Technical data

11 Safety information

11.1 Safety regulations for working on fuel supply

11.2 Safety precautions when working on charge air system

21.3 Safety precautions when working on injection system

21.4 Safety precautions when working on the cooling system

32 Identification

52.1 Engine number/engine data

53 Repair instructions

73.1 General notes on the lubrication system

73.2 General notes on fuel system

73.3 Instructions for working on fuel system

83.4 Rules for cleanliness when working on fuel supply system

103.5 Rules for cleanliness during work on fuel system

103.6 Rules for cleanliness when working on injection system

11Removing and installing engine

121 Removing and installing engine

121.1 Removing engine

121.2 Securing engine on engine and gearbox support

301.3 Installing engine

321.4 Modifying engine bracket T10229

351.5 Converting adapter 10 - 222 A /23 with adapter 10 - 222 A /23-1

362 Assembly mountings

382.1 Assembly overview - assembly mountings

382.2 Supporting engine in installation position

402.3 Removing and installing engine mounting

412.4 Removing and installing engine mounting

47Crankshaft group

511 Cylinder block (pulley end)

511.1 Assembly overview - cylinder block (pulley end)

511.2 Assembly overview - sealing flange, belt pulley end

531.3 Assembly overview - poly V-belt drive

551.4 Removing and installing poly-V belt

611.5 Removing and installing tensioner for poly V-belt

631.6 Removing and installing bracket for ancillaries

641.7 Removing and installing vibration damper

671.8 Renewing crankshaft oil seal - belt pulley end

681.9 Removing and installing sealing flange on pulley end

712 Cylinder block, gearbox end

772.1 Assembly overview - cylinder block, gearbox end

772.2 Removing and installing flywheel

782.3 Removing and installing sealing flange on gearbox side

803 Crankshaft

923.1 Assembly overview - crankshaft

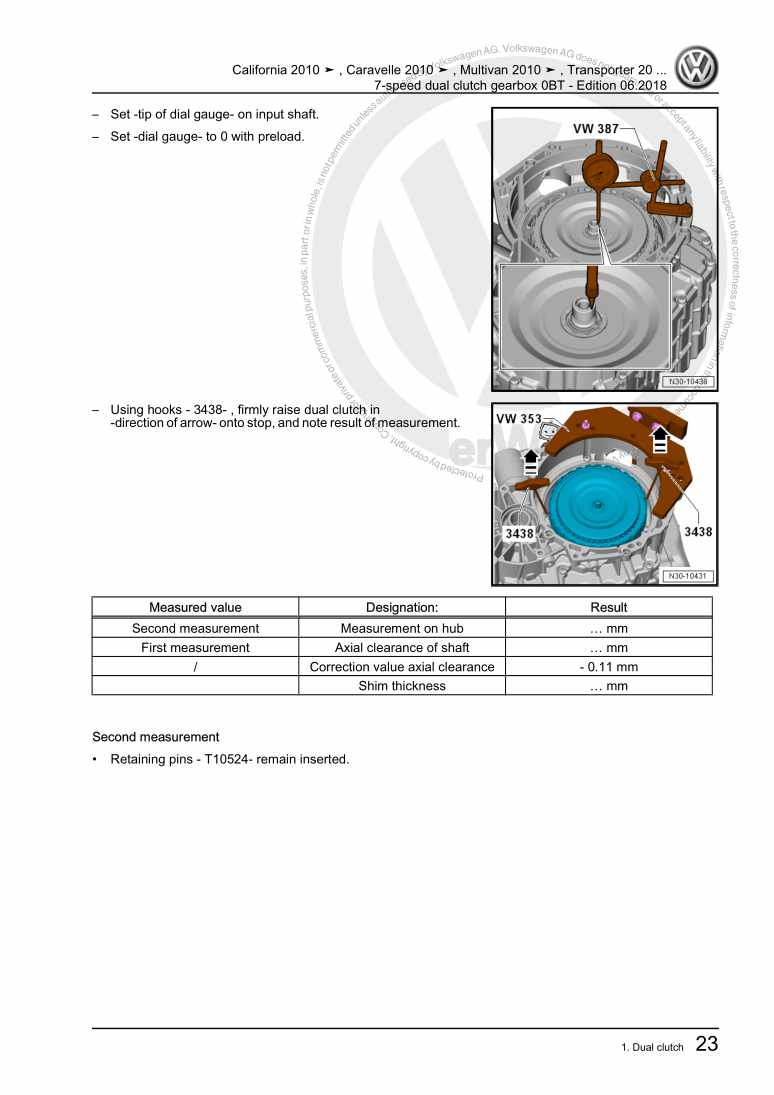

923.2 Crankshaft dimensions

933.3 Allocation of main bearing shells

943.4 Measuring axial clearance of crankshaft

943.5 Measuring radial clearance of crankshaft

953.6 Renewing needle bearing in crankshaft

963.7 Renewing spur gear for crankshaft

984 Pistons and conrods

1024.1 Assembly overview - pistons and conrods

1024.2 Removing and installing pistons

1054.3 Separating new conrod

1064.4 Checking pistons and cylinder bores

1074.5 Checking radial clearance of conrods

1084.6 Measuring piston projection at TDC

1094.7 Removing and installing oil spray jets

111Cylinder head, valve gear

1131 Cylinder head

1131.1 Assembly overview - cylinder head

1131.2 Assembly overview - cylinder head cover

1171.3 Removing and installing cylinder head

1221.4 Removing and installing cylinder head cover

1341.5 Removing and installing injector seals

1411.6 Removing and installing vacuum pump

1451.7 Checking compression

1492 Fully enclosing toothed belt guard

1512.1 Assembly overview - fully enclosing toothed belt guard

1512.2 Removing and installing upper toothed belt guard (fully enclosing)

1532.3 Removing and installing lower toothed belt guard (fully enclosed)

1542.4 Removing and installing rear toothed belt guard (fully enclosing)

1563 Toothed belt drive

1603.1 Assembly overview - toothed belt

1603.2 Removing and installing toothed belt

1624 Valve gear

1804.1 Assembly overview - valve gear

1804.2 Measuring axial play of camshaft

1834.3 Measuring radial play of camshaft

1844.4 Removing and installing camshaft oil seal

1844.5 Removing and installing camshaft

1874.6 Checking hydraulic compensation elements

1964.7 Removing and installing valve stem seals

1975 Inlet and exhaust valves

2025.1 Reworking valve seats

2025.2 Checking valve guides

2025.3 Valve dimensions

203Lubrication

2041 Sump, oil pump

2041.1 Assembly overview - sump/oil pump

2041.2 Removing and installing sump

2101.3 Removing and installing oil pump

2151.4 Engine oil:

2171.5 Removing and installing oil level and oil temperature sender G266

2182 Engine oil cooler

2202.1 Assembly overview - engine oil cooler

2202.2 Removing and installing engine oil cooler

2222.3 Checking engine oil cooler for leaks

2263 Oil filter, oil pressure switch

2293.1 Assembly overview - oil filter housing

2293.2 Removing and installing oil pressure switch F1

2293.3 Checking oil pressure

2303.4 Removing and installing oil filter housing, mono-turbo

2323.5 Measuring oil consumption

2354 Balancer shaft module

2374.1 Removing and installing balance shaft module

237Cooling

2451 Cooling system/coolant

2451.1 Draining and adding coolant

2451.2 Checking cooling system for leaks

2541.3 Assembly overview - coolant hoses

2561.4 Connection diagram for coolant hoses - vehicles with basic equipment

2581.5 Connection diagram for coolant hoses - vehicles with additional heat exchanger

2601.6 Connection diagram for coolant hoses - vehicles with auxiliary heater

2652 Coolant pump, regulation of cooling system

2872.1 Assembly overview - coolant pump and ball thermostat (4/2-way valve)

2872.2 Assembly overview - Continued coolant circulation pump V51

2882.3 Removing and installing coolant pump

2882.4 Removing and installing continued coolant circulation pump V51

2912.5 Removing and installing 4/2-way valve with thermostat

2932.6 Removing and installing Y-thermostat

2982.7 Removing and installing coolant temperature sender G62

2992.8 Removing and installing radiator outlet coolant temperature sender G83

3023 Radiator, radiator fan

3073.1 Assembly overview - radiator/radiator fan

3073.2 Assembly overview – radiator cowl and radiator fan

3093.3 Removing and installing radiator

3093.4 Removing and installing radiator cowl with radiator fan V7

317Fuel supply system

3191 Procedure in event of misfuelling

3191.1 Procedure in event of misfuelling

3192 Fuel

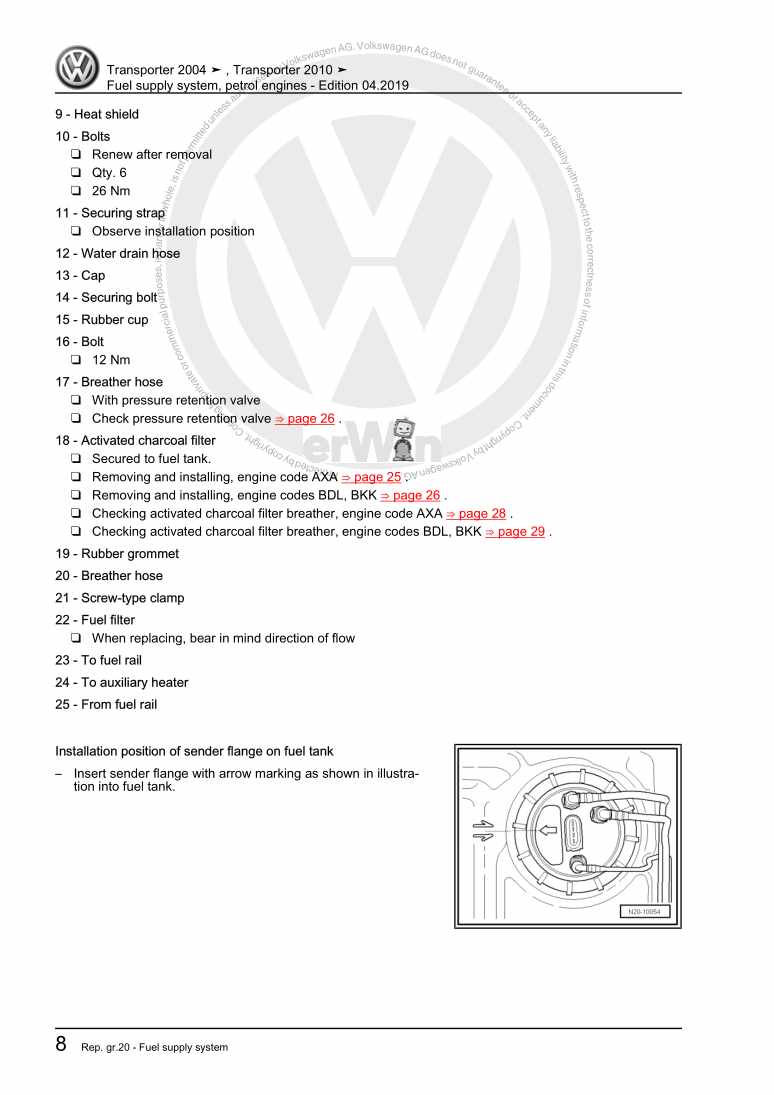

3232.1 Assembly overview - fuel tank

3232.2 Removing and installing fuel tank

3253 Fuel delivery unit, fuel gauge sender

3303.1 Removing and installing fuel delivery unit

3303.2 Removing and installing fuel gauge sender G

3314 Fuel pump

3324.1 Assembly overview - supplementary fuel pump V393

3324.2 Removing and installing supplementary fuel pump V393

3344.3 Checking supplementary fuel pump V393

3374.4 Checking delivery pressure of fuel system pressurisation pump G6

3394.5 Checking fuel delivery rate of fuel system pressurisation pump G6

3404.6 Checking voltage supply of fuel system pressurisation pump G6

3424.7 Checking current draw of fuel system pressurisation pump G6

3435 Accelerator pedal

3465.1 Function

3465.2 Assembly overview - accelerator mechanism

346Turbocharging/supercharging

3481 Turbocharger

3481.1 Assembly overview - turbocharger

3481.2 Assembly overview – connecting pipes (bi-turbo)

3581.3 Removing and installing turbocharger

3601.4 Removing and installing exhaust manifold gasket (bi-turbo)

3951.5 Removing and installing compressor housing and turbine housing (bi-turbo)

4051.6 Checking vacuum unit for turbocharger

4081.7 Renewing vacuum unit for turbocharger

4171.8 Removing and installing connecting pipes (bi-turbo)

4312 Charge air system

4392.1 Assembly overview - charge air system

4392.2 Assembly overview - charge-air hose connections

4432.3 Removing and installing charge air cooler

4472.5 Removing and installing exhaust gas flap valve N220

4532.7 Removing and installing charge pressure control solenoid valve N75

4542.8 Checking charge air system for leaks

4562.9 Removing and installing charge pressure sender 2 G447

460Mixture preparation - injection

4621 Injection system

4621.1 Overview of fitting locations - injection system

4621.2 Schematic overview - fuel system

4721.3 Assembly overview - fuel system

4741.4 Checking fuel system for leaks

4802 Vacuum system

4812.1 Connection diagram - vacuum system

4812.2 Testing vacuum system for leaks, bi-turbo

4852.3 Testing vacuum system for leaks, mono-turbo

4942.4 Checking vacuum system for leaks, “four-wheel drive”

5013 Injectors/high-pressure accumulator (rail)

5093.1 Removing and installing fuel rail

5093.2 Removing and installing high-pressure lines

5133.3 Removing and installing injectors

5203.4 Testing injectors

5263.5 Testing jammed-open injectors

5343.6 Check pressure retention valve in fuel return line

5363.7 Checking low pressure fuel system

5393.8 Checking fuel pump delivery rate

5414 Air filter

5434.1 Assembly overview - air filter housing

5434.2 Removing and installing air filter housing

5465 Intake manifold

5495.1 Assembly overview – intake manifold

5495.2 Removing and installing intake manifold

5495.3 Removing and installing throttle valve module GX3

5546 Senders and sensors

5566.1 Removing and installing air mass meter G70

5566.2 Removing and installing fuel pressure regulating valve N276

5576.3 Checking fuel pressure regulating valve N276

5606.4 Removing and installing fuel pressure sender G247

5626.5 Removing and installing exhaust gas pressure sensor 1 G450

5647 Engine control unit

5687.1 Removing and installing engine control unit J623

5688 High-pressure pump

5708.1 Removing and installing high-pressure pump

5708.2 Checking high-pressure pump

574Exhaust system

5781 Exhaust pipes and silencers

5781.1 Assembly overview – silencers

5781.2 Removing and installing front exhaust pipe

5821.3 Separating exhaust pipes from silencers

5841.4 Checking exhaust system for leaks

5851.5 Aligning exhaust system free of stress

5861.6 Installation position of clamp

5872 Emission control

5882.1 Assembly overview - particulate filter

5882.2 Assembly overview - catalytic converter, four-wheel drive vehicles

5932.3 Removing and installing particulate filter

5952.4 Removing and installing catalytic converter, four-wheel drive vehicles

6023 Exhaust gas recirculation

6053.1 Assembly overview – exhaust gas recirculation

6053.2 Removing and installing exhaust gas recirculation cooler

6083.3 Removing and installing exhaust gas recirculation valve 1 GX5

6203.4 Pressure loss test for exhaust gas recirculation cooler

621Glow plug system

6251 Glow plug system

6251.1 Checking glow plug system

6251.2 Removing and installing glow plug

6251.3 Checking glow plug

6281.4 Optical characteristics of glow plugs

6291.5 Removing and installing engine speed sender G28

6291.6 Removing and installing Hall sender G40

631