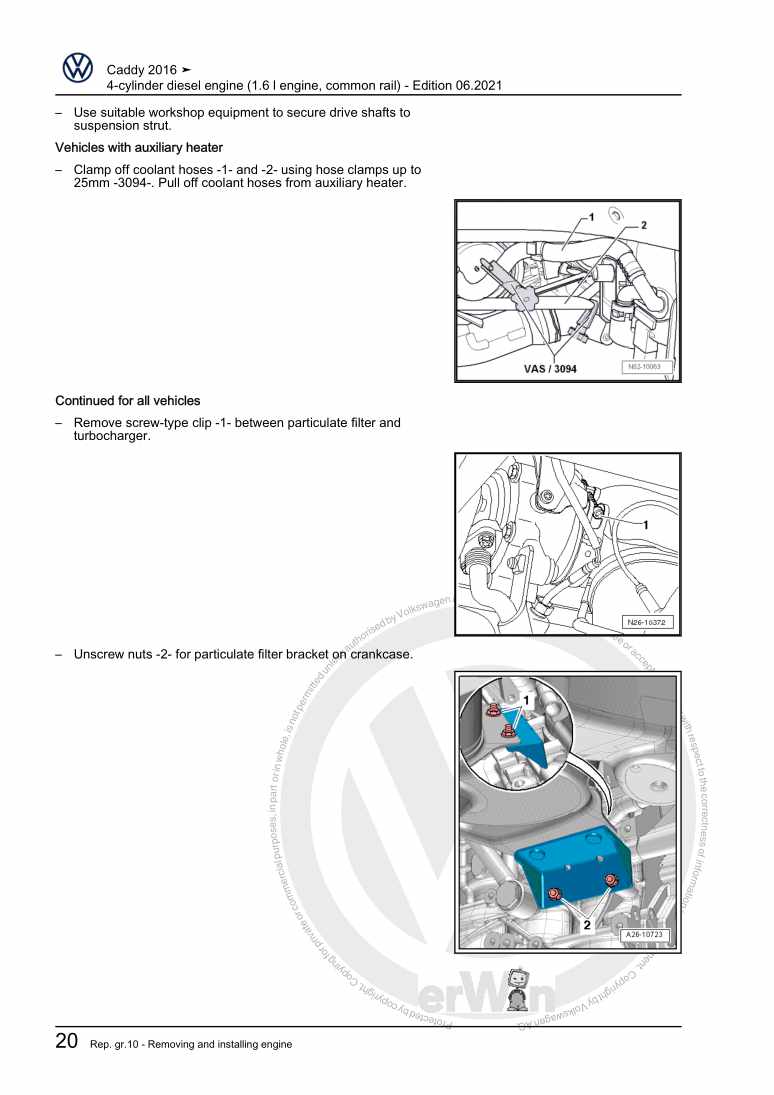

101.1 Removing engine

101.2 Separating engine and gearbox

181.3 Securing engine on engine and gearbox support

221.4 Installing engine

232 Assembly mountings

272.1 Assembly overview – assembly mountings

272.2 Removing and installing engine mounting

302.3 Removing and installing gearbox mounting

322.4 Removing and installing pendulum support

332.5 Supporting engine in installation position

342.6 Adjusting assembly mountings

372.7 Checking adjustment of assembly mountings

403 Engine cover panel

423.1 Removing and installing engine cover

42Crankshaft group

431 Cylinder block (pulley end)

431.1 Assembly overview - cylinder block (pulley end)

431.2 Assembly overview - sealing flange, belt pulley end

451.3 Removing and installing poly-V belt

471.4 Removing and installing tensioner for poly V-belt

491.5 Removing and installing vibration damper

491.6 Removing and installing bracket for ancillaries

501.7 Removing and installing engine support

521.8 Removing and installing sealing flange on pulley end

532 Cylinder block, gearbox end

562.1 Assembly overview - cylinder block, gearbox end

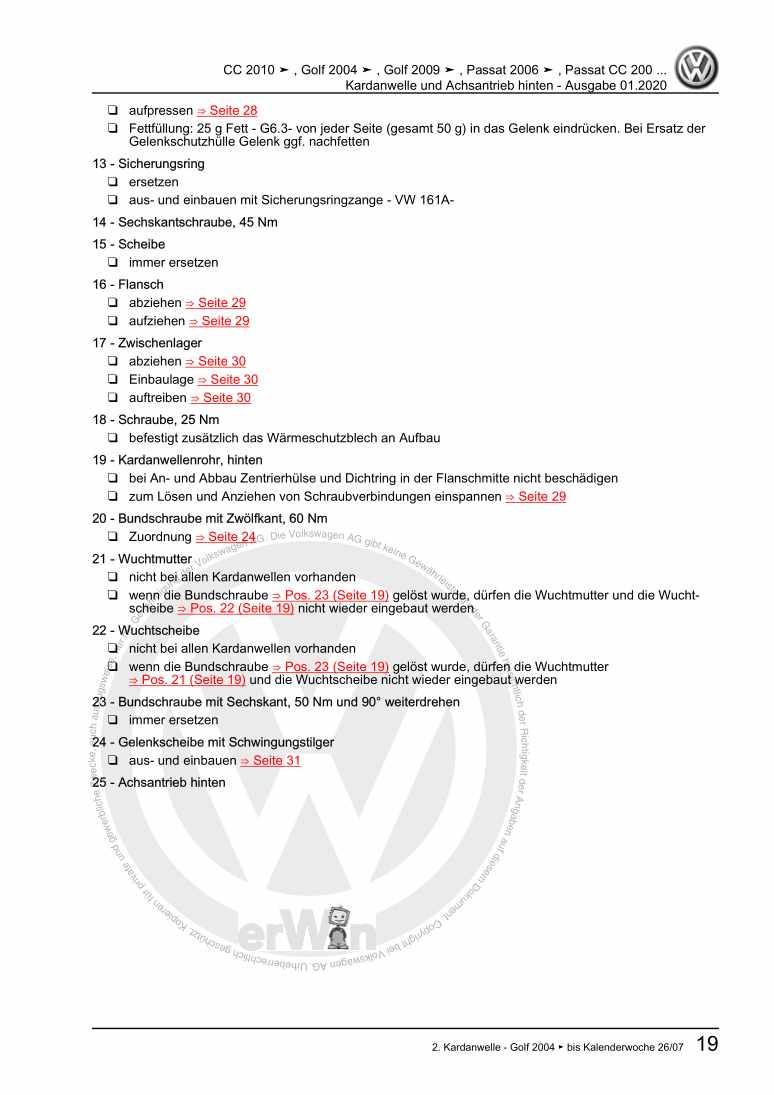

562.2 Removing and installing flywheel

572.3 Removing and installing sealing flange on gearbox side

593 Crankshaft

703.1 Assembly overview - crankshaft

703.2 Crankshaft dimensions

723.3 Renewing needle bearing in crankshaft

723.4 Measuring axial clearance of crankshaft

743.5 Measuring radial clearance of crankshaft

754 Pistons and conrods

764.1 Assembly overview - pistons and conrods

764.2 Removing and installing pistons

794.3 Measuring piston projection at TDC

804.4 Checking pistons and cylinder bores

824.5 Separating new conrod

854.6 Checking radial clearance of conrods

854.7 Removing and installing oil spray jets

86Cylinder head, valve gear

881 Cylinder head

881.1 Assembly overview - cylinder head

881.2 Assembly overview - camshaft housing

911.3 Assembly overview - cylinder head cover

911.4 Removing and installing cylinder head

931.5 Removing and installing cylinder head cover

1001.6 Removing and installing injector seals

1021.7 Removing and installing camshaft housing

1041.8 Checking compression

1102 Toothed belt drive

1122.1 Assembly overview - toothed belt cover

1122.2 Assembly overview - toothed belt

1122.3 Removing and installing toothed belt guard

1142.4 Removing and installing toothed belt

1192.5 Removing toothed belt from camshaft

1323 Valve gear

1373.1 Assembly overview - valve gear

1373.2 Measuring axial play of camshaft

1413.3 Removing and installing camshaft oil seal

1423.4 Removing and installing camshaft adjuster

1443.5 Checking hydraulic compensation elements

1473.6 Removing and installing valve stem seals

1484 Inlet and exhaust valves

1584.1 Checking valve guides

1584.2 Checking valves

1594.3 Valve dimensions

159Lubrication

1601 Sump, oil pump

1601.1 Assembly overview - sump/oil pump

1601.2 Engine oil

1631.3 Removing and installing oil sump

1631.4 Removing and installing oil pump

1651.5 Removing and installing oil level and oil temperature sender G266

1672 Engine oil cooler

1693 Oil filter, oil pressure switch

1703.1 Assembly overview - oil filter housing, oil pressure switch

1703.2 Removing and installing oil pressure switch F1

1723.3 Removing and installing oil pressure switch for reduced oil pressure F378

1743.4 Checking oil pressure

1763.5 Removing and installing oil filter housing

1763.6 Removing and installing oil pressure regulating valve N428

1794 Oil circuit

1814.1 Removing and installing oil supply line

1814.2 Removing and installing oil return line for turbocharger

184Cooling

1871 Cooling system/coolant

1871.1 Connection diagram - coolant hoses

1871.2 Draining and adding coolant

1911.3 Checking cooling system for leaks

1972 Coolant pump, regulation of cooling system

2002.1 Assembly overview - coolant pump, thermostat

2002.2 Assembly overview - coolant temperature sender

2042.3 Assembly overview - electric coolant pump

2042.4 Removing and installing coolant pump

2052.5 Removing and installing charge air cooling pump V188

2062.6 Removing and installing auxiliary pump for heating V488

2082.7 Removing and installing thermostat

2102.8 Checking thermostat

2142.9 Removing and installing coolant temperature sender G62

2142.10 Removing and installing coolant valve for cylinder head N489

2163 Coolant pipes

2173.1 Assembly overview - coolant pipes

2173.2 Removing and installing coolant pipes

2194 Radiator, radiator fan

2334.1 Assembly overview - radiator/radiator fan

2334.2 Assembly overview – radiator cowl and radiator fan

2354.3 Removing and installing radiator

2354.4 Removing and installing radiator cowl with radiator fan

2374.5 Removing and installing radiator fan VX57

2384.6 Removing and installing radiator fan 2 V177

2394.7 Removing and installing auxiliary radiator

240Turbocharging/supercharging

2441 Turbocharger

2441.1 Assembly overview - turbocharger

2441.2 Removing and installing turbocharger

2501.3 Renewing vacuum unit for turbocharger

2561.4 Removing and installing connection for turbocharger

2591.5 Removing and installing pulsation damper

2612 Charge air system

2632.1 Assembly overview - charge air system

2632.2 Removing and installing charge air cooler

2632.3 Removing and installing charge pressure sender G31

2632.4 Checking charge air system for leaks

2642.5 Removing and installing charge air pipe

266Mixture preparation - injection

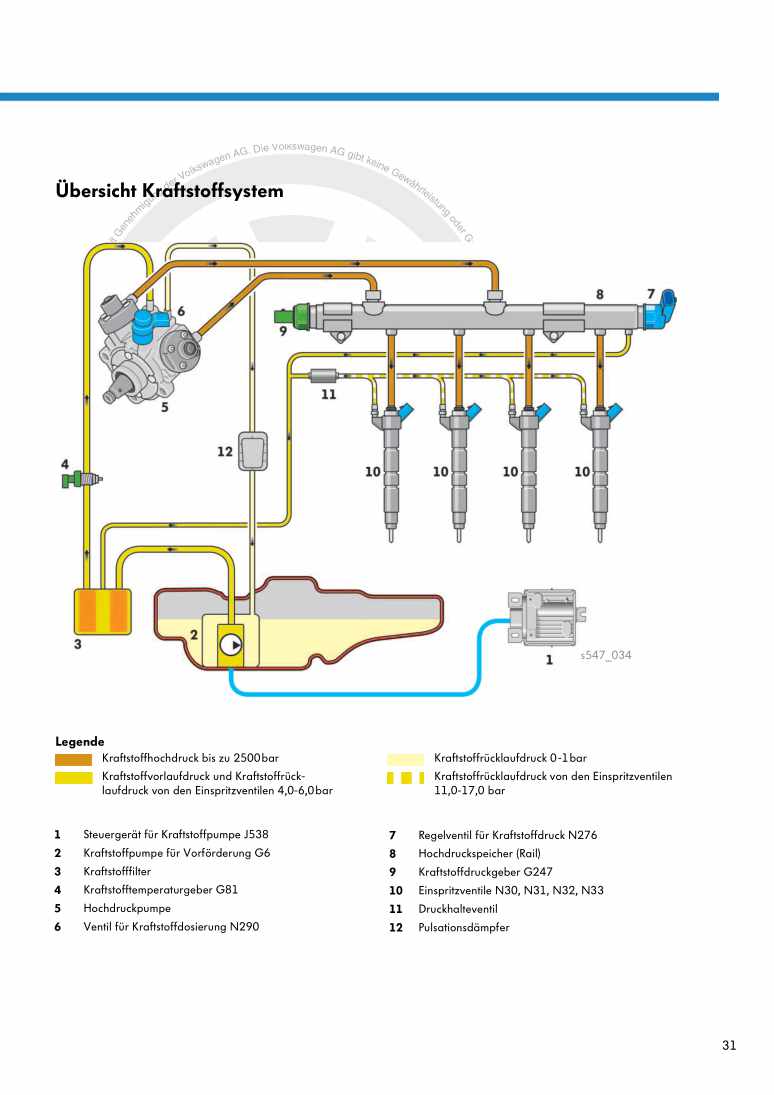

2671 Injection system

2671.1 Schematic overview - fuel system

2671.2 Filling/bleeding fuel system

2681.3 Checking fuel system for leaks

2692 Vacuum system

2702.1 Connection diagram – vacuum system

2703 Injectors/high-pressure accumulator (rail)

2713.1 Assembly overview - injectors

2713.2 Assembly overview - fuel rail

2733.3 Adapting correction values for injectors

2743.4 Checking return flow rate of injectors with engine running

2763.5 Checking return flow rate of injectors at starter speed

2793.6 Testing jammed-open injectors

2803.7 Removing and installing injectors

2823.8 Removing and installing high-pressure lines

2863.9 Removing and installing fuel rail

2924 Air filter

2944.1 Assembly overview - air filter housing

2944.2 Removing and installing air filter housing

2964.3 Removing and installing air guide on lock carrier

2985 Intake manifold

3005.1 Assembly overview – intake manifold

3005.2 Removing and installing intake manifold

3035.3 Removing and installing throttle valve module GX3

3076 Senders and sensors

3106.1 Removing and installing fuel temperature sender G81

3106.2 Removing and installing air mass meter G70

3116.3 Removing and installing fuel pressure regulating valve N276

3126.4 Checking fuel pressure regulating valve N276

3146.5 Removing and installing fuel pressure sender G247

3166.6 Removing and installing pressure differential sender G505

3176.7 Removing and installing exhaust gas pressure sensor 1 G450

3196.8 Removing and installing control unit for NOx sender J583/NOx sender G295

3206.9 Removing and installing control unit for NOx sender 2 J881/NOx sender 2 G687

3227 Engine control unit

3257.1 Removing and installing engine control unit J623

3258 High-pressure pump

3298.1 Assembly overview - high-pressure pump

3298.2 Removing and installing high-pressure pump

3298.3 Checking high-pressure pump

3339 Lambda probe

3379.1 Assembly overview - Lambda probe

3379.2 Removing and installing Lambda probe 1 before catalytic converter GX10

338Exhaust system

3411 Exhaust pipes and silencers

3411.1 Assembly overview – silencers

3411.2 Assembly overview - front exhaust pipe

3421.3 Removing and installing front exhaust pipe

3451.4 Separating exhaust pipes and silencers

3521.5 Removing and installing rear silencer

3531.6 Aligning exhaust system free of stress

3541.7 Checking exhaust system for leaks

3551.8 Installation position of clamp

3552 Emission control

3572.1 Assembly overview – emission control

3572.2 Removing and installing catalytic converter

3652.3 Removing and installing particulate filter

3652.4 Removing and installing emission control module

3712.5 Removing and installing exhaust flap control unit J883

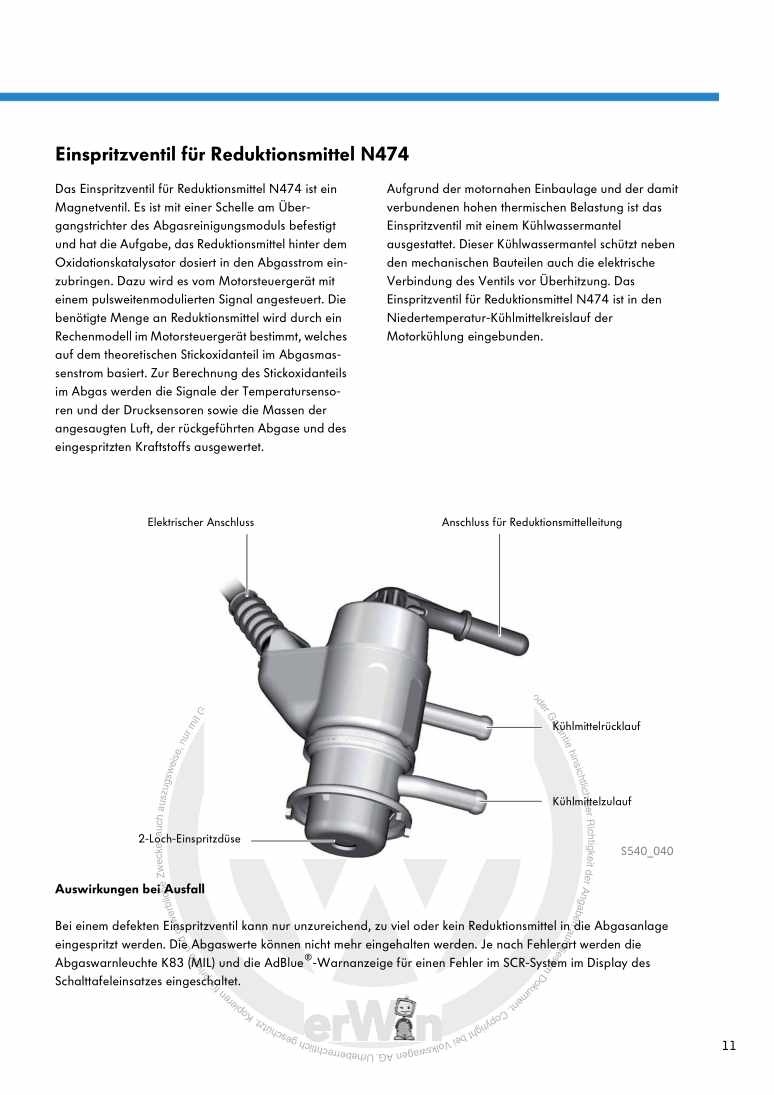

3803 SCR system (selective catalytic reduction)

3823.1 Assembly overview – reducing agent tank

3823.2 Assembly overview - delivery module for reducing agent

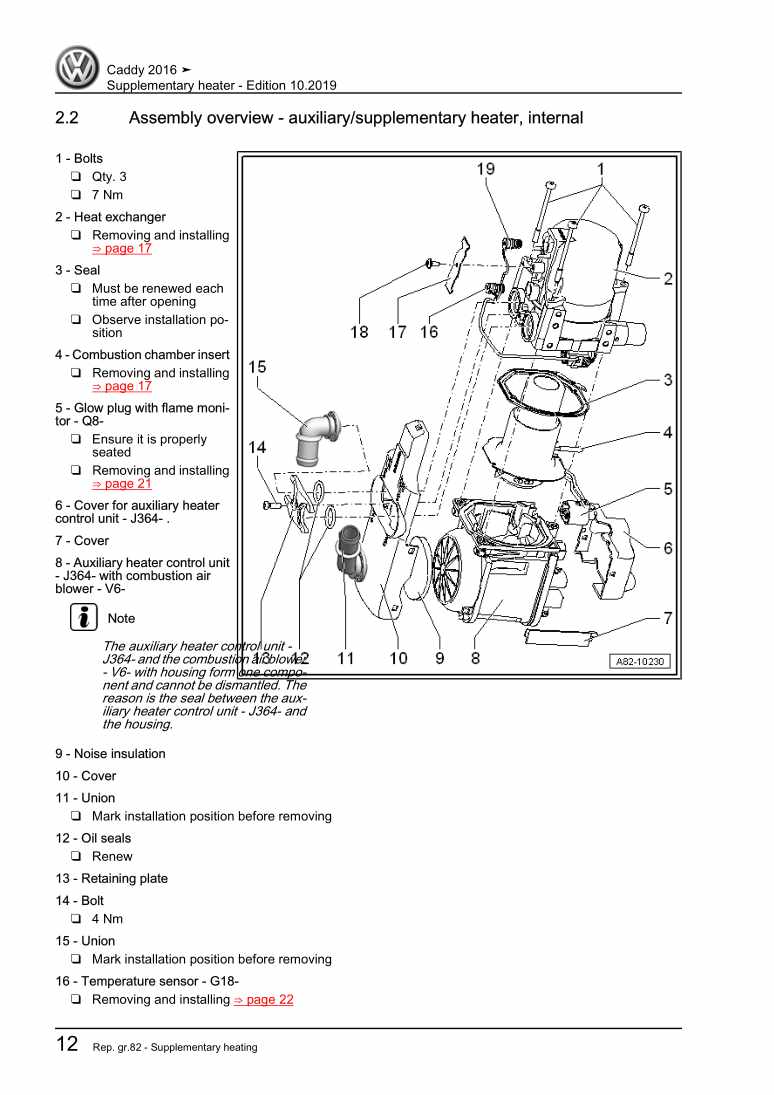

3833.3 Assembly overview - injector for reducing agent

3833.4 Draining reducing agent tank VX85

3843.5 Removing and installing reducing agent tank VX85

3873.6 Removing and installing front section of reducing agent supply line

3903.7 Removing and installing delivery unit for reducing agent metering system GX19

3933.8 Removing and installing injector for reduction agent N474

3963.9 Removing and installing control unit for reducing-agent heater J891

3994 Exhaust gas temperature regulation

4004.1 Assembly overview – exhaust gas temperature regulation

4004.2 Removing and installing exhaust gas temperature sender 1 G235

4024.3 Removing and installing exhaust gas temperature sender 2 G448

4064.4 Removing and installing exhaust gas temperature sender 3 G495

4074.5 Removing and installing exhaust gas temperature sender 4 G648

4095 Exhaust gas recirculation

4125.1 Assembly overview – exhaust gas recirculation

4125.2 Assembly overview - exhaust gas recirculation valve

4165.3 Removing and installing exhaust gas recirculation cooler

4175.4 Checking exhaust gas recirculation cooler for leaks

4265.5 Removing and installing exhaust gas recirculation valve 1 GX5

4265.6 Removing and installing exhaust gas recirculation valve 2 GX6

4275.7 Removing and installing bracket for exhaust gas recirculation cooler

4295.8 Removing and installing exhaust gas recirculation pipes

4315.9 Removing and installing exhaust gas recirculation temperature sensor G98

435Glow plug system

4381 Glow plug system

4381.1 Assembly overview – glow plug system

4381.2 Removing and installing glow plug

4391.3 Removing and installing automatic glow period control unit J179

4421.4 Removing and installing Hall sender G40

4431.5 Removing and installing engine speed sender G28

444